Piles under CFA constitute widely applicable foundation systems all over the construction domain, regarding their endless array of efficiency, versatility, and economy. From the supports subjected to a low-rise construction to those of massive infrastructural works, they remain unconquered means for solving geotechnical problems of different natures. One would want to analyze the basic advantages and disadvantages of CFA piles in order to help decision-makers, engineers, and practitioners in the industry establish their suitability for a project. In this guide, you will read all about the essential characteristics of performance, applicability, and limitations of CFA piles, which will allow you to make well-informed decisions about your construction projects.

Understanding CFA Piles

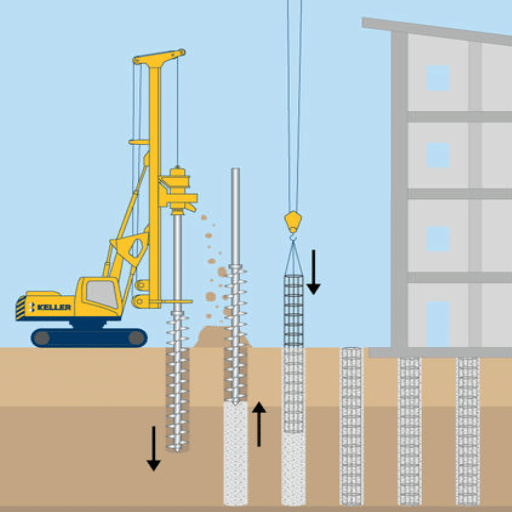

Continuous flight auger piles are a special type of deep foundation that is drilled into the ground to the required depth using the auger, and the fluid concrete is then injected through the hollow stem of the auger as it gets withdrawn. This allows for no casing or temporary support to be employed, rendering it ideal for collapsible or weak soils. Once the concrete has been poured, a reinforcement cage can also be lowered into it to add strength to the pile. These piling systems find wide applications in general construction work where the generation of noise and vibration must be kept to a minimum or where the ground conditions do not permit the use of traditional piling methods.

What are CFA Piles?

CFA piles are foundation elements, and this is how one of the many variations may be achieved by drilling with a hollow stem auger to the required depth. The concrete is pumped through the hollow stem as the auger gradually withdraws from the hole, thus replacing the soil being removed with fresh concrete. Since the concrete keeps the hole open, there is no need for conventional casing or a temporary support system, and this makes the method highly convenient for unstable or collapsible soils. Reinforcement will then be inserted into the wet concrete to enhance the strength of the pile, usually in the form of a steel cage. These piles are used where minimum noise and vibrations are an issue during construction, such as in urban or sensitive areas, and where ground conditions are suitable for this technique, especially in those where other piling methods cannot be applied.

Construction Process of CFA Piles

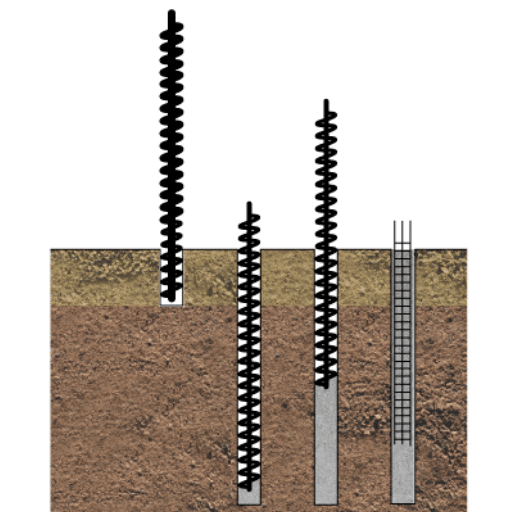

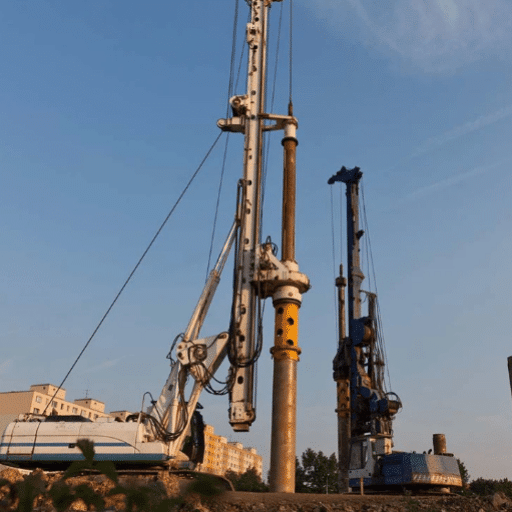

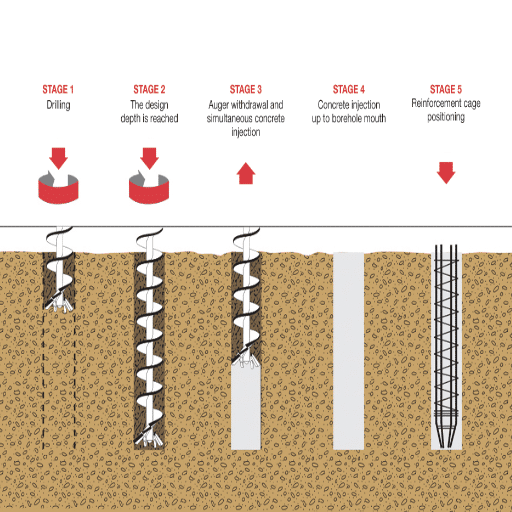

There is a definite sequence to the installation of CFA piles that is to be followed for structural integrity and adequate performance. The CFA drilling rig positions the auger at the desired location and starts drilling, with the auger boring discontinuously through the soil to the proper depth. The continuous flight auger helps in that there is no soil collapse during the drilling process, as it supports the boreholes on all sides.

Once the placement quality of concrete is suitable, it is pumped under pressure into the auger through the hollow shaft as the auger is gradually withdrawn from the ground. This creates sufficient pressure to fill the bore with concrete and prevents any voids or contamination. To give the immersed concrete stability and strength, a pre-assembled steel reinforcement cage is placed either after the concrete has been put or vibrated in the piles at greater depths. Thus, the advantages of this technique include less noise, less disturbance to the ground, and the ability to be used for any soil inspection.

Strict monitoring during the whole operation is indispensable. Advanced instrumentation has been designed, which literally monitors parameters like depth of auger, pressure, and volume of concrete to ensure compliance with design criteria. A careful vigilance guarantees the best performance with these types of piles, thus rendering CFA piles as one of the most reliable methods to tackle complex construction issues in urban or environmentally sensitive areas.

Quality Control Measures in CFA Piling

A certain amount of precautionary measures needs to be invested in continuous planning for efficient implementation of QC for CFA piling. Soil investigations and interpretations are done to establish site-specific conditions so that pile design can meet structural requirements. Then, during the installation of piles, parameters of measurements may be carried on in real time using advanced instrumentation systems, e.g., auger depth, torque, speed of withdrawal, flow rate of concrete, and pressure. These data are confronted and matched continuously against the design specifications, and in case of departure from them, appropriate measures should be taken at once.

Another noteworthy quality point is that the concrete’s quality is inspected more thoroughly. Tests are made on-site, including slump and compressive strength tests, for the concrete mix to meet set standards. It is essential that the grouting or concreting work be delivered continually and without interruptions. Machinery calibration and maintenance are hence carried out regularly to guarantee reliability and accuracy in the working chain.

Post-concreting testing, like the integrity test (sonic logging or dynamic load testing), gives some further assurance of the pile’s effectiveness. Together, these procedures ensure that the piling work is done to stringent standards, guaranteeing safe and reliable foundations that can stand engineering needs for the long term.

Advantages of CFA Piles

Minimal-Noise and Vibration: The CFA method produces less noise and vibration than the driving of piles; this aspect makes them more suitable in city areas or projects adjacent to sensitive structures.

Rapid Installation: Continuous augering offers the possibility for faster installation without having to apply additional casing or drilling fluids.

Cost-Effectiveness: Less equipment contributes to cost savings; together with swift installation, this leads to a reduction in costs.

Adaptable to Site Conditions: CFA piles can be adequately installed in a range of soil conditions, including loose granular soils and cohesive soils.

Structural Strength: Continuous monitoring during the installation procedure guarantees a uniform pile diameter coupled with good structural strength.

Environmental Considerations: Absence of drilling fluids reduced environmental care and simplified site clean-up.

Cost-Effectiveness of CFA Piles

The cost-effectiveness of Continuous Flight Auger (CFA) piles from maximum efficiency in installation and material usage. Their installation is quick because drilling and concrete filling processes are executed simultaneously, which decreases the presence of time spent at the construction site compared to traditional methods. Shortening project time is, in fact, saving money: that is, fewer work hours when laborers monopolize machinery. CFA piles also eliminate the need for casing or slurry support systems, thus further cutting down on material costs. The ability to tailor CFA piles for different soils means fewer expensive alterations in the soil, making CFA piles an ideal solution for complex ground profiles. Thus, when all benefits are combined, CFA piles are touted as being highly cost-saving without compromising on structural and environmental performance.

Reduced Noise and Vibration

CFA piles are said to have the lowest noise and vibration values among piling techniques-theoretically attributed to the drilling process versus the impact-driven installation, whereby the vibrations and noise disturbances in the ground are immensely increased. Lower noise levels give a win to CFA piles if placed in an urban area or a residential area with a hospital or a school-based project near it. Also, because of the low vibration levels, there will be no risk of any structural damage to the nearby building or underground utilities, thus contributing in times of emergencies to a reduction in the stoppage of work. These features make CFA piles compatible with excellent regulations concerning noise and vibration in construction, alongside their great performance.

Enhanced Load-Bearing Capacity

Due to their uniform composition and seamless bond with the surrounding soil, the Continuous Flight Auger (CFA) piles exhibit extraordinary bearing capacity. This is achieved through simultaneous and continuous drilling and casting of the pile, thus reducing soil disturbance and achieving a dense, well-compacted structure. Due to their large diameter and variable depth, CFA piles can sustain large vertical and lateral loads and hence can be opted for a variety of uses, including high-rise structures and bridge foundations. Aside from this, steel reinforcement cages can be placed in the CFA piles as per design requirements, enabling an increase in their structural capacity and stability. In contrast to conventional piles, which may face difficulties when submerging heterogeneous ground, CFA piles prove to be a more reliable and effective method under such challenging geotechnical environments.

Disadvantages of CFA Piles

Limited suitability in hard ground: The CFA piles may find it difficult to go through dense or hard grounds, thus limiting their application in certain areas of geotechnical engineering.

Risk of defects: In the absence of proper monitoring, faults such as necking, segregation, and inadequate concrete cover might come up, thereby adversely affecting the performance of the pile.

Requirement of equipment and expertise: The installation process requires specialized equipment and skilled operators, thereby enhancing the price of a project and hampering its access in locales void of such resources.

Noise and vibration considerations: While usually very low compared to that generated by other piling systems, these vibrations and noise can have injurious effects upon adjoining structures or environments during installation.

Disadvantages of CFA Piles in Construction

Complex Ground Conditions: CFA piles are ineffective in strata with highly variable or difficult ground conditions since these can restrict drilling operations and essentially restrict the pile quality, hence lower pile performance or provisions of corrective measures.

Quality Control Problems: It is challenging to ensure uniform pile integrity, particularly in poor soil conditions. Defects such as voids or inclusions may develop if stringent monitoring of the piling process through advanced instrumentation is not maintained, thereby detracting from structural reliability.

Ground Stability Issues: Excavation may bring about localized ground instability, particularly in loose or granular soils. The instabilities may then cause soil collapse during drilling, thereby lessening piling efficiency.

High Setup Cost: The deployment of a CFA pile requires high initial costs due to the requirement for special equipment and highly skilled personnel. Such requirements may thus demote its feasibility in projects where costs are critical.

Environmental Impact: Being less noisy than many other piling methods, CFA piling generates vibrations and noise with the spoil material, which might have an impact on areas sensitive to the setting or some sufficiently populated areas.

In light of the foregoing drawbacks, it must be appreciated that the successful implementation of the CFA piles calls for excellent planning, expert working procedures, and tailored working-to-site conditions.

Limitations in Soil Conditions

Certain limitations are imposed on CFA piling operations when subjected to some specific soil considerations. In the case of sandy or loose granular soils, borehole stability may be compromised during drilling, which could lead to partial collapse or over-excavation. Conversely, the resistance offered by dense or gravelly soils can oppose pile installation, culminating in undue wear of the auger flights or inefficient formation of the piles. Furthermore, cohesive types of soils, namely those clayey in nature, can hinder the process as their stickiness tends to clog the auger, thereby inhibiting the efficient removal of spoil. Careful attention to these soil constraints, from the outset, will ensure that CFA piles are structurally safe and reliable. Thorough ground investigations should be coupled with the appropriate selection of equipment and well-informed on-site management to surmount these challenges.

Potential for Quality Issues

A lot of times, the construction of CFA piles has problems with quality due to the deficient execution of procedures or a lack of good quality control. One of the very common issues that arises in economies involves the formation of voids or other defects in the pile shaft. Said defects can arise if the concrete flow is not steady or is stopped midway during the pouring stage. This can seriously diminish the pile’s ability to bear load and, over time, reduce durability. Another peril involves placing inadequate reinforcement into certain positions that will cause structural weakness, lateral, or axial load-wise.

Also, soil inclusions can pose challenges, reducing the homogeneity of the pile when native soil is mixed with concrete. This often occurs due to improper auger withdrawal techniques or improper ground conditions. The concrete mix used should be designed carefully; otherwise, it might lead to segregation and impact workability, thereby affecting the overall quality of the pile. Finally, inadequacy in monitoring key parameters during the installation stage, e.g., auger penetration rates, concrete pressure, and flow consistency, may further aggravate these problems, therefore requiring strong on-site supervision and highly advanced monitoring technologies.

CFA Piles vs. Driven Piles

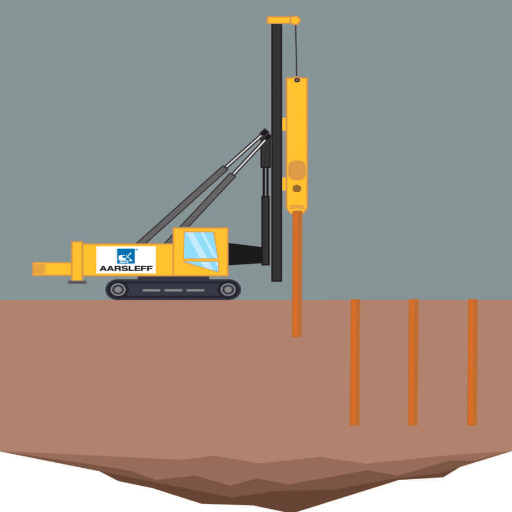

CFA piles and driven piles differ mainly in their installation methods and their suitability to various soil conditions. With CFA piling, an auger drills into the ground whilst concrete is simultaneously pumped in: basically, the void left by the auger is filled in. This method causes very little vibration or noise, and so is suited to urban sites and softer, cohesive soil.

In contrast, driven piles are prefabricated piles driven into the ground by an impact hammer because they are best for penetration resistance on denser or compact soils. Noise and vibration generated through driven piling methods would not be favored in sensitive sites.

Choosing between CFA piles and driven piles depends on the soil conditions, environmental impact considerations, and requirements of specific projects.

Comparison of Construction Methods

Noise and Vibration Generation

One of the advantages of CFA piles is that they minimize noise and vibrations in comparison with driven piles, which must be taken into consideration in urban environments or those considered sensitive. Basically, driven piles consist of driving piles with the help of a hammer, producing noise and vibrations, and these vibrations and noise levels can be disturbing in sensitive environments.

Performance in the Different Soil Types

CFA piles work well in soft to medium-density ground, where drilling is easier and displacement is minimal. Driven piles are preferred in dense or compact soils so that they can penetrate through resistant strata while still achieving high frictional resistance.

Installation of CFA piles causes only minor noise and vibration; hence, these activities can be done in residential or sensitive areas without any disturbances. Driven piles create a huge noise and vibration level while being installed, calling for mitigation measures in noise-sensitive areas.

Cost and Time Efficiency

Generally, CFA piles are a relatively low-cost option for medium-load applications and can be installed rapidly in accommodating soil. Driven piles are generally higher in material cost for prefabrication but can be more productive on large-scale projects that need high-load foundations, due to their production in a controlled factory environment and the assurance of a high level.

For Project Applications

The decision over whether to use CFA piles or driven piles depends on each project configuration, including factors such as loading, soil conditions, environmental regulation, and urban constraints. While CFA piles are typically recommended where noise and vibrations must be kept to a minimum, driven pellets are mostly preferred in heavy-capacity situations within dense soils.

Performance in Different Soil Types

The capacity of both CFA and driven piles greatly depends on the soil conditions considered. CFA piles are better in cohesive soils and granular types and subsist on clays, silts, and sandy layers. The drilling process involves watching the vibrations, making it suitable for urban areas or close to existing facilities. Nevertheless, CFA piles may face some limitations in very dense or obstructive soils, where borehole stability is rather difficult to maintain.

The displaced soils around these piles are usually driven in dense, non-cohesive soils, like gravels or compacted sands, therefore increasing the load-bearing capacity through their displacement mechanisms. They can also give good results in soft soils if they are driven to a sufficient length to reach a stable load-bearing stratum. Yet, the noise, vibration, and environmental effects of installing driven piles may restrict their applications in certain sensitive areas.

Careful consideration of subsurface conditions and project-related parameters when selecting the appropriate pile shall ensure optimal performance of the foundation.

Cost Implications of CFA and Driven Piles

Costs related to CFA (Continuous Flight Auger) piling and driven piling may vary depending on several factors, including soil conditions, project scale, and equipment considerations. CFA piling usually proves to be cheaper for sites that have softer soil and where vibrations cannot be tolerated much, especially in urban environments or areas sensitive to noise. It is often faster to install and requires less site work, hence less labor and equipment cost. By contrast, CFA piling would probably need to bear quality assurance costs, including piling integrity tests and monitoring during installation.

On the counter view for this, heavy machinery and specialized equipment involved in the installation of driven piles usually predict high initial costs. These piles possess a higher load-bearing capacity and can be cost-efficient in the big construction projects that involve strong structural capacities. The condition of adverse soil requiring longer piles or frequent hammering may further increase the cost. In addition, additional costs are incurred if noise protection measures for the driven piles are needed in populated areas.

A complete review of locations, specificity in materials, and constraints pertaining to the project is thus required for efficient and cost-effective solutions, based on costs, so many times the CFA and driven piles stand in opposition to each other.

CFA Piles vs. Bored Piles

The very nature of their construction methods sets CFA piles and bored piles apart. Thus, in application, they differ in being mutually exclusive. In the case of CFA (Continuous Flight Auger) piles, the drilling process consists of a continuous hollow auger being penetrated into the ground through rotation, and concrete is injected through the hollow stem of the auger as it is withdrawn, thus causing very little disturbance to the soil. They suit softer soils, get installed very quickly, and produce little noise and vibration.

Conversely, bored piles drill holes within the soil, plant reinforcements, and cast concrete. It is better suited for harder soils and sites in need of higher load capacities. Thus, stability in a variable-ground condition is of paramount importance, and bored piles are usually chosen.

Some case-dependent considerations regarding the possibility of having CFA piles or bored piles may include ground type, load requirements, and other site constraints.

Differences in Installation Techniques

Few distinctions exist in the installation techniques for CFA (Continuous Flight Auger) piles and bored piles due to being dissimilar methods. In the case of CFA piles, the main process involves drilling with a continuous auger while simultaneously injecting concrete through the hollow stem of the auger as it is withdrawn. This facilitates seamless and continuous formation of the pile while minimizing displacement of the soil, to the extent that the method can be applied in both cohesive and granular soils. Reinforcement is inserted after the concrete has been poured.

Bored piles, on the other hand, are installed through multiple operations. The hole is initially drilled to the desired depth, and temporary casing or drilling fluids are provided in unstable soils to avoid collapse. Reinforcement is then lowered into the drilled shaft, and the hole is filled with concrete. This method provides for a greater degree of control over pile dimensions, making it more appropriate for those large diameter piles with big load-bearing requirements, or in firm or hard soils.

The primary distinction lies in the continuous nature of CFA pile installation versus the staged procedure of bored piles, making each method suitable for specific geotechnical and environmental conditions.

Advantages and Disadvantages of Bored Piles

From my perspective, the major advantages of bored piles are their suitability for service under heavy loads, construction to fairly great depths, and adaptation to all kinds of ground conditions. Another advantage is that little vibration occurs during installation, thus minimizing the possibility of disturbance to structures located nearby. Disadvantages are the longer construction time and higher cost in comparison with some alternate methods. Also, it needs to be under tight quality control to maintain structural integrity, in particular in adverse soil or groundwater conditions.

Which Method is More Suitable?

Very project-specific conditions, such as soil conditions, construction budget, structural requirements, and environmental impact, will determine the suitability of a construction approach. Driven piles can be used and are usually preferred for a cradle foundation deep in difficult geotechnical conditions since they allow high loads to be applied, and they provide immediate confirmation of load application through driving resistance. Bored piles, on the other hand, tend to be chosen by projects wishing to keep noise and vibration to a minimum or in the presence of obstructions in the ground. Though usually the time needed for installation of driven piles is probably less, with fewer variable conditions, bored piles are adaptable to a wide range of soil conditions while permitting exact diameter selection with respect to heavy loads. In conclusion, a chosen method should obey the terms of geotechnical investigation, cost analysis, and match the project objectives.

Reference Sources

Frequently Asked Questions (FAQs)

What are the pros and cons of CFA piles?

CFA piles or Continuous Flight Auger piles carry several advantages, such as speedier installation and less noise and vibration during installation. These are quite well suited for urban areas where disturbance or interruption to the surroundings has to be kept minimum. The only problem with CFA piles is that their load-bearing capacity is less compared to driven piles, and there could be other issues regarding the soil conditions, particularly beneath the water table.

So, how do CFA pile systems measure up against driven piles?

Choosing between CFA and driven piles is usually based on the requirements posed by the particular project and the condition of the ground. CFA piles tend to be quieter and less upsetting and are hence good for urban projects. Driven piles, on the other hand, would generally fare much better in hard or dense soil and also have the highest bearing capacity, though the noise and disturbance created during their installation are harsh.

What’s the difference between CFA piles and bored piles?

CFA piles and bored piles are a type of deep foundation, but their method of installation differs. CFA piles use a continuous flight auger to drill into the earth and place concrete, and bored piles first drill the earth and then fill the drilled hole with concrete. CFA piles are installed more quickly and cause less noise, whereas bored piles may sometimes be chosen when the soil, through more controlled drilling processes, dictates such an option.

Can CFA piles resist tension loads at stability elements?

CFA piles can be designed for tension load applications in stability elements and are suitable for various foundation types. However, their suitability for tension applications may depend on soil conditions and depth of installation. They require a much more rigorous engineering design to adequately provide for the load-bearing capacity the project calls for.

What noise levels are associated with CFA piles?

CFA piles, as reversible applications, have certain advantages with respect to noise and vibrations. Noise control is an important concern in typical urban environment settings. On the other hand, driven piles cause much noise when the impact hammer hits the ground.

How does the drilling process for the CFA piles proceed?

The drilling process for the CFA piles entails using an auger with continuous flight to drill into the ground until the desired depth is attained. At the designated depth, concrete is forced through the hollow stem of the auger so that concrete placement occurs simultaneously as the auger is being withdrawn. This method serves to reduce soil disturbance and provides quality control during installation.

Soil conditions considered good for CFA piles?

Often, CA piles are used in different soil conditions, and their value may vary with factors like soil density or the presence of groundwater. They work best with soil that is soft or medium. Dewatering might come into the picture, among other things, to ensure proper installation if there are hard soils or high levels of groundwater.

In what way do CFA piles improve the ground?

CFA piles serve as a technological means of ground improvement by improving the load distribution system and stabilizing the foundations in weak soil conditions. By transferring the loads to deeper, more stable layers of soil, they also improve the bearing capacity to some extent and hence render sites susceptible to adverse geotechnical conditions an effective solution.