Have you ever thought about how the gas station pump knows when to stop the flow of gasoline when you are filling your vehicle’s gas tank? It is not merely a question of luck or guesswork; this is a highly accurate and automated process—the pump is engineered and designed in a very scientific manner. The pump’s function of recognizing a full tank is a very interesting point of connection between technology and daily life, as it consists of precise and safe mechanisms that prevent the loss of fuel and enhance safety. In this post, we will delve into the remarkable engineering that was behind the design of this everyday convenience, clarifying the scientific and technical methods involved. Whether you belong to the group of everyday drivers who are simply curious or the group of tech lovers who want to know in detail, this thorough description will help you see the feature that we usually ignore but is nevertheless based on extraordinary creativity.

The Mechanism of the Gas Pump

The ability of a gas pump to inform the customer when the tank is filled is achieved through a combination of fluid mechanics and vacuum pressure technology. A tiny vent hole is present at the bottom of the pump nozzle, which is connected to a vacuum tube inside the pump. Whenever gasoline is flowing, air is sucked in through this vent hole, and the suction is kept constant. But when the tank reaches the level of the nozzle’s tip, the air is blocked. This blockage results in a pressure change that activates a switching mechanism inside the pump handle. The switch then cuts off the fuel flow automatically, thereby preventing spillage.

This system is super effective as it utilizes pressure detection for safety and waste reduction. Just like the design, which accommodates the various challenges of operation, such as tank shape differences and varying fuel flow rates, the system guarantees reliable performance even under difficulties. Modern fuel pumps, by combining these components, provide a seamless and at the same time sophisticated fueling process.

Core Operating Principles

- Fluid Mechanics: The system leverages fundamental principles of fluid dynamics

- Vacuum Pressure Technology: Creates and monitors pressure changes for automatic detection

- Vent Hole System: Small opening connected to vacuum tube for air flow monitoring

- Pressure Detection: Identifies blockage when fuel reaches nozzle tip level

- Automatic Switching: Mechanical mechanism triggers fuel flow cutoff

How the Gas Pump Knows When to Shut Off

The automatic shut-off feature of gas pumps is based on a mechanical system combining the venturi effect and pressure sensitivity at the same time. Inside the nozzle, a small tube is there that measure the pressure changes. The tank gets filled with liquid, and at this point, the displaced air is reduced a lot. The air that is released from the tank goes through the small tube, and in doing so, suction is usually created. In this case, the fuel level is rising, blocking the nozzle opening, and consequently, the flow of air is interrupted, creating a pressure shift that activates a valve to close, thus stopping the flow of fuel. This system is entirely mechanical and does not use any electrical components, which is why it is very reliable and efficient at the same time. The design of the system makes it able to work in all kinds of tank designs and with different filling rates while still being consistent in its performance.

Components of a Gas Pump and Their Functions

The gas pump consists of several crucial elements, each of which is responsible for the safe and efficient delivery of fuel:

Nozzle

The nozzle is the part of the gas station that the customer can see and touch, and it is designed to take the fuel from the pump to the vehicle’s tank. A trigger mechanism controls the flow of fuel, while an automatic shutoff system protects against overflows by ascertaining when the vehicle’s tank has reached its limit.

Hose

A pipe or hose connects the nozzle to the pump and is the means by which fuel is delivered. It is made of strong, bendable materials so that it can move without breaking and also fight off fuel and weather.

Breakaway Coupling

This safety device is fitted in the hose to control the risk of accidents. If a car pulls away with the nozzle still in the fuel tank, the coupling becomes disconnected, which seals both ends, thus preventing spillage and damage.

Metering Unit

This element precisely gauges the volume of fuel released. It employs turbine or piston technologies; the metering unit offers the most accurate readings that are then passed on to the pump’s display.

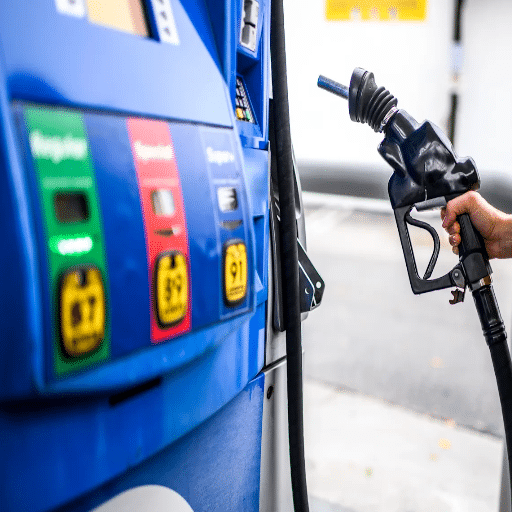

Display and Control System

The display shows instantaneously the quantity and price of fuel being dispensed, while the control system lets the user choose the grade of fuel as well as the mode of payment. These systems are connected to back-end networks for smooth transaction processing.

Pump and Motor Assembly

The pump takes the fuel from the underground storage tank, while the motor drives the process. The two types of pumps commonly used in this case are submersible or suction pumps, depending on the configuration of the station.

Vapor Recovery System

This ecological unit captures the fuel vapors emitted during the dispensing process, thus preventing air pollution and ensuring adherence to environmental laws.

Important Note: All these components work together to make sure that gas pumps are able to function reliably, accurately, and safely under different conditions, thus satisfying both consumers and regulators.

The Role of the Nozzle in Automatic Shut-Off

The automatic shut-off system in fuel nozzles is an essential attribute that has the purpose of averting tank overfills as well as spills. The system is operated on the basis of the venturi or vacuum-feeding principle to control the fuel flow. There is a tiny aperture, known as the sensing port, in the proximity of the nozzle’s tip. Once the fuel rises to the height of the sensing port in the car’s tank, it will then cut off the air flow into a tube that is linked to a diaphragm of the nozzle. The change in pressure is what activates the diaphragm, which in turn activates the lever mechanism that instantly stops the flow of fuel.

This method has a very high efficiency, and it is perfectly accurate in the control without the need for human supervision. The design has passed safety regulation tests and also reduces the risk of environmental damage caused by fuel spillage to the least. The adoption of this technology, which is at the forefront of nozzles, is a pointer to very high standards of engineering accuracy that are devoted to the improvement of comfort, safety, and environmental protection.

The Mechanism Behind Automatic Shut-Off

The automatic shut-off mechanism works on a simple but efficient principle. When the fuel in the tank reaches the tip of the nozzle, the flow of fuel causes a change in pressure. This pressure difference triggers a small vacuum system inside the nozzle, which in turn activates the shut-off valve. The valve closes, thus stopping the fuel flow, and this whole process prevents overfilling, which is safe and convenient. This dependable design has undergone strict testing and complies with important engineering and safety standards.

How the Pump Knows When to Shut Off

The fuel pumps have an automatic shut-off mechanism that is basically a venturi and fluid dynamics using the most basic principles. The nozzle contains a small hole at its tip that is attached to a vacuum line. On the fuel’s way out, the vacuum line becomes filled with air in a way that keeps the suction going. On the other hand, as soon as the fuel level in the tank rises and covers the hole at the nozzle’s tip, the airflow gets blocked. This interruption causes a very rapid change in pressure in the vacuum line, which activates a mechanical diaphragm or valve in the nozzle. The valve closes instantaneously, thereby stopping the flow of fuel. This system has been set up in such a way that it works reliably in all kinds of service conditions, thus it is efficient and spill-proof. It has been designed with fail-safe features that comply with the modern engineering standards and regulations, and that also maximize the accuracy and safety of the users.

The Automatic Shut-Off Process

- Initial Fuel Flow: Fuel begins dispensing when trigger is engaged, creating normal flow conditions

- Vacuum Line Activation: Air fills the vacuum line, maintaining continuous suction throughout the process

- Sensing Port Monitoring: Small hole at nozzle tip continuously monitors air flow and pressure

- Fuel Level Rising: As tank fills, fuel level approaches the nozzle tip opening

- Airflow Blockage: Rising fuel covers the sensing hole, interrupting the air flow path

- Pressure Change Detection: Blocked airflow creates rapid pressure shift in vacuum line

- Diaphragm Activation: Pressure change triggers mechanical diaphragm or valve mechanism

- Fuel Flow Cessation: Valve closes instantaneously, stopping fuel dispensing and preventing overflow

Components Involved in the Shut-Off Mechanism

The shut-off system of a fuel nozzle uses the coordinated action of different major parts to achieve an accurate operation. These parts are:

| Component | Function | Role in Shut-Off |

|---|---|---|

| Vacuum Tube | Recognizes pressure changes | Detects when fuel reaches nozzle end and signals mechanical diaphragm |

| Mechanical Diaphragm or Valve | Main actuation component | Responds to pressure changes in vacuum line and causes immediate valve closure |

| Spring-Loaded Shut-Off Valve | Fuel supply channel closure | Spring mechanism guarantees fast and reliable closing, stopping flow when engaged |

| Fuel Nozzle Trigger | User control interface | Connected to both user control and shut-off system; permits manual operation but gets automatically overridden |

| Venturi Tube | Creates pressure differential | Helps produce pressure difference in vacuum system for accurate fuel level detection |

Engineering Excellence: All these parts are designed together in such a way that they are capable of going through fluid dynamics and mechanical engineering principles for accurate operation under different conditions without fail.

The Importance of Accurate Fuel Measurement

Having the correct fuel measurement is necessary for the safety, efficiency, and cost-effectiveness of the systems that depend on fuel. Accurate measurements avoid the situation of filling the tank to the brim, which can be very dangerous for the environment and also damage the equipment. They also help in optimizing the use of fuel, hence cutting waste and bringing down the costs in the aviation, maritime, and transportation industries. Moreover, keeping accurate fuel records is a must for compliance with regulations since it proves the observance of environmental laws and industry standards. Generally, advanced measurement systems use technologies such as flow meters, sensors, and automated shut-off mechanisms; these combine the principles of fluid dynamics and thermodynamics to provide very accurate and reliable results in a wide range of operating conditions. In addition to accuracy, industries can gain operational performance and also be part of the earth-friendly practices that are sustainable.

Safety Enhancement

Prevents overfilling that could lead to environmental hazards and equipment damage

Cost Efficiency

Optimizes fuel usage, reducing waste and operational costs across industries

Regulatory Compliance

Ensures adherence to environmental laws and industry standards through accurate records

Environmental Protection

Supports sustainable practices by minimizing fuel waste and emissions

Understanding Fuel Flow and Tank Capacity

Fuel flow indicates the speed of fuel supply from a tank to an engine or system, largely lit up by units such as gallons per minute (GPM) or liters per hour (LPH). Tank capacity is the total volume of fuel the tank can accommodate, normally communicated in gallons or liters. Keeping track of both fuel flow and tank capacity is a necessity for efficient operations, eliminating the risk of overfilling and guaranteeing safe practices. Usually, these measures are done through the use of modern sensors and gauges, which provide accurate data to facilitate decision-making in operations.

How Fuel Flow is Regulated

Fuel flow regulation is a multifaceted process that is performed by mechanical, electronic, or hybrid systems to guarantee optimal performance and safety. The essential method of flow control is the combination of fuel pumps, pressure regulators, and flow meters working together as a team. Fuel pumps transport the needed amount of fuel to coincide with the engine requirements, while pressure regulators hold the system at a steady fuel pressure, thus preventing surges or drops that can negatively affect engine efficiency.

Nowadays, the systems usually integrate electronic control units (ECUs), which analyze real-time data from sensors, such as temperature, pressure, and engine load, to modify fuel flow dynamically. Moreover, flow meters deliver exact rates of fuel consumption, which helps in the precision of monitoring and controlling. These modernized systems are essential not only for sustaining fuel efficiency but also for cutting down on emissions and keeping the risk of fuel system malfunction at bay.

Modern Fuel Flow Regulation Components

- Fuel Pumps: Transport precise amounts of fuel matching engine requirements

- Pressure Regulators: Maintain steady fuel pressure, preventing surges or drops

- Flow Meters: Deliver exact consumption rates for monitoring and control

- Electronic Control Units (ECUs): Analyze real-time sensor data for dynamic adjustments

- Sensors: Monitor temperature, pressure, and engine load continuously

What Happens When the Tank is Full?

A fuel system, more often than not, containing a vent or overflow prevention device, will cut off the addition of the fuel when the fuel tank has been filled to its full capacity. To prevent overfill, modern cars are fitted with a fuel filler cap and a pump nozzle with an automatic shutoff sensor that recognizes when the fuel level has risen high enough to cut off the airflow in the filler neck. This, in turn, stops the dispensing of the fuel from the nozzle, thus avoiding any spillage or overfilling. Excess fuel pouring can cause the vapor recovery system to take in fuel, which could potentially harm the charcoal canister that is there to take care of the vapors, thereby resulting in increased repair costs or reduced system efficiency. Compliance with this automatic shutoff mechanism not only ensures the best operation but also prevents dangers to the environment from accidental fuel spillage or vapor emissions.

The Impact of Tank Size on Refueling

Fuel tank size has a direct impact on how often a vehicle needs to be refueled and on the cost of doing so. The advantage of big tanks is that they allow vehicles to drive for long distances without making many stops; this is especially true for long-distance truckers or people living in isolated places with few gas stations. Still, the cost of refueling will be higher initially, and this is because the amount of fuel to be consumed will be larger. On the other hand, small tanks make it possible for a driver to pay less for fuel on each visit, but they will have to stop more often, which may be inconvenient depending on their driving habits or the location. The size of the tank also has an impact on the effectiveness of the automatic shutoff system; smaller tanks may require reduced flow rates to ensure accurate filling, while larger tanks usually allow for faster fuel flow without triggering premature shutoff. At the end of the day, the choice of tank size is always a matter of trade-off between convenience, operating range, and economic aspects for the driver.

| Tank Size | Advantages | Disadvantages | Shut-Off Considerations |

|---|---|---|---|

| Large Tanks | Extended driving range, fewer refueling stops, ideal for long-distance travel | Higher initial refueling cost, heavier when full | Allows faster fuel flow without premature shutoff |

| Small Tanks | Lower cost per visit, lighter vehicle weight | More frequent stops required, inconvenient for long trips | May require reduced flow rates for accurate filling |

Factors Affecting the Gas Pump Operation

The functioning of gas pumps mainly depends on three factors: pressure, flow rate, and nozzle design. The pressure applied to the fuel delivery system allows the gas to flow steadily and in sufficient amounts; however, changing the pressure can affect the refill rate and the refilling process’s efficiency. The flow rate is the one controlling how much fuel is dispensed per second; this has to be carefully set in order not to have either overflowing or very slow refueling. Furthermore, the design of the nozzles is a very significant factor that contains within it the automatic shutoff mechanism, which detects the fuel level in the tank and stops pouring so that there is no overflow. All of these factors combined give a safe, fast, and convenient refilling experience to the user.

Pressure

Controls steady flow and sufficient fuel delivery; variations affect refill rate and efficiency

Flow Rate

Determines fuel dispensed per second; must be balanced to prevent overflow or slow refueling

Nozzle Design

Contains automatic shutoff mechanism for fuel level detection and overflow prevention

Impact of Tank Size on Pump Performance

The size of the tank plays a crucial role in pump performance as it directly influences the flow rate and pressure levels required for refueling operations. A larger tank’s fast filling will require detaching the higher flow rates, thus, the demanding pumps for their parts to work under higher pressure levels, possibly resulting in wear due to the long functioning period. On the other hand, the small tank will need accurate flow control in order not to have the problems due to overfilling and turbulence that may lead to inaccuracy. Advanced pumps with high-tech sensors and variable-speed drive systems can smooth the transition for pumps working in different-sized tanks and ensure minimum energy consumption and no accidents in all applications. The right setting of machines according to tank size is the key factor that determines the quality of maintenance and service in the long run.

How Gas Station Infrastructure Influences Pump Efficiency

The infrastructure of gas stations is a major factor in determining the efficiency of the pumps, which is greatly affected by the design, the integration of technology, and the standards of maintenance. For example, the arrangement of underground storage tanks has a direct effect on the speed of fuel delivery; using shorter pipes minimizes the friction losses and, hence, increases the flow rates. Moreover, using high-grade piping materials and leak-proof connections stops the leaks, which in turn keeps the pressure constant and reduces the energy waste. Among the technological breakthroughs, the likes of automated controls, artificial intelligence in sensors, and smart meters are all working towards fuel dispensing, as they detect the real-time demand changes and adjust the output accordingly. Underground preventive maintenance, which consists of cleaning filters and inspecting seals, ensures the uninterrupted functioning of the system by lowering the chances of clogging or wear. Therefore, a gas station infrastructure that is well-optimized not only increases the efficiency of pumps but also cuts down on the costs, energy consumption, and environmental pollution associated with them.

Infrastructure Elements Affecting Efficiency

- Underground Storage Tank Arrangement: Shorter pipes minimize friction losses and increase flow rates

- High-Grade Piping Materials: Leak-proof connections maintain constant pressure and reduce energy waste

- Automated Controls: Advanced systems detect real-time demand changes and adjust output

- AI-Enabled Sensors: Smart technology optimizes fuel dispensing operations

- Smart Meters: Provide accurate measurement and monitoring capabilities

- Preventive Maintenance: Regular cleaning of filters and seal inspections ensure uninterrupted operation

Common Issues with Gas Pumps Not Shutting Off

The issue of gas pumps not shutting off properly is a common problem that can be caused by a variety of technical and mechanical reasons:

Damaged Nozzle Sensor

A small sensor that senses pressure or airflow changes when the tank is full generally controls the automatic shutoff function in gas pump nozzles. If this sensor is not working due to dirt, wear, or mechanical failure, the gas station may still be dispensing fuel unnecessarily.

Vapor Recovery System Problems

To control emissions, gas stations have started using vapor recovery systems in their pumps. If there’s a blockage or malfunction in the system, flow and pressure control will be affected, leading the shutoff mechanism to not realize that the tank is full.

Misalignment or Damage

Nozzle misalignment or physical damage can prevent the sensor from operating well. If the nozzles are bent, seals are cracked, or there is debris in the nozzle tip, these problems may all lead to the pump not shutting off as expected.

High Flow Rate Settings

Pumps set at very high flow rates may lead to the fuel splashing back or creating turbulence in the tank, thus confusing the sensor and causing a delayed shutoff.

Malfunctioning Fuel Tank Vent

Cars must have a venting system for the air to escape while fuel fills the tank. If the vent is obstructed or not working, the nozzle’s shutoff mechanism might not be activated due to backpressure and thus, overfilling the tank.

Prevention and Solutions

To fix such problems, the gas pumps should have their components regularly maintained, like cleaning the nozzles, checking the seals, and ensuring that the flow rate and vapor recovery systems are properly calibrated. Besides that, checking for a user error, like incorrect nozzle positioning while filling the tank, can also minimize such situations.

Safety and Maintenance Considerations

To address concerns while ensuring the correct operation of the fuel dispensing systems, it is recommended to adopt a few practices:

Routine Inspections

Regularly inspect the full pump assembly, including seals, nozzles, and hoses. Through this, it will be possible to detect and eliminate the wear and tear early so that there will be no need for malfunctions.

Cleaning and Calibration

Clean the nozzle and vapor recovery systems periodically so that clogs will not form. Besides that, make sure the flow rate and shutoff mechanisms are correctly calibrated so that there will be no incidents of overfilling.

Vent and System Check

Check the venting system to make sure it is not blocked and that it is working as it should. The proper backpressure that triggers the automatic pump shutoff is maintained through this, and thus it is very important.

Staff Training and Monitoring

Train staff to detect and solve problems like user errors during refueling. The correct positioning of the nozzle and the following of standard operating procedures lessens the cases of improper use.

Equipment Replacement

Replace faulty or aging parts without delay so that the efficiency and safety standards of the system will not decrease over time.

Important: If these actions are taken regularly, the risks involved in dispensing fuel will be greatly reduced.

Regular Maintenance for Fuel Dispensers

The proper maintenance of fuel dispensers is vital for both operational effectiveness and safety compliance. Here are the major guidelines extracted from the best sources in the industry:

Routine Inspection and Cleaning

Dispenser inspection should be done on a routine basis for visible signs of wear, leaks, or damage that may interfere with its proper working. The cleaning of nozzles, hoses, and filters in the dispenser should be carried out regularly to remove any blockages or contamination that might affect the quality of the fuel and the performance of the system.

Calibration and Accuracy Testing

Fuel dispensing systems should be periodically calibrated to make sure they give out correct and precise measurements. Incorrectly calibrated equipment not only affects revenue but can also lead to the failure of regulatory compliance.

Component Checks and Replacement

Important parts such as nozzles, hoses, seals, and breakaway couplings should be inspected for wear or damage. Any faulty parts should be replaced without delay in order to reduce risks and keep up with smooth operations.

Software and System Updates

For dispensers that come with digital interfaces or payment systems, always make sure that the software is up-to-date, not only to safeguard against cybersecurity threats but also to keep in line with the fast-changing industry standards.

Preventive Maintenance Schedule

Create a preventive maintenance schedule that follows the manufacturer’s recommendation and is comprehensive. This will involve regular servicing intervals to prevent the occurrence of failure and enhance the equipment’s longevity.

Best Practice: Strict adherence to these maintenance practices will lead to reduced downtime, compliance with regulations, and sustained overall good fuel dispensing operations in the long run.

Safety Features in Modern Gas Pumps

Today’s gas pumps come with many safety features that make their use safe and efficient at the same time. One of them is the vapor recovery, which works to reduce harmful emissions, thus protecting both people and nature. Then there are emergency shutoff valves that build a sort of barrier between the operator and a possible danger by quickly stopping the flow of fuel. Plus, there are high-tech underground leak detectors that constantly monitor the area, and if they find any leaks, they will shut them off right away. All these measures, including fire-fighting systems that work even before the fire spreads and devices that prevent tampering, demonstrate my dedication to keeping fuel dispensing operations as safe as possible.

Vapor Recovery Systems

Reduce harmful emissions, protecting people and the environment from toxic fumes

Emergency Shutoff Valves

Quickly stop fuel flow in dangerous situations, creating safety barriers

Underground Leak Detectors

Constantly monitor for leaks and automatically shut off systems when detected

Fire-Fighting Systems

Automated suppression systems activate before fires can spread

Anti-Tampering Devices

Prevent unauthorized access and manipulation of fuel dispensing equipment

What to Do if a Gas Pump Malfunctions

Emergency Response Protocol

In the event of a gas pump problem, the safety of the customers and the gas station should always come first. The following are the steps that should then be taken:

- Stop Fueling Right Away: If you see anything abnormal, like the fuel not coming out right, a strange sound, or leaking, just stop and put the nozzle back in the place right away. It is like a safe measure of preventing any further issues or risks.

- Alert the Gas Station Attendant: As soon as possible, inform the station workers about the malfunction. Mention the pump number and what seems to be wrong so they can act quickly.

- Look for Instructions on the Pump: It is common to see emergency procedures or a customer service number on the pumps. In case there are such instructions, do as stated to have the problem sorted out quickly.

- Don’t Try to Fix the Pump: It is not advisable to attempt to resolve the issue yourself. Gas pumps are intricate devices with both mechanical and electrical parts that should only be operated by a technician.

- If Required, Move Your Car: In case the problem is serious, for example, fuel leaking, slowly drive your car to a place where it will not be exposed to the hazards and thus, still be in the safe zone.

Safety First: Following these steps will not only help reduce the risks involved but also guarantee that the problem is reported and resolved quickly.

Conclusion: The Engineering Marvel Behind Everyday Convenience

The automatic shut-off mechanism in gas pumps represents a remarkable achievement in mechanical engineering and fluid dynamics. What appears to be a simple, everyday action—refueling your vehicle—is actually the result of sophisticated design principles that seamlessly combine vacuum pressure technology, venturi effects, and pressure-sensitive components to create a fail-safe system that has served millions of drivers for decades.

Understanding how gas pumps know when to stop reveals the incredible attention to detail and engineering expertise that goes into creating reliable, safe, and efficient fuel dispensing systems. From the tiny sensing port at the nozzle tip to the mechanical diaphragm that responds to pressure changes, every component plays a crucial role in preventing overfills, protecting the environment, and ensuring user safety.

The beauty of this system lies not only in its effectiveness but also in its simplicity. By relying on fundamental principles of physics rather than complex electronics, the automatic shut-off mechanism operates reliably under various conditions, from different tank sizes and shapes to varying fuel flow rates and environmental factors. This mechanical reliability has made it an industry standard worldwide, demonstrating that sometimes the most elegant solutions are those that leverage basic scientific principles in innovative ways.

As technology continues to advance, modern gas stations are incorporating even more sophisticated safety features, from vapor recovery systems to underground leak detectors and emergency shutoff valves. Yet, at the heart of it all remains the simple but brilliant automatic shut-off mechanism—a testament to human ingenuity and our ability to engineer solutions that make daily life safer and more convenient.

The next time you’re at the gas station and hear that distinctive click as the pump automatically stops, take a moment to appreciate the remarkable engineering behind this everyday convenience. It’s a perfect example of how science and technology work quietly in the background, making our lives easier while keeping us safe—one fill-up at a time.

Key Takeaways

- Gas pumps use a combination of fluid mechanics and vacuum pressure technology to detect when tanks are full

- The automatic shut-off mechanism is entirely mechanical, requiring no electrical components for reliability

- A small sensing port at the nozzle tip monitors airflow changes to trigger the shut-off valve

- Multiple components work together: vacuum tubes, mechanical diaphragms, spring-loaded valves, and venturi tubes

- The system is designed to work reliably across different tank sizes, shapes, and fuel flow rates

- Regular maintenance of nozzles, vapor recovery systems, and calibration ensures optimal performance

- Modern safety features include vapor recovery, emergency shutoff valves, and leak detection systems

- Understanding the mechanism helps users recognize malfunctions and respond appropriately

- Proper tank size and flow rate settings are crucial for accurate automatic shut-off operation

- The technology represents a perfect balance of simplicity, reliability, and engineering excellence

Final Thoughts

The automatic shut-off feature in gas pumps is more than just a convenience—it’s a critical safety mechanism that protects users, the environment, and equipment. By understanding how this system works, drivers can better appreciate the engineering excellence that makes modern refueling safe, efficient, and environmentally responsible. Whether you’re a casual driver or a technology enthusiast, the science behind this everyday feature demonstrates how thoughtful engineering touches every aspect of our daily lives, often in ways we never notice until we take the time to look closer.

Reference Sources

Frequently Asked Questions (FAQs)

How does the Gas Pump know when to stop?

The stopping of gas from a pump is determined by an automatic mechanism consisting of a pressure change and a sensor combination. The filling of the tank leads to a change in air pressure due to the rise in the fuel level, and this leads to the shutting off of the nozzle and stopping of the gas flow, thus preventing overflowing.

Why Is the Gas Pump Automatically Shut Off?

The gas pump is automatically shut off to control overfilling and avoid instances of gas spilling. The automatic shutdown is necessary for safety and environmental protection, whereby it is ensured that there is no overflowing and no gas is wasted.

What Stops the Flow of Fuel at the Nozzle?

At the nozzle, a mechanism of vacuum that detects the fuel level in your tank is going to stop the flow of gas. The sensor, when the tank is near full, gets activated by the rising fuel, and that causes the nozzle to stop the flow of gas. So you can be sure spill isn’t your worry while filling.

What Happens When the Tank is Full, and the Fuel Pump Cuts Off?

When the tank gets full, and the fuel pump shuts off, it signifies the gas has reached the marked level. The upswing in the air pressure levels due to the fuel rise leads the nozzle’s automatic shut-off to engage.

Will My Gas Pump Automatically Shut Off if I am Not Careful?

To make sure your gas pump stops, just insert the nozzle properly into the tank opening and turn on the pump. The nozzle’s mechanism will immediately recognize the full tank and cease the gas flow, allowing you to fill your tank without any trouble at all.

What Triggers the Closure of the Valve in a Gas Pump?

The valve in a gas pump that shuts off the flow is controlled by the rising level of gas in your tank, which causes air pressure changes that trigger the nozzle sensor to stop gas flow and thereby prevent overflow.

Can the Automatic Shut-Off Feature of Gas Pumps Fail?

Yes, there are several reasons, such as a defective sensor or blockage in the nozzle through which the automatic shut-off feature of gas pumps may fail. In case you see that the pump does not turn off as anticipated, please inform the gas station attendant to ensure safety and appropriate upkeep.

How Air Pressure Affects Gas Pump Dynamics?

Air pressure is an essential factor in gas pump operation. When gas is being drawn, the tank fills and consequently, the air pressure alters. The nozzle sensor detects this alteration and thus aids in regulating when the fuel level is sufficient to trigger the automatic cut-off function and halt the gas flow.