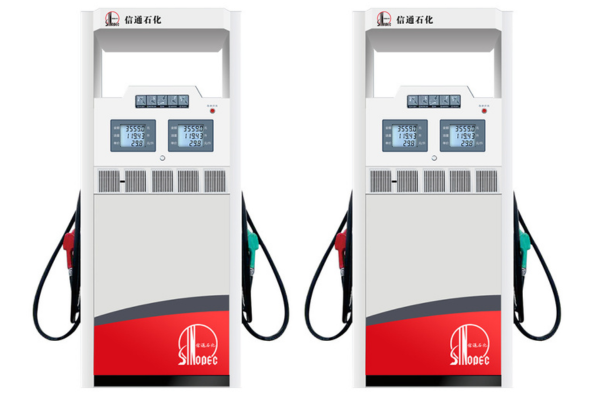

Top Gas Dispenser Manufacturer in China

Partner with the top gas dispenser manufacturer in China, known for quality, efficiency, and innovation. Specializing in state-of-the-art designs, their gas dispensers are built to meet international safety and performance standards. With a commitment to customer satisfaction, they offer competitive pricing and tailored solutions to fit your business needs. Enhance your operations with a trusted industry leader.

What Are Gas Dispenser

Gas dispensers, commonly referred to as fuel or gas pumps, are devices used to deliver fuel like gasoline, diesel, or alternative fuels to vehicles at gas stations. They are equipped with a nozzle and a hose connected to an underground fuel storage tank, allowing for safe and controlled fuel transfer. Additionally, some dispensers integrate advanced technology for card payments or touchless transactions, making them an essential part of the fuel distribution system.

Functions of our Gas Dispenser

Gas dispensers play a vital role in delivering fuel efficiently and safely. Designed with precision, they ensure reliability, accuracy, and enhanced functionality for both commercial and everyday use.

Accurate Fuel Measurement

Equipped with advanced sensors, the gas dispenser ensures precise fuel delivery while minimizing errors. This accuracy helps businesses and customers alike achieve cost-effective fueling and lower wastage.

Enhanced Safety Systems

Built-in safety features prevent leaks and spills during operation. These systems protect against hazards, ensuring compliance with safety regulations and safeguarding users and the environment from potential risks.

High-Speed Dispensing

Offering fast refueling capabilities, the dispenser reduces wait times, significantly increasing efficiency. It’s ideal for high-traffic fuel stations requiring quick service to accommodate large volumes of vehicles.

Key Benefits of Gas Dispenser

Modern gas dispensers combine advanced technology with user-friendly interfaces to ensure reliability, accuracy, and convenience. They play a critical role in energy distribution, focusing on precision and safety for both operators and customers.

Enhanced Accuracy

Advanced metering technology ensures precise fuel dispensing, reducing errors and wastage, while fostering customer trust through reliable and consistent performance.

Robust Safety Features

Equipped with safety mechanisms like leak detection and emergency shut-off, gas dispensers minimize risks and protect users and the environment.

User-Friendly Operation

Modern dispensers feature intuitive interfaces, digital displays, and automation to streamline transactions, ensuring a smooth and efficient refueling experience for customers.

Durable and Weather-Resistant Design

Constructed with high-quality, weather-resistant materials, gas dispensers withstand harsh environmental conditions, guaranteeing long-lasting performance and minimal maintenance.

What Is The Difference Between A Gas Pump And A Gas Dispenser?

- A gas pump traditionally integrates a suction mechanism to pull fuel from underground tanks, while a gas dispenser only dispenses fuel, relying on a separate pumping system.

- Gas pumps combine fuel transfer and dispensing in one unit, whereas gas dispensers focus solely on delivering fuel to vehicles, receiving fuel from an external pump in modern setups.

- The key difference is functionality—gas pumps handle fuel extraction and distribution, while gas dispensers are designed to simply release pre-pumped fuel to vehicles at the station.

How to Choose the Right Gas Dispenser for Your Application?

- Understand Your Gas Type: Identify the gas type and requirements, such as pressure and flow rate, to ensure compatibility with the dispenser's specifications for safe and efficient operation.

- Evaluate Dispenser Design: Consider the dispenser design, including nozzle type, durability, and safety features, ensuring it suits your application’s environment and usage demands for long-term reliability.

- Focus on User Needs: Assess user-specific needs, such as automation level, ease of use, and maintenance requirements, to choose a dispenser that optimizes convenience and performance in your operations.

Comparison Table for the Gas Dispenser Specifications

| Parameter | Description | Typical Value/Example |

|---|---|---|

| Flow Rate | The volume of gas dispensed per minute. | 5-50 liters/minute |

| Dispensing Pressure | The pressure at which gas is dispensed. | 0.5-4.0 MPa |

| Nozzle Type | Design of the nozzle for gas delivery. | Automatic shut-off nozzle |

| Display Type | Type of screen showing dispensing data. | Digital LED/LCD |

| Metering Accuracy | Level of accuracy in measuring dispensed gas. | ±0.3% |

| Hose Length | The length of the hose attached to the unit. | 3-5 meters |

| Power Supply | The electrical input required to operate. | AC 110V/220V |

| Operating Temperature | The range of operating ambient temperatures. | -25°C to 55°C |

Top Application Of Gas Dispenser

Fueling Stations

Industrial Applications

Medical Facilities

Laboratory Operations

Why Choose Our Gas Dispenser

-

Durability - Built with high-quality materials, our gas dispenser ensures long-lasting performance and minimal maintenance requirements.

-

Efficiency - Designed for optimal fuel flow, it saves time during refueling with fast and precise dispensing.

-

Safety - Advanced safety features protect users and facilities, adhering to top industry standards for gas handling equipment.

-

Customization - Flexible options and configurations available to meet specific operational needs and branding preferences.

-

Eco-Friendly - Engineered for reduced environmental impact, it minimizes fuel waste and promotes greener operations overall.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“The gas dispenser I purchased is incredibly efficient and easy to use. It delivers fuel at a consistent rate without any leaks or issues. Highly recommend this product for both personal and professional use.”

John Mitchell

Automotive Technician

“This gas dispenser has exceeded my expectations. The build quality is impressive, and it saves so much time during fueling. It’s reliable and hassle-free. A fantastic choice for anyone managing multiple vehicles or looking for dependable equipment.”

Lisa Carter

Fleet Manager

Gas Dispenser Manufacturers Expert Answers

What is the life expectancy of a gas station dispenser?

The life expectancy of a gas station dispenser typically ranges between 10 to 15 years, depending on factors such as usage, maintenance, and environmental conditions.

How do gas stations fill their tanks?

Gas stations fill their underground tanks using delivery trucks equipped with specialized hoses. These trucks pump fuel into the storage tanks through clearly marked fill pipes, ensuring the appropriate type of fuel goes into the correct tank.

What are the different types of dispensers?

Gas dispensers are commonly categorized into two main types: mechanical dispensers, which are primarily powered by mechanical components and require manual operation, and electronic dispensers, which feature digital displays and automation for enhanced accuracy and user convenience.

How often should gas dispenser filters be changed?

It is recommended to change gas dispenser filters every three to six months or after dispensing approximately 100,000 gallons of fuel. Regular filter changes ensure clean fuel delivery and prevent contaminants from clogging the dispenser.

What makes a good gas dispenser?

A reliable gas dispenser is characterized by durability, accuracy, ease of use, and low maintenance requirements. Features like clear digital displays, robust material construction, and compliance with safety standards make a dispenser more efficient and user-friendly.

How to operate a gas dispenser?

To operate a gas dispenser, begin by selecting the type of fuel and payment method. Insert the nozzle into the vehicle’s fuel tank and squeeze the handle to start fueling. Once the required amount of fuel has been dispensed, release the handle and securely return the nozzle to its holder.

What is an automated gas dispenser?

An automated gas dispenser is equipped with advanced technology, such as card readers and touch screens, to allow customers to complete transactions and pump fuel without assistance. These systems improve efficiency and convenience for both customers and gas station operators.

What not to do when pumping gas?

When pumping gas, avoid the following actions:

- Smoking or igniting flames near the dispenser, as fuel vapors are highly flammable.

- Leaving the pump unattended during fueling.

- Using your cell phone, as it can create static electricity.

- Overfilling the fuel tank, which can cause spills.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Carbide teeth are a must when it comes to foundation drilling, where precision, durability, and speed are of the essence. […]

Fuel dispensers act as the most critical component of any fuel distribution setup. They, therefore, constitute the connection between the […]

The efficient and safe bridging of the gap between manufacturers and conventional logistics, agricultural firms, and construction requires a very […]

Owning a gas station is often considered a stable and profitable venture; however, the question remains: what do gas station […]

Auger cast piles, often interchangeably called continuous flight auger (CFA) piles, are an essential modern foundation solution in geotechnical engineering. […]

When it comes to safeguarding your top-notch documents, a fireproof document box is irreplaceable. In a sudden fire incident, loss […]

The Ambler Texaco Gas Station, sitting beside the iconic Route 66, represents much more than just a crossing or refueling […]

Pulling up to a gas pump is, for many, just another mundane exercise of selecting fuel, detaching the nozzle, and […]

Get Gas Dispenser For Sale Price

Take advantage of unbeatable deals on high-quality gas dispensers today! Whether you need reliable equipment for your station or business, now is the perfect time to make your purchase. Don’t miss the chance to get premium gas dispensers at an incredible sale price. Explore our options and upgrade with confidence!

Frequently Ask Questions

Q: What are ground protection mats?

A: Ground protection mats are durable, portable mats designed to protect surfaces from damage and provide stable surfaces for heavy equipment or construction activities.

Q: What materials are ground protection mats made from?

A: Most ground protection mats are made from high-density polyethylene (HDPE), which is lightweight, durable, and resistant to environmental damage like water and chemicals.

Q: Can ground protection mats support heavy machinery?

A: Yes, ground protection mats can support heavy equipment, such as cranes, excavators, and trucks, thanks to their high load-bearing capacity.

Q: Are ground protection mats reusable?

A: Yes, ground protection mats are designed to be reusable, making them a cost-effective and environmentally friendly solution for multiple projects.

Q: How do ground protection mats help in construction sites?

A: These mats protect the ground from being damaged by heavy machinery, prevent soil erosion, and enhance site safety by providing traction and stability.

Q: Are construction mats easy to install?

A: Yes, ground protection mats are lightweight and easy to install, typically requiring minimal effort or additional tools to set up.

Q: Can ground protection mats be used in all weather conditions?

A: Ground protection mats are engineered to perform in various weather conditions, including extreme heat, rain, and snow, offering reliable protection and traction.

Q: What are the common sizes of ground protection mats?

A: Ground protection mats come in a variety of sizes to suit different needs, with standard dimensions typically ranging from 4×8 feet to larger custom options depending on the project type.