Vehicle fueling is a fairly simple operation, but the important difference between diesel and gas nozzles prevents proper engine functioning and costly mishaps from taking place. Both fuel types serve as important forms of energy to different varieties of engines; yet because their qualities vary, they each require special handling and delivery systems. In this article, we shall analyze diesel and gas nozzles from the perspective of design and operation, and see how the so-called complementary operations are geared to their fuel types. We will also explore built-in safety measures in fuel pumps designed to prevent misfuelling. By the end of this article, you will see why these differences are important and hence become armed to make an informed choice at the fuel station.

Introduction to Fuel Types

The two greatest types of fuel utilized in engines for the combustion process are diesel and gasoline, and each is prepared to satisfy the particular needs of the separate engine designs. Diesel fuel, being denser, contains more energy in a gallon and is suitable for engines that require high torque, such as those used in trucks and heavy machinery. Gasoline is lighter and is distilled at a lower pressure to suit engines in most passenger vehicles, where it allows efficient high-speed performance. Both fuels are mutually incompatible owing to the different combustion and engineering methods of their respective engines. Hence, the determination of the appropriate one will ensure the proper functioning of the engine and save heavy damage.

Overview of Diesel Fuel

Diesel fuel is a kind of distillate fuel, generally derived from crude oil in the process of refining. It is said to have higher energy density than gasoline, with approximately 35.8 megajoules per liter (MJ/L). Because of this, diesel would be the right fuel for any task that involves high energy output in heavy-duty transportation, industrial machinery, and marine applications. Diesel engines are optimal for using this fuel because they work on compression ignition rather than spark ignition, providing greater torque and better fuel economy.

Diesel fuels made with ULSD are part of environmental regulations designed to quell sulfur oxide emissions. The ULSD diesel contains sulfur not exceeding 15 parts per million (ppm), whereas traditionally, diesel had sulfur levels that sometimes even exceeded the 500ppm mark. This not only enabled emission standard compliance but also reduced the environmental impact of diesel-powered systems.

Increasing awareness regarding renewable sources of bio-gasoline, such as vegetable oils and animal fats, is recovering the diesel industry. B5 and B20 are other mixtures with sustainability aspects, and they reduce greenhouse gas emissions by about 74% in comparison with conventional diesel. These are also helping in the energy diversification process and in reducing fossil fuel import dependency.

Overview of Gasoline

Gasoline is just a highly refined variant of petroleum oil and is fundamentally used as fuel for internal combustion engines. Its composition is a complex mixture of hydrocarbons, including alkanes, cycloalkanes, and aromatic hydrocarbons, designed particularly to produce high energy and great combustion efficiency. In the second stage, gasoline was produced from crude oil in the refinery, where fractional distillation and cracking treat the crude and eliminate impurities. Additives such as detergents, oxygenates, and anti-knock compounds are sometimes blended with gasoline to enhance engine performance, reduce emissions, and stave off corrosion.

Concerns about the environment have led to developments in the formulations for gasoline and fuels, including ethanol blend fuels, E10-type being 10% ethanol, and E85-type being 85% ethanol. These blends serve to help reduce carbon emissions from their traditional gasoline emission and, therefore, lessen the environmental impact. Still, the way that gasoline is synthesized and used puts enormous amounts of greenhouse gases into the atmosphere, turning that outside impediment, alongside cleaner transportation technologies, into one of the major factors impelling the threat toward sustainable fuel alternatives.

Importance of Choosing the Right Fuel

Choosing the appropriate fuel for a vehicle is imperative for ensuring optimal engine performance, fuel efficiency, and emission control. Therefore, depending on the engine compression ratio and operating temperature, fuels are assigned with varying octanes: regular, midgrade, and premium. Using fuel with a lower octane value than recommended for the engine would cause it to knock and lose power, eventually damaging its inner workings. Also, the alternative fuels such as ethanol blends or compressed natural gas (CNG) need to be compatible with the vehicle to prevent operating problems. Such considerations aside, selecting a fuel with sustainable credentials will help to combat climate change on a global scale by lessening greenhouse gas emissions and encouraging cleaner sources of fuel. Choosing from the three parameters has been concluded as the last decision to make: engine applicability, cost, or environmental consciousness.

Differences Between Diesel and Gas Nozzles

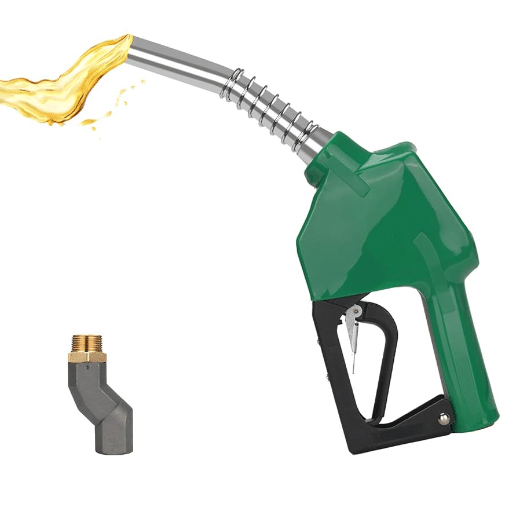

Summarizing the differences between diesel and gas nozzles, one may note that size, shape, and compatibility are the factors at work. In general, diesel nozzles are larger in diameter than gas nozzles, thereby preventing diesel nozzles from entering gasoline-fueled vehicles with a smaller fuel filler neck. This is in order to reduce accidental filling. Also, diesel nozzles must be able to deal with the thicker consistency of diesel fuel, while gasoline nozzles must be suited for the thinner viscosity of gasoline. This ensures that fuel delivery remains efficient and safe for the specific type of engine for which each nozzle is made.

Nozzle Size and Design

Fuel nozzle size and design are important for proper delivery of fuel and to maintain operational integrity. Diesel nozzles are slightly larger in diameter, around 0.85 inches, while gasoline nozzles measure about 0.81 inches. This intentional size difference ensures that diesel fuel nozzles will have a hard time fitting into the smaller filler necks of gasoline vehicles, thus reducing the possibility of misfueling incidents. On the other hand, gasoline nozzles are meant to fit the relatively narrow fuel ports of gasoline vehicles but are too small to fit into diesel tanks; hence the additional safety check.

Definitely, design differences are extended in fuel flow optimization for viscosity. Diesel nozzles are engineered to deal efficiently with the higher density and lower volatility of diesel fuel. This means keeping proper pressure to maintain consistent flow rates and adapting to the slower evaporation rates of diesel for clean combustion in diesel engines. In contrast, the gasoline nozzles are made to deal with the density and volatility of gasoline, ensuring rapid delivery and minimal vapor buildup. With all these features in combination, nozzle size and internals are highly engineered solutions for safe and efficient vehicle fueling.

Fuel Delivery Mechanism

In modern engines, the delivery of fuel is an elaborate mechanism that ensures careful attention to variability in the rate of fuel flow for best performance and efficiency. At the base of this system lie the fuel tank, the fuel pump, the fuel filter, and the injectors or carburetors, each designed in accordance with the task they are expected to perform. The fuel pump levels fuel from the tank and pressurizes the fuel to meet engine requirements, whereas the fuel filter does the job of preventing contaminants from entering engine components. For diesel engines, high-pressure fuel injection systems enable adequate atomization of fuel, which is essential for efficient combustion. For the gasoline variety, direct injection or port fuel injection systems are employed to generate the proper air-fuel mixture for combustion.

Currently, an EFI system replaces mechanical systems for better fuel delivery control. Sensors, such as oxygen and mass airflow sensors, will consequently provide inputs to the ECU, which will monitor engine conditions and make adjustments to fuel delivery in real-time. They minimize emissions and maximize fuel economy, allowing the engine to adapt to the circumstances of driving. The combination of high-pressure pumps and accurate injector timings further helps in reducing inefficiencies and meeting the peculiar demands of respective fuel types, thereby ensuring that engines deliver optimum performance.

Compatibility with Fuel Pumps

This variation of fuel injection requires a soft calibration for compatibility with many fuel pump designs. High-pressure fuel injection systems operate basically at higher than 30,000 psi (around 2,068 bar) and require strong fuel pumps to maintain such extreme pressure without losing efficiency. The materials used might be hardened steel or advanced composites for resisting wear and tear against continued operation under high pressure.

Compatibility extends also to variations in fuel. Should corrosion be a threat in pumps resulting from these fuels being less chemically stable forms of gasoline or diesel, for engines using alternate fuels such as E85 (ethanol blends), biodiesel, or possibly hydrogen, the pump must resist it. In the latest pump technologies, DLC coatings were applied to improve corrosion resistance and lower friction.

Further improvements in control systems also bring about synchronization between mechanically mismatched fuel pumps and injectors through electronic monitoring to ensure correct timing of fuel delivery, less possible mechanical mismatch, and greater efficiency. Data has shown that employing such high-precision synchronization systems yields a 15% increase in fuel economy relative to conventional designs, as well as up to 40% reduction in particulate emissions.

In fact, compatibility with fuel pumps is not only evidence for engineering ingenuity but also a stimulating constraint towards achieving strict efficiency and emission targets by regulatory bodies around the globe.

Gas Fuel Pumps and Nozzles

Fuel gas pumps and nozzles convey gasoline, ensuring its safe delivery from storage tanks to vehicles. The pump is designed to lift the gasoline at a steady flow, whereas the nozzle will discharge gasoline exactly as allowed and preventing spills and overfilling. Modern nozzles have automatic shut-off devices that stop fuel from dispensing once the tank has reached its capacity, thereby reducing possible environmental hazards and increasing safety. Pump and nozzle inspection and maintenance are required to keep them functioning properly in accordance with industry standards.

Function of Gas Fuel Pumps

Gas capital pumps are essential for the fueling infrastructure, and they have been designed so that the fuel flows efficiently and reliably from the storage tanks into the dispensing units. Depending on the operating systems, these pumps operate either by submersible or suction systems. The submersible pumps are located inside storage tanks and provide relatively higher flow rates: the suction pumps suck fuel into the pipes downstream. Key technical features include pressure control, flow measurement, and leak detection, ensuring safety and environmental conformance during operations. These features can be linked with digital monitoring systems that can keep track of fuel levels, flow rates, and pump performance in real-time to help maintain the functionality of gas pumps. Gas pumps should be calibrated regularly and kept in accordance with the standards of the industry to guarantee precision, prevent contamination, and permit efficient operation in the long run.

Design of Gasoline Nozzles

Modern gasoline nozzle design is all about precision engineering, safety, and user-friendly features. By and large, they face welding out of high-grade aluminum or stainless steel constructions destruction of which is corruption by corrosion due to exposure to fuel. They are automatically shut off; while detecting a change in back pressure of having the container is full, the device stops all filling offenses. Its main innovation is the incorporation of an integrated venturi sensor that accurately identifies changes in tank pressure for effective refilling and to ensure that no fuel is spilled.

Gasoline nozzle flow rates are subject to application, where standard-type, consumer-grade nozzles range from 7-10 gallons each minute; industrial or commercial-grade nozzles accommodate larger tanks or faster fueling operations and can top out at 60 GPM. Moreover, the very advanced designs of nozzles today allow the recovery of vapors from fuel molecules during the refilling of tanks, so more environmentally friendly, even with stringent emissions regulations.

An ergonomic handle coupled with a lightweight structure makes handling easier and less tiring for the operator, especially in high-use settings. As an added convenience, some contemporary nozzles are swivel-style and hinder hose twisting during use. All these factors, coupled with rigorous testing procedures and adherence to the standards set by concerned bodies such as the American Petroleum Institute (API), ensure that gasoline nozzles can carry out their operational and environmental obligations toward the immediate fuel industry.

Maintenance of Gas Fuel Pumps

Gas-fired supplier pump maintenance is critical in order to ensure operational efficiency, safety, and industrial compliance. Here are a few important maintenance checks:

- Checking Pump Components – Pumps undergo routine visual inspections for wear and tear in hoses, nozzles, and seals in order to prevent leakages and costly machinery failures. If any component gets damaged, it has to be replaced as per the manufacturer’s recommendations.

- Calibration and Testing of Accuracy – Periodic pump calibration is a must to ensure accurate measurements of fuel dispensed. Customer trust is maintained in this manner while also observing local and federal laws regarding fuel dispensing accuracy.

- Cleaning and Lubrication – Filtration should be kept clean, and moving parts should be lubricated appropriately to decrease wear and operate smoothly. If filters get clogged, then during such periodic service, they should be replaced.

- Electrical Component Checks – Examine wiring, sensors, and circuit boards for any indications of damage or corrosion. The faulty electrical systems can interrupt service and can always be a hazard; thus, they need immediate professional repair.

- Preventive Maintenance Procedures – Following a preventive maintenance schedule consisting of inspections, replacement of parts, and software updates, ensures the reduction of unexpected downtime and extends the life of the pump.

Following these would ensure the reliability of gas fuel pumps, conforming to industry standards and consumer expectations. It is advisable to join hands with a certified technician for specialized repairs and thorough diagnostics.

Similarities and Differences in Fuel Systems

Fuel systems, while variable in design, have a handful of core similarities and a few differences. All types of fuel systems perform the essential function of checking the fuel and feeding it into the engine properly. A few infrastructure components include fuel tanks, pumps, filters, and injectors, which ensure the correct supply of fuel to the combustion chambers.

However, several differences come into play concerning the type of fuel and peculiar mechanisms involved; thus, gasoline fuel systems and diesel fuel systems differ in pump pressure and injector design since the properties of these oils are different. Also, these days, fuel systems tend to be electronically controlled in contrast to mechanical operations in the past, hence gaining increased precision and efficiency. Such distinctions are very crucial for appropriate system selection and maintenance depending on the application and type of fuel.

Comparative Analysis of Diesel and Gas Systems

Though gasoline and diesel fuel systems demonstrate fundamental differences in operational characteristics, fuel efficiency measures, and applications, these engines prioritize different types of combustion. Diesel engines give compression ignition priority: air is compressed at extremely high pressures in the cylinder, raising its temperature considerably, and fuel injection takes place immediately thereafter. In contrast, gasoline engines normally rely on spark ignition, implying that they are designed for a low compression ratio and employ the spark plug to initiate combustion. These differences usually give diesel engines greater thermal efficiency, often beyond 40% in present-day systems, whereas that of the gasoline engine averages about 30-35%.

Diesel engines, from the point of view of the emissions, produce a lesser amount of carbon dioxide (CO2) per unit quantity of fuel burned, given their efficiency, but may produce higher concentrations of nitrogen oxides (NOx) and particulate matter (PM), provided their after-treatment systems are less advanced. Modern-day diesel engines are usually equipped with SCR systems and DPFs to allay those concerns. On the contrary, gasoline engines give higher CO2 emissions when in operation, but usually release very low NOx levels, which may be required for specific regulations.

Another testimony is the performance characteristics that set the two types of engines apart from each other. Diesel engines deliver greater torque at lower RPMs and hence are preferred for heavy-duty jobs such as commercial trucks or those required by industrial machinery. Gasoline engines, on the other hand, churn out more RPMs and can accelerate faster, which makes them suitable for lightweight passenger vehicles and high-performance applications. Based on a 2019 study on consumer vehicles, diesel engines offer a fuel economy improvement of 25 to 30 percent compared to gasoline engines under about the same operating conditions.

Economically, diesel fuel usually bestows better mileage; hence, diesel consumers spend less on fuel as time goes by. While diesel engines might be more costly by upfront purchase and maintenance because of their heavy-duty construction and additional features like turbochargers and SCR systems, gasoline engines are less costly to produce and maintain, which makes them more suitable for consumers.

More and more, technology is actually making the two closer. Direct injection systems, turbocharging, and hybrid implementation are equally standard in diesel and gasoline platforms and contribute toward better performance in efficiency and emissions control. The choice of diesel versus gasoline depends on specific application parameters such as load capacity needed, operating costs, and environmental approach; each offers variations depending on its best use-cases.

Environmental Impact of Diesel vs Gasoline

In the realm of environmental impacts, the effects of diesel and gasoline engines on the environment are primarily distinguished by emissions and fuel efficiency. Being more fuel-efficient, diesel engines produce fewer quantities of carbon dioxide (CO2) when compared with gasoline engines. However, diesel engine emissions include greater quantities of nitrogen oxides (NOx) and particulate matter (PM), both of which are pollutants and have major health implications. Conversely, gasoline engines emit less NOx and particulates but greater CO2, thus contributing more to global greenhouse gas concentrations.

Diesel engines enjoy a reputation for being high-powered engines serving longer distances, thereby lowering the relative environmental impact, under certain circumstances, that is. On the other hand, gasoline engines are favored for lighter duties in which the greater NOx emissions produced by the diesels are contrary to the environmental motive. The newer designs of emission control and fuel systems for alternative fuels help to lessen the impact on both diesel and gasoline engines. Therefore, considering the specific application and the pollution-related regulations, a diesel-gasoline judgment has to be made.

Cost Considerations for Diesel and Gas Fuel

The price of diesel and gasoline fuels basically involves consideration of initial prices, operational efficiency, and maintenance costs. At a point in time, diesel fuel usually carries a heavier price tag per gallon than gasoline, just because the production costs are higher, and in some regions, they attract higher taxes. However, diesel engines are generally more fuel-efficient as long as they are merely delivering the power for distance driving and heavy-duty applications, and the price of fuel eventually tends to balance out. A diesel engine is also more durable and lasts longer, thereby translating to lower maintenance costs over time. With gasoline engines, the lower upfront costs of the vehicles have generally lower-cost repairs and maintenance.

The diesel fuel price keeps fluctuating, and hence users have to adjust to the price or availability in that area. Commercial operations are more diesel-friendly for heavy-duty vehicles requiring high torque and fuel mileage, whereas gasoline is preferred for personal vehicles simply because of the price and their application for short-distance commuting. Each fuel has its good and bad points, wherein users and location points should consider these against their individual requirements, cost matters, and overall cost of ownership throughout the vehicle’s life span.

Choosing the Right Nozzle for Your Needs

First, in nozzle selection, one has to check the fluid being dispensed, the requirements of the application, and the equipment compatibility. For diesel or gasoline, ensure that you use a nozzle designed for the fuel-check to prevent cross-fueling and to stay on safety standards. Select an automatic shut-off nozzle to guarantee safety and avoid spillage. For high-volume tasks, choose one of the large flow-rate nozzles for better output. Never broadcast your machine standards and check the nozzle to guarantee compatibility with your dispensing application for smooth operation.

Factors to Consider When Choosing a Fuel Nozzle

| Factor | Considerations |

|---|---|

| Fuel Type Compatibility | Nozzle compatibility with the fuel being dispensed cannot be emphasized enough: Nozzles for gasoline, diesel, and alternative fuels like biodiesel or ethanol must be carefully selected. An incompatible nozzle can create inefficiencies during operations, hazards to safety, or damage to the equipment. |

| Flow Rate and Application | One has to consider the flow rate for the application. With refueling standard vehicles, a medium flow rate, i.e., 10 to 15 GPM, should be suited; whereas, for commercial and gigantic operations, a nozzle greater than 20 GPM would work quite efficiently in terms of time. |

| Safety Features | Prioritize nozzles that feature safety means along with an automatic shut-off to prevent the tank from overflowing and to reduce spillage. Pressure-activated automatic shut-off is highly recommended whenever safety is of greatest concern. |

| Construction Material and Durability | Make sure the nozzle is constructed of materials that are durable enough to withstand harsh environmental conditions and frequent use. For corrosive fuels, choose nozzles with corrosion-resistant seals and components. |

| Compliance with Industry Standards | Check the nozzle for compliance with safety and performance standards, such as those implemented by the Occupational Safety and Health Administration (OSHA) or Underwriter Laboratories (UL), for regulatory compliance and operational reliability. |

Considering these factors will allow a fuel nozzle to be chosen that is efficient, safe, and durable, and will suit the specific requirements of your application.

Common Mistakes in Fuel Pump Usage

I commonly witness mistakes with fuel pump usage that generally fall into two categories such as improper handling of the nozzle or putting the wrong type of fuel into the equipment. Also, neglecting to inspect the pump and its components on a regular basis for signs of wear will cause efficiency losses and can even lead to safety hazards. Another common mistake lies with overfilling the tanks, spills, and environmental hazards. By consciously keeping an eye on these issues, I allow for the best operation while nullifying any setbacks during operation.

Best Practices for Fueling

- Choose the Correct Fuel Type – Always use the prescribed fuel type recommended for your equipment. Using the wrong fuel can technically damage the engine, reduce its efficiency, and void the warranties. Check the equipment manual to verify the exact fuel requirement.

- Inspect the Equipment Regularly – Regularly inspect the fuel pump, hoses, and nozzles for wear, leaks, or damage. Repairing or replacing them immediately will avoid inefficiencies and maintain safety standards in operations.

- Handling of the Nozzle – Handle the fuel nozzle carefully to prevent spilling and ensure a secure connection to the tank. Such actions lead to fuel wastage and impact the environment. Always disengage the nozzle properly after refueling to avoid dripping.

- Never Overfill the Tank – Stop filling as soon as the tank attains its recommended capacity to avoid spills, fire hazards, and environmental issues. Always use the auto shut-off system if it is there.

- Safety Is Key – Store the fuel in a decent area away from open flames or sources of heat. Wear suitable personal protective equipment (PPE) as and when required, and follow all safety regulations for the workplace.

Good safety measures will ensure the longevity of equipment and protect human life, as well as add to the proper efficiency of fuel. All operators should be trained so that they can adhere to these procedures consistently.

Reference Sources

- Key Findings: This paper highlights the role of these ME diesel engines in the conservation of energy and environmental protection. It underlines the requirement of intelligent diagnostic technologies for the enhancement of efficiency and reliability of electronically controlled fuel injection systems.

- Key Findings: It studies characteristics of fuel spray penetration and gas inflow in a DI diesel engine effects of nozzle configurations on spray dynamics and combustion efficiency.

“Modified Piston Design for Better Combustion Efficiency”

- Key Findings: This research investigates the effect of a modified piston design on combustion efficiency in diesel engines. It finds placing the diesel injector with six nozzles at the top of the cylinder to enhance fuel atomization and combustion.

Frequently Asked Questions (FAQs)

Diesel and gasoline nozzles – what makes them different?

Diesel nozzles, generally bigger, are meant for diesel fuel, while gasoline nozzles are smaller and are used for petrol or unleaded gasoline. It is very important to note these distinctions in order not to contaminate the fuel and properly fill the vehicle.

How do I select the right fuel nozzle for my vehicle?

It is a matter of choosing the right nozzle. Diesel vehicles demand diesel fuel nozzles; gasoline cars use gasoline nozzles. At least this way, no mix-ups in fuel will happen.

What will happen if I place a diesel nozzle inside a gas tank?

Gasoline engines are severely damaged by the injection of diesel into a gas tank. Diesel fuel is much thicker; hence, it contaminates the fuel, affecting the performance of the engine. Be sure to use the nozzle that corresponds to your vehicle’s fuel type.

Are diesel and gasoline fuel pumps different?

Yes, the pumps for diesel fuel and the pumps for petrol are designed differently. The heavy-duty components in diesel fuel pumps allow for the thicker diesel fuel to pass through, while gasoline pumps are used for lighter fuels-almost like petrol. Such a difference is necessary for the safe and efficient transfer of fuel.

Why are the diesel nozzles color-coded?

Diesel nozzles are usually green in color to differentiate them from gasoline nozzles, which are usually black or red. Such color coding instantly tells the driver which nozzle to use and avoids accidental use of the wrong fuel.

Can I use an unleaded nozzle to pump diesel?

No, unleaded nozzles cannot be used interchangeably with diesel nozzles. Diesel nozzles are designed with diesel fuel in mind, while unleaded nozzles work for petrol. Wrong nozzle use can cause contamination of fuel and damage to your vehicle.

How do fuel dispensing nozzles operate?

A fuel dispenser nozzle has its own purpose: intuitively transferring fuel from the dispenser through the filler neck to the vehicle fuel tank. Somewhere in the middle of its simple purpose of dispensing fuel, some nozzles generate an automatic shut-off to prevent overflow, and sometimes in the interest of safety. Knowing how these nozzles work is one prerequisite for an effective fueling operation.

How do diesel and gasoline fuel systems interact with each other, and how do they differ from each other?

Each system is intended to deliver fuel to the engine. But, of course, in this narrow category of a dichotomy, fuel nozzles, pump designs, and types of fuels do differ. Unlike gasoline engines, diesel engines go about their work and require special parts and methods of fuel delivery.