Advanced Aluminum-Magnesium Explosion-Proof Barrier Material in China

We are a premier innovator in industrial safety, providing state-of-the-art Aluminum-Magnesium explosion-proof barrier materials for fuel storage systems. This advanced alloy material, engineered into a lightweight yet robust mesh structure, is the definitive solution for passive explosion suppression. By rapidly dissipating heat and quenching flame propagation, it effectively neutralizes the risk of catastrophic explosions caused by sparks, impact, or static discharge. Our technology not only safeguards critical infrastructure but also reduces fuel sloshing and vapor loss, enhancing operational stability. Committed to excellence and unwavering reliability, we deliver a new standard in protection, ensuring maximum safety and ultimate peace of mind for your fueling operations.

What Is Aluminum-Magnesium Explosion-Proof Barrier Material?

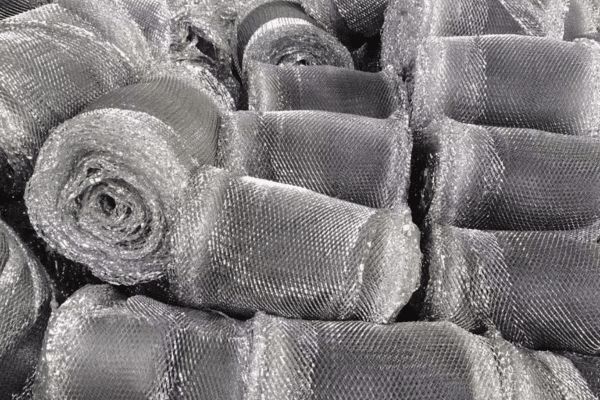

Aluminum-Magnesium explosion-proof barrier material is a specialized safety product engineered for installation within fuel tanks to prevent deflagration and detonation events. It is designed to create a passive suppression system that neutralizes the explosive potential of volatile fuel-air mixtures, thereby protecting critical assets and ensuring operational safety. Typically manufactured from a high-grade aluminum-magnesium alloy, the material is formed into a three-dimensional honeycomb or mesh structure that fills the tank's volume. Furthermore, this design provides excellent anti-static properties, reduces fuel sloshing and evaporation, and maintains its integrity over a long service life, making it a foundational safety technology for modern fuel storage applications.

Working Principle of Gas Station Aluminum-Magnesium Explosion-Proof Barrier Material

Our advanced Aluminum-Magnesium barrier material unique metallic structure and superior physical properties, which fundamentally alter the tank environment to neutralize ignition threats and ensure complete safety.

Rapid Thermal Conduction and Heat Sink

The high thermal conductivity of the alloy mesh rapidly draws heat away from any ignition point. This massive heat sink effect cools the fuel vapor below its combustion temperature, preventing a flame from ever establishing itself.

Cellular Confinement and Flame Quenching

The material divides the tank into millions of tiny, interconnected cells. This structure confines any potential flame, preventing it from propagating by instantly quenching it against the cool metallic surfaces before it can spread.

Anti-Static Grounding and Surge Damping

The conductive alloy mesh prevents hazardous static electricity buildup by safely grounding the entire fuel volume. Its structure also dampens fuel sloshing, further reducing the generation of static charges during transit or refueling.

Major Features Of Aluminum-Magnesium Explosion-Proof Barrier Material

Aluminum-magnesium explosion-proof barrier material is the gold standard for passive safety in fuel storage. Its engineered alloy construction and unique physical properties deliver a fail-safe, permanent solution to mitigate the most severe explosive threats in any fuel environment.

Unmatched Thermal Conductivity

Engineered from a high-performance alloy, the material acts as a massive heat sink. Its exceptional thermal conductivity rapidly absorbs and dissipates heat from any potential ignition source, instantly cooling fuel vapors below their flash point and effectively neutralizing the threat of combustion.

Lightweight & High Strength Design

Constructed from an advanced aluminum-magnesium alloy, the barrier material is both incredibly strong and exceptionally lightweight. This ensures maximum durability and corrosion resistance without adding significant weight or displacing a meaningful volume of fuel.

Inherent Anti-Static Protection

The interconnected metallic mesh structure creates a natural Faraday cage within the tank. This design completely eliminates the buildup of hazardous static electricity by safely grounding the entire fuel volume, a critical safety feature during refueling and transport operations.

Long-Term Durability

The inert alloy is chemically stable and resistant to degradation from all types of fuels and additives. This ensures a one-time, permanent installation that provides continuous protection for the life of the tank, requiring no maintenance, inspection, or replacement, and delivering ultimate peace of mind.

What Differentiates Alloy Barriers From Other Explosion-Proof Methods?

- The alloy barrier functions as a passive heat sink, proactively neutralizing ignition energy through superior thermal conductivity before a flame can form.

- In contrast, active systems are reactive, deploying suppressants only after ignition, while non-metallic barriers primarily manage pressure waves.

- While the alloy offers permanent, maintenance-free protection, active systems demand power, regular servicing, and checks to ensure operational readiness.

How to Guarantee The Effectiveness of an Alloy Barrier Installation?

- Calculate The Required Packing Density: Ensure The Correct Volume Of Material Is Installed To Meet The Specified Percentage Of The Tank's Total Capacity.

- Ensure Uniform Distribution: The Material Must Be Installed To Create A Consistent, Homogeneous Matrix Throughout The Tank, Eliminating Voids Or Gaps.

- Verify Electrical Continuity And Grounding: Confirm The Entire Barrier Matrix Is Properly Bonded To The Tank Shell To Guarantee Anti-Static Protection.

Specifications Table for Aluminum-Magnesium Explosion-Proof Barrier Material

| Parameter | Description | Typical Value/Example |

|---|---|---|

| Material | The primary alloy used to manufacture the barrier material. | High-Grade Aluminum-Magnesium Alloy (e.g., 5000 series) |

| Structure | The geometric design and physical form of the barrier material. | Expanded Three-Dimensional Cellular Metallic Mesh |

| Installed Density | The mass of the material per unit of volume once installed in the tank. | 30 kg/m ³ - 50 kg/m ³ |

| Fuel Volume Displacement | The percentage of the tank's volume occupied by the material itself. | Less than 2% of total tank volume (>98% void space) |

| Explosion Suppression | The core principle for preventing deflagration and mitigating explosions. | Rapid Thermal Conduction, Flame Front Quenching |

| Anti-Static Capability | The material's ability to prevent the buildup of hazardous static electricity. | Inherently Conductive, Provides Full Volume Electrical Grounding |

| Service Life | The expected operational lifespan of the material inside the tank. | Lifespan of the tank (>20 years), Maintenance-Free |

| Operating Temperature | The safe temperature range for maintaining structural and chemical integrity. | -50°C to +150°C (-58°F to +302°F) |

| Fuel Compatibility | Suitability for long-term immersion in various types of fuel without degradation. | Compatible with Gasoline, Diesel, Kerosene, Jet Fuels, Ethanol Blends |

Application Industries of Aluminum-Magnesium Explosion-Proof Barrier Material

Petrochemical & Bulk Storage

Gas Station Storage Tanks

Military & Defense Applications

Marine & Offshore Fueling

Why Choose Aluminum-Magnesium Explosion-Proof Barrier Material

-

Unrivaled Thermal Suppression: Our advanced alloy mesh provides the ultimate proactive safety by instantly dissipating heat from any ignition source, effectively neutralizing explosive threats before combustion can even begin.

-

Permanent "Fit and Forget" Solution: Engineered for the life of the tank, this corrosion-resistant alloy provides a one-time, permanent installation that requires zero maintenance, inspection, or power, ensuring absolute reliability and low total cost of ownership.

-

Inherent Anti-Static Protection: The interconnected conductive alloy creates a natural Faraday cage within the tank, completely eliminating hazardous static electricity buildup during fueling and transport operations—a primary cause of fuel explosions.

-

Minimal Volume Displacement: The high-porosity, lightweight structure displaces less than 2% of the tank's volume, maximizing your usable fuel capacity and preserving operational efficiency without compromise.

-

Superior Structural Durability: Constructed from a high-strength aluminum-magnesium alloy, the material is incredibly robust and resistant to compaction or degradation, guaranteeing consistent, long-term performance in the harshest fuel environments.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“Upgrading our underground storage tanks with this alloy mesh was the single best safety decision we’ve made. The passive, ‘fit-and-forget’ nature means zero maintenance, and its heat dissipation capability is simply unmatched. It provides a level of proactive protection that is essential for public safety.”

Michael Adams

Refinery Safety Director

“The anti-static properties of this aluminum-magnesium material are phenomenal. We retrofitted our entire transport fleet, and it has completely eliminated concerns about static discharge during loading and unloading. Its durability and reliability are exactly what our high-stakes operation requires.”

Jessica Miller

Head of Logistics

Discover the Power of Gas Stations Aluminum-Magnesium Explosion-Proof Barrier Material

How does it prevent explosions?

It works on two main principles:

Rapid Heat Dissipation: The alloy’s high thermal conductivity acts as a massive heat sink, instantly drawing heat away from any ignition source (like a spark) and cooling the fuel vapor below its combustion point.

Flame Quenching: The material divides the tank into millions of tiny, interconnected cells. If a flame were to start, it would be instantly extinguished (quenched) as it contacts the cool metallic surfaces, preventing it from propagating.

How does it handle static electricity?

The interconnected metallic mesh is highly conductive. It effectively grounds the entire volume of fuel, preventing the buildup of hazardous static electricity, which is a primary cause of fuel tank explosions.

Does it also reduce fuel sloshing (surge)?

Yes, the three-dimensional matrix significantly dampens the movement of fuel during transport. This enhances vehicle stability, reduces mechanical stress on the tank, and further minimizes the generation of static electricity.

Does it affect fuel flow or pumping speed?

No, the open cellular structure allows fuel to flow freely. It does not impede the performance of fuel pumps during filling or dispensing operations.

What is the material's operating temperature range?

It is designed to maintain its structural and chemical integrity in extreme climates, typically with an operating range from -50°C to +150°C (-58°F to +302°F).

Will the material corrode inside the fuel tank?

No. The specific aluminum-magnesium alloy used is highly resistant to corrosion from all common fuels, including gasoline, diesel, ethanol blends, kerosene, and aviation fuels.

How is the barrier material installed?

It is typically supplied in rolls or pre-cut sections that are inserted into the tank through an access hatch and expanded to create a uniform, tightly packed matrix that fills the entire vapor space.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

There is a perception of gas stations as mere stops for fill-ups and mini snacks for car-travelers; well, on the […]

Safety comes first in hazardous working settings. Facilities located in areas where flammable gases, vapors, or combustible dust might exist […]

Gasoline is the lifeblood of your vehicle’s engine, but what happens when the fuel you rely on is bad? Bad […]

Although siphoning gas from a car might be a methodical task in the case of emergencies, vehicle maintenance, or fuel […]

Gasoline is a perennial topic of discussion, as it affects consumers, businesses, and economies. Well, what are the actual elements […]

Gas pump nozzles may seem like simple, everyday devices, but they are an integral element of the safe and efficient […]

Generally speaking, filling up your vehicle’s gas tank is a simple procedure, but if you happen to experience slow fuel […]

If we take efficient transfer of fuel or any other liquid from one place to another, transfer pumps are among […]

Get a Quote for Aluminum-Magnesium Barrier Material

Secure your critical infrastructure with the ultimate proactive safety. Our aluminum-magnesium alloy barrier material offers unmatched thermal suppression for any fuel storage application. From large-scale refineries to mobile tankers, we provide a permanent solution. Contact our experts to design a system for your specific needs.

Frequently Ask Questions

Q: Can it be installed in existing fuel tanks (retrofit)?

A: Yes, it is suitable for both new tank manufacturing and retrofitting existing tanks with minimal downtime, making it a versatile upgrade for enhancing safety.

Q: What kind of maintenance does it require?

A: The system is virtually maintenance-free. Once properly installed, it provides protection for the entire service life of the tank without needing inspection, repair, or replacement.

Q: What is the expected lifespan of the material?

A: The material is engineered to last for the lifetime of the fuel tank, often exceeding 20 years, providing a permanent, one-time safety solution.

Q: How is this different from explosion-proof polymer balls?

A: While both are passive systems, the alloy mesh primarily works by thermal conduction (as a heat sink) and offers superior anti-static grounding. Polymer balls primarily work by suppressing pressure waves and absorbing energy, and they are non-conductive.

Q: How does it compare to chemical foam suppression systems?

A: The alloy mesh is a permanent, physical barrier. Foam systems are often single-use, require maintenance, have a limited shelf life, and can contaminate fuel. The alloy provides continuous, clean, and permanent protection.

Q: Is it compatible with biofuels like ethanol and biodiesel?

A: Yes, the high-grade alloy is chemically inert and has been proven to be fully compatible with long-term immersion in biofuels and various fuel additives without degrading.

Q: Has this technology been tested and proven?

A: Yes, this technology has undergone extensive testing by independent laboratories and military organizations worldwide. It has been proven effective in preventing explosions from various ignition sources, including sparks, open flames, and ballistic impacts.

Q: Does the material meet any industry safety standards?

A: Reputable manufacturers ensure their material is designed and tested to meet or exceed stringent international safety standards, such as those from UL (Underwriters Laboratories), ATEX (for explosive atmospheres in Europe), and various military specifications (MIL-SPEC).