A very important task in industries such as agriculture, construction, automotive, and marine operations is the transfer of liquids such as fuel and water. Transfer pumps play a key role in easing this task by providing competent, effective solutions for the speedy transfer of water. Transfer pumps find their use in fueling machinery, draining flood-ridden areas, and transferring water for irrigation; knowing about the capabilities and applications of these tools weighs heavily in their favor. Here, our article will entertain you with the paramount features, types, and benefits of transfer pumps, enabling you to make a good choice according to your needs. Stay tuned as we break down everything you need to know about these indispensable tools.

What is a Transfer Pump?

A transfer pump is a device that makes it possible to move liquids from one point to another efficiently and effectively. Usually, they are used for water or fuel transfer from one liquid to another in residential or industrial settings. They work by pushing the liquid through a hose or pipe, making them good for irrigation, draining flooded areas, or refueling equipment. Transfer pumps are valued for their versatility and are offered in many types to meet specific requirements, including manual, electric, and gas-powered.

Transfer pumps are mechanical devices for wet transfer from point A to point B while ensuring maximum efficiency. Such pumps, thus, have various uses and tools in agriculture, construction, and household sectors for water removal, irrigation, or fuel transfer. The pump creates a flow that pushes the liquid through attached hoses or pipes for quick and dependable transportation.

Types of Transfer Pumps

Manual Transfer Pumps

The manual transfer pumps are really the pumps of choice for smaller applications not requiring electricity or fuel to run. These transfer pumps tend to be lightweight and portable for the transfer of various kinds of liquids, such as oil or water, into situations where power sources for lifting do not exist.

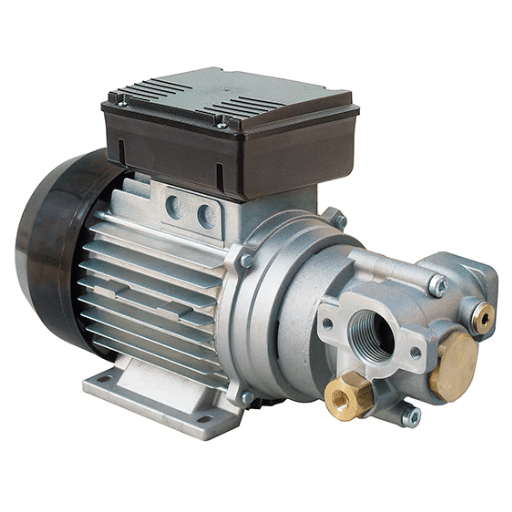

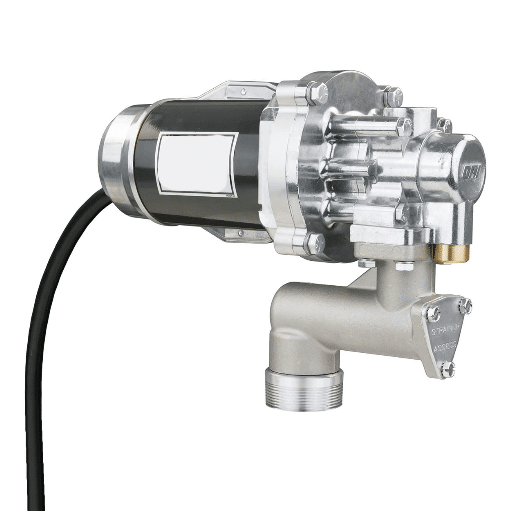

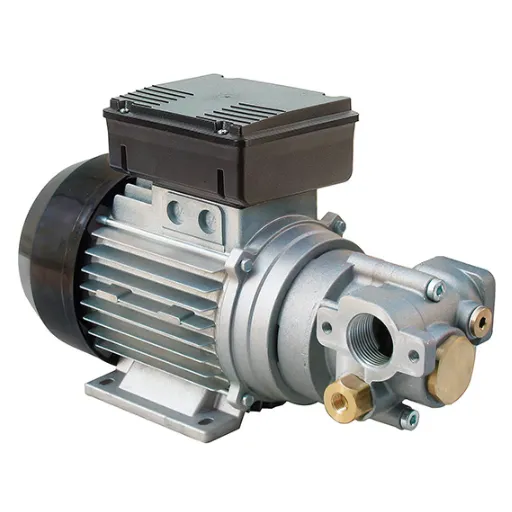

Electric Transfer Pumps

Electric transfer pumps use electricity to energize them, thus providing steady performance, ease of use, and are widely speculated to be valuable in residential and industrial drainings of basements filled with water or for filling tanks. These pumps perform well in medium to high-flow operations, with variable flow rate models being available to suit the specific needs of liquid transfer, some having a top capacity of 100 GPM.

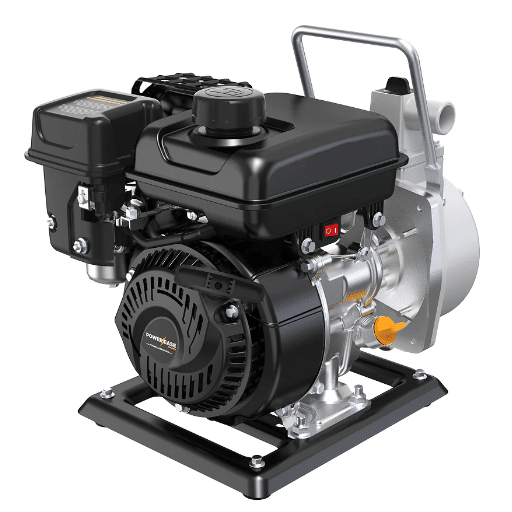

Gas-Powered Transfer Pumps

Gas-powered transfer pumps are built for and do handle heavy-duty jobs without an electrical power supply. They often find their use in large projects like agricultural irrigation, dewatering on a construction site, or fuel transfer to heavy equipment. These pumps feature higher flow rates, some models functioning at about 300 GPM, coupled with operational demands.

Utility and High-Pressure Pumps

A few other specialized pumps are utility and high-pressure, depending on their needs and specifications. Utility pumps are general-purpose pumps for liquid transfer, whereas high-pressure models are designed for long-distance firefighting or water supply applications.

Modern transfer pumps come with all sorts of innovative features that allow corrosion resistance, smart shut-off, among others, and versatile uses for many different kinds of liquids, from fresh water to chemicals. The consideration for purchasing a pump will be on the basis of the actual case, flow rate required, and the type of liquid involved.

Common Uses of Transfer Pumps

Transfer pumps serve in a wide range of industries and settings due to their efficiency in moving liquids. Some of the most common fields and their relevant details are as follows:

Agriculture and Irrigation

In agriculture, transfer pumps take irrigation water from should irrigation water be provided to maximize crop growth. In many instances, these pumps draw water from rivers, ponds, or reservoirs and then directly discharge it into the fields. For example, a medium-sized transfer pump can provide flow rates in the region of 50-250 gallons per minute (GPM), ideal for small-scale farms and large-scale agricultural operations.

Construction and Dewatering

On construction sites, transfer pumps help in the dewatering operations by removing accumulated water from trenches, foundations, or basements. Heavy-duty Transfer pumps for dewatering may be required to pump thousands of gallons of water per hour so as to allow for safe and efficient operation in support of infrastructure development.

Emergency Flood Management

They may also be used to pump out water during floods or other water disasters. Portable gas-powered or electric transfer pumps are preferred solutions due to freeing with their mobility and deployment speed. These pumps can handle both freshwater and stormwater filled with debris.

Firefighting

High-pressure transfer pumps are used by fire brigades to move a large volume of water to suppress fires. Some specialized types can only supply water at pressures greater than 150 PSI to allow for efficient firefighting in remote areas where no hydrant system is present.

Chemical and Industrial Applications

Transfer pumps are utilized to move chemicals, fuels, and other specialized liquids within industrial settings. Being corrosion-resistant and made up of materials such as stainless steel or polypropylene ensures durability while transferring caustic solutions. For instance, industries may require transfer pumps to handle fluids with viscosities of up to 500 centipoise for their daily activities.

Household and Utility Applications

A transfer pump consists of homeowners who do everything from draining water heaters to pool maintenance and removing excess water arising from leaks. Such applications for small electric models that can transfer 10-20 gallons per minute are most popular.

Transfer pumps vary greatly in design and specifications, so users can select the correct model according to their specific requirements. Their adaptability continues to make them indispensable in many fields, whether the use is everyday at home or of a high-capacity nature in a commercial environment.

Key Components of a Transfer Pump

Motor

The motor gives the transfer pump its power to work. Electric motors are usually used for portable small transfer pumps, whereas larger industrial models may have gasoline or diesel engines. For example, a very good performance electric motor can give up to 2 HP for residential models, whereas industrial electric motors range from 5 to 50 HP and even higher as per heavy-duty applications.

Impeller

The impeller is the square medium for moving liquids via a centrifugal action. It is usually fabricated of stainless steel, cast iron, or thermoplastics so as to have resistance against corrosion and wear. However, depending upon the type of impeller design used, whether it is an open, semi-open, or closed type, the pump will display good to poor efficiencies for handling certain types of liquids.

Pump Housing

Consisting of a casing enclosing the impeller, the pump housing acts as the passage for the liquid transferred by the pump. The pump casings may be made of cast iron or suitable thermoplastics to enhance the life and resistance to high pressure. Proper design of the casing is required to facilitate an easy flow of liquid while preventing leakage or damage.

Seals and Gaskets

Seals and gaskets ensure that the pump cannot leak. The seals and gaskets hold the pressure inside the pump system. Modern transfer pumps often use mechanical seals in carbon-ceramic or silicon carbide materials for longer life and wear resistance.

Intake and Discharge Ports

These ports are channels for the liquids to flow into the pump and out of the pump. Liquid coming in through the intake port and discharged out of the discharge port flows into or out of the pump within the ports. The various sizes—from those with 1-inch diameter to those with 6-inch diameter and above—indicate that the flow rate of the liquids will vary. Industrial applications need to have ports with a bigger diameter to ensure that high-capacity operations are well handled.

Check Valve

Most transfer pumps are fitted with an internal check valve to prevent backflow, thus allowing liquid flow only in one direction. This feature becomes more important when transporting water or other fluids over long distances.

Pump Controls

Some advanced transfer pumps may be equipped with digital or manual controls, allowing for the alteration of flow rate, pressure levels, and automatic shut-off for safer and more efficient operation.

Understanding these components and how they function ensures proper selection and maintenance of transfer pumps for achieving maximum efficiency in residential, commercial, or industrial arenas.

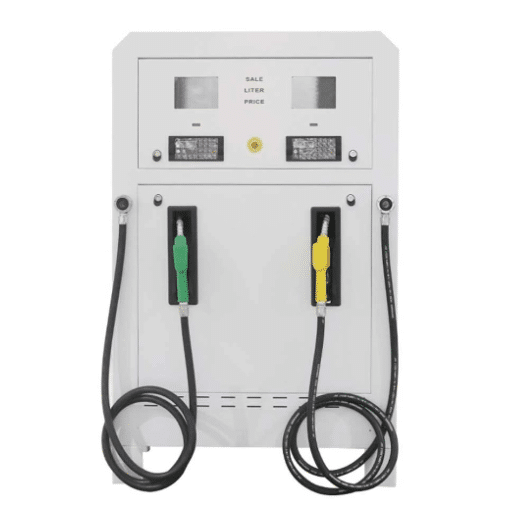

Fuel Transfer Pumps

Fuel transfer pumps are meant to carry fuel from one spot to another efficiently and safely. They may be used in the agricultural, industrial, and transportation sectors for handling gasoline, diesel, or other fuel types. A few features it may have are being durable, easy to use, and compatible with the specific fuel that it is transferring. If maintained properly and if safety protocols are observed, the pump should perform well and pose little risk of spilling or accidents.

Types of Fuel Transfer Pumps

Fuel transfer pumps are diversified in types, each suited for specific applications depending upon the fuel type, flow rate, and efficiency demanded. Among the most common ones are:

| Type | Power Source | Best For | Key Features |

|---|---|---|---|

| Manual Fuel Transfer Pumps | Manual operation (crank/lever) | Small operations, areas without power | Highly reliable, reasonably priced, simple design |

| Electric Fuel Transfer Pumps | Battery or mains electricity | Large industrial, high-demand operations | Higher speeds and flow rates, efficient for gasoline, diesel, kerosene |

| Diaphragm Pumps | Varies | Thicker, viscous fuels | Safer for hazardous materials, better control with corrosive substances |

Choosing the correct type of pump should consider fuel properties, operational environment, and usage frequency. Each type exhibits different advantages depending on specific task requirements.

How Fuel Transfer Pumps Work

Fuel transfer pumps work by transferring fuel from one area to another, for instance, from storage tanks into vehicles, machinery, or equipment. Preparation and mode of operation depend on the pumps in question, which can be based on suck, pressure, or a mix of both. A motor or manual force typically drives the pumps, so that fuel is pulled through the inlet and forced out through the outlet hose.

Electric fuel transfer pumps are usually preferred where a high level of efficiency is maintained to keep a steady flow rate using an electric motor. Manual pumps are those where an operator manually acts upon them using their hands or a lever for smaller or low-volume transfer amounts. The intake valve, discharge valve, and pumping device are the critical parts that facilitate the fuel flow without leaks or spillage.

The efficiency of a fuel transfer pump depends on several parameters, such as fuel type, viscosity, distance of transport, etc. It is worth stressing that pumps need to be put in use according to the properties of their corresponding fuel for safety and working considerations. Proper maintenance on filters, etc., with respect to filtrations and damage level, will prolong the life of the pump and help it perform at its best.

Benefits of Using Fuel Transfer Pumps

- Efficiency: Transfer fuels more efficiently and precisely so that less fuel is wasted and more is used properly; this is valuable in big operational activities, like agriculture, automotive, and construction

- Safety: Prevent spills, leaks, or contamination that would have proved to be an environmental or safety hazard

- Time and Labor Savings: Automatically transfer fuel faster and more reliably compared to doing so manually

- Durability: Due to their durability and compatibility with many types of fuel, they present the best long-term investment for any industrial or household purposes

Electric vs. Diesel Transfer Pumps

Electric and diesel transfer pumps perform the function of fuel transfer, and both have their respective advantages. Electric transfer pumps are best suited for places where electricity is consistently available. They are generally quiet and require less maintenance in comparison to diesel transfer pumps. Diesel transfer pumps might be great in remote or off-grid locations without electricity on hand. They are ultra-portable, yet put to heavy-duty uses. More so, the decision is made depending on the availability of power, application, or level of portability required.

Advantages of Electric Transfer Pumps

- Steady Performance: Provide steady and efficient performance, suitable for applications requiring steady flows of liquids

- Cost Efficiency: Operating at an optimal power rate ensures decreased operational costs in the long term

- Environmentally Friendly: Do not emit any exhaust, so they are best suited to environmentally sensitive places

- Quiet Operation: Much quieter operation when compared with diesel pumps, contributing to comfortable working conditions

- Low Maintenance: Lower maintenance costs and higher reliability for industrial or residential applications

Pros and Cons of Diesel Transfer Pumps

Pros:

- High Power: Capable of moving large volumes of fuel quickly, fit for heavy industrial and agricultural purposes

- Durability: Designed to withstand adverse weather conditions, durable and reliable in hostile environments

- Versatility: Can handle different fuel types and is suited for situations requiring mobility and self-priming capabilities

- No Electricity Needed: Function in areas that do not provide electricity

Cons:

- Maintenance: Diesel engines need regular servicing, adding to maintenance costs

- Noise and Vibration: Make more noise and vibrations than electric ones

- Environmental Impact: Emit fumes and pollutants, less eco-friendly

- Initial Cost: Higher initial cost than other types of pumps

Energy Efficiency and Cost Considerations

Diesel transfer pumps should be chosen by keeping in mind operational necessities vis-à-vis long-term costs, from the perspective of energy efficiency and costs. Diesel pumps boast plenty of strength and reliability, especially when heavy-duty applications are concerned, and hence they consume a lot of energy. On the cost side, a diesel pump will have a relatively higher price in terms of fuel than an electric pump because of the continuous consumption of diesel fuel and variable prices of the different fuel types over time. However, from the standpoint of fuel efficiency, they give the best performance in that fuel is available everywhere, in case of nonavailability of electricity in remote or off-grid areas.

From a cost standpoint, diesel pumps typically have higher upfront costs compared to some alternatives. Still, durability and the ability to function in arduous situations often assist in compensating for these costs with maintenance considerations over time. On proper maintenance and adequate servicing, these pumps can be kept in an excellent state of repair and with a good life, which eventually cuts their total cost of ownership.

In a nutshell, a diesel transfer pump would more likely be a balanced approach to consider cost versus operational implications concerning energy efficiency, usage conditions, and potential environmental impact to ensure that the pump meets the desired financial versus practical considerations.

Factors Affecting Pump Performance

Some factors can significantly influence a pump’s performance:

- Flow Rate Requirements: The functional efficiency and applications of a given pump are determined by the volume of fluid that is required to be transferred from it for a given unit of time. If it does not have the appropriate sizing with respect to the flow requirements, it cannot do its intended work.

- Fluid Characteristics: The viscosity, density, and presence of solids in the fluid can affect how a pump operates. If a pump is permitted to operate with fluid whose properties are not in its range, its performance will deteriorate.

- Pump Material: Depending upon the fluid type and operating conditions, the pump material may or may not be durable against corrosion or wear. Keep in view the operating conditions and select materials accordingly to reduce maintenance requirements.

- Operating Conditions: Temperature, pressure, and altitude are among the operating conditions that may affect pump performance. Compatibility with the working environment is indispensable.

- Energy Efficiency: Energy-efficient pumps consume less power and, consequently, have lower operating expenses over time, rendering them sustainable and economical.

These considerations assure users of reliable and efficient pump operations in several applications.

Flow Rate and Pressure

Flow rate and pressure stand as the primary considerations when selecting and operating pumps, as they ultimately determine system performance. Flow rate is the volume of fluid a pump moves in a determined period and is generally given in GPM (gallons per minute), or in L/s (liters per second). Pressure, simultaneously, is the force exerted by the fluid as it passes through the system, typically in PSI (pounds per square inch) or bars. The pressure and flow rate in a pump are inversely linked-much depending on system parameters and constraints-with increasing pressure usually resulting in decreasing flow rate.

To calculate the flow rate and pressure needed, consider the specific needs of the application, such as system requirements, elevation change, line loss, and others. Properly matching pump capability to system requirements will assure system performance, reduce energy consumption, and avoid occurrences of cavitations or wear with time. It is nowadays possible to modify flows and pressures with variable speed pumps or controllers, thus enabling increased efficiency and flexibility in different applications. Once they understand and balance these parameters, the possibilities for successful and reliable pump operation become available to the user.

Horsepower Requirements

Selecting the proper power requirement for a pump system involves an evaluation of many elements. These include the TDH (total dynamic head), flow rate, and efficiency of the pump. A power (horsepower) being able to be calculated with this formula:

The flow rate is the volume of fluid the pump has to discharge, while the TDH accounts for vertical lift, friction losses in piping, and pressure at discharge. Specific gravity is a way of making an allowance for the fluid density compared with water, and efficiency pertains to how well a pump uses the supplied input energy that deliver useful work. Choosing the right horsepower of a pump will ensure that the system works without any problems and that it is not being overworked with expensive energy costs. A proper set of calculations agreed upon by the manufacturers will ensure that the pump is neither too large for the system nor too small.

Material and Build Quality

Material and build quality in pumping machinery are strictly relative to the intent for which it will be used and the fluids which it will be handling. In corrosive or abrasive service environments, the materials used must be such as to resist wear and degradation-stainless steel, cast irons, or specialty alloys are a few examples. Nonmetallic materials, including engineered plastics, are lighter and have some corrosion resistance; they are suitable for chemical or light-duty uses. Usually, manufacturers provide detailed specifications that include materials compatibility, and one should consider these specifications when considering performance reliability over time.

Top-quality pumps have superior machining, seals, and coatings applied to them to keep the pump in operating condition for extended periods. For instance, the installation of mechanical seals or advanced gasket material will prevent leakage, while protective coatings can shield equipment from environmental or chemical damage. Also worthy of consideration are the certification standards, such as ANSI, ISO, or API, which verify that industry guidelines have been followed in pursuing safety, efficiency, and durability. The investment in better materials and construction will lower future maintenance costs while extending the useful life of the equipment.

Buying Guide for Transfer Pumps

Key Considerations for Purchase

- Purpose of Use: Identify the primary application for the pump, such as water transfer, chemical transfer, fuel transfer, or any others. With each liquid, differing types of pump materials, as well as designs, are required to accommodate the liquid in terms of compatibility and/or efficiency.

- Flow Rate and Pressure Requirements: Determine the flow rate required (usually gallons per minute or liters per second) and the pressure level for the system in accordance with your operation’s demand. Applications requiring high performance usually require pumps with high capacity.

- Material Durability: Select pumps from materials compatible with the liquid to be transferred. Corrosion-resistant metal, such as stainless steel or some kind of high polymer material, generally gives the best results for chemicals or saltwater.

- Power Source: Decide on the power to be provided to the pump: electric, gasoline, diesel, or human. Factors include power source availability and operational environment. Fuel-powered or manual pumps are usually better off for portable or remote applications.

- Portability and Size: Consider space and portability limitations. The commercial or industrial kind may call for a larger pump; the domestic or small-business variety is fine with a smaller counterpart.

- Certification Standards: A pump with an accepted certification-ANSI, ISO, or API-is much better. Such adherence guarantees reliability, safety, and an industry-accepted benchmark.

Considering these inquiries will help you select a transfer pump that best meets your specific needs for efficient and effective performance throughout the years.

Price Range and Budgeting

When setting up transfer pump prices, transfer pump price ranges need to be set with consideration of the requirements versus the budget. Entry-level and small transfer pump types for light-duty operations commonly start somewhere between fifty and one hundred fifty dollars. The more mid-range pumps used for medium-duty applications and small industries are priced somewhere in the range of one hundred fifty to five hundred dollars. A high-performance pump that is meant for industrial uses or large-scale operations would likely cost beyond the $1,000 mark, depending on its refinements and durability.

So, when budgeting, consider what the pump will be used for, what its capacity will be, and its build quality. A good pump may require some money initially, but when we consider standards of certification like ANSI, ISO, or API, this guarantees that the pump can be relied upon and safe across time. Other expenses may also be involved, such as maintenance or accessories, and maybe the cost of energy consumption, all of which factor into the long-term ownership expenses.

When all things are considered and you thoroughly analyze what you stand to gain from each undertaking and consider various options that fall within your budget, you will very well be able to make an informed decision that offers the very best compromise between cost and functionality.

Top Brands and Models

When it comes to the top brands and models, I recommend focusing on the manufacturers of dealerships who have long upheld quality standards and performance. For Bosch, Makita, and DeWalt, machines are highly regarded for their durability and are seldom seen innovating, offering tools and equipment. If conservation of energy is at the top of your list, stick to energy-saving technologies or eco-friendly designs in your choice. The best choice for you shall depend on your requirements and use; otherwise, there is nothing to go wrong with placing these brands in the front line.

Evaluating Inlet and Discharge Specifications

In consideration of inlet and discharge specifications for equipment, one must pay attention to the size, flow rate, and system compatibility. Inlet size governs the amount of material or fluid getting into the equipment; on the other hand, discharge size modulates the speed at which the output is realized from the equipment. The flow rate is important as this would be the rate at which the equipment works on materials. Compatibility should also be ensured so that one is not faced with performance mismatches caused by the new equipment within existing setups. Several models will fit into the standard fitting, which is best left to be confirmed from the specification call-out of the instrument before purchase to avoid mismatches and hindered operation.

Reference Sources

1. Pump Fault Detection Based on MFCC‐MLCNN

2. Reducing Environmental/GHG Impacts from Groundwater Remediation

3. Matching Performance of Single-Channel Pumps

Frequently Asked Questions (FAQs)

What is a transfer pump, and how does it work?

A transfer pump is a machine designed to move liquids from one place to another by utilizing suction and discharge hoses. This type of pump is meant to handle a variety of fluids, including gas and water, at certain flow rates, like 8 GPM or 15 GPM, the typical rates for commercial RF pumps. A transfer pump is quite versatile, being powered either by electricity or hydraulics, making the pump suitable for applications as diverse as fueling vehicles and general water transfer.

What are the various applications of fuel transfer pumps?

Fuel transfer pumps are commonly used to transfer gasoline, diesel, and other fuels from tanks to vehicles or machinery. They find applications in farms with tractors, construction sites, and industrial settings that require quick and efficient fuel delivery. These pumps can also be used to transfer fuel oil to heating units in heating applications.

What is the maximum flow capacity of a transfer pump?

The maximum flow rate of the transfer pump is very much dependent upon the model and design. Some designs, such as Fill-Rite, can go up to 15 GPM, while others flow less than 8 GPM at maximum flow rate. The flow rate is very important in determining the time it takes for a pump to transfer a certain amount of liquid from one tank to another.

How to choose the right transfer pump?

To select the right transfer pump, it depends on the purpose, i.e., what type of liquid you want to transfer, the flow rate, and the power of the pump. Also, the somewhat lesser considerations would be the kind of nozzle, the length of the hose, and whether you want flow control or other features. In case of light-duty pumping, a 12V electric pump may be preferable, whereas hydraulic pumps are preferable for heavy-duty use.

What are the essential main components required by fuel transfer pumps?

Fuel transfer pumps consist of typical components that include an impeller, a motor, inlet and discharge hoses, and a nozzle. The impeller moves the fuel through the system; the motor provides the power needed to do so. Discharge hoses deliver fuel wherever it needs to be, while the nozzle regulates its flow during delivery.

Can you buy transfer pumps online, and what should I look for?

Sure, transfer pumps could be bought online from many retailers. While buying, check the product specs, particularly its flow rate and horsepower, to see if it fits your needs. Also, consider the reviews and ratings of the customers to know about its reliability and performance.

How are transfer pumps maintained?

Maintenance of transfer pumps involves the regular inspection and cleaning of hoses and nozzles to avoid clogging and leaks. Further, checking whether the motor and power cord show wear signs is necessary. Make sure it is stored safely and protected against adverse weather conditions when not in use, especially if it is used for transferring fuels or heating oil.

Using a transfer pump: what safety precautions need to be followed?

Practice safety while using a transfer pump by wearing protective gear, ensuring proper ventilation, and avoiding spills. It is also a good idea to set up your work area in a brightly lit environment and keep flammable materials away. Lastly, always adhere to the manufacturer’s guidelines for safe operation and maintenance.