Top Gas Station Pipe Supplier in China

Looking for a Class A gas station oil pipeline and gas station weed pipe? Having been regarded as the most renown gas station pipeline manufacturer in China, we put our utmost efforts into supplying durable and reliable products to meet your specific requirements. Made with the latest manufacturing methods and under stringent quality control, our pipelines are ideal for transferring oil in a highly efficient manner while our weed pipes are methodically designed for superior performances. Choose a reputed Chinese manufacturer weighing highly on the aspects of product excellence and customer satisfaction.

What Are Gas Station Pipe

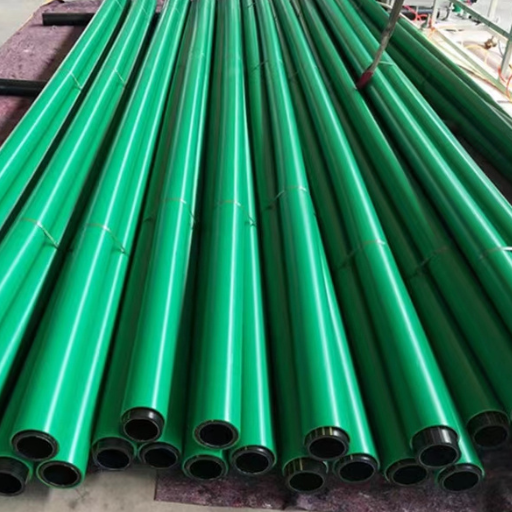

Pipelines are some vital components of fuel dispensing systems at service stations. These pipelines carry fuel from the underground storages to the pumps safely, thus enabling efficient and safe servicing. Usually, some environmental and safety regulations must be followed during the construction and installation of gas station pipes. This helps minimize risks, including potential dangers to the surrounding environment. These pipes are constructed to withstand high pressure and corrosion and to avoid fuel leakages, generally made of steel or fiberglass reinforced plastic.

Functions of our Gas Station Pipe

Our gas station pipe is designed with cutting-edge technology to ensure optimal efficiency, safety, and durability. It delivers outstanding performance, meeting the needs of modern fueling stations.

Enhanced Durability

Crafted with high-quality materials, the pipe withstands extreme weather and heavy usage, providing a long-lasting solution for consistent fueling operations.

Leak Prevention

Seamless construction and advanced sealing design reduce risks of fuel leakage, ensuring safety and protecting the surrounding environment.

Efficient Fuel Flow

Engineered to maximize fuel transfer rates, the pipe improves operational efficiency while minimizing downtime, ensuring smooth and reliable fueling experiences.

Key Benefits of Gas Station Pipe

Gas station pipes are crucial for ensuring safe and efficient fuel distribution. Designed to handle varying conditions, these pipes are durable, reliable, and optimized for environmental safety and operational excellence.

Durability and Longevity

Designed with high-strength materials, gas station pipes resist corrosion and wear, ensuring a dependable operation for years under challenging environmental and operational conditions.

Leak Prevention Technology

Advanced sealing mechanisms and robust construction minimize the risk of leaks, protecting the environment and adhering to stringent safety standards for fuel handling and distribution.

Environmental Protection

With eco-conscious designs, these pipes limit emissions and spills, supporting sustainability goals while meeting industry compliance regulations for ecological safety.

Remote Management Support

Enables off-site monitoring, diagnostics, and updates for the dispenser, allowing operators to manage performance and address issues quickly and efficiently from afar.

What Is The Difference Between A Gas Station Oil Pipe And A Gas Station Pipeline?

- A gas station oil pipe transfers fuel within the station's premises, while a gas station pipeline is part of a broader network transporting fuel over long distances to distribution centers.

- Gas station oil pipes are smaller, managing local on-site fuel delivery. Conversely, gas station pipelines are large, designed for long-distance fuel transport between production facilities and stations.

- Oil pipes at gas stations primarily support fuel dispensing. Pipelines serve as essential infrastructure connecting refineries to distribution hubs or storage facilities before the fuel reaches gas stations.

How to Choose the Right Gas Station Pipe for Your Application?

- Consider material durability, such as stainless steel or fiberglass, to ensure resistance against corrosion and chemical damage when selecting a gas station pipe that meets your application needs.

- Evaluate compatibility with fuel types, checking for certifications that ensure the pipe's ability to handle gasoline, diesel, or other fuels safely without compromising performance or safety.

- Assess pipe dimensions and installation constraints, ensuring they fit the specific requirements of the gas station system while meeting industry regulations and long-term reliability standards.

Comparison Table for the Gas Station Pipe Specifications

| Parameter | Description | Typical Value/Example |

|---|---|---|

| Material | The primary material used to manufacture the pipe for durability and chemical resistance. | Steel, HDPE, PVC |

| Diameter | The internal or external diameter of the pipe, important for fuel flow and installation. | 2 inches, 4 inches |

| Length | The standard or customizable length of the pipe sections. | 10 feet, 20 feet |

| Pressure Rating | The maximum operating pressure the pipe can withstand. | 150 PSI, 250 PSI |

| Temperature Range | The operational temperature range suitable for the pipe material and fuel type. | -20°F to 120°F |

| Corrosion Resistance | The pipe's ability to resist damage from exposure to fuel, chemicals, and environmental conditions. | High, Anti-corrosive Coating |

| Certification | Industry regulations or certifications ensuring safety and performance. | API, UL Listed |

| Compatibility | Compatibility with fuel types like gasoline, diesel, or ethanol blends. | Gasoline, Diesel, E10 |

| Installation Method | The intended method for installing the pipe, such as underground or aboveground. | Underground, Flexible Installation |

Top Application of Gas Station Pipe

Fuel Transportation

Underground Fuel Storage Integration

Vapor Recovery Systems

Durability in Hazardous Environments

Why Choose Our Gas Station Pipe

-

Made from durable materials, ensuring longevity and resistance to harsh environmental conditions for reliable performance.

-

Designed for optimal fuel flow, minimizing blockages and maximizing efficiency in gas station operations.

-

Meets international safety standards, providing peace of mind and enhanced safety for users and operators.

-

Easy to install and maintain, reducing downtime and associated operational costs for businesses.

-

Resistant to corrosion and chemical degradation, ensuring consistent quality and functionality over an extended period.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“The gas station pipe I purchased was incredibly durable and easy to install. It’s well-constructed and perfectly suits our needs for fuel transportation. I highly recommend it for anyone seeking reliable equipment for professional or industrial use. ”

Kate Martinez

Construction Manager

“Using the Fuel Dispenser has been a breeze. It enhanced our fleet’s fuel tracking, and the installation staff demonstrated exceptional professionalism.”

Lauren Johnson

Small Business Owner

Discover the Power of Gas Station Pipe

How safe are oil pipelines?

Oil pipelines are generally built with safety as a priority, using advanced materials and technology to minimize risks. Regular inspections, maintenance, and monitoring systems, such as leak detection sensors, further enhance their safety. While pipelines are considered one of the safest methods of transporting oil, there are still risks of leaks and ruptures, often due to aging infrastructure, natural forces, or human error. However, strict regulations and industry standards aim to reduce such risks significantly.

How far down is the oil line buried?

Oil pipelines are typically buried at depths of 3 to 6 feet below the surface, depending on local regulations, land use, and environmental considerations. The burial depth ensures the pipeline is protected from physical damage caused by surface activities such as construction or farming, as well as from erosion and extreme weather conditions.

Do oil pipelines go underwater?

Yes, oil pipelines can go underwater. These are referred to as subsea pipelines and are commonly used to transport oil from offshore drilling sites to the mainland. Subsea pipelines are designed with special materials and coatings to withstand the underwater environment, including high pressures, corrosive saltwater, and shifting seabed conditions.

What problems will arise if oil pipelines are buried underground for a long time?

Over time, underground oil pipelines can face several challenges, including corrosion, natural wear and tear, or damage caused by external environmental factors. Prolonged exposure to moisture and soil chemicals can lead to material degradation. Additionally, ground movements due to natural disasters, such as earthquakes or floods, may cause structural stress. Without proper maintenance, these issues can result in leaks or ruptures, posing environmental and safety risks.

How long do underground oil pipelines last?

The lifespan of underground oil pipelines depends on factors such as material quality, environmental conditions, and maintenance practices. On average, oil pipelines have a lifespan of 30 to 100 years, with modern pipelines designed to last on the higher end of this range. Regular inspections and upgrades can extend their durability, ensuring they remain safe and operational.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Building a gas station from scratch is no small matter; it is a complex project that calls for planning, decisions […]

Pumping is a vital necessity in every industry, be it chemical processing, water treatment, or so on. Distributor pumps are […]

The fuel quality at the different gas stations have at the town and even how frequently you visit the gas […]

Refueling any vehicle may occur as if it were any average gas station. From the quality of fuel offered to […]

Gasoline is the lifeblood of your vehicle’s engine, but what happens when the fuel you rely on is bad? Bad […]

Fuel dispensing systems are critical in facilitating the day-to-day retail transactions in fuel businesses. For businesses in this industry, commercial […]

Due to the safety and efficiency in working conditions, drivers are allowed to bring their vehicles to get refueled easily […]

Few devices are as ordinary yet indispensable as the gasoline pump. Every morning, commuters, long-haul drivers, and service fleets rely […]

Get More Information About Gas Station Pipe

Discover everything you need to know about gas station pipes, including materials, design standards, and durability. Learn how these essential components ensure safe fuel delivery and storage. Explore reliable solutions to meet industry requirements and optimize efficiency. Click here to find in-depth information on gas station piping systems and more!

Frequently Ask Questions

Q: What is a gas station pipe?

A: A gas station pipe is a tubular system designed for the transportation of fuel, such as gasoline or diesel, from storage tanks to dispensing units at gas stations.

Q: What materials are gas station pipes typically made of?

A: Gas station pipes are usually made of durable and corrosion-resistant materials like steel, fiberglass, or high-density polyethylene (HDPE) to ensure safety and longevity.

Q: How are gas station pipes maintained?

A: Regular inspections, pressure testing, and cleaning are conducted to ensure the integrity of the pipes and prevent leaks or contamination issues.

Q: Are gas station pipes environmentally safe?

A: Modern gas station pipes are designed to meet strict environmental standards, often including secondary containment systems to minimize the risk of fuel leakage into the ground.

Q: Can gas station pipes deteriorate over time?

A: Yes, gas station pipes can deteriorate due to factors like age, environmental conditions, and poor maintenance practices, though modern materials are built to last for decades.

Q: What safety measures are taken when installing gas station pipes?

A: Safety measures include proper pipe placement, sealing joints, leak testing, and adherence to local regulations to prevent fuel leakage and ensure safe operation.

Q: How does the design of gas station pipes prevent fuel leaks?

Q: How does the design of gas station pipes prevent fuel leaks?

A: Most gas station pipes include features like double-wall construction, leak detection systems, and high-quality joints to prevent fuel leakage.

Q: Why is it important to use certified gas station pipes?

A: Certified pipes ensure compliance with safety and environmental regulations, reducing risks of accidents, contamination, or fuel system failure.