Top Explosion-Proof Barrier Material for Explosion Proof Oil Tank Manufacturers in China

Implementing advanced explosion-proof barrier materials and systems is fundamental for ensuring safety within hazardous oil tank environments. These specialized solutions, often including certified flame and detonation arrestors, are engineered to prevent the propagation of ignition sources or explosions through tank vents or connected pipelines. Deploying robust barrier technology is vital for mitigating risks in critical applications involving flammable liquids and vapors, providing essential protection for personnel, valuable assets, and ensuring the operational integrity of storage facilities in volatile locations.

What Are Explosion-Proof Barrier Material for Explosion Proof Oil Tank

Explosion-proof barrier materials and systems are essential components used to enhance safety within environments containing oil tanks and other storage vessels for flammable liquids. These specialized solutions are designed to prevent the transmission of flames or explosions through vents, pipelines, or other openings that could otherwise propagate an ignition from inside or outside the tank. Utilizing robust materials and engineered systems like flame arrestors, they provide a critical layer of protection, ensuring operational security and safeguarding facilities in hazardous locations against catastrophic events.

Functions of our Explosion-Proof Barrier Material for Explosion Proof Oil Tank

Our specialized barrier solutions for oil tanks are engineered with integrated functions to ensure the highest level of safety in hazardous locations.

Flame & Detonation Prevention

Engineered to quench or stop flames and detonations from passing through openings like vents, preventing explosions from propagating into or out of the tank structure.

Corrosion & Pressure Resistance

Constructed from robust materials designed to withstand corrosive vapors and internal pressure fluctuations inherent in oil storage, ensuring long-term reliability and structural integrity.

Safety Compliance & Asset Protection

Provides critical safety compliance for hazardous area operations, safeguarding personnel and assets by significantly reducing the risk of ignition in potentially explosive atmospheres.

Key Benefits Of Explosion-Proof Barrier Material for Oil Tanks

Explosion-Proof Barrier Materials are crucial for secure operations in hazardous oil tank environments, offering key advantages like superior safety features, extreme durability, high performance, and vital compliance requirements. They are built to endure demanding conditions and ensure reliable protection.

Enhanced Explosion Prevention

Specifically designed to contain or quench flames and detonations, preventing ignition from spreading into or out of the tank, providing essential safety assurance for personnel and infrastructure.

Critical Compliance & Risk Reduction

Meets stringent international safety standards for hazardous locations, ensuring regulatory compliance. Significantly reduces the risk of catastrophic events, protecting valuable assets and supporting secure operations.

Extreme Durability & Resilience

Constructed with robust materials capable of withstanding harsh conditions, including corrosive substances and extreme temperatures. Ensures long-term reliability and operational integrity.

Reliable Performance & Integrity

Provides continuous, passive protection without complex moving parts. Offers consistent, dependable safety performance over extended periods, minimizing potential downtime associated with safety failures.

What Are The Requirements For Oil Tank Explosion-Proof?

- Assess the hazardous area classification around and connected to the tank, identifying the specific flammable substances and their properties. This determines the level of protection needed.

- Utilize certified explosion protection devices, such as flame or detonation arrestors on vents and pipelines, designed to prevent flame propagation into or out of the tank atmosphere.

- Ensure construction and installation meet rigorous international and local safety standards for hazardous locations, including proper grounding and bonding to prevent static sparks.

How to Choose the Right Explosion-Proof Barrier Material for Explosion Proof Oil Tank for Your Application?

- Identify the precise flammable liquids and vapors stored, including their explosion group and temperature class, to ensure the barrier material is certified to contain the specific type of explosion.

- Consider the tank's operational parameters, such as required flow rates, potential pressure surges, and operating temperature range, to select a barrier material that performs reliably under these conditions.

- Verify that the barrier material and system hold the necessary certifications for the tank's hazardous location classification (e.g., ATEX, UL) and that the materials are compatible with the stored product.

Explore Our Explosion-Proof Barrier Material for Oil Tanks Series

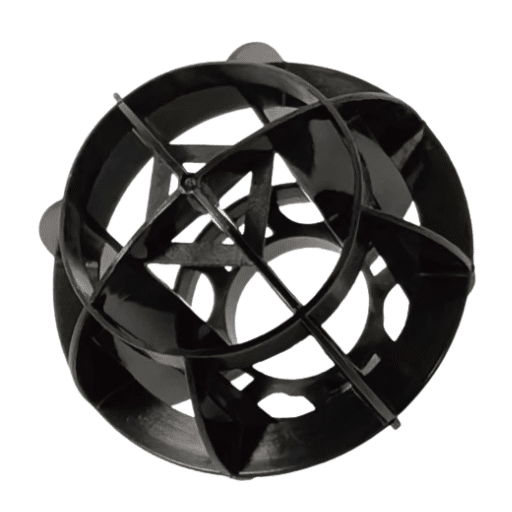

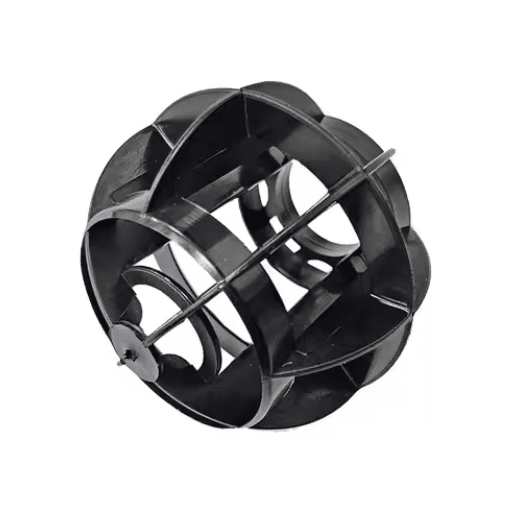

Gas Stations Explosion-Proof Barrier Balls

Engineered from a high-strength, lightweight polymer, our barrier balls are the definitive solution for passive explosion safety in a wide range of applications. Their unique multi-sided, hollow 3D structure acts as a dense matrix that effectively breaks up explosive pressure waves and quenches flame fronts. Ideal for both new and existing tanks, their simple pour-in installation minimizes downtime while providing superior surge resistance, enhancing the stability of mobile fuel tankers.

Gas Station Aluminum-Magnesium Explosion-Proof Barrier Material

Representing the gold standard in proactive explosion prevention, our aluminum-magnesium barrier material is a permanent, maintenance-free solution. The advanced alloy mesh functions as a massive heat sink, instantly dissipating thermal energy to prevent ignition. Its conductive structure also provides unparalleled anti-static protection by grounding the entire fuel volume, making it the ideal choice for high-stakes applications like aviation, military, and bulk storage facilities.

Explosion-Proof Barrier Material Specifications Chart

| Parameter | Description | Parameters |

|---|---|---|

| Safety Certification | Compliance with international safety standards | ATEX, UL Listed, FM Approved, IECEx Certified |

| Hazardous Area Classification | Approved locations for safe installation | Zone 0, Zone 1, Zone 2; Div 1, Div 2 |

| Explosion Group Rating | Rating for specific flammable gas or vapor group | IIA, IIB1, IIB2, IIB3, IIC; Dust Grouping |

| Temperature Class | Maximum surface temperature rating for ignitable mixtures | T1, T2, T3, T4, T5, T6 |

| Material Construction | Construction material for durability and resistance | Stainless Steel (304/316L), Aluminum Alloy |

| Connection Type | Method for attaching to tank vents or piping | Flanged, Threaded, Wafer |

| Nominal Size | Diameter or size of the connection | DN50 - DN800 (2" - 30") |

| Operating Temperature Range | Safe ambient/process temperature limits for performance | -40°C to +250°C (variable) |

| Pressure Drop | Resistance to flow during venting | (Specific values based on flow rate/size) |

| Corrosion Resistance | Suitability for specific chemical environments in the tank | (Rating based on stored product/material) |

Top Applications of Explosion-Proof Barrier Material for Explosion Proof Oil Tank

Oil and Gas Sector

Chemical and Petrochemical Plants

Pharmaceutical Manufacturing

Bulk Liquid Storage Terminals

Why Choose Our Explosion-Proof Barrier Material for Explosion Proof Oil Tank?

-

Uncompromising Safety Compliance: Engineered and certified to meet the strictest global safety regulations for hazardous tank locations, ensuring maximum protection against flame and detonation propagation in volatile oil storage.

-

Robust Durability In Harsh Environments: Built with highly corrosion-resistant and robust materials designed to withstand the aggressive chemical atmospheres and demanding conditions found in oil tanks, guaranteeing reliable, long-term performance.

-

Critical Risk Mitigation & Asset Protection: Provides an essential safety layer by preventing explosions from entering or exiting the tank structure, significantly reducing the risk of catastrophic events and protecting valuable assets and personnel.

-

Proven Performance & Reliability: Our barrier systems are designed and tested to offer dependable passive protection against ignition sources, ensuring continuous safety assurance without the need for active intervention, minimizing operational concerns.

-

Expertise & Application Matching: Benefit from our specialized knowledge in hazardous tank safety. We offer dedicated support to help you select and implement the ideal barrier solution precisely tailored to your specific oil tank application requirements.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“Installing these explosion-proof barrier materials on our oil storage tanks was a critical safety upgrade. The peace of mind knowing these certified systems actively prevent flame propagation through vents is invaluable for our team. Their robust construction ensures reliable performance even in corrosive environments, providing essential protection for our operations.”

Robert Jones

Tank Farm Supervisor

“We selected this explosion-proof barrier material for its proven reliability and compliance with stringent hazardous area standards. It offers crucial protection for our oil tanks, effectively mitigating the risk of explosion ignition. The durability of the material in demanding conditions ensures long-term safety and helps maintain the integrity of our entire facility infrastructure.”

Maria Garcia

EHS Manager

Discover the Power of Explosion-Proof Barrier Material

What materials are explosion proof?

Materials used in explosion-proof barrier systems, like those for oil tanks, are chosen for their ability to withstand and prevent the passage of flames or detonations. Common materials include stainless steel (such as 304 or 316L) and aluminum alloys, selected for their strength, corrosion resistance, and thermal properties to effectively quench flames and prevent ignition of surrounding hazardous atmospheres.

What are the requirements for explosion proof enclosure?

While barrier materials aren’t typical electrical enclosures, they function similarly by preventing explosion propagation. Requirements for such barriers involve rigorous design and testing to contain or quench flames from entering or exiting a hazardous volume, like an oil tank. They must withstand the force and heat of a potential internal deflagration or detonation to ensure the integrity of the protection system.

What is the most explosion resistant material?

In the context of flame and detonation arrestors used as barrier materials for oil tanks, the “most explosion resistant” material is one that, in combination with the device design (e.g., element crimp geometry), can reliably quench the specific flame or detonation type and temperature of the stored flammable substance without failure. High-grade stainless steels and robust alloys are typically used for their durability under extreme conditions.

What is explosion-proof material?

Explosion-proof material, in this application, refers to materials used in the construction of barrier devices like flame and detonation arrestors that are certified to prevent the passage of flames and resulting explosions. These materials are selected for their thermal conductivity, mechanical strength, and corrosion resistance, allowing the device to cool hot gases and stop a flame front from igniting the hazardous atmosphere.

What is the standard for explosion-proof?

Standards for explosion-proof equipment and barrier materials in hazardous locations are set by organizations like UL (Underwriters Laboratories), FM Approvals, ATEX (European Union directives), and IECEx (International Electrotechnical Commission System). For oil tanks specifically, NFPA 30 (Flammable and Combustible Liquids Code) also outlines requirements for venting and explosion protection, often referencing devices certified to these standards.

What are the requirements for a flammable liquid storage tank?

Flammable liquid storage tanks require designs and components that minimize ignition risks. This includes proper venting equipped with certified flame or detonation arrestors (explosion-proof barrier materials), robust construction (often meeting API or UL standards), appropriate grounding and bonding to dissipate static electricity, and adherence to stringent codes regarding location, spacing, and fire suppression measures.

What are the different types of explosion-proof enclosures?

In hazardous locations, “explosion-proof enclosure” typically refers to electrical housings (Type Ex d or Div 1) built to contain an internal explosion. Explosion-proof barrier materials for oil tanks, such as flame and detonation arrestors, are a different category of protective device, specifically designed as passive barriers to prevent flame propagation through openings in the tank system rather than enclosing electrical components.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Setting up a gas station appears to be a pretty ordinary operation, but behind the familiar architecture lies a complex […]

Fuel dispensers are truly the heart of a gas station, working ceaselessly to serve its customers fast and efficiently. What […]

Pulling up to a gas pump is, for many, just another mundane exercise of selecting fuel, detaching the nozzle, and […]

The fuel dispensers are what the petroleum retail sector completely relies on, and thus, they are the ones that daily […]

Fuel dispensers serve as the lifeblood of any gas station, where technical ingenuity and operational robustness come together to deliver […]

Previously, sitting in an electric vehicle while it charges might have seemed silly. However, it now raises several safety concerns […]

Operating a gas station may have its share of difficulties and large financial considerations, but it can still be a […]

A rotary rig is one of the most important inventions of modern drilling technology for the efficient extraction of resources […]

Secure Your Oil Tanks with Advanced Barrier Material

Implement essential safety for your hazardous oil storage tanks with our certified Explosion-Proof Barrier Material. Engineered to prevent dangerous flame and detonation propagation through vents and openings, these robust solutions ensure compliance with stringent safety standards. Protect your personnel, valuable assets, and maintain secure operations by integrating our reliable barrier technology designed for demanding environments.

Frequently Ask Questions

Q: What materials are explosion proof?

A: In the context of explosion-proof barrier materials for oil tanks, this primarily refers to materials like stainless steel (commonly 304 or 316L) and specific aluminum alloys. These materials are not inherently “explosion-proof” on their own but are used in the construction of certified devices like flame or detonation arrestors. Their properties, combined with the device design, enable them to quench flames and prevent ignition from propagating, acting as explosion proof material in a system.

Q: What are the requirements for explosion proof enclosure?

A: For oil tank barrier materials (which function as containment but aren’t electrical enclosures), the explosion proof requirements focus on their ability to prevent the passage of a flame or detonation front. This is achieved by meeting specific testing standards (like those from UL, FM, ATEX, IECEx) that certify the device, constructed from the chosen explosion proof material, can safely contain or quench an explosion from a specified gas or dust group and temperature class without igniting the external atmosphere.

Q: What is the most explosion resistant material?

A: Determining the “most explosion resistant material” for oil tank barriers depends on the specific hazardous substance stored. For flame and detonation arrestors, it’s less about a single material and more about the engineered combination of material properties (like thermal conductivity and corrosion resistance) and the intricate design of the flame element (often crimped metal). High-grade explosion proof metal, particularly stainless steel alloys, are selected for their durability and ability to withstand the heat and force of explosions specific to certain flammable substances.

Q: What is explosion-proof material?

A: An explosion-proof material, when discussing oil tank barriers, is material used in the construction of certified safety devices (like arrestors) that form a physical barrier designed to cool or quench a flame front passing through, preventing it from causing a larger explosion in the surrounding hazardous atmosphere. These materials, often specific alloys, possess the necessary thermal and mechanical properties to perform this critical function safely.

Q: What is the standard for explosion-proof?

A: The standard for explosion-proof equipment, including barrier materials used in oil tanks, is defined by international and national certification bodies. Key standards include those from ATEX directives (Europe), IECEx (international), UL (Underwriters Laboratories), and FM Approvals (North America). These standards classify hazardous locations and specify rigorous testing protocols that a device and its explosion proof material must pass to be certified for use in those areas.

Q: What are the requirements for a flammable liquid storage tank?

A: Flammable liquid storage tanks have stringent explosion proof requirements. These include robust construction, proper venting to manage pressure and vacuum, and crucially, incorporating certified explosion proof material systems like flame or detonation arrestors on vents. These barriers prevent external ignition sources (like lightning) from entering the tank or internal flashes from exiting, all while meeting standards like NFPA 30.

Q: What are the different types of explosion-proof enclosures?

A: While oil tank barrier materials are not typical explosion proof enclosure material (which are electrical), explosion-proof enclosures are housings designed to contain an internal explosion of flammable gas or dust. Types include flameproof (Ex d or Div 1), which contains the explosion; increased safety (Ex e), which prevents sparks; intrinsic safety (Ex i), which limits energy; and pressurized (Ex p), which uses pressure to keep hazards out. Oil tank barriers use principles of flame quenching or deflagration containment specific to process connections.