Top Pipeline Oil Tank Leak Detector Manufacturers in China

We are the trusted providers of latest technologies Pipeline Oil Tank Leak Detector Solutions catering to oil-gas and industrial sectors. Our detectors are designed to locate leaks accurately, with very high reliability and safety standards. We also provide an ample spectrum of systems to monitor leaks effectively, integrate real-time data, and work in challenging environments with strength. Choose us to get the best, most innovative technology for leak detection that suits the needs of any modern pipeline operation.

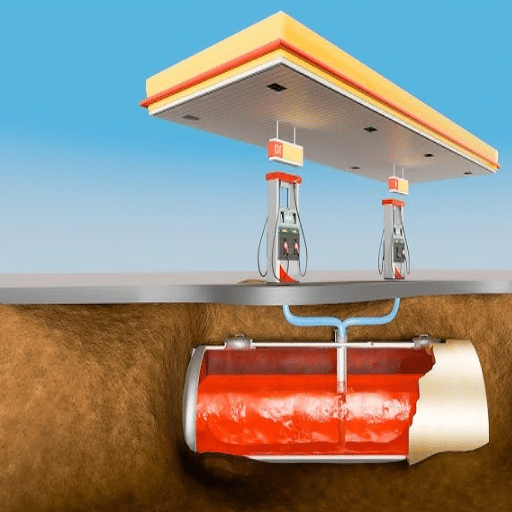

What is a Pipeline Oil Tank Leak Detector

The Pipeline Oil Tank Leak Detector is a cutting-edge solution designed to ensure safety and environmental protection in industrial operations. Utilizing advanced hydrocarbon detection technology, it identifies leaks through physical contact absorption, delivering quick and accurate results. This reliable system is ideal for monitoring pipelines and storage tanks, helping industries comply with safety standards while minimizing environmental risks.

Functions of our Pipeline Oil Tank Leak Detector

Our Pipeline Oil Tank Leak Detector performs precise leak detections with the help of an advanced hydrocarbon absorption technique allowing quick identification for prompt remediation. This is an important facet in environmental safety measures, precluding any kind of hazardous spills and the enforcement of safety regulations.

Accurate Leak Detection

Utilizes advanced hydrocarbon absorption technology to quickly and precisely identify leaks in pipelines and storage tanks, ensuring timely action.

Environmental Protection

Prevents hazardous spills by detecting leaks early, minimizing environmental damage and ensuring compliance with safety regulations.

Continuous Monitoring

Provides reliable, real-time monitoring for pipelines and tanks, offering peace of mind and reducing operational risks in industrial applications.

Key Benefits Of Pipeline Oil Tank Leak Detector

The Pipeline Oil Tank Leak Detector enhances safety by accurately detecting leaks and thereby protecting personnel and equipment. It prevents environmental hazards by causing hazardous spills and assures compliance with strict safety and environmental regulations.

Enhanced Safety

The detector ensures the safety of personnel and equipment by quickly identifying leaks in pipelines and storage tanks. By providing early warnings, it helps prevent accidents, fires, or explosions caused by undetected hydrocarbon leaks, making it an essential tool for high-risk industrial environments.

Environmental Protection

Designed to minimize the impact of hazardous spills, the detector plays a critical role in protecting ecosystems and water sources. By detecting leaks early, it prevents contamination and helps industries adhere to strict environmental regulations, promoting sustainable and responsible operations.

Cost Efficiency

Leakage detection at an early stage minimizes the cost of repairs, environmental clean-up, and stoppage of operations. Thus, under early detection, issues of leakage are addressed, saving penalties, allowing operations to run smoothly, and ultimately saving costs.

Reliable Performance

Using advanced techniques for the absorption of hydrocarbons, the detector was built to monitor continuously and in real time with great precision. Its rugged design promises to perform dependably even when subject to untoward industrial conditions, making it viable to be deployed for a wide array of oil and gas-related applications, chemical processing, and storage.)

What Is The Difference Between an Oil Leak Detection Spray And a Diesel Leak Detector?

- Oil Leak Detection Spray: Typically works by being sprayed onto the suspected area, where it reacts with oil to highlight the leak visually, often through color changes or fluorescence under UV light. Diesel Leak Detector: Often uses sensors or chemical absorption technology to detect diesel leaks, providing more precise and automated detection without requiring visual inspection.

- Oil Leak Detection Spray: Best suited for small-scale, localized inspections, such as identifying leaks in machinery, engines, or pipelines during maintenance. Diesel Leak Detector: Designed for larger-scale or continuous monitoring, such as in pipelines, storage tanks, or industrial systems handling diesel fuel.

- Oil Leak Detection Spray: Requires manual application and inspection, making it more labor-intensive and time-consuming for large areas. Diesel Leak Detector: Offers automated, real-time monitoring, making it more efficient for detecting leaks in critical or hard-to-access

How Do I Choose A Best Pipeline Oil Tank Leak Detector?

- Detection Technology:Look for advanced detection methods, such as hydrocarbon absorption or sensor-based systems, that offer high accuracy and quick response times. Ensure the technology is suitable for the specific type of liquid (oil, diesel, etc.) and the operating environment.

- Application Compatibility:Consider the scale and type of your application. For pipelines and large storage tanks, opt for detectors with continuous, real-time monitoring capabilities. Ensure the detector is compatible with the materials and conditions of your system, such as temperature, pressure, and chemical exposure.

- Reliability and Compliance:Choose a detector from a trusted manufacturer with a proven track record of reliability. Ensure it meets industry safety and environmental standards, providing peace of mind and compliance with regulations. Additionally, prioritize systems with low maintenance requirements and robust durability for long-term use

Comparison Table For The Pipeline Oil Tank Leak Detector Specifications

| Feature | Basic Model | Advanced Model | Industrial Model |

|---|---|---|---|

| Detection Method | Acoustic sensor | Acoustic + pressure sensor | Acoustic + pressure + thermal |

| Sensitivity | 0.1 L/min | 0.05 L/min | 0.02 L/min |

| Material | Corrosion-resistant steel | Stainless steel + polymer coating | High-grade alloy + epoxy coating |

| Power Supply | 12V DC | 24V DC + battery backup | 24V DC + solar option |

| Operating Range | -10°C to 50°C | -20°C to 60°C | -30°C to 70°C |

| Response Time | 10 seconds | 5 seconds | 2 seconds |

| Connectivity | Wired output | Wi-Fi + wired | Wi-Fi + 4G + wired |

| Durability | 5-year lifespan | 10-year lifespan | 15-year lifespan |

| Applications | Small oil tanks | Medium pipelines | Large industrial oil systems |

Top Applications of Pipeline Oil Tank Leak Detector

Oil and Gas Industry

Chemical Processing Plants

Industrial Storage Facilities

Marine and Offshore Operations

Why Choose Our Pipeline Oil Tank Leak Detector

-

Advanced Detection Technology: Our detector utilizes cutting-edge hydrocarbon absorption and sensor-based technology, ensuring precise and rapid leak identification. This advanced system minimizes false alarms and provides reliable performance in critical applications.

-

Comprehensive Real-Time Monitoring: Designed for continuous operation, our detector offers real-time monitoring of pipelines and storage tanks. This ensures immediate detection of leaks, allowing for swift action to prevent accidents and minimize downtime.

-

Robust and Durable Design: Built to withstand harsh industrial environments, our detector is resistant to extreme temperatures, pressure, and chemical exposure. Its durable construction ensures long-term reliability and low maintenance requirements.

-

Environmental and Safety Compliance: Our leak detector meets stringent industry standards for safety and environmental protection. By preventing hazardous spills and ensuring compliance with regulations, it supports sustainable and responsible operations.

-

Versatile Applications: Suitable for a wide range of industries, including oil and gas, chemical processing, and marine operations, our detector is adaptable to various systems and environments. Its versatility makes it the ideal choice for diverse industrial needs.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“The Pipeline Oil Tank Leak Detector has been a game-changer for our operations. As an Environmental Safety Manager, I’m always on the lookout for tools that enhance safety and minimize environmental risks. This product’s advanced detection technology and real-time monitoring have significantly improved our ability to identify and address leaks before they become major issues. I highly recommend it to anyone in the oil and gas industry!”

Sarah Thompson

Environmental Safety Manager

“I’ve been using the Pipeline Oil Tank Leak Detector for several months now, and it’s exceeded my expectations. As a Maintenance Supervisor, I need equipment that’s both efficient and dependable. This detector’s quick and accurate leak detection has saved us time and money by preventing costly repairs and downtime. Its robust design works perfectly even in harsh industrial conditions, and the continuous monitoring gives me peace of mind knowing our pipelines and tanks are secure. It’s a must-have for any industrial operation!”

Michael Carter

Maintenance Supervisor

Discover the Power of Pipeline Oil Tank Leak Detector

How do you Detect Leaks in Oil Pipelines?

Leaks are detected using acoustic sensors, pressure drop monitoring, thermal imaging, or flow rate analysis, identifying anomalies in real-time.

What are two indicators of a surface leak from a Liquid Pipeline?

Two indicators are visible oil slicks or wet spots on the ground and unusual odors from escaping hydrocarbons.

How to trace an Oil Leak?

Trace an oil leak by following oil stains, using thermal cameras to detect temperature changes, or employing leak detection sensors along the pipeline route.

What is the leak detection system in the Oil Pipeline?

A leak detection system uses sensors (acoustic, pressure, or flow), data analysis software, and alarms to monitor and identify leaks, ensuring prompt response in oil pipeline operations.

What is a Pipeline Oil Tank Leak Detector?

A device designed to detect leaks in pipelines and oil tanks using advanced technologies like hydrocarbon absorption, ensuring safety and environmental protection.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

A very important task in industries such as agriculture, construction, automotive, and marine operations is the transfer of liquids such […]

Fuel dispensing systems are critical in facilitating the day-to-day retail transactions in fuel businesses. For businesses in this industry, commercial […]

Device fuel dispenser systems are very important in the fuel retail and distribution industry, and they are the main factors […]

Gas serves as the lifeforce of any engine, powering anything from lawnmowers to cars. Still, not all fuel remains valuable […]

There is a perception of gas stations as mere stops for fill-ups and mini snacks for car-travelers; well, on the […]

Are gas stations a vital daily matter, essentially providing refueling avenues for fuel vehicles? How much do we really know […]

Imagine the convenience of filling up on fuel for the vehicles without having to make the trip to a gas […]

Fuel dispensing systems play a crucial role in the global energy system, ensuring the efficient and safe supply of fuel […]

Pipeline Oil Tank Leak Detector Solution

Protect your pipeline with our Pipeline Oil Tank Leak Detector Solution, developed by industry leaders. Employing state-of-the-art acoustic and pressure sensors, these detectors detect leaks in real-time with a sensitivity of 0.02 L/min, allowing for quick intervention against environmental damage. Suitable for oil, gas, and industrial applications, contact us for bespoke high-performing systems at competitive prices!

Frequently Ask Questions

Q: How does the leak detector work?

A:It uses physical contact absorption technology to identify hydrocarbon leaks quickly and accurately, providing real-time monitoring.

Q: What industries can benefit from this detector?

A: Industries like oil and gas, chemical processing, manufacturing, and any sector requiring safe and efficient pipeline and tank operations.

Q: Why is leak detection important?

A: It prevents hazardous spills, protects the environment, ensures safety, and helps industries comply with regulations.

Q: What are the key features of the detector?

A: Advanced hydrocarbon detection, real-time monitoring, high accuracy, and compatibility with various pipeline and tank systems.

Q: How does it enhance safety?

A: By quickly identifying leaks, it prevents accidents, equipment damage, and potential harm to personnel.

Q: Does it help with regulatory compliance?

A: Yes, it ensures adherence to safety and environmental standards, avoiding penalties and legal issues.

Q: Is it cost-effective?

A: Absolutely. It reduces downtime, maintenance costs, and potential fines, making it a valuable investment.

Q: Can it detect small leaks?

A: Yes, the detector is designed to identify even minor leaks with high precision, ensuring early intervention.