When it comes to ensuring safety in environments where flammable substances are stored or transported, explosion-proof oil tank barrier materials play an essential role. These materials have been designed to minimize explosion-related risks. They are mainly used as the first line of defense in hazardous industries such as oil and gas, chemical processing, and transportation. So, what exactly are these materials, and how do they protect people and infrastructure? This blog will walk you through the various types of explosion-proof oil tank barrier materials available in the market, their unique characteristics, and the industries where their usefulness is most pronounced. This article will surely give you the necessary insights, be it for professional safety applications or purely out of scientific curiosity.

What is the description of Explosion-Proof Oil barrier materials?

The explosion-proof oil tank barriers are special materials designed to prevent explosions by hindering the free flow of flames or combustible vapors inside oil tanks. Usually, explosion-proof barrier materials are fire-resistant and non-conductive to avoid any cause of ignition. These are formulated to offer a consistent, long-lasting protection that, on its own, acts as a safety barrier in the presence of flammable liquids or gases. These barrier materials are an absolute must in, for instance, oil & gas, chemical process, and transportation industries that demand utmost safety.

Understanding the Basics of Explosion-barrier Materials

Explosion-barrier materials are specially developed to mitigate explosion threats in hazardous zones. Their main characteristics include thermal resistance, which allows them to survive extreme temperatures caused by an explosive event. Many materials possess fire-retardant coatings or are composites that resist fire propagation to ensure minimum damage.

Materials for explosion barriers are designed with high mechanical strength to remain intact under high pressures. Tensile strength is a significant criterion, checking the force to which a material can be subjected without breaking. Such high-end barriers might show tensile strengths of more than 50 MPa when used.

Additionally, chemical resistance is of the utmost importance. These must withstand corrosion during exposure to harsh chemicals such as ammonia or hydrocarbons in industrial environments. Statistics show that these materials, such as reinforced polymers or ceramic composites, can provide at least tenfold the resistance of traditional materials.

They have to be proven through standards tests, including ISO 22899-1 for explosion resistance and EN 13501-1 for fire performance. These benchmarks place explosion-barrier materials at the highest safety and reliability stages in industrial uses. Because of their high-performance features, these materials rescue lives and properties.

Key Components of an Explosion-Proof Oil Tank

An explosion-proof oil tank is built with parts that matter the most when every second counts. Its safety gear is anything but ordinary.

Explosion-proof vent systems act first. They open just enough to release extra gas, so pressure never becomes a ticking time bomb.

Flame arresters are located right at the openings. Sparks or tiny flames hit the grate and die before reaching the tank’s flammable stew.

Many manufacturers spray on an anti-static coating. This slick layer keeps electricity from building up and jumping to something that will burn.

The shell itself is made of high-strength steel or special alloys. Even a rough backhoe knock won’t cave it in, nor will heavy oil pressure on the inside.

Pick sensors over puddles whenever possible. Leak detection systems continuously sniff for signs of escape, giving crews a shout before the problem grows.

Grounding wires and bonding straps finish the job. They quietly bleed off static charge, letting static drift away instead of popping like a firecracker.

Together, all these features pass the toughest safety tests. Operators walking by know that stored oil stays in the tank and out of trouble.

How Does the Explosion-Proof Barrier Work?

Explosion-proof barriers employ a fusion of modern engineering techniques and advanced materials, firmly containing hazardous occurrences and mitigating their effects. First, the materials used must be those that can withstand extreme temperatures and pressures, such as stainless steel or reinforced alloys. This creates an adequately strong integrity in the barrier walls, so the barrier would never fail under stress in a scenario where an explosion occurred.

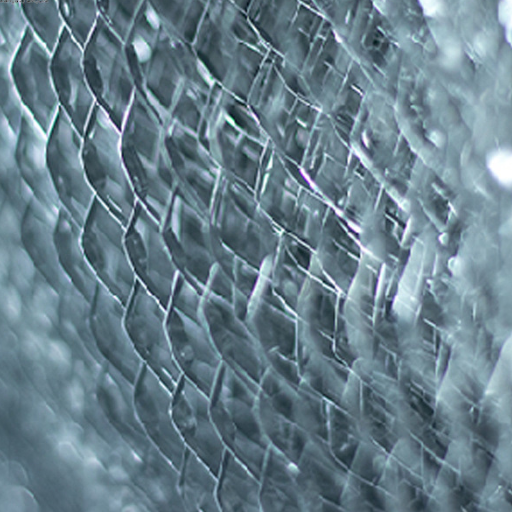

Next, the barrier encompasses flame-arresting technology capable of preventing flames or fire propagation from escaping the system. Heat dissipation is accomplished by using perforated plates or metal mesh while blocking the passage of fire. Furthermore, pressure relief mechanisms are essential to deflect the force of an explosion in a safe direction away from at-risk zones and personnel.

An essential aspect of advanced explosion-proof barriers is real-time monitoring. Sensors, for instance, can detect conditions such as temperature changes, pressure surges, or combustible gases. These systems, therefore, provide a timely warning and allow automated safety measures to take effect, such as shutting down the operation flow or activating fire suppression.

Recent data show that explosion-proof barriers reduce the possibility of catastrophic damage by up to 60% in industrial setups. The effectiveness of such a barrier translates into worker safety and equipment safety in combustible environments, apart from simple regulatory adherence. The combination of innovative designs and stringent tests makes barriers necessary for mitigating risks in high-hazard industries.

How to Find Info on Different Types of Explosion-barrier Materials?

To obtain authentic information about different categories of explosion-barrier materials, begin by reaching out to esteemed agencies such as industrial bodies and organizations concerned with safety standard regulations; also, check with material manufacturers. For guidelines and technical specifications, sites like OSHA, NFPA, or ISO work well. Various manufacturers’ websites may also contain pertinent descriptive information about explosion-barrier materials concerning product certification and performance standards. Trade journals and publications on industrial safety or engineering would also throw some light on this matter from the expert perspective. Give credit to recognized authoritative bodies to get the most reliable and updated information.

Comparing Explosion-Proof Aluminium to barrier materials

The unique combination of being lightweight and highly corrosion-resistant puts explosion-proof aluminum at the forefront of materials used in markets where formidable yet easy-to-handle safety barriers are sought. These barriers are excellent as they resist corrosion in themselves. Thanks to the natural formation of an oxide film on its surface, Aluminum is highly resistant to chemical exposure and oxidation, making it very suitable for harsh environmental conditions. Moreover, alloying and heat-treatment procedures can considerably enhance the tensile strength of aluminum, making it a worthy safety guard against explosion hazards.

In terms of strength-to-weight ratio, aluminum provides a level of protection similar to steel but at a considerable weight disadvantage. To illustrate, aluminum weighs less than steel by almost a factor of three; hence, they are easier to handle and install and lighter on the supporting structures. Still, steel barriers sometimes offer higher absolute strength and remain the preferred choice for high-pressure installations and applications.

Considering thermal conductivity, aluminum dissipates heat more efficiently than most steel types, which may be advantageous in temperature control areas. By contrast, steel may have a higher melting point, which might sometimes be required in specific industrial processes involving intense heat.

Regarding costs, aluminum will be more expensive due to the manufacturing and alloying process. Yet, its further economic advantages, like lesser maintenance requirements and better resistance against corrosion, tend to overbalance the initial cost of investment levels, given scenarios of long-term exposure to corrosive agents.

In the final analysis, the preference rests on particular application needs, relative weight issues, environmental conditions, thermal aspects, and monetary considerations. Both barriers provide excellent safety support; aluminum is, however, evidently gaining the stature of a competitive alternative in more specific instances.

The Role of Alloy in Explosion-Proof Technology

The choice of alloys in explosion-proof technology is thus critical in ensuring safety and enhancing performance in various industries. Aluminum-magnesium and aluminum-silicon alloys, for instance, combine the benefit of aluminum’s light weight with added strength, corrosion resistance, and thermal conductivity. Such strength and toughness are required in environments where a protective system needs to be durable yet light.

For example, aluminum-magnesium alloys are a good choice, mainly when exposed to harsh environments, such as human exposure to salt water. There is a bona fide need for such alloys in the marine and offshore industries. Various scientific studies have indicated that such alloys can reduce the weight of materials by approximately 30% compared to their traditional steel counterparts, hence improving efficiency with no compromise on strength.

Moreover, due to electrical conductivity, the alloying materials ensure fewer chances of sparking in a gaseous medium. Copper-based alloys that are great conductors retain resistance against deformation and corrosion, making them an ideal candidate for explosion-proof electrical enclosures and contacts. It constitutes evidence indicating the superior performance of copper-beryllium alloys with fatigue strength of more than 1,600 MPa under dynamic loading.

Another way modern metallurgy contributes to explosion-proof technology is by developing tailor-made alloys suited to an industry’s specific demands. The development of high-grade aluminum-lithium alloys is a case in point. They show promise in the aerospace sector, providing safety and functionality through lowered density and increased stiffness.

Essentially, the suitability of a particular alloy for explosion-proof technology is chosen based on not just the alloy’s physical and chemical properties but also the hazards of the environment in which the technology is expected to be applied. These developments emphasize the activities undertaken to uphold safety while maximizing performance and cost-effectiveness in vital industries.

Exploring Patent Developments in Explosion-barrier Materials

Recently, steady progress has been made in designing new explosion-barrier materials, with modern innovations improving safety, life expectancy, and versatility. For instance, many research and patents have been created on nanocomposite materials because of their incredible strength and lightweight nature. These materials use nanosized fillers in polymer matrices to produce barriers that have high impact resistance but are lightweight, which is ideal from a safety point of view.

The most recent development includes graphene-reinforced composites. Patents have stressed graphene’s incredible tensile strength and thermal conductivity, making it the most suitable material for explosion-proof compositions. Researchers have theorized encapsulated multilayer graphene sheets that would absorb and disperse the shockwaves of explosions, thereby prolonging the lifespan of these materials and their protective attributes.

Patents are also investigating self-healing coatings for application on explosion-barrier surfaces. These coatings are embedded with microcapsules filled with reactive agents that seal up any tiny erosion or cracks, thereby maintaining the barrier’s integrity as it matures. Such a solution is targeted to reduce maintenance costs while extending the life of equipment placed in a hazardous setting.

More detailed data from industry reports point toward worldwide investments in explosion-barrier materials going beyond $3 billion by 2025, with oil and gas, defense, and chemical production among the demand-generating sectors. These innovations promise higher safety standards and are now being touted as cost-effective and environment-friendly, heralding a new dawn in explosion-proof technologies.

What are the Benefits of using explosion-barrier materials in Oil Tanks?

Explosion prevention materials for oil tanks offer certain benefits. First and foremost, they significantly reduce the chance of explosions by suppressing the spread of fire, thereby ensuring greatly enhanced safety for personnel and infrastructure. Second, the tanks last longer since they can withstand extreme conditions, such as high temperatures and heavy mechanical impact. Thirdly, they save money because any losses, damages, and downtime foregone from an accident are avoided. Finally, they are environmentally safe by preventing leaks and uncontrolled fires, thus protecting the environmentally adjacent culture.

Enhancing Safety in Oil Storage

Modern enhancements in oil storage safety embrace numerous technologies and best practices. The primary improvement is the introduction of automatic fire detection and suppression systems. For example, advanced flame detectors can detect fires in mere milliseconds, giving the foam-based suppression system time to suppress the fire immediately and minimize damage and potential escalation.

Further, double-walled tanks have become a standard design to reduce the possibility of leakages. Such tanks afford a secondary barrier against the environment if the primary containment fails. Statistically, a double-walled storage system reduces environmental risks by up to 90%.

Further digital monitoring technologies augment physical improvements. IoT-based sensors constantly track a tank’s pressure, temperature, and volume, providing operators with real-time data to detect any anomaly at an early stage. An industry report in 2023 indicated that such systems reduced incidents from equipment failure by 40%.

Finally, international codes such as API 650 and NFPA 30 have standardized periodic maintenance and safety inspections. This is to enforce compliance to safety protocols and drastically reduce incidences of catastrophic failure. Combining the two will provide an even safer and more secure system for oil storage.

Increasing Longevity and Durability of Storage Tanks

Ensuring service life and enhancing durability require next-generation materials, innovative maintenance, and modern protective techniques. Corrosion-resistant materials, comprising stainless steel alloys or tanks coated with epoxy resins, are paramount in enhancing the service life of storage tanks. Such materials are effectively resistant to environmental parameters such as moisture, chemicals, and extreme temperatures and present slight degradation with time.

Cathodic protection systems are technologies meant to prevent corrosion in steel storage tanks. They eliminate corrosive activities on the tanks’ surfaces, extending their service life. Thermal insulation can also protect tanks when exposed to ambient temperature changes, preventing weakening due to thermal stress.

Regular inspection of the storage tanks through nondestructive testing methods such as ultrasonics or radiography gives accurate data on the thickness of the material while also showing cracks and other structural weaknesses. Studies show that periodic measures such as cleaning and repainting tanks can enhance durability by about 30%, helping to uphold safety standards and minimize breakdowns.

The integration with Industry 4.0 advances this durability through predictive maintenance tools that use real-time sensor data and AI-based analytics to forecast possible failures before they happen, thus cutting down on repairs and extending the infrastructure’s lifespan. Introducing innovative materials, advanced monitoring technologies, and maintaining routines guarantees optimum performance and sustainable storage tanks for decades.

Reducing Risks during Transportation and Processing

Such operations are fraught with dangers- spillage, contamination, and possible accidents while handling the tank material during transport and processing. All these factors are taken into consideration, and industries across the globe are adopting newer safety concepts and technologies. Industry reports have found that an average of 25% accident reductions have been reported in transportation due to the adoption of IoT-enabled tracking systems, which use GPS and various other sensors to provide real-time condition monitoring from the tank, thus contributing to the integrity of the materials being transported.

Furthermore, processing-side loading/unloading systems have reduced human-error-induced accidents by up to 30%. The new generation of leak-detection sensors detects potential weak areas accurately, helping avoid expensive spills and correlated environmental damage. Furthermore, continuous personnel training has improved staff adherence to safety standards by 40%, making the processing environment far safer and more secure. In parallel, all these improvements have been vital in risk reduction and safe handling of valuable resources on the entire supply chain.

How Does the Manufacturing Process Affect the Explosion-Proof Properties?

And it is the manufacturing process that directly affects the explosion-proof property of the equipment, as it ensures the materials and design comply with very rigid safety standards. The materials must be of their kind’s best, withstanding temperature, pressure, and corrosion operating under severe conditions. The engineering and assembly processes must attain accurate tolerances and sealing for all components against the ingress of gases or dust that may ignite within. Testing is conducted at each stage to ascertain compliance with industry certificates and safety requirements. These create an environment where a safe and reliable performance can be ensured in hazardous environments.

The Technical Aspects of Producing Explosion-Proof Materials

Producing explosion-proof materials requires laser focus on design and strict consideration for safety standards. These materials are created not to cause explosions if flammable substances are present- a scenario common in hazardous environments such as oil refineries, chemical plants, and mines. The main technical criteria of the process demand that the most appropriate materials be selected- stainless steel, for instance, or aluminum- they possess resistance to pressures, very high temperatures, and chemical corrosion. Afterward, the materials are made into enclosures or components that function with explosion-proof realization, either by experiencing an internal explosion or preventing ignition from outside.

The interior of the enclosure is sealed with utmost care so that no ingress or egress of gas, dust, or vapors can occur. This procedure employs reinforced gaskets, exact machining of joints, and threaded connectors for the joints. Moreover, these devices are thermally managed to regulate heat dissipation, ensuring the temperature remains below a critical threshold. The certification and testing are performed, which are an integral part of the entire procedure, wherein every single product is subjected to assessments to conform to ATEX, IECEx, or UL standards. This multi-pronged modality theoretically ensures that explosion-proof materials perform safely and reliably, thus keeping human beings and equipment safe in hazardous environments.

The Impact of Manufacturing Techniques on Material Quality

Manufacturing techniques are crucial for the quality, durability, and reliability of materials that different industries employ. These days, new-age technology methods- the additive manufacturing approach, for example, along with precision machining and injection molding- provide a new perspective on component manufacturing. Thus, 3D printing, or additive manufacturing, can create complex designs and minimize material wastage: statistics have proven that, depending on the application, material wastage reduction of up to 90% is possible compared with the conventional subtractive method, such as CNC machining.

Heat treatment further affects the material properties, increasing its hardness, tensile strength, and wear resistance. According to data, in some metals, tensile strength can be increased up to 20% when water-quenching is carried out; this ensures capacity for and resistance to highly demanding working conditions. Another example would be cleanroom manufacturing, a must in industries such as semiconductors and pharmaceuticals to minimize contamination to microscopic levels and maximize the product’s consistency.

Also, with the advent of new technologies capable of fully automating various operations, the variation was reduced while repeatability was intensified, thus lowering defects. Automated manufacturing has been noted to increase production efficiency by 30%, affecting the quality of materials produced. For this reason, newer technologies must be adopted to manufacture materials for use in high-risk industries that demand higher safety and performance standards.

Innovations in Production for Enhanced Safety

Recent cutting-edge manufacturing technologies have offered newer solutions for the above industries to increase safety standards. A significant innovation is the implementation of AI and ML in manufacturing. These technologies monitor equipment performance through past data and predict failures before they occur. Industry reports claim this has reduced workplace-related accidents due to malfunctioning machinery by 20-30%.

Robotics advancements have transformed safety in high-risk environments and applications. Robotic systems are applied for handling hazardous materials, working under extreme conditions, and assembly requiring precision. For example, cobots can collaborate with human operators to reduce injuries and have increased production by 40% in some areas.

The application of materials science in manufacturing may be equally transformative. Self-healing materials and composites of greater durability enhance product life and, to some extent, make applications safer in aerospace and automotive industries. For example, lightweight yet strong materials reduce the forces due to impact in a crash, thus improving passenger safety.

Amidst this, though, there is IoT-enabled real-time monitoring of environmental and equipment conditions, providing a mitigation boost to workplace safety. Such a system can detect irregularities such as gas leaks or overheating and immediately issue an alert. It has been recorded that IoT-based safety measures have halved incident response times by 50%.

With these innovations, manufacturers can provide a safe workplace while responding to the growing demand for efficient, high-performance solutions for safety-critical applications.

Where to Find Details and Prices for Explosion-Proof Materials?

To research reliable information and pricing on explosion-proof materials, one must go to trusted manufacturers and suppliers of industrial safety equipment. Company websites like Eaton, ABB, or Emerson typically display catalogues, specs, and price options. Other sites, such as Grainger and GlobalSpec, function like searchable databases, making it easy to compare explosion-proof products. The materials are to ensure compliance and quality by meeting required safety standards, e.g., ATEX or IECEx.

Reliable Sources for Info on Material Specifications

Several reputable sources offer high-grade insight if one wants accurate and up-to-date information on material specifications. Industry-standard bodies, such as ASTM International and ISO, issue meticulously detailed guidelines and specifications for various materials to ensure international compliance and product performance. Databases like MatWeb provide exhaustive material data, containing the mechanical, thermal, and chemical properties of metals, plastics, ceramics, and composites.

Academic institutions and research publications, such as those hosted on ScienceDirect or ResearchGate, typically feature studies and whitepapers concerning the recent developments or test data for particular materials. Manufacturing companies worldwide, with big names like 3M, BASF, and DuPont included, present technical datasheets on their respective web pages that describe the formulation, durability, and application suitability of the particular products. Always cross-check among several sources to ensure the data’s accuracy and the match of specifications with the given project-related needs or safety norms. That way, one can make a perfect choice of materials.

Comparing Prices for Different Explosion-Proof Solutions

When prices are considered when placing different explosion-proof alternatives, I always balance expenses with quality and safety standards. My first step is to find products that meet the necessary certifications and get quotations from various manufacturers or suppliers. Apart from upfront cost considerations, I recall installation charges, maintenance needs, and equipment service life being considered. This way, I am assured that the chosen solution shall satisfy the economic criteria and be reliable.

Contacting Suppliers for Details and Inquiries

When contacting suppliers, one must draw up detailed questions to efficiently capture all relevant information. Begin by asking for complete specifications of the product, dimensions, materials, and certifications they possess to ascertain that they conform to the standards required. For example, recent data shows suppliers offering ISO-certified products have been more reliable with good quality assurance. Also, inquire about the minimum order quantities, lead times, and shipping logistics to determine whether the supplier can meet the project schedule milestones.

Also, request references from previous clients or obtain case studies of successful projects with their products. Trends suggest that suppliers who give case studies are generally transparent in their approach, thus committing themselves to quality and customer satisfaction. Negotiating warranty terms and after-sales support is critical, since products with extended warranty periods and easily accessible service centers guarantee better long-term value. Drawing up all this information allows a clear comparison between suppliers, aiding in the independence of securing a partnership that marries quality together with price and reliability.

Reference Sources

Application of Inherent Safety Explosion-Proof Technology in Oil Storage & Transportation Devices

Study of the Explosion Suppression Mechanism of Different Separate and Explosion-Proof Materials

Frequently Asked Questions (FAQs)

Q: What is explosion-proof aluminium material used for in oil tanks?

A: Explosion-proof aluminium material is used as a barrier in oil tanks to prevent explosions. It benefits the petro industry and ensures the safety of oil tankers loaded with fuel.

Q: How does an explosion-proof barrier material work in a stainless steel tank?

A: An explosion-proof barrier material works using explosion suppression theory. It absorbs and dissipates energy in the unit volume to prevent deformation or rupture, ensuring the stainless steel tank remains intact even under high pressure or heat.

Q: What are the benefits of using explosion-proof aluminium in oil storage tanks?

A: The benefits include increased safety, explosion prevention, long service time, and resistance to corrosion and wear. This material is ideal for use in oil storage tanks, ensuring liquid security during transportation.

Q: Can you provide details and prices for explosion-proof barrier materials?

A: For specific details and prices about explosion-proof barrier materials, it is best to contact manufacturers like Guangtai Intelligent Manufacture, which has a strong technical force and specializes in producing and selling these materials.

Q: What types of containers can benefit from explosion-proof materials?

A: Explosion-proof materials can benefit various types of containers, including fuel tanks, oil storage tanks, and petrochemical containers. These materials enhance the safety and integrity of the containers, especially in high-risk environments.

Q: What industries commonly use explosion-proof oil tank materials?

A: Industries such as petrochemical, electronics, aeronautics, processing machinery, and energy supply equipment frequently use explosion-proof oil tank materials to ensure safety and efficiency.

Q: Why is explosion-proof aluminium material preferred in the petro industry?

A: Explosion-proof aluminium material is preferred in the petro industry due to its ability to withstand harsh conditions, prevent explosions, and maintain the integrity of oil tankers and storage tanks. It is durable and effective in protecting against potential hazards.

Q: What role does Guangtai Intelligent Manufacture play in producing explosion-proof materials?

A: Since its establishment, Guangtai Intelligent Manufacture has been a leader in producing and selling explosion-proof materials. It offers innovative solutions and strong technical support to meet the demands of various industries.

Q: How does using explosion-proof materials influence the longevity of oil tanks?

A: Using explosion-proof materials significantly enhances the longevity of oil tanks by preventing damage from explosions, reducing wear and tear, and protecting against corrosive elements. This ensures that the tanks have a long service life and remain reliable.