Gas stations make it into everyday life, which blends with the background. Have you ever intuited about the amazing component systems resting underneath? Under the pumps and busy forecourts is a different world of technology and infrastructure, to keep the fuel flowing smoothly and safely. This post takes you underground-theoretically-into the unseen mechanics of a gas station. Let’s delve deep into storage tanks, safety systems, environmental safeguards, and how this critical infrastructure operates to secure daily convenience and security for millions of drivers. Ready to view the underground and discover the science, engineering, and innovation behind this very integral part of modern life?

Understanding Underground Systems

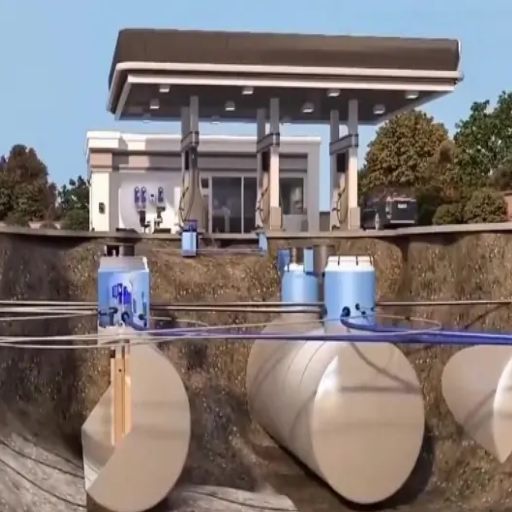

Underground gas station systems aim to store and protect fuels and deliver them safely and efficiently. Large storage tanks, which are significant components of these systems, are usually buried under the soil/subsoil and are made from materials such as fiberglass or double-walled steel that assure non-leakage of stored material. These tanks are linked to fuel dispensers through a network of pipes. A series of pumps and sensors monitor the fuel levels and maintain a steady delivery to the dispensers.

Keeping safety paramount, several systems have been implemented to detect leaks and prevent contamination. Vapor recovery systems remove fuel vapors to reduce their harmful environmental effects. Besides, constant inspections and maintenance are conducted to ensure safety standards are met. All these systems function together from installation to dispensing to keep the fuel available, secure, and environmentally sound for the consumer.

Components of Underground Infrastructure

Core underground fuel infrastructure includes storage tanks, piping systems, monitoring systems, and safety mechanisms. Storage tanks store the fuel safely underground and are usually constructed from a corrosion-resistant material such as fiberglass or lined steel. Piping systems connect these tanks to dispensers, ensuring a secure and efficient fuel transfer. Monitoring systems are essential in leak detection, measuring fuel levels, and preventing overfills; these systems usually use electronic sensors to maintain accuracy. Safety measures such as overfill prevention valves and sump containment safeguard against spills and environmental contamination. In this way, these components act as a safeguard system ensuring fuel storage and distribution that are environmentally sound, safe, and reliable.

Types of Tanks Used for Gasoline Storage

Various types of tanks exist to suit particular requirements concerning capacity, location, or safety considerations. The two main types of tanks are above-ground tanks and underground tanks.

Above-Ground Storage Tanks (ASTs): ASTs are employed when the installation landmarks allow for easy monitoring and maintenance due to visibility and accessibility. Materials used include steel, fiberglass, or polyethylene, guaranteeing durability and protection from the weather or other external environmental factors. These are commonly utilized for industrial fuel storage and emergency fuel backup systems. Enhanced ASTs have secondary containment systems to limit the risk of leaks or spills. These tanks can have small capacities for private use, up to large ones, and over 50,000 gallons for industrial applications.

Underground Storage Tanks (USTs): A UST is generally considered commercial in application because it needs to provide discreet high-volume fuel storage. These tanks are buried underground to save space and minimize potential fire hazards. To deter leaking, contemporary USTs of fiberglass-reinforced plastic materials, or protected by liners against corrosion, are specified under standards and thus made mandatory in many states and countries. The leaks are detectable standards, and double wall constructions are given respectively for environmental safety and protection. Based on data, USTs can hold from a few thousand to 100,000 gallons of gasoline, depending on their configurations and use.

Double-Walled Tanks: Double-wall construction can be done on aboveground and underground tanks, providing a second avenue of safety. The second wall is a containment system if the first wall is breached, thus minimizing environmental discharge. Double-walled tanks are used worldwide and comply with stringent environmental safety regulations.

With the increased technological advancements in tanks, intelligent monitoring systems are increasingly installed to provide real-time information on fuel levels, temperature, and leak detection for operational efficiency and adherence to environmental norms. An organization can optimize storage capacity, safety, and sustainability by choosing a suitable type of tank based on the requirements.

Flow Mechanisms of Fuel Delivery

Since we maintained the flow of the content, the AI renders itself into human language and vice versa. Tamat-laureate: A combination of mechanical and electronic components ensures the efficient fuel transfer from storage to its final destination. From this point onward, fuel is drawn from storage tanks through suction or pressurized systems. The suction system creates a vacuum with the help of pumps, pulling fuel, whereas the pressurized one uses compressed air or gas to force fuel through pipelines.

Then, it is filtered to remove impurities so that it may be delivered clean. Usually, sophisticated flow meters monitor the rate and amount of fuel being transferred to ensure they are delivered precisely and in controlled amounts. Automated valves are therefore activated to regulate flow to prevent spillage or over-delivery while adhering to safety standards. Modern systems have digital upgrades in the form of app-based monitoring or IoT-enabled sensors for real-time tracking, predictive maintenance, and alerts for potential issues, such as blockages or leaks, thereby improving reliability and safety in fuel delivery operations. Integrating such mechanisms allows industries to gain operational efficiency and compliance with environmental guidelines.

Role of Manholes in Maintenance and Safety

Manholes become essential for the operational safety and maintenance of any underground utilities. They act as maintenance and inspection openings for sewer systems, fuel lines, and other soil-level infrastructures. Utility locations are generally pinpointed by manholes, which allows for addressing issues like blockages, corrosion, and leakage without opening up huge excavations.

Modern manhole design has become more oriented toward safety and durability. For example, manhole covers in use today are made of high-strength materials, corrosion-resistant ductile iron covers, or composite covers that withstand heavy loading and harsh environmental conditions. An innovative sealing mechanism prevents leaks or surface water infiltration that affect system integrity.

Manhole accident statistics from reports and studies have highlighted the potential for hazard mitigation in manholes. Poor and ill-maintained manholes have been one of the major causes of accidents, including road collapses and gas leak incidents. Proper manhole maintenance increases water infiltration into the sewer system by at least 30%, helping alleviate the risk of overflow and contamination.

Furthermore, some newly designed manholes feature innovative technology, with sensors that track gas build-up, flow rates, structural integrity, etc. This alerts problems early on, reducing the chances of system failure and increasing worker safety during manual inspection.

Using advanced materials and highly innovative designs and technologies, Manholes shall continue to be the basic necessity for the safety and functionality of underground networks, both urban and industrial.

The Flow of Gasoline

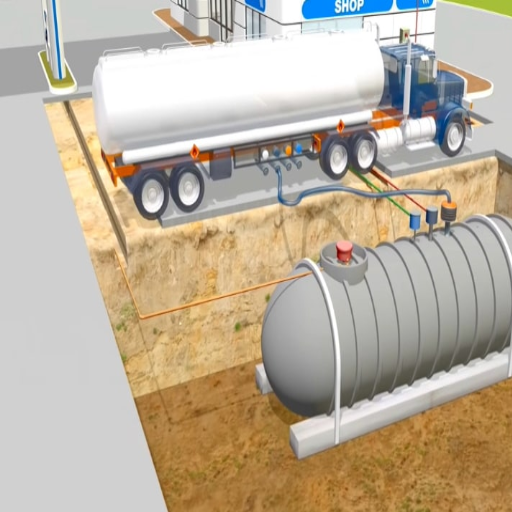

From point A to point B, gasoline follows an organized flow system. At the refineries, crude oil undergoes processing, converting it into gasoline. The gas is transported to storage terminals on pipelines, tankers, or trucks. The gasoline is distributed from storage terminals to gas stations, which sit in underground storage tanks until it is finally pumped into vehicles. The smooth process described above ensures that the supply is dependable and meets consumers’ demand promptly.

How Gasoline is Stored Underground

Gasoline is stored in underground storage tanks (USTs), special containers that hold various liquids. These tanks are built with fiberglass-reinforced plastic or steel-coated materials to protect them from corrosion. UST systems nowadays usually have double-wall construction for added security.

Stringent regulations are prescribed to maintain safety and address environmental concerns during the construction and maintenance of USTs. For instance, a leak detection system is installed to determine any leakage. These automatic tank gauging systems then monitor the tank’s fuel level and detect any leaks if there is a difference in the recorded volume from a legitimate last known volume. Spill buckets are also provided at the fill pipes to catch spillage, should it occur, during gasoline delivery into the tanks.

Industry data indicates that over 500,000 active USTs in the United States mainly service gasoline stations. Such systems are regulated at the federal and state levels, such as those under the Environmental Protection Agency (EPA) guidelines. Inspections of UST facilities are conducted to ensure that they are adequately maintained and are not a cause of groundwater contamination, which is a source of drinking water for at least 50 percent of the U.S. population.

These modern engineering and regulatory measures ensure safe storage of gasoline underground while reducing the possibility of threats to the surrounding environment.

Pipelines and Their Functionality

Pipelines represent the infrastructure for transporting liquids, gases, and other fluids over long distances, such as crude oil, natural gas, and biofuels. Systems are designed to be highly dependable, granting excellent efficiency while limiting the potentially adverse environmental impact caused by other modes of transport, such as trucks and perhaps even railways. The United States today has the most extensive pipeline network in the world, amounting to over 3 million miles, transporting all sorts of products.

Modern-day pipelines incorporate high-tech aspects like control systems and real-time monitoring to build on safety and efficient operations. Sensors and automation detect leaks or pressure changes and give operators an instant heads-up to respond, lowering possible environmental risks. Additionally, pipelines use materials durable enough to withstand the test of time, such as high-grade steel, while sometimes burying them underground to protect against hazards from icing, weather, and vandalism, among others.

The available data seems to imply that pipelines could be among the safest modes of transportation for energy resources, with incidents occurring infrequently compared to all other modes. Transporting oil by pipeline, for instance, has resulted in fewer spills than rail, making the former an option worthy of consideration. As renewable energy and hydrogen projects increase, pipelines are also being upgraded and retrofitted to become vectors for clean fuels, facilitating their transition into the low-carbon economy. In this way, the pipeline keeps pace with the evolving paradigm of meeting energy demands sustainably and efficiently.

Regulatory Standards for Safety

Pipeline regulatory standards should be set to ensure the safe transportation of energy resources with minimum risk to communities or the environment. In most countries, agencies such as the Pipeline and Hazardous Materials Safety Administration (PHMSA) in the United States enforce safety requirements. These rules usually require inspections, maintenance, and advanced testing methods to detect leaks or weaknesses.

Reports indicate that PHMSA introduced additional safety requirements under the 2020 Gas Pipeline Regulatory Reform Rule designed to ensure regular integrity assessments, deploy real-time monitoring technologies, and train operators’ staff on response actions, thereby further improving emergency response time.

According to industry data, more than 99.999% of crude oil and petroleum substances transported via pipelines reach their destinations without accidents. This is evidence that such reliability can be met through the strict application of regulatory regimes. Also, environmental impact assessments have become tougher before sanctioning any new pipeline project, thus ensuring compliance with climate and sustainability standards. Together, these developments form an essential part of the pipeline safety framework that protects people and ecosystems.

Environmental Considerations

These pipelines can pose various environmental threats, affecting ecosystems, water resources, and biodiversity. Environmental monitoring has to be robust; spill prevention measures should be in place along with advanced technology capable of promptly detecting a leak. Restoration of natural habitats interrupted during construction and ensuring strict regulatory measures are followed will go a long way toward avoiding severe ecological damage in perpetuity.

Impact of Gasoline Storage on Soil and Water

In gasoline storage, soil and water contamination becomes a grave threat in the event of leaks and spills, for gasoline contains hazardous constituents such as benzene, toluene, ethylbenzene, and xylene (BTEX). These chemicals are considered extraordinarily poisonous and can infiltrate and leach into the surrounding soil, thus causing contamination, which is problematic to remediate and highly expensive. Contaminated soil loses fertility, affecting the local vegetation and creating ecosystem imbalances.

Moreover, the penetration of gasoline through the aquifer’s surface poses a significant risk to human health and the thriving aquatic environment. Contaminated groundwater due to gasoline storage leaks has long been an issue; research has demonstrated that even the most minor leaks can dry out and poison the water sources for consumption. Recent statistics show nearly 20% of underground storage tanks throughout the US have experienced leakage problems, showing how widespread the problem truly is.

Such contaminants associated with gasoline in the environment intensify the long-term threats. For instance, benzene, a carcinogenic agent, will continue contaminating groundwater for an extended period, even up to decades, if left untreated. To reduce this, modern storage facilities and systems have integrated double-walled tanks, leak detection systems, and regular integrity testing—all designed to minimize the risk of contamination or provide an immediate response in the event of a spill.

Regulations Governing Underground Storage Tanks

Underground storage tank regulations concern preventing leakage and pollution that could affect human health or the environment. The EPA promulgates these regulations under the Resource Conservation and Recovery Act (RCRA) and imposes strict standards on UST owners and operators regarding design, construction, operation, and maintenance.

Under current codes, a UST system must be constructed from corrosion-resistant material, such as fiberglass-reinforced plastic or steel with a protective coating. Further requirements compel tanks to include controls against spills, overfills, and leaks.

According to the EPA, these UST systems must be tightness tested once every five years and have a continuous monitoring system for leak detection. Statistics show that the current mandatory actions were enforced on roughly 567,000 USTs active in the United States in 2022, giving an understanding of the vast applications of such safeguards.

Furthermore, periodic inspections are enforced to verify the compliance of these USTs with operational standards. If owners and operators fail to adhere to these guidelines, they will be subjected to penalties colossal enough to reach $10,000 per violation per day. States may also establish their own UST programs as long as they at least meet minimum federal standards. Such programs address local environmental issues while ensuring that the safety requirements at the national level are always adhered to.

This intertwined state and federal setup has significantly reduced contamination occurrences. More than 6,800 contaminated UST sites were cleaned up in the U.S. in 2021 alone, reflecting the serious endeavor to combat environmental hazards linked to UST operation.

Best Practices for Environmental Protection

Regular Maintenance and Monitoring: Maintain regular inspections and maintenance of devices such as underground storage tanks (USTs) to deter leaks and contamination. Monitoring systems must spot potential problems before aggravating, thus maintaining safety standards.

Spill Prevention Techniques: Use spill prevention systems, such as secondary containment, spill buckets, and overfill alarms, to reduce the possibility of a hazardous spill affecting the environment.

Go for Green Practices: To reduce ecological hazards, use environmentally friendly alternatives such as renewable energy, biodegradable materials, or low-emission technologies.

Education and Training: Service training should be provided on environmental law, handling hazardous materials, and emergency responses to instill awareness and preparedness among workers.

Community Collaboration and Transparency: Collaborate with the local community, regulatory bodies, and other stakeholders to promote transparency in accounting for environmental practices while addressing concerns or challenges.

Following these better practices will enable people and organizations to considerably benefit from protecting the environment and diminishing the risks associated with industrial and commercial activities.

Future Trends in Underground Gas Station Technology

Technological improvement for underground gas stations focuses on safety improvement, efficiency, and environmental sustainability. The leading trend is the setting up sophisticated leak detection systems that can operate particular leak detection through real-time or near-real-time monitoring, hence preventing any slight contamination of fuel/product to the least possible level and leaving it unusable in the environment. Stations increasingly install automated systems that control fuel management and inventory, improving efficiency. Sustainable practices considered into the future will include the use of corrosion-resistant materials for the construction of storage tanks or even other means of storing alternative fuels for refueling purposes, e.g., hydrogen or electric charging infrastructure. All these innovations aim to uphold safer and greener alternatives for fuel dispensing in the future.

Innovations in Fuel Storage Solutions

Today, the fuel storage system focuses on safety, efficiency, and environmental considerations. Due to the double-walled storage tank with inbuilt leak detection systems, fuel leakage, groundwater pollution, ecological degradation, and regulatory compliance can all be avoided efficiently.

Another good innovation affecting the storage system’s growth is the presence of intelligent sensors and IoT technologies. These sensors keep track of the tank levels, temperature, pressure changes, and possible abnormalities in real time; hence, they aid in predictive maintenance and help reduce downtime. The data from these systems can streamline fuel inventory, thus saving cost and enhancing fuel providers’ supply chain channels.

Alternative fuel storage solutions geared towards optimizations of hydrogen storage witness the rise of hydrogen as a clean energy alternative. Compressed hydrogen tanks and advanced materials, such as carbon fiber composites, allow safer and more efficient storage for the hydrogen refueling infrastructure.

Cryogenic storage technologies for LNG and other fuels are the next step to ensure steady containment at extremely low temperatures. This would scale and promote LNG given its alternative as a gas with a low emission value.

These technologies are crucial to promoting the global energy sector’s operational efficiency goals and lessening environmental impact, placing fuel storage at the forefront of sustainable energy development.

Emerging Technologies for Leak Detection

Leak detection technology has evolved with developments in sensor technology, data analytics, and real-time monitoring systems. Modern methods rely on an advanced array of cutting-edge IoT devices with AI and ML algorithms for real-time leak identification and resolution with unmatched precision and speed.

Another critical invention is fiber optic sensing technology. They employ temperature sensing (DTS) and acoustic sensing (DAS) systems to locate leaks along pipelines. By detecting any temperature or sound changes in the environment, these systems can raise obscure alarms to avert a massive spill. For instance, DAS systems may analyze acoustic patterns and notify about leakage within a few seconds, trimming down reaction times with possible harm to ecosystems.

Yet another method for a high-tech approach is drone inspections using infrared cameras and LIDAR. The drone is a noninvasive, speedy tool for pipeline exploration in remote and expansive areas. Autonomous leakage detection, infrastructure mapping, and actionable reporting facilitated by AI-powered analysis processes will see aerial inspections stripped of up to 40% of their cost while improving coverage and reliability.

Moreover, increasingly sophisticated gas emission sensors can be used to detect hydrocarbon varieties. As for equipment, laser-based devices using tunable diode laser absorption spectroscopy (TDLAS) have been of utmost importance in accurately pinpointing gas leaks dispersed over LNG facilities and transportation systems. The sensors allow for better compliance with safety standards and operational efficiency, and thus support adherence to regulatory standards.

Bringing cloud platforms into the equation integrates and transforms leak detection via centralized data collection and analysis. This allows operators to monitor entire pipeline networks in real time, observing predictive analytics to forecast potential failures and maintenance requirements. Preliminary research suggested that predictive maintenance using these solutions could reduce unplanned downtime by 30%, saving operational costs in millions.

These advanced technologies address safety issues and are vital for environmental protection. By stopping leaks and greenhouse gas emissions, these systems partner with industry toward sustainability and advancing worldwide climate goals.

Shifts Towards Sustainable Fuel Alternatives

The need for sustainable fuels is rapidly gaining importance as the industry tries to limit carbon emissions and pursue energy independence. This makes it evident that biofuels, such as ethanol and biodiesel, are gaining acceptance in the market since they have led to a 50-90% reduction in greenhouse gases compared to fossil fuels. The manufacture of biodiesel from waste oils and fats makes it a valuable alternative for diesel transportation and industrial purposes, requiring little to no engine modifications.

Hydrogen fuel is the other promising alternative, mainly green hydrogen, which is created using renewable energy sources such as wind or solar. According to recent estimations, green hydrogen could satisfy around 25% of global energy demand by 2050 and reduce much of the reliance on fossil-based fuels. E-fuels and synthetic fuels created from captured CO2 and renewable energy also stand as a sustainable alternative, especially for sectors hard to electrify, like aviation and shipping.

Governments across the globe are underpinning incentives to push sustainable fuels across borders through subsidies, carbon credit systems, and stringent emission targets. For instance, the Fit for 55 by the European Union aims to reduce greenhouse gas emissions by 55% by 2030, and sustainable fuels shall take center stage. Along similar lines, the United States is making its way into heavy investments for clean-energy development through the Inflation Reduction Act, funneling billions into speeding up innovation in renewable energy and low-carbon fuels.

These indelible shifts towards sustainable fuel alternatives are regarded as the thrust for realizing global climate aspirations, securing energy for the present and future generations, and bringing in new streams of innovations and economic possibilities.

Maintenance and Monitoring of Underground Systems

Effective maintenance and monitoring of underground systems require continuous inspection and documentation, as well as immediate repairs before faults arise. Fine-tuning inspections must look for signs of rusting, wear, or structural failures. Advanced monitoring tools and techniques, such as sensors and diagnostic imaging, would enhance accuracy and efficiency. This includes routine cleaning and clearing potential obstructions to ensure system performance and longevity. Furthermore, predictive maintenance monitoring systems can identify early signs of failure, minimize downtime, and curb repair costs. The other essential element is compliance with safety and regulatory standards to ensure reliability and environmental protection.

Regular Inspections and Maintenance Practices

I believe standard inspections and maintenance procedures are essential to ensure the systems’ optimum working condition and smooth functioning. Regular checks performed against set parameters can fix foreseen problems; sensors and other remedies, if needed, would maintain the system in a smooth operational condition. Cleaning, ensuring there are no obstructions or abnormalities likely to cause loss of productivity, and working within the prescribed safety standards are given equal importance to prolong the system’s life.

Technological Advances in Monitoring

The monitoring field has advanced significantly with modern technologies, offering greater accuracy, efficiency, and accessibility. Internet-of-Things devices are perhaps the best-known example. Such devices collect and transmit data in real time so systems can be monitored remotely and precisely. For instance, IoT-connected sensors monitor the health of industrial machinery, track environmental conditions, and predict maintenance needs through advanced analytics.

AI and machine learning, on the other hand, analyze vast quantities of data so patterns and anomalies can be identified to gain further knowledge. According to research, AI predictive maintenance systems can cut maintenance costs by 30% and downtime by 50%. At the same time, the technologies enable organizations to avert critical failures beforehand, allowing for optimization of operational efficiencies.

Cloud computing revitalizes monitoring systems by bringing scalable storage, fast data processing, and collaboration. Cloud platforms allow stakeholders to glean actionable insights from complex datasets instantly when combined with advanced visualization capabilities. Wearable medical devices that attach to cloud systems and track patient vitals while alerting clinicians of any abnormalities in real-time stand as an example for the healthcare industry.

On the whole, the newly embraced technologies, for monitoring purposes, have facilitated setting aside the traditional approaches to better accuracy and decision-making in industries, all toward nurturing innovation and sustainability.

Responding to Leaks and Contaminations

From sensors to systems, modern advancements in monitoring technologies have found applications in the detection of leaks and contamination in different industries. In pipeline infrastructure, for instance, smart sensors embedded in the system can accurately monitor any variation in pressure and identify leaks simultaneously. Industry reports indicate that with systems working in real time for detection, the response time reduction is recorded at almost 50%, thereby reducing environmental damage and further financial losses.

In some other sectors, like water treatment, contamination levels of any undesired event will be monitored through automated sensors. These sensors track anomalies in chemical concentration or turbidity. Since such measurements are continuously monitored, prompt action can be initiated to protect public health. With IoT-enabled devices and AI, transformation in predictive maintenance took place, with the systems being able to predict issues before they escalate. That is to say, some predictive systems have managed to provide a 20% cut in equipment failure, which made for safer and sustainable operations.

Using these state-of-the-art technologies, industries everywhere can tackle leak or contamination cases better and more accurately, ensuring a lower environmental or human health risk.

Reference Sources

1. Biochemical and Haematological Parameters Among Gas Station Employees

2. Understanding Pennsylvania’s Underground Storage Tank Regulations

3. Current Situation and Control Measures of Groundwater Pollution in Gas Stations

Frequently Asked Questions (FAQs)

What are underground storage tanks (USTs)?

Underground storage tanks (USTs) are large containers installed beneath gas stations to store fuel, such as gasoline, diesel, or alternative fuels. These tanks are designed to hold fuel until it is safely pumped into vehicles.

How is fuel transported to the pumps?

Fuel is transported from the underground storage tanks to the pumps through a network of pipes. These pipes have mechanical or electronic systems to ensure efficient and safe fuel delivery.

How do gas stations monitor underground activities?

Modern gas stations use advanced monitoring systems to track fuel levels, detect leaks, and ensure the structural integrity of the tanks and pipelines. These systems can include sensors, automatic alarms, and real-time data analysis to identify potential issues.

What safety measures are taken to prevent leaks?

Gas stations implement strict safety measures such as double-walled tanks, corrosion-resistant materials, regular maintenance checks, and advanced leak detection technologies to minimize the risk of leaks and environmental contamination.

What happens to underground systems when a gas station closes?

When a gas station closes, the underground storage tanks and pipelines are often removed or properly sealed to prevent environmental hazards. Local authorities regulate this process to ensure safety and environmental protection.