Top Explosion-Proof LED Light Supplier in China

We offer advanced LED lighting systems engineered for hazardous environments. Our explosion-proof LED lights provide superior illumination, energy efficiency, and enhanced safety in areas prone to explosive gases, vapors, or dust. Designed for maximum durability and compliance with strict safety standards, these lights ensure reliable performance in petrochemical plants, mines, offshore platforms, and other critical industrial applications. Choose our innovative lighting technology for robust, long-lasting solutions that protect personnel and property while reducing operational costs.

What Are Explosion-Proof LED Light

Explosion-proof LED lights are specialized lighting fixtures designed to operate safely in environments containing flammable gases, vapors, dust, or fibers which could ignite under normal conditions. These robust units are constructed using durable materials and sealed to prevent internal sparks or heat from escaping and causing an explosion. They utilize energy-efficient LED technology to provide bright, long-lasting illumination while meeting stringent international safety certifications for hazardous locations. Essential for ensuring safety and visibility in industries like petrochemicals, mining, and manufacturing, they represent a critical investment in reliable and secure operations.

Functions of our Explosion-Proof LED Light

Our advanced Explosion-Proof LED Lights are designed to deliver safe and reliable illumination in hazardous locations, offering a range of integrated functions to ensure optimal performance.

Safe Illumination & Spark Prevention

Provides powerful lighting in areas with flammable materials. Engineered to prevent internal sparks or heat from igniting explosive atmospheres, ensuring site safety.

Robust Durability & Environmental Resistance

Constructed with heavy-duty materials designed to withstand corrosive substances, vibrations, and harsh weather conditions. Guarantees long-term reliable operation in demanding environments.

Energy Efficiency & Cost Reduction

Utilizes advanced LED technology for significant energy savings compared to traditional lighting. Reduces power consumption, lowers electricity bills, and minimizes the need for frequent bulb replacements.

Key Benefits Of Explosion-Proof LED Lights

Explosion-Proof LED Lights are vital for safe operations in hazardous locations, offering key advantages like superior safety features, extreme durability, high energy efficiency, and minimal maintenance requirements. They are built to endure demanding environments and ensure reliable illumination.

Enhanced Safety Protection

Specifically designed to prevent ignition in explosive atmospheres containing flammable gases, vapors, dust, or fibers. Provides essential safety assurance for personnel and infrastructure in hazardous industrial areas.

Outstanding Energy Efficiency

Leverages advanced LED technology for substantial reductions in power consumption compared to conventional lighting methods. Lowers electricity costs and supports environmentally conscious operations.

Extreme Durability & Resilience

Constructed with rugged materials capable of withstanding harsh conditions, including corrosive substances, vibration, and temperature extremes. Ensures long-term reliability and operational integrity in challenging environments.

Extended Lifespan & Low Maintenance

Offers a significantly longer operational life than traditional hazardous location lighting. Reduces the need for frequent replacements and maintenance, minimizing downtime and overall ownership costs.

What is The Difference Between Explosion-Proof and Non Explosion-Proof?

- Explosion-Proof Light: Specifically engineered for hazardous locations where flammable gases, vapors, dust, or fibers are present, designed to prevent internal ignition from causing an external explosion.

- Non Explosion-Proof Light: Standard lighting fixtures intended for general-purpose areas without explosive atmospheres. They lack the necessary safety features and certifications for hazardous environments.

- Key Difference: Explosion-proof lights contain potential sparks or heat within their enclosure, ensuring they do not ignite surrounding flammable substances, unlike standard lights which pose an ignition risk.

How to Choose the Right Explosion-Proof LED Light for Your Application?

- Assess Hazardous Area Classification: Determine the specific Zone or Division and the type of hazardous substance (gas, dust) present at your site. Choose lights with the appropriate safety rating and certification (e.g., ATEX, UL, IECEx).

- Identify Required Performance: Consider the necessary light output (lumens), beam angle, and operating temperature range for effective illumination and reliable performance in your specific environmental conditions.

- Evaluate Construction and Compliance: Select fixtures with robust, corrosion-resistant materials, suitable IP ratings for environmental ingress protection, and verified compliance with relevant local and international safety standards.

Comparison for the Explosion-Proof LED Light specifications

| Parameter | Description | Parameters |

|---|---|---|

| Safety Certification | Compliance with international safety standards | ATEX, UL Class/Division, IECEx |

| Hazardous Area Classification | Approved locations for safe operation | Zone 1, Zone 2, Div 1, Div 2 |

| Power (Wattage) | Electrical power consumption | 20W - 200W (variable) |

| Luminous Flux (Lumens) | Total light output | 2,500 - 25,000 lm (variable) |

| Operating Voltage | Compatible electrical input | AC 100-277V, 50/60 Hz |

| Operating Temperature Range | Safe ambient temperature limits for performance | -40°C to +55°C |

| Ingress Protection (IP) Rating | Protection against dust and water intrusion | IP66, IP67 |

| Impact Protection (IK) Rating | Resistance to mechanical impacts | IK08, IK10 |

| Lifespan | Expected operating hours | ≥ 50,000 hours |

| Housing Material | Construction material for durability and resistance | Aluminum Alloy, Stainless Steel |

Top Applications of Explosion-Proof LED Light

Oil and Gas Sector

Chemical and Petrochemical Plants

Mining Industry

Pharmaceutical Manufacturing

Why Choose Our Explosion-Proof LED Light

-

Uncompromising Safety Standards: Engineered and certified to meet the strictest global safety regulations for hazardous locations, ensuring maximum protection against explosions.

-

Exceptional Durability and Performance: Built with robust, high-quality materials designed to withstand harsh industrial environments, guaranteeing reliable and long-lasting illumination.

-

Superior Energy Efficiency: Utilizes cutting-edge LED technology to provide bright light output with significantly lower energy consumption, reducing operating costs and environmental impact.

-

Tailored Lighting Solutions: Offers flexible options in wattage, beam angle, and mounting styles to meet the specific lighting requirements of diverse hazardous applications.

-

Expert Support and Availability: Benefit from direct manufacturer expertise, streamlined supply chains, and dedicated support for seamless selection, installation, and maintenance.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“We installed these explosion-proof LED lights in our chemical processing plant, and the difference is remarkable. The illumination is incredibly clear and consistent, making our workspace safer and more productive. Knowing these lights are certified for hazardous locations gives us complete peace of mind. The durability and performance exceed our expectations.”

David Chen

Operations Manager

“These explosion-proof LEDs have been a game-changer for our underground facility. The extended lifespan and significantly reduced energy consumption are major benefits, cutting down on maintenance costs and power bills. The quality of light improves visibility dramatically, enhancing safety for our team. Highly recommend them for demanding environments.”

Sarah Mille

Procurement Specialist

Discover the Power of Explosion-Proof LED Light

Is it safe to leave LED lights on all night?

Yes, it is generally safe to leave standard LED lights on all night. They produce significantly less heat than older technologies like incandescent bulbs, which drastically reduces the risk of overheating or fire hazards. Explosion-proof LEDs are designed for continuous operation in challenging environments and are built for safety.

How to tell if a light is explosion-proof?

You can tell if a light is explosion-proof by checking for specific certifications from recognized testing laboratories such as UL, ETL, ATEX, or IECEx. The fixture, packaging, or datasheet will prominently display these certifications and the relevant hazardous location classifications (Classes, Divisions, Zones) that indicate it’s rated for potentially explosive atmospheres.

What is the standard for explosion-proof lighting?

Standards for explosion-proof lighting govern equipment used in hazardous locations where flammable substances may be present. Key standards bodies include UL (Underwriters Laboratories) and NFPA (National Fire Protection Association) in North America, the ATEX directives in Europe, and IECEx internationally. These standards specify the classification of hazardous areas, design requirements, and rigorous testing methods.

What is the difference between Class 1 and Class 2 explosion proof?

In hazardous location classification (common in North America), Class 1 refers to locations where flammable gases or vapors are or may be present in the air in sufficient quantities to produce explosive or ignitable mixtures. Class 2 refers to locations where combustible dusts are or may be present. This classification dictates the type of explosion-proof or hazardous location equipment required.

What makes a light explosion-proof?

A light is made explosion-proof by designing its enclosure to contain any potential internal explosion that might occur (e.g., from electrical arcing), preventing it from igniting the surrounding flammable gases or dust in the hazardous atmosphere. Components are sealed, and the housing is constructed from robust materials capable of withstanding and containing an internal blast.

How do I know if my LED lights are fire rated?

To know if your LED lights are fire-rated, you must check the product specifications, packaging, or labels for explicit fire rating certifications. These certifications, often from testing labs like UL or similar bodies, indicate the duration (e.g., 30, 60, 90 minutes) for which the fixture maintains the fire integrity of the building structure (like a fire-rated ceiling or wall) it’s installed within during a fire event.

What is the fire risk of LED lights?

The fire risk of standard LED lights is generally very low compared to traditional lighting technologies because they generate significantly less heat. While the electronic driver component could potentially overheat if faulty or poorly made, certified LED products incorporate safety measures. Most fire incidents linked to lighting are due to improper electrical installation or wiring issues, not the LED components themselves.

Are battery operated LED lights a fire hazard?

Battery-operated LED lights themselves produce minimal heat, making the LED source low risk. However, the battery component, especially rechargeable lithium-ion batteries, can pose a fire risk if damaged, defective, overcharged, or used with an incompatible charger. Using certified products from reputable manufacturers and following charging guidelines minimizes this potential hazard.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Modern fueling stations depend on fuel dispensers as a vital part, which provide the vehicles with fuel in an effective […]

Gas stations, really, are not just a quick stop for refueling, but some of the unseen possibilities of global infrastructure, […]

When it comes to ensuring safety in environments where flammable substances are stored or transported, explosion-proof oil tank barrier materials […]

In consideration of life and property in a hazardous environment, safety is the right choice to be made when deciding […]

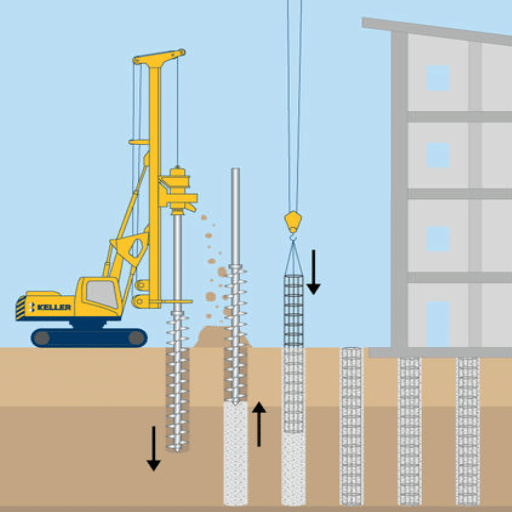

Piles under CFA constitute widely applicable foundation systems all over the construction domain, regarding their endless array of efficiency, versatility, […]

The very act of dispensing fuel has been an essential part of the transportation and logistics sectors for generations. There […]

Many drivers tend to overlook the fact that water contamination in a gas tank occurs quite often, and it also […]

Fuel stations have long found their place on the map of daily living: they provide journeys with the necessary fuel […]

Elevate Safety with Explosion-Proof LED Lighting

Ensure unparalleled safety and reliability in your hazardous environments with our certified explosion-proof LED lights. Engineered for peak performance under volatile conditions, these fixtures offer brilliant illumination, exceptional durability, and meet stringent safety standards. Benefit from reduced maintenance needs and significant energy savings, securing your operations with dependable, cutting-edge lighting technology designed for ultimate protection.

Frequently Ask Questions

Q: What are explosion proof LED lights?

A: Explosion proof LED lights are specialized luminaires designed for installation in hazardous locations where flammable gases, vapors, combustible dusts, or ignitable fibers may be present. They use durable LED technology and are constructed to prevent any internal electrical spark or thermal effect from igniting the surrounding potentially explosive atmosphere, ensuring maximum safety in industrial settings.

Q: Where are explosion proof industrial lights typically installed?

A: Explosion proof industrial lights are commonly installed in environments such as oil and gas refineries, chemical processing plants, mines, grain elevators, paint finishing areas, and manufacturing facilities handling volatile substances. These locations require robust, certified lighting solutions that can operate safely without becoming sources of ignition.

Q: What makes an explosion proof light fixture different from a standard one?

A: An explosion proof light fixture is built with a sturdy, often heavy-duty enclosure designed to contain any explosion originating within the fixture itself. This containment prevents the ignition of flammable materials outside the enclosure. Components like switches and wiring are sealed, and materials are chosen for their ability to withstand harsh conditions and prevent sparking.

Q: Are portable explosion proof lights available for temporary needs?

A: Yes, portable explosion proof lights are available and are essential for temporary illumination during maintenance, inspections, or emergencies in hazardous zones. These units are typically rugged, often battery-powered or designed for safe connection to power sources, providing flexible and safe lighting where permanent fixtures might not reach.

Q: Is there such a thing as an explosion proof LED emergency light?

A: Absolutely. Explosion proof LED emergency lights combine the safety requirements for hazardous locations with emergency lighting functionality. They are designed to provide critical illumination during power outages or emergencies, ensuring safe egress paths or continued essential tasks in potentially explosive environments while maintaining their explosion-proof integrity.

Q: Are explosion proof LED flood lights suitable for large outdoor hazardous zones?

A: Yes, explosion proof LED flood lights are specifically designed to provide wide, powerful illumination over large areas like exterior processing plants, loading docks, or storage tank farms in hazardous locations. Their robust construction withstands outdoor elements, and the explosion-proof certification ensures safe operation in these potentially volatile environments.

Q: What considerations are there for installing explosion proof LED light ceiling fixtures?

A: When installing explosion proof LED light ceiling fixtures, it’s crucial to consider the fixture’s weight and the structural integrity of the mounting surface. Proper conduit sealing and gland connections are essential to maintain the hazardous area classification. Adhering strictly to electrical codes and manufacturer instructions is paramount for safety.

Q: How can I determine the best explosion proof LED light for my specific hazardous location?

A: Selecting the best explosion proof LED light involves understanding your specific hazardous location classification (Class, Division, Zone, Group), required lumen output, operating temperature range, desired beam pattern (e.g., for an explosion proof led flood light or ceiling fixture), and required safety certifications (UL, ATEX, IECEx). Consulting with a lighting specialist experienced in hazardous locations is highly recommended to ensure compliance and optimal performance.