Leader Fuel Tank Explosion Supplier in China

We are the premier supplier of explosion-proof barrier balls, specializing in advanced safety systems for fuel storage tanks. We guarantee unparalleled protection, durability, and performance to safeguard your entire fueling infrastructure. For more than a decade, we have earned our reputation as the trusted name in the industry with our commitment to innovation and engineering excellence. Custom or standard, our solutions deliver the highest standards for maximum safety and operational peace of mind.

What Are Gas Station Explosion-Proof Barrier Balls

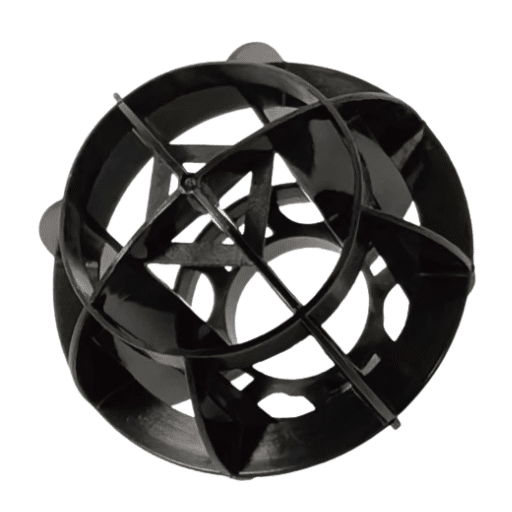

Gas station explosion-proof barrier balls are advanced safety components designed to be installed inside fuel storage tanks to prevent catastrophic explosions. They are engineered to suppress the ignition and propagation of flames within the volatile fuel-vapor environment, thereby protecting infrastructure and personnel. Typically constructed from lightweight, non-metallic polymer materials, the balls feature an optimized multi-sided, hollow 3D structure that effectively dissipates the energy of a potential detonation. Furthermore, this design provides a significant flame-retardant effect, can withstand explosive wave overpressure, and offers excellent surge resistance, making them a crucial component for enhancing the safety systems of modern fuel stations.

Working Principle of Gas Stations Explosion-Proof Barrier Balls

Our explosion-proof barrier balls are a critical safety innovation for fuel storage systems. Through their unique physical structure and material properties, they neutralize explosive threats before they can escalate, safeguarding assets and lives in demanding environments.

Pressure Wave Suppression

The complex 3D lattice breaks up the shockwave of an initial ignition event. By dissipating the explosive overpressure into many smaller, manageable wavelets, the balls prevent the tank from rupturing.

Flame Front Arresting and Heat Absorption

The multi-sided hollow structure acts as a dense matrix, rapidly absorbing heat from a potential flame front. This effect prevents the flame from propagating through the fuel tank’s vapor space.

Fuel Surge and Static Reduction

By filling the tank, the balls significantly reduce fuel sloshing (surging) during transport or filling operations. This minimizes the buildup of hazardous static electricity.

Major Features Of Gas Stations Explosion-Proof Barrier Balls

Gas Stations Explosion-Proof Barrier Balls are essential safety components in modern fuel storage systems, ensuring maximum protection and operational reliability. With advanced materials and an innovative design, they provide a passive, fail-safe solution to mitigate explosion risks.

Superior Explosion Suppression

Engineered with an optimized 3D structure, these balls effectively dissipate explosive overpressure and act as a flame arrestor. This technology neutralizes ignition sources, preventing catastrophic deflagration in volatile fuel environments and ensuring unparalleled safety.

Efficient Filling & Wide Adaptability

The lightweight, individual ball design allows for fast and easy filling of new or existing fuel tanks with minimal downtime. The inert polymer material is chemically stable, ensuring compatibility with a wide range of fuels, including gasoline, diesel, and aviation fuels.

Lightweight Polymer Design

Constructed from advanced, non-metallic polymer materials, the balls are exceptionally lightweight yet possess remarkable structural strength. This innovative construction ensures long-term durability inside the tank without adding significant weight or displacing large volumes of fuel.

Excellent Surge Resistance

By filling the free space within a tank, the barrier balls significantly dampen fuel surging and sloshing during transport and refueling operations. This enhances the stability of mobile tankers, reduces mechanical stress on the tank, and minimizes hazardous static electricity buildup.

What Is The Difference Between Barrier Balls And Traditional Safety Systems?

- Barrier balls function as a built-in flame arrestor, physically preventing flame propagation and absorbing heat energy directly inside the fuel tank.

- Conversely, traditional methods like foam or inert gas systems are typically activated after an ignition event has occurred to control its external impact.

- While barrier balls offer constant, maintenance-free protection, traditional systems often require power, regular inspections, and maintenance to ensure they are ready to operate.

How to Ensure Optimal Performance of Explosion-Proof Barrier Balls?

- Determine Correct Fill Volume: Calculate the precise quantity of balls needed to match your tank's size and the specific fuel type.

- Verify Material Compatibility: Ensure the barrier balls are certified for use with the type of fuel being stored to prevent material degradation and guarantee safe and chemical stability.

- Follow Proper Installation Protocol: Adhere to the guidelines for the installation process, ensuring the balls are evenly distributed to create a uniform suppression matrix that eliminates voids.

Specifications Table for Explosion-Proof Barrier Balls

| Parameter | Description | Typical Value/Example |

|---|---|---|

| Material | The primary substance used to manufacture the barrier balls. | High-Performance, Non-Metallic, Anti-Static Polymer |

| Structure | The geometric design and physical form of the barrier ball. | Multi-Sided, Hollow, 3D Spherical Lattice |

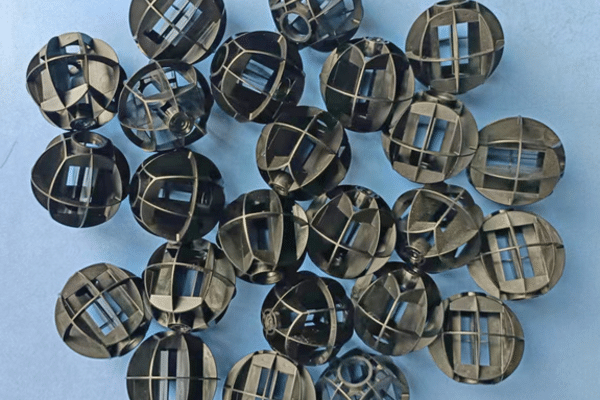

| Ball Diameter | The standard size of an individual spherical barrier ball. | 35 mm - 50 mm |

| Weight per Unit | The mass of a single, individual barrier ball. | 5 g - 10 g |

| Explosion Suppression | The core function of preventing deflagration and mitigating explosive overpressure. | Flame Front Arresting, Shockwave Dissipation |

| Flame Retardancy | The material's ability to resist ignition and self-extinguish when exposed to a flame. | Self-Extinguishing, UL94 V-0 Rating |

| Fuel Volume Displacement | The percentage of the tank's volume occupied by the material of the balls themselves. | Less than 3% of total tank volume |

| Operating Temperature | The safe temperature range for maintaining structural and chemical integrity. | -40°C to +80°C (-40°F to +176°F) |

| Fuel Compatibility | Suitability for long-term immersion in various types of fuel without degradation. | Gasoline, Diesel, Kerosene, Aviation Fuels |

Application Industries of Gas Stations Explosion-Proof Barrier Balls

Military & Defense Operations

Public & Commercial Fueling Stations

Bulk Fuel Transportation

Aviation Fueling Systems

Why Choose Gas Stations Explosion-Proof Barrier Balls

-

Unmatched Explosion Protection: Our advanced 3D structure provides proven flame-arresting and pressure-wave suppression, offering the highest level of passive safety against fuel tank explosions.

-

Passive Fail-Safe Design: Functions continuously without power, maintenance, or activation, ensuring reliable, around-the-clock protection that can't fail due to mechanical or human error.

-

Advanced Lightweight Material: Constructed from a high-strength, non-metallic polymer that is lightweight, durable, and minimizes fuel displacement, maximizing your tank's usable capacity.

-

Superior Surge Mitigation: Effectively dampens fuel sloshing in mobile tanks, enhancing vehicle stability, reducing mechanical stress, and preventing hazardous static electricity buildup.

-

Rapid, Cost-Effective Installation: A simple and fast filling process allows for quick deployment in both new and existing tanks, significantly reducing operational downtime and associated labor costs.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“Installing these barrier balls in our fuel has been a game-changer. The reduction in fuel surge is incredible, making our fleet safer on the road. Knowing we have constant, passive explosion protection gives us unparalleled peace of mind. A vital investment for any logistics company.”

Carmen Keith

Fleet Operations Manager

“The explosion suppression capability of these balls is truly impressive. We retrofitted our fuelers, and the added survivability is a critical advantage. Their passive, no-maintenance design means they are always ready to perform in the most demanding conditions. Essential.”

Carmen Keith

Safety Officer

Discover the Power of Gas Stations Explosion-Proof Barrier Balls

What are the barrier balls made of?

They are constructed from a high-performance, non-metallic, anti-static polymer. This material is lightweight, chemically inert to fuels, and has significant flame-retardant properties.

What specific hazards do they protect against?

They primarily protect against deflagration (rapid combustion) and detonation events within a fuel tank. They also significantly reduce fuel surge (sloshing) and the buildup of hazardous static electricity.

Are they suitable for all types of fuel?

Yes, they are designed for wide fuel adaptability. They are compatible with gasoline, diesel, kerosene, aviation fuels (like Jet A-1), and other hydrocarbon-based flammable liquids.

How much fuel volume do the balls displace?

The displacement is minimal. Because the balls are hollow and have thin walls, the material itself typically occupies less than 3% of the tank’s total volume, maximizing fuel capacity.

How are the barrier balls installed in a fuel tank?

Installation is straightforward. The balls are simply poured or loaded into the tank through an access port until the specified fill volume is reached. Their individual, free-flowing nature allows them to fill any tank shape evenly.

Can they be installed in existing tanks that are already in service?

Yes, retrofitting existing tanks is one of their key advantages. The process is fast and requires minimal downtime, making it a practical safety upgrade for in-service equipment.

What are the requirements for fuel dispenser bases?

The fuel dispenser base must meet several requirements to ensure safety and performance. These include high load-bearing capacity, resistance to weather and corrosion, proper alignment, vibration absorption, and compliance with industry standards and safety regulations. The base must also be compatible with the fuel dispenser’s design for seamless integration and functionality.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Most drivers are aware of the process of refueling their vehicles, yet few consider the numerous improvements made to speed […]

A very important task in industries such as agriculture, construction, automotive, and marine operations is the transfer of liquids such […]

Gas stations are a staple of modern infrastructure, yet their design often goes unnoticed as we come and go in […]

Fuel dispensers act as the most critical component of any fuel distribution setup. They, therefore, constitute the connection between the […]

Safety in hazardous environments is not just a priority, but a necessity. Whether it is chemical plants, oil refineries, or […]

Lots of them are intangible to feel the right fuel transfer pump. Depending on your needs, for example, working in […]

When viewed from on high, a minute fuel pump might well be classified as a producer of life in a […]

If one’s mind goes into the fuel system of a vehicle, the idea of an electronic fuel pump submerged in […]

Get a Quote for Explosion-Proof Barrier Balls

Protect your valuable assets and personnel with the ultimate passive fuel safety. Discover how our explosion-proof barrier balls can be tailored to your specific storage needs, from commercial stations to military fleets. Contact us now for a custom assessment and find the perfect safety solution for your application.

Frequently Ask Questions

Q: Do the barrier balls require any maintenance?

A: No. They are a passive, fail-safe safety system. Once installed, they require no power, no activation, and no maintenance for their entire service life.

Q: What is their expected lifespan?

A: They are engineered for long-term durability. Made from a robust polymer that resists degradation from fuel and environmental factors, their lifespan is designed to match or exceed that of the fuel tank itself.

Q: Will they clog or interfere with fuel pumps and sensors?

A: No. The balls are designed to be larger than the inlet of fuel pumps and suction lines. They form a stable matrix that allows fuel to flow freely through it without causing blockages or interfering with most standard fuel level sensors.

Q: Do the balls affect the quality or chemical composition of the fuel?

A: No, the polymer material is chemically inert and does not leach any substances into the fuel. It will not contaminate or alter the fuel’s properties in any way.

Q: Are the balls resistant to chemical degradation from fuel additives?

A: Yes, the advanced polymer is selected for its high resistance to a wide range of chemicals, including common fuel additives, ensuring long-term structural integrity.

Q: What is the operating temperature range for these balls?

A: They are designed to perform reliably across a broad temperature spectrum, typically from -40°C to +80°C (-40°F to +176°F), making them suitable for virtually all global operating climates.

Q: How do they compare to foam-based explosion suppression systems?

A: Barrier balls offer several advantages over foam. They do not degrade or shed particles over time (which can clog filters), they allow for easy draining and inspection of the tank, and they have a much longer service life without needing replacement.

Q: Are they certified or do they meet any industry standards?

A: High-quality barrier balls are typically tested and certified to meet stringent international safety and military standards for explosion suppression and material safety (e.g., related to flame retardancy like UL94).