Safety is not just something that can be GIVEN priority for industries dealing with hazardous materials–it’s an ABSOLUTE MUST. Explosion-proof oil tanks provide a safe barrier against catastrophic accidents with their very presence, but how reliable are the materials used in making them “explosion proof”? This question has instigated a continued discussion on industrial standards and innovations. In this article, we shall lay down some scientific principles informing these specialized materials, their reliability in high-stress conditions, and ongoing advances to improve their performance. Whatever you may be, a practicing engineer or simply someone seeking to understand the technology that safeguards critical industries, this article will give you an insight into explosion-proof oil tanks.

What are Explosion-Proof Materials?

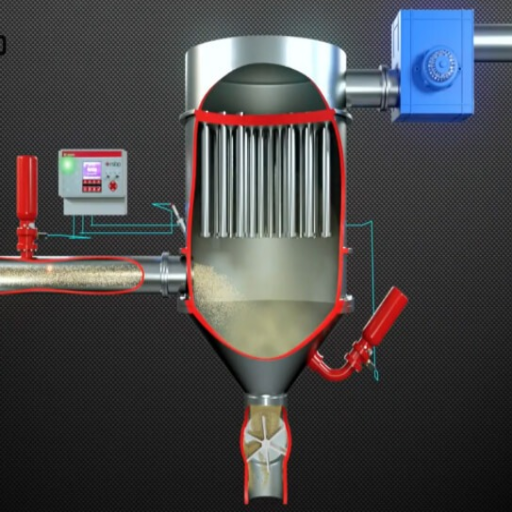

Explosion-proof materials are substances specially designed to withstand explosions and contain them without allowing the spread of flame or pressure into adjacent areas. They are generally constructed using strong metals such as steel or aluminum, combined with a design that allows energy dissipation. For instance, they are substances used in environments where flammable gases, vapors, or dust may be found. Oil refineries, chemical plants, and industrial facilities necessarily employ such equipment. They mainly enhance safety by reducing the risk of damage and injury during an explosion.

Common Materials Used in Explosion-Proof Oil Tanks

Explosion-proof tanks are typically made of materials designed to ensure durability, strength, and resistance to severe conditions. These commonly used materials are:

Steel Alloys: High-strength steel alloys are the most common materials due to their durability and ability to withstand high pressures and temperatures. They are often coated to resist corrosion.

Aluminum: Lightweight and corrosion-resistant aluminum is a second option for explosion-proof tanks, especially in applications where weight reduction is an issue.

Fiberglass-reinforced plastic (FRP) is a widely accepted solution for maintaining chemical resistance and non-corrosiveness in tanks exposed to harsh chemical-inducing conditions or highly moisture-laden environments.

Stainless Steel: Extremely corrosion-proof environment solutions weigh in for oil storage.

Each of these materials applies depending on the field application, surrounding environment, and operational needs; manufacturer—or community-based selection usually addresses safety standards or regulatory requirements.

Understanding Explosion-Proof Construction Techniques

Such explosion-proof techniques align with safety requirements concerning environments where ignitable gases, dust, or vapors could present hazards. In an explosion-proof arrangement, these techniques entail special designs, materials, and systems that aim to contain or prevent any explosion and protect people, equipment, and buildings.

Another essential feature of an explosion-proof design is the construction of enclosures that can contain and hold the force of an explosion occurring within without allowing flames or heat to escape into the atmosphere. For example, flame-proof enclosures have been constructed using materials such as cast aluminum or stainless steel to withstand high internal pressures. Sometimes, these enclosures also have very accurate gap dimensions, which cool the escaping gases and thus prevent them from igniting the atmosphere outside.

Then, we have intrinsically safe electrical arrangements that restrict electrical energy in circuits to levels that cannot ignite hazardous substances. They do this using current-limiting devices, among other things. In some systems, pressurization may also be used, whereby the enclosure is purged with an inert gas or clean air to exclude the hazardous substance.

Explosion-proof construction also depends on standards and certifications like IECEx, ATEX, and UL, which specify the testing methods and the safety criteria. For instance, these certifications may be required for safe operations in the hydrocarbon-handling industry, such as oil and gas. Based on recent industry data, the global explosion-proof equipment market is expected to witness a CAGR of 5.5% from 2023 to 2030, reflecting huge investment in safety systems.

Modern explosion-proof systems, equipped with high-end monitoring technology such as gas sensors and automated shutdown systems, actively avoid hazards. These solutions mitigate downtime and operational hazards while enhancing safety standards in high-risk industries.

The Role of Safety Standards in Explosion-Proof Applications

Safety standards ensure the utmost reliability and effectiveness in explosion-proof systems in high-risk industries such as oil and gas, chemical manufacturing, and mining.

These internationally recognized standards, including IEC (International Electrotechnical Commission) standards, or the ATEX (Atmosphères Explosibles) directive in Europe, define the entire spectrum in explosion-proof equipment design and installation. For example, IECEx certification means that the equipment was tested strictly and determined to perform safely in explosive atmospheres, mitigating the risk of ignition.

Recent data suggest that the trend towards safety compliance continues to be fueled by industrial developments and regulatory requirements. Due to the increased acceptance of stringent standards, the demand for certified explosion-proof solutions increased 8% in the last five years. Materials and designs such as corrosion-resistant alloys and sealing technologies have been developed and incorporated to meet the durability requirements outlined in these safety standards.

However, the standards call for integrating real-time monitoring and predictive analytics, which have been shown to reduce equipment failures in critical facilities by 25%. By following the evolving safety standards, companies maintain the welfare of workers, enhance operational efficiency, and embrace sustainable practices.

How Does the Oil Industry Implement Explosion-Proof Guidelines?

The explosion-proof standards in the oil industry involve conforming to strict regulatory standards by installing and maintaining explosion-proof equipment, especially those purposely designed to avoid any kind of ignition in a hazardous area. Hence, this means installing enclosures, which are explosion-proof, and intrinsically safe systems and electrical components with proper ratings to reduce the likelihood of any risk. Also, it is fortified with regular inspections and maintenance, coupled with safety training for personnel at all levels. It greatly minimizes the chances of accidents, thereby keeping the volatile working environment safe.

Adhering to Safety Guidelines in Hazardous Locations

Safety guidelines must be rigidly observed while working in and around hazardous locations to ensure workers’ and equipment’s safety. Accepted safety standards exist worldwide and are promulgated by organizations such as the National Fire Protection Association (NFPA), the International Electrotechnical Commission (IEC), and the Occupational Safety & Health Administration (OSHA). For example, the NFPA 70 (National Electrical Code or NEC) stipulates the technical requirements of electrical installations in hazardous locations to prevent an ignition source.

According to recent statistics, explosions account for many oil and gas, chemical processing, and mining accidents because of improper handling of flammable substances. Using test-certified equipment like ATEX or IECEx standards certifies that such equipment has met exhaustive test procedures and is fit for use in conditions prone to hazards. Companies employing interim controls such as gas monitoring and sophisticated knockdown controls saw as much as a 40 percent reduction in incidents related to their flammable environments.

Last but not least, it is essential that employees are regularly trained. Evidence illustrates that businesses investing in yearly hazard recognition courses show marked improvement in emergency response time and a 25 percent decrease in safety violations. Coupling such instruction with the latest monitoring technology means these high-risk industries remain compliant and protected.

Ensuring Intrinsically Safe Equipment in Oil Tanks

Since highly explosive substances coexist in oil storage applications, intrinsically safe equipment avoids explosions and assures operational safety. Intrinsically safe devices purposely work with such low energy that they can never ignite an explosive atmosphere of gases or dust. This dramatically reduces the chance of any accident that any faulty electrical system or spark could trigger.

Today, some systems use other hardy technologies like explosion-proof enclosures, barriers considered to be intrinsically safe, or flame arrestors. So, for instance, the use of inherently safe gas detectors for the real-time monitoring of combustible gases gives a nearly irresistible immune factor against a fire possibility in this oil storage and oil transfer process. With the implementation of these systems, fire hazards have reduced by almost 40 percent in facilities studied over five years; this warrants the talk of these technologies.

This reinforces the necessity of equipment inspection and maintenance so that wear or corrosion does not affect the safety mechanisms. In addition, adherence to standards such as IEC 60079 and NFPA 70 ensures that equipment is correctly certified and installed in a safety-compliant manner. Integrating these technologies with effective preventative measures can promote operational efficiency and workplace safety in oil tank environments.

Challenges in Gas and Dust Atmosphere Control

The challenge of controlling gas and dust atmospheres in fields like oil and gas, jewelry, and mining has emerged as a matter of enormous importance. One of the most extraordinary precautions is identifying and eliminating explosion hazards. Combustible dust contributes to around two-thirds of all industrial dust explosions, rendering the presence of any minimal ignition sources a real danger. For example, it is established that particles under 420 μm diameter can readily ignite under generic industrial abrasions, and hence, dust control must be severe.

Another hurdle is monitoring compliance with regulatory requirements because industrial facilities must follow specific standards such as the ATEX and the IECEx, which lay down the protocols for equipment safety and operations, among others. Neglecting can invite huge fines, the closure of operations, and disastrous accidents. In addition, keeping a tab on environmental conditions like humidity, ventilation, and temperature is crucial because these parameters significantly influence the behavior of gases and dust particles in confined spaces.

The integration of state-of-the-art monitoring systems with advanced predictive analytical tools is emerging as another critical aspect. The device can collect real-time data and analyze it to avoid perilous situations before they become risks. For instance, particulate density or gas concentration sensors are critical for early warning. Implementing and maintaining such systems, however, are known to be prohibitively costly and require high-level skill sets.

A proactive approach to these concerns includes carrying out stringent risk assessments, conducting routine equipment inspections, and training personnel at an unprecedented level, not to mention investing heavily in high-tech safety equipment. By giving these priorities, one fulfills compliance and guarantees worker protection while considerably lowering the risks of expensive interruptions.

What Are the Construction Standards for Explosion-Proof Oil Tanks?

Explosion-proof oil tanks are designed and constructed according to stringent safety standards to minimize the risk of fire and explosions. Typically, these standards dictate using high-strength, corrosion-resistant materials such as steel to ensure a durable and structurally sound tank. Tanks are also required to comply with specifications regarding pressure resistance, vent systems, and grounding to prevent the formation of static electricity. API (American Petroleum Institute) and NFPA (National Fire Protection Association) provide detailed construction guidelines covering secondary containment systems and protective coatings. Abiding by these standards ensures safe storage and operation within hazardous environments.

Understanding Classifications and Explosion-Proof Ratings

Classifications and explosion-proof ratings are important safety considerations in flammable gases, vapors, or dust areas. These ratings are defined by internationally known standards such as IECEx, ATEX, or the National Electrical Code in the United States. Equipment for hazardous locations is classified based on the type of dangerous material present, its probability, and the conditions that could cause it to ignite.

The NEC divides hazardous locations into three classes: Class I for flammable gases and vapors, Class II for combustible dusts, and Class III for ignitable fibers. These classes are subdivided into divisions or zones, indicating the frequency of hazardous material presence. For example, Class I Division 1 (or Zone 0/1 according to IEC/ATEX standards) means that flammable materials are present continuously or frequently. In contrast, Division 2 (or Zone 2) refers to abnormal or intermittent conditions.

Explosion-proof equipment is designed to confine an explosion within an enclosure and prevent the ignition of the surrounding atmosphere. The respective authorities test and certify the equipment, ensuring that it meets the standards of UL or CSA. For example, explosion-proof motors and lighting fixtures are designed using reinforced housings and special sealing arrangements to enclose any possible ignition.

Statistics support these ratings. The latest industry reports indicate that human error, improper equipment installation, and insufficient hazard assessment are among the leading causes of industrial incidents involving hazardous materials. Classifying and installing equipment according to explosion-proof standards increases safety and reduces downtime and liability from accidents. Understanding and implementing these systems is fundamental to hazard mitigation in the oil and gas, chemical processing, and manufacturing industries.

The Importance of Electrical Equipment Resistance

The resistance of electrical equipment is a factor that ensures safety, efficiency, and quality of life in industries. The resistance material resists leakage currents, prevents electrical shocks, and prevents potential short circuits that can start fires. Some industry studies have established that electrical failure is among the highest causes of downtime, incurring billions in manufacturing. Choosing and maintaining the right resistance can significantly reduce such risks, reducing failure-related costs by 40%.

High-insulation materials such as silicone, ceramic, or special polymer are welcomed as they offer the highest resistance to extreme voltage and temperature. They have been proven to withstand extreme conditions greater than 200°C while resisting moisture, improving reliability in harsh environments.

Moreover, by using another more rigorous test, such as a dielectric withstand test and insulation resistance test, to uphold safety standards such as the International Electrotechnical Commission (IEC) and National Electrical Code (NEC), the durability of electrical systems is thus improved, and consequently, the maintenance cost is lowered in places like chemical plants and offshore drilling rigs. Maintenance innovations in electrical equipment resistance contribute to industrial excellence and workplace safety and provide a platform toward a more sustainable and robust industrial solution.

Evaluating Manufacturer Specifications and Material Resistance

When evaluating the manufacturer’s specifications and the resistance properties of the materials, essential characteristics such as tensile strength, chemical resistance, thermal stability, and compliance with industry standards need consideration. For example, stainless steel and reinforced polymers are often cited as viable materials for corrosive environments. From an industry perspective, 316-grade stainless steel is considered to have the best chloride-induced corrosion resistance and is thus a preferred material in the marine and chemical processing sectors.

Consideration also has to be given to thermal performance; insulators of high grade, like those made of ceramic or composite material, can withstand more than 900°F, which is accepted as a criterion in high-temperature processes. The material specification shows that dielectric strength is considered relevant for electrical applications, where insulators coated with epoxy resin can hold up under extreme voltages and temperatures.

In addition, a review of vendor certifications confirms that the materials conform to ISO 9001 frameworks. Electrical enclosures rated IP67 and NEMA 4X show substantial and long-term ingress protection by preventing water and dust from entering, which is paramount. Detailed product evaluation criteria encompass procurement processes to ensure correct material selection, mitigate operational risks, and associated maintenance costs.

Are Explosion-Proof Oil Tanks Suitable for All Environments?

That is to say that explosion-proof oil tanks are unsuitable for all environments. Designed to prevent ignition and safely store flammable substances, their efficiency depends on the environmental conditions. Unless specifically rated to meet those conditions, they might not be the best option when dealing with temperature extremes, high corrosive exposure, or special chemical hazards. It is essential to evaluate what environmental requirements exist and whether the tank has been accepted as meeting those requirements in safety practice for any given environment.

Evaluating Hazardous Area Classification

Unsafe area classification is a meticulous procedure that involves locating and classifying areas where flammable gases, vapors, or combustible dusts may present an ignition hazard. Much of this involves the safe design, installation, and operation of equipment in such environments.

Classifying classified hazardous areas based on an international standard, such as IEC 60079 and NFPA 497, includes zones which denote varying degrees of the possibility and duration of the presence of an explosive atmosphere: Zones 0, 1, and 2 for gases, and Zones 20, 21, and 22 for dusts. Their intangibles denote specific zone characteristics: for instance, Zones 0 and 20 mean that explosive atmospheres exist incessantly, whereas Zones 2 and 22 refer to circumstances where explosive atmospheres are unlikely to exist or only do so for short periods.

Recent studies revealed that selecting the right ones for each zone classification is paramount to selecting rated equipment, such as explosion-proof enclosures or intrinsically safe devices. Industry expert data show that about 70% of incidents in hazardous locations could have been avoided if proper assessments and compliance with classification standards had been undertaken. Further, due to the development of digital tools, more advanced hazard zone modeling and mapping can now be conducted, enhancing present risk management approaches.

Proper evaluation considers these other factors, such as ventilation, temperature classification, and gas group categorization, to protect all ignition sources. If these factors are systematically evaluated, industrial sites can drastically minimize hazards and improve the working environment in hazardous areas.

Adaptation to Combustible Atmosphere Conditions

Adapting to combustible atmosphere conditions involves applying ever-changing technologies, code adherence, and best operational practices. Data from recent years shows that the industries using predictive maintenance technology, including Internet-of-Things-enabled sensor-based systems and real-time monitoring systems, have successfully reduced hazardous situations by as much as 30%. These prediction technologies assist in detecting anomalies such as minute gas leaks or pressure changes, which are crucial in mitigating the potential ignition.

Moreover, classification of hazardous zones, following international standards such as IEC and NEC, provides a direct guideline for using equipment in zones with the possibility of explosion atmospheres. Along with that, there has been an increase in industries adopting explosion-proof enclosures and intrinsic safety techniques to reduce hazard exposure. For example, the market demand for intrinsically safe equipment meant to be used in safely volatile environments is estimated to grow at a rate of 6% between 2022 and 2027, according to reports from the industry.

Further, the design and installation of ventilation systems greatly diminish the concentration of flammable gases; CFD modeling is increasingly applied to ensure that the airflow design will achieve even gas dispersion and minimize the existence of high-risk zones. These and comprehensive worker training on hazard recognition and emergency responses constitute the basic foundation of adaptation to combustible atmosphere conditions. Equipped with all these advanced strategies and sophisticated tools, the industry can offer safer and more efficient working environments that ultimately protect people and assets against the hazards present in combustible atmospheres.

Understanding National Electrical Code Compliance

The National Electrical Code (NEC) is an essential standard for electrical safety in domestic, commercial, and industrial establishments. It provides requirements for properly designing, installing, and inspecting an electrical system that could threaten life and property due to shock, fire hazards, or system failure. Adherence to these regulations is necessary for the safety and integrity of electrical installations.

In the areas where the NEC is adopted, many regulations point out some of the proper considerations for classifying hazardous locations, mainly about combustible atmospheres. Class I locations are those where flammable gases or vapors are or may be present in quantities sufficient to produce explosive or ignitable mixtures, under normal atmospheric conditions. Class II locations are those where combustible dust, under certain conditions, may or could be present, and Class III locations are those where ignitable fibers or flyings are present but are not likely to be in quantities sufficient to produce ignitable mixtures with air. From a strict safety view, anything electrical must be designed not to present an ignition source in these areas. Electric equipment in these areas is designed with special sealing requirements and explosion-proof designs.

Another significant advance in NEC history is the move towards technological remedies for improving safety. GFCIs, AFCIs, and surge protection systems are all key parts of many installations nowadays. GFCIs, for example, are installed in areas where water and electricity could meet, such as bathrooms, kitchens, and even outdoors, thus creating the risk of shock. AFCIs work with these to stop an electrical fire from occurring due to arc faults that can happen in other kitchen or living areas not covered by GFCI requirements.

Industry sources emphasize reducing electrical hazards in regions where NEC compliance is vigorously enforced. Data from a study by the Electrical Safety Foundation International (ESFI) showed that implementing NEC-compliant measures in the last ten years has brought about nearly a 20% decline in electrical fires. Furthermore, frequent inspection of newer or older electrical systems is highly recommended to ensure non-compliance is rectified and brought up to current code.

Following NEC standards guarantees quality safety standards and that industries and homeowners comply with the law and attain conditions of safe, reliable, and efficient electrical systems. Since these standards are periodically updated, knowledge of such amendments and implementing recommended practices will help develop a safer environment for mankind and infrastructure.

How to Ensure the Reliability of Explosion-Proof Materials?

To ensure reliability, the explosion-proof materials should always be procured from certified manufacturers conforming to industrial standards, including NEC, IECEx, or ATEX. Routine maintenance, inspection, and testing should be performed on the materials to certify their integrity and performance. Installation should be carried out by competent personnel, and strictly following operational guidelines will significantly lower the chances of any hazards and ensure long-term reliability in the respective hazardous environment.

Periodic Inspection and Maintenance Guidelines

Stringent periodic inspection and maintenance procedures must be followed for equipment safety, reliability, and efficiency in hazardous environments. According to industry best practices, the inspection intervals must correspond with the degree of use and environmental conditions and, where applicable, should conform to the manufacturer-recommended interval. For electrical equipment, it is deemed proper for inspections to include visual examination on an annual basis and more thorough examination in a period ranging from three to five years, depending on operating conditions.

Maintenance factors should include determining equipment wear and tear, testing for proper grounding, and maintaining data on the integrity of the explosion-proof enclosure. The data suggest that following these guidelines can reduce the chance of equipment failure in hazardous locations by up to 60%.

Some possible methods of detecting hidden faults, such as hotspots, leaks, or imminent component failures, can be carried out without halting operations. Mechanical parts require lubrication, while fasteners require torque checks. Studies suggest that organizations practicing predictive maintenance using condition monitoring have reported an increase of 20-30% in operational efficiency.

Complete documentation of maintenance activities, inspections, and corrective action must be kept to comply with safety regulations and for audit purposes. Adherence to these guidelines will greatly enhance equipment life and provide a safer working environment in hazardous areas.

Role of Preventive Measures in Maintaining Safety

Proper and timely preventive action is one of the many ways to keep the workplace safe. I inspect equipment and machines regularly while following a schedule for their maintenance. Furthermore, I constantly endeavor to identify hazards before they turn into issues. These practices help prevent accidents or mishaps, improving equipment reliability and operational efficiency.

Ensuring Aluminum and Fiber Resistance to Sparks

While aluminum is generally recognized as a light and durable metal that does not spark, it is unsuitable for any environment where spark generation might pose fire hazards. Some aluminum alloys are supplemented with elements such as magnesium or silicon that increase their strength and temperature tolerance to make them resistant to sparks. Aluminum alloys like 6061-T6 have been found to perform well under high-stress conditions while still retaining their non-sparking property.

Fiber types, alternatively, see extensive industrial applications because of their nondestructive and heat-resistant properties. Advanced fibers such as aramid and carbon fiber composites show excellent spark and high-temperature resistance; thus, they are well-suited for protective gear or insulation. Certain aramid fibers, for example, will easily resist temperatures over 500°F (260°C) without any degradation.

Material safety-testing data also confirm that aluminum combined with a protective layer of fibers increases safety in spark-prone conditions, double-sheet durability, and resistance. To reduce fire risk, such materials remain critical in mining, chemicals, and aerospace. If used in the right combinations and regularly checked for replacement cycle incidents, such materials can provide long-term reliability and safety in the workplace.

Reference Sources

1. Application of Inherent Safety Explosion-Proof Technology in Oil Storage & Transportation Devices

2. Explosion-Proof Equipment in Hazardous Areas

3. Mathematical Model of Explosion-Proof Performance of Pressure Container Packaging

Frequently Asked Questions (FAQs)

Q: What are explosion-proof materials, and how are they used in oil tanks?

A: Explosion-proof materials are designed to contain and prevent explosions, withstanding high temperatures and pressures. They play a crucial role in ensuring safety by preventing the ignition of flammable substances. Using explosion-proof materials in oil tanks is essential to protect the safety of personnel and equipment.

Q: How reliable are explosion-proof oil tanks in hazardous environments?

A: Explosion-proof oil tanks are highly reliable in hazardous environments when constructed with the appropriate materials and meet the necessary safety standards. They are designed to contain potential explosions and prevent the ignition of flammable gases present in the air in quantities sufficient to cause an explosion.

Q: What classes of explosion-proof materials are most effective?

A: The class of explosion-proof materials most effective for a specific application depends on the environment and the types of hazardous substances present. Materials that can withstand high temperatures and are designed to contain explosions are generally considered adequate across various industries, including oil and gas.

Q: Why is the choice of explosion-proof materials necessary for oil tanks?

A: The choice of explosion-proof materials is crucial for oil tanks because it ensures they can safely contain flammable substances and prevent potential explosions. This choice plays a vital role in protecting the safety of personnel and minimizing risks to the environment and equipment.

Q: Are there specific regulations for using explosion-proof materials in Canada?

A: Canada has specific regulations and standards for using explosion-proof materials, especially in industries dealing with hazardous environments. These regulations ensure that materials and equipment meet safety requirements to protect personnel and property from explosion risks.

Q: How do explosion-proof oil tanks protect electrical equipment in hazardous areas?

A: Explosion-proof oil tanks protect electrical equipment in hazardous areas by preventing the ignition of flammable vapors or gases. The tanks are designed to contain explosions, which helps ensure that nearby electrical equipment does not become an ignition source.

Q: Can explosion-proof materials withstand the high temperatures in oil tanks?

A: Yes, explosion-proof materials are specifically designed to withstand high temperatures. This capability is essential for maintaining the integrity of oil tanks and ensuring the safety of operations in environments where high temperatures and flammable substances are present.

Q: How do explosion-proof materials contribute to the overall safety of oil tank operations?

A: Explosion-proof materials contribute to the overall safety of oil tank operations by preventing explosions, which can cause significant harm to personnel and equipment. Their ability to contain explosions and withstand harsh conditions ensures a safer working environment.

Q: What role does proper maintenance play in the effectiveness of explosion-proof materials in oil tanks?

A: Proper maintenance is vital for the effectiveness of explosion-proof materials in oil tanks. Regular inspections and upkeep ensure that the materials continue to perform as intended, reducing the risk of explosions and ensuring the safety of personnel and equipment.

Q: Are explosion-proof oil tanks necessary in all oil storage facilities?

A: Explosion-proof oil tanks are necessary in oil storage facilities where there is a risk of flammable gases or vapors being present in the air in quantities sufficient to cause an explosion. These tanks are crucial for maintaining safety standards in such environments.