Few devices are as ordinary yet indispensable as the gasoline pump. Every morning, commuters, long-haul drivers, and service fleets rely on the same compact assembly to convert a card swipe and a nozzle squeeze into the reassuring glug of fuel. Because the dispenser is routine, its mechanics can feel invisible; consumers seldom stop to wonder what happens after the receipt prints. The following sections unpack the pump-piping, electronics, and emergency safeguards, hoping the next fill-up inspires at least a moment of technical wonder.

What is a Fuel Dispenser and How Does it Operate?

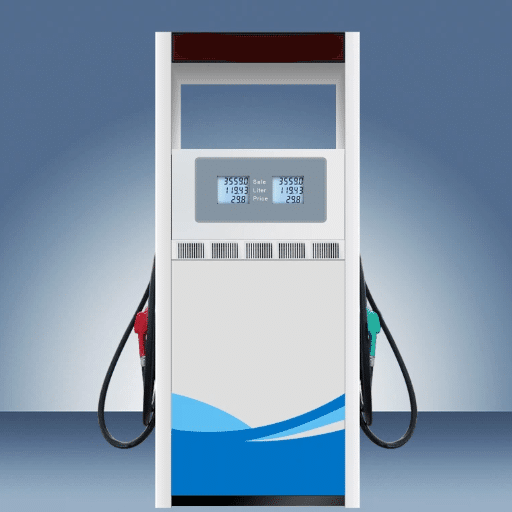

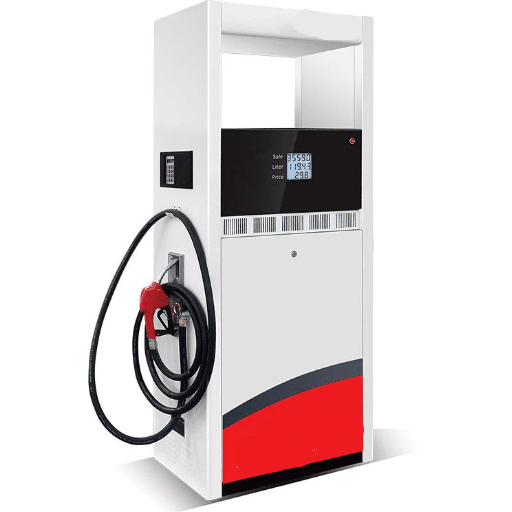

A fuel dispenser is a unit designed to dispense fuel, that is petrol or diesel, or any other type of fuel, into a vehicle or a receptacle from an underground storage tank. Generally, it comprises a pump that helps pump fuel under the precise amount required by the consumer from hoses reaching the nozzle, where the user operates the pump to produce the desired action. Advanced fuel stations also have scaling devices that accurately record the amount of gas purchased in such transactions and come with pricing and leveraging indicators. Protective characteristics, such as being cut off automatically, are provided as a means of safe fuel dispensing to mitigate any spillages due to over-filling.

Components of a Fuel Dispenser

A typical fuel dispenser bundles several mechanical, electronic, and hydraulic elements, all working together to move liquid fuel from a tank into a customer’s vehicle.

The hydraulic core, which includes a high-volume pump and a series of pressure-controlled valves, pushes product up to the nozzle and keeps the flow steady, even when hundreds of gallons per hour are drawn.

Mounted just behind the nozzle, the metering unit organizes the transaction by measuring every drop that travels through the line and recording it with a precision that regulators routinely audit.

The hand-held dispensing portion is completed by an operator-friendly nozzle paired with a flexible hose; most nozzles feature a spring-loaded shutoff that kicks in the instant the tank reaches the rim.

Digital readouts atop the dispenser track current prices, accrued volume, and payment confirmations, while a hidden microprocessor crunches the totals, applies taxes, and logs the sale.

Safety hardware protects users and retail staff: pressure-relief valves ease excess strain, anti-siphon collars prevent backdraft, and brightly colored emergency buttons kill pump power at a glance.

Some modern dispensers also include a vapor-recovery system that snares escaping fumes and channels them back into the tank. This practice reduces local air pollution and keeps the site in compliance with emissions rules.

The Role of the Fuel Pump in Dispenser Functionality

A fuel pump initiates the journey of gasoline, diesel, or any other product from a buried tank to a customer’s fuel neck. Without it, the entire dispenser lineup waits for something to happen. That technical dependency makes the pump a linchpin.

Submersible versions sit submerged inside the tank itself. Because they are already immersed, they can push out large volumes without adding much sound to the forecourt, and they cut down service calls since most moving parts spend their lives inside fluid. A suction setup, in contrast, mounts at the dispenser and drags product upward via vacuum. Such an arrangement works well for low-turnover sites but struggles if the pipe run stretches beyond a certain distance.

Manufacturers chase watts like any industry does, so modern pumps carry readouts that flag flow rate dips, pressure drops, or the odd leak long before an inspector arrives. Some even switch among grades on the fly, blending mid-grade, premium, and diesel so a single nozzle can hand the driver whatever blend matches that dash-mounted request.

Testing conducted at various commercial sites shows that a properly calibrated dispenser pump can move 10 to 40 gallons of product per minute, a range primarily driven by the choice of nozzle and the specification of the fuel itself. That kind of throughput translates directly into shorter waits for motorists and healthier sales figures for the station owner. More recently, manufacturers have begun fitting energy-hungry motors with smart-frequency drives and cloud-linked controllers; the upgrades help trim electricity bills and shave a few extra grams of exhaust from the site.

When every nozzle is hooked to a pump that spins freely and torques steadily, spills become rare, attendants breathe easier, and a single outage no longer drags on for hours. Reliability like that turns the pump from a mere accessory into the backbone of the entire retail system.

Understanding the Working Principle of the Fuel Dispenser

A typical roadside fuel pump combines mechanical gearing with electronic sensors in a way that feels almost effortless when you squeeze the nozzle. Beneath the asphalt, a submersible turbine or a suction pump pulls product from a buried tank and kicks it toward the dispenser. Before reaching the hose, the liquid snakes through one or two filters that catch rust fragments, dust, and water droplets that might lurk in the line.

Inside the cabinet, a flow meter records the passing gallons with stopwatch precision. Manufacturers now favor positive-displacement models or, when budget allows, Coriolis units because both types stay reliable and need little upkeep. A microprocessor collects the meter readout, tags it with the price per gallon, and lights the figure on the customer-facing display.

Safety regulators have made vapor recovery hoses standard, so escaping fumes glide back toward the tank instead of ballooning into the air. The latest machines go a step further, automatically correcting for temperature changes in the fuel and sending usage data over Wi-Fi to a cloud dashboard that lets station owners troubleshoot pumps from a laptop half a state away.

Recent engineering trials indicate that state-of-the-art digital flow meters now operate within a remarkable ±0.2 percent tolerance, dwarfing the margins typical of legacy designs. Manufacturers credit this leap to high-resolution sensors and firmware that self-calibrate after every transaction. Meanwhile, rugged stainless-steel internals let fueling hardware endure round-the-clock service without noticeable drift. A final feature rarely advertised is the automatic bleed-off vent, which quietly protects drivers from overpressure while keeping vapors out of the atmosphere.

How Does the Petrol Pump Accurately Dispense Fuel?

Without the risk of fuel pilferage and spillage, advanced digital dispensers at filling stations are more accurate for measuring and dispensing fuel. A greater understanding of this is possible with flow meters. These are calibrated so that their diffusion rate can be easily gauged for the flow of fluids in vessels. Also, excess discharges are catered for since automatic nozzles have their shut-off sensors and mechanisms that stop the liquid’s flow immediately after the tank is full or the set quantity of fuel dispensed is achieved. In simple terms, such advanced facilities provide the exact amount of fuel required and save consumers both time and cash.

Mechanisms to Ensure the Accuracy of Fuel Dispensers

Accurate fuel dispensing rests on interlocking devices that secure correct measurement and delivery. At the heart of this architecture sits the calibration unit, a safeguard that forces each dispenser to meet government benchmarks and disburse the proper quantity. Inspectors return regularly, as the rules demand, because even minor mismatches can snowball into sizeable losses.

Temperature-induced expansion and contraction are other persistent headaches, yet modern pumps shrug them off thanks to built-in compensation schemes. Sensors planted along the flow path monitor thermal shifts, and computers rewrite the volume readout on the fly, so consumers never notice anything amiss. Drive across town in January or August; the ticket still reads the same number.

Metering heads add another layer of precision and come in two primary flavors: positive-displacement and Coriolis. The former bills itself as a mechanical journalist, trapping fixed fuel pockets and counting them like tally marks. The latter, somewhat nobler, reckons mass flow on the fly, thereby handling ethanol, diesel, and jet fuel equally calmly.

Finally, screens and software now oversee the ballet from a dispatch office miles away. Alarms light up if a leak springs, a flow drifts, or a sensor goes quiet, letting technicians stroll in before the situation gets expensive. That constant alertness trims downtime, increases customer trust, and quietly elevates the profit margins most owners never bother to tally.

Comprehensive durability testing is a cornerstone of reliable dispensing accuracy. Each material slated for a fuel dispenser undergoes intensive examination for mechanical abrasion, chemical toxicity, and harsh weather effects, a practice that preserves measurement integrity throughout the device’s operational life. This series of safeguards converges to deliver fuel with exceptional consistency, satisfying the expectations of motorists and the regulatory standards of the petroleum sector alike.

The Importance of Calibration and Fuel Management

Accurate calibration sits at the heart of effective fuel dispensing, translating directly into consumer confidence and regulatory approval. When a pump is correctly tuned, every liter delivered matches precisely what the meter shows, minimizing financial discrepancies and public mistrust. Uncalibrated equipment, by contrast, hands out either too much or too little product, quietly eroding a dealer’s bottom line and brand reputation until someone finally notices the drift.

Even a mere 0.5-percent error—a figure from recent field surveys—can result in thousands of dollars in lost revenue once the number of transactions hits the daily or monthly totals retailers typically rack up. New, semi-automated calibration rigs can slash testing time by as much as 30 percent, giving technicians a fighting chance to keep pace with their equipment.

Meanwhile, fuel management is more than just tank inventory and weekly deliveries; it flags leaks, schedules shipments, and pairs supply with surging local demand before a shortage registers on customers’ dashboards. Fresh installations of intelligent monitoring software have trimmed operating costs by 15 to 20 percent, mainly by catching theft early and tracking stock levels down to the specific nozzle. Real-time data feeds stitch together terminals, transporters, and back-office planners, turning what used to feel like guesswork into a timetabled, low-waste dance.

Accurate calibration paired with innovative fuel management technology lets organizations trim waste, hit demanding measurement benchmarks, and run cleaner from one shift to the next.

How Does the Flow Meter Measure the Amount of Fuel?

Fuel meters aim to be more precise, reliable, and technologically advanced in measuring the amount of fuel. It calculates flow rates and the diesel volume that has gone through the calibrated chamber in the meter using the assigned flow sensors or mechanical valves. The modern flow measuring instruments frequently integrate turbine, positive displacement, and Coriolis technologies, among others, given the conditional factors. For instance, the billings for Coriolis flow go directly to the fuel mass as it detects the frequency of the fuel-induced changes. This means the accuracy is highly rated even when the conditions are different.

Hence, the flow meters have undergone a revolution in form and function. Today, most of them have become digital with data and sensors that give real-time feedback on fuel delivery quantities, rates, and temperature, which are essential for all fuel management calculations. Fuel monitoring can be enabled so that there is no margin for error by reducing excesses in fuel consumption. They believe that by the year 2025, implementing all these aspects while leaving nothing to chance, their flow meters installed will maintain an accuracy in the region of ±0.2cy under the capacity. These devices cannot be dispensed within modern petrol distributing and conveying facilities that work securely, and responsibility must be observed.

What Role Does Vapor Recovery Play in Fuel Dispensing?

The recovery of surplus fuel is crucial during refilling activities as it functions to capture noxious fuels being emitted during these processes. These gases are usually burned in the air through the breather crater unless trapped in a storage tank or provided with the proper equipment. This eliminates the release of vapors and encourages the protection of the surroundings. The performance of vapor recovery systems is also instructional for engineers to conform to pertinent environmental regulations.

Understanding the Process of Vapor Recovery

Vapor recovery is a crucial intervention designed to catch and recycle the hydrocarbons that slip into the air when fuel is stored, pumped, or moved around. The operation is divided neatly into two acts: first, the vapors are gathered, and then they are put through a refinement step. In the gathering stage, specially calibrated nozzles, piping runs, and custom-built tanks trap gasoline fumes before they disperse. Once collected, the gas heads for a dedicated recovery unit, where engineers compress and chill the mixture until it turns back into a usable liquid.

Technology has marched ahead, giving the market Stage I and II setups. Stage I systems grab the vapors that bubble out of a tank when it is filled at the station; Stage II outfits deal with the fumes that escape while a motorist tops off a car. Recent industry surveys suggest the newest configurations trim air emissions by as much as 98 percent, a figure that keeps regulators and residents alike within safer breathing room.

Installing vapor recovery systems offers a pragmatic intersection of ecological responsibility and workplace productivity. When volatile organic compounds are captured rather than released, firms stop wasting money on gas that disappears into the atmosphere. The approach reads as straightforward climate action and, significantly, lowers the risk of respiratory irritants for nearby residents.

Benefits of Vapor Recovery in Petrol Pumps

Installing vapor-recovery equipment at a service station does more than check a regulatory box; it quietly trims back the layers of smog hovering over busy intersections. The hardware grabs the phone-book-thick plume of volatile organic compounds that sometimes puffs out during a fill-up and does so with surprising efficiency. Field tests now routinely report that 90-plus percent of those evaporating fumes end up in a tank, not the skyline. Fewer VOCs over the hood means fewer mystery coughs, fresher morning air, and, in the long run, less strain on everybody’s lungs and the country’s natural credit card for clean-up.

Beyond the public-health story, the pumps get a second lease on value. Every gallon of gasoline logged as vapor is money that simply drips into the ether, yet a closed-loop system redirects that gas back into the dispensers, almost like catching rainwater on a windshield. Small-to-mid-size stations running steady traffic have been known to bag an extra 4,000 to 10,000 gallons a year, flipping what used to be waste into a tidy line on the profit side of the ledger. Given current prices, even conservative operators admit that the savings pay for the equipment rental and labor in a matter of months.

Blending vapor recovery systems with existing operations frequently satisfies regional regulations demanding tight management of volatile organic compound emissions. Meeting those rules shields companies from costly fines and publicly signals a seriousness about air quality. Choosing this technology also goes a step beyond the letter of the law, visibly backing the broader push to ease climate change pressures.

How is Fuel Stored and Delivered to the Fuel Dispenser?

Underground or above-ground fuel tanks hold fuel as per design in significantly large volumes and are powerful. Moreover, these tanks have protective devices that constantly enable fuel leak prevention and security. Fuel is produced from a storage tank, which is then led to the dispensers with tubes. A pump in the system moves the fluid to the dispenser so that there is no hindrance in the distribution. The dispenser further posits good containment inside vehicles and can transfer fluid accurately, wasting less energy and time.

Exploring the Storage Tank Systems

Storage tank technology has come a long way since gauges were read by hand. Most modern systems now bundle pumps, sensors, and display panels into a single package that runs software updates, trying to catch problems before they become problems. Automated monitors track fuel height, temperature flux, and even in their quiet moments, silence that might mean a leak is starting to speak up.

Engineers have also leaned hard on tank-in-tank designs, where one shell sits snugly inside another, and a gap the thickness of a paperback carries the wires for an emergency alarm. Field tests say this simple, almost mechanical redundancy chops the odds of a spill reaching soil or water by as much as seventy percent, an eye-opening figure that keeps older single-walled units parked in the museum wing.

Faced with salt air, acid rain, and the occasional spider-web of micro-cracks, many companies now build with fiberglass-reinforced plastic because the stuff shrugs off rust as casually as an umbrella shrugs off morning mist. A well-made FRP tank sits, unpainted and unbothered, through humid summers and chemically spiced winters, and inspectors can forget about cathodic protection schedules for a decade or more. Over a long horizon, that reliability saves both money and headaches.

Many fuel-storage terminals are outfitted with vapor-recovery rigs in response to stricter environmental rules. Those rigs grab the volatile organic compounds that would otherwise slip into the air during product transfers, cutting emissions, boosting local air quality, and returning data hinting at reductions topping 95 percent.

Meanwhile, cloud-linked sensors let operators monitor tanks and pumps from almost anywhere. The dashboards display trend charts, flag maintenance chores before they escalate into crises, and generally tighten control over fuel handling.

The new hardware and more innovative software give terminals a powerful safety and stewardship upgrade. Firms that install the gear stay inside the letter of the law while nudging their operations toward the longer-range goal of real, measurable sustainability.

The Journey of Fuel from Underground Storage Tanks

Fuel journeys begin hundreds of feet underground, where strict rules dictate every move from tank to nozzle. Those wells hide massive steel chambers that cradle gasoline, diesel, or specialty blends until a demand spike lifts the lid. Once pumped out, hydrocarbons glide through private pipes on their way to retail pumps or awaiting transporters.

Modern tanks boast smarter guts: sensors ping alarms, alerting operators of slips in level or mystery drips. Roughly nine in ten American stations rely on this kind of storage, sheltering enough fuel to refill the nation’s fleets repeatedly. Dual-walled shells and automatic monitors turn these silos into unlikely environmental sentinels.

High-pressure booster pumps shove product into public dispensers, where commuters and contractors click a trigger. Long-haul tankers repeat the routine, heading toward factories, hospitals, and runways that depend on steady fuel veins. Each hand-off and transfer hookup unfolds under watchful safety codes designed to edge spills toward zero and keep the product clean.

Reliable fuel-handling systems minimize leakage, streamline deliveries, and curb greenhouse gases. Ongoing research and design improvements give underground-tank operations a firmer ecological footing even as global energy appetites rise.

Role of Suction Pumps and Submersible Pumps

Suction and submersible pumps are vital in moving fuel from an underground storage tank to the surface dispensers. A suction pump makes that transfer by creating a vacuum that lifts the liquid upward through piping. Such pumps tend to be found in smaller configurations where the tank sits close to the point of sale. Their straightforward design, minimal upkeep, and lack of elaborate control gear help explain their enduring popularity in those compact systems.

In contrast, a submersible pump is installed directly within the tank, pushing fuel rather than pulling it. Because of that pushing action, the unit can maintain a strong flow even when the discharge line stretches considerably. Larger fueling terminals dealing with heavy-volume demands or placing tanks away from dispensing outlets rely on these in-tank pumps. Their high efficiency and consistent discharge pressure make them a standard feature in underground-fuel operations.

Recent surveys of petroleum-handling equipment show that modern submersible pumps deliver 50 to 60 gallons per minute, comfortably exceeding the 20 to 25 GPM most suction pumps manage. Fresher designs trim kWh per barrel by letting operators dial in flow rates rather than running the motor flat out. That minor tweak saves power and quietly nudges the technology toward greener territory.

Selecting the right pump for an underground storage tank is never purely technical; economies, distances, and legal limits argue their case. A decision that ignores those practicalities can stall a dispensing site or draw a compliance warning, neither of which looks good on the quarterly report. When properly matched, the two pump types keep fuel moving smoothly and reliably from tank to nozzle, preserving the uptime every fleet operator lives by.

How Have Modern Fuel Dispensers Evolved?

Fuel dispensers have transformed from their old-fashioned mechanical guts into sleek, digital problem-solvers. What was once a simple dial and lever now runs on microcontrollers that log gallons to the penny, track sales, and almost settle a journal every night. Touchscreens walk users through prompts in multiple languages, near-field payment zaps ease that last-minute wallet hunt, and built-in safety cutoffs watch over the whole thing like a quiet co-pilot.

Technological Advancements in Automated Fuel Dispensers

On the back end, vapor recovery collars snag fumes before drifting into the air, so the pump does its job without leaving a trail. That combination of accuracy and ecology lets station owners boast about reducing their carbon footprint without leaning on guesswork. Modern pumps prove that reliability, user comfort, and environmental duty can ride the same line at a busy intersection.

Integration with Management Systems for Better Control

Many gasoline retailers are now outfitting their nozzles with intelligent management dashboards. That configuration gives supervisors a clear view of every tank and every pump, trimming the guesswork of daily reconciliations. When a single software hub threads the dispensers together, choreographed duties, audit logs, and service alerts follow almost by reflex. Such tight coupling safeguards against leakage and eases the grind of compliance paperwork. Operators appreciate the arrangement even more when cloud servers let them review metrics from the freeway shoulder instead of the lot.

Reference Sources

Design and Implementation of a Fuel Dispenser using RFID

Automatic Vehicle Fueling System using PLC Controlled Robotic Arm (2022)

Fuel Automata: Smart Fuel Dispenser using RFID Technology and IoT-based Monitoring (2023)

Frequently Asked Questions (FAQs)

Q: What is a fuel dispenser?

A: A fuel dispenser, often called a gas pump, is a machine at a filling station that pumps gasoline, diesel, or other fuels from underground tanks into vehicles. It is a complex system designed to ensure safe and efficient refueling.

Q: How does the fuel flow from the underground storage to the vehicle?

A: The fuel flow starts with the pump dispenser drawing fuel from the underground tanks. The electric motor powers the pump, which moves the fuel through a series of pipes to the fuel nozzle, dispensing it into the vehicle’s gas tank.

Q: How is the fuel volume accurately measured?

A: Fuel dispensers use electronic counting systems to measure the amount of fuel being dispensed accurately. These systems often include a transducer and electronic counting display to ensure precision in the refueling process.

Q: What role does the fuel nozzle play in the dispensing system?

A: The fuel nozzle is critical to the dispensing system, allowing users to control fuel flow into their vehicle. It has a trigger mechanism and often includes an automatic shut-off feature to prevent overfilling.

Q: Why is filtration necessary in the fuel supply process?

A: Filtration is crucial to remove impurities from the fuel before they reach the vehicle. This process helps protect the vehicle’s engine and fuel injection system from damage caused by contaminants.

Q: How do pump manufacturers ensure the safety of fuel dispensers?

A: Pump manufacturers incorporate safety features, such as explosion-proof components and oil-gas separators, to prevent accidents. These measures ensure the safe handling and dispensing of volatile fuels like gasoline and diesel.

Q: What is the purpose of the fuel gun in the refueling process?

A: The fuel gun, another term for the fuel nozzle, delivers fuel from the dispenser to the vehicle’s tank. It is designed for easy handling and precise control over the fuel flow.

Q: How does the electronic counting display assist users?

A: The electronic counting display provides real-time information on the dispensed fuel volume and total cost, helping users monitor their refueling process and manage expenses efficiently.

Q: What are underground tanks, and why are they used?

A: Underground tanks are storage containers buried beneath filling stations to hold large fuel volumes. They maximize space and provide a safe, secure method for storing oil and gas products until they are needed for refueling vehicles.

Q: How does a fuel filter contribute to the fuel dispenser system?

A: The fuel filter is an essential component that removes debris and contaminants from the fuel as it travels through the dispensing system. This helps maintain the quality and performance of the fuel, protecting the vehicle’s engine and fuel system.