The fuel dispenser industry has undergone rapid evolution in recent years, driven by technological advancements, shifting consumer preferences, and global pressures, resulting in changes in energy consumption. Looking ahead to 2025 and beyond, manufacturers are at the forefront of innovation, developing cutting-edge solutions that promote mobility while considering their environmental impact and operational efficiency. This piece will highlight key trends in the industry, including the integration of innovative technology, the emergence of alternative fuels, and the growing demand for dispensing systems that are adaptable, reliable, and environmentally friendly. Join us on a journey of discovery as we explore how these manufacturers will meet tomorrow’s needs while reinventing the refueling experience for a world-transforming experience.

Understanding Fuel Dispensing Equipment

The machinery used for dispensing fuel transfers fuel from storage tanks to various vehicles and equipment. These setups are generally composed of a pump, a hose, a nozzle, and an accurate metering system that work together to transport the fuel safely to its destination. In modern fuel dispensers, measurements are taken digitally and may have the option to interface with payment systems and management monitors, increasing convenience and efficiency. Their consideration for reliability and safety ensures consistent performance that meets regulatory standards.

Types of Fuel Dispensers

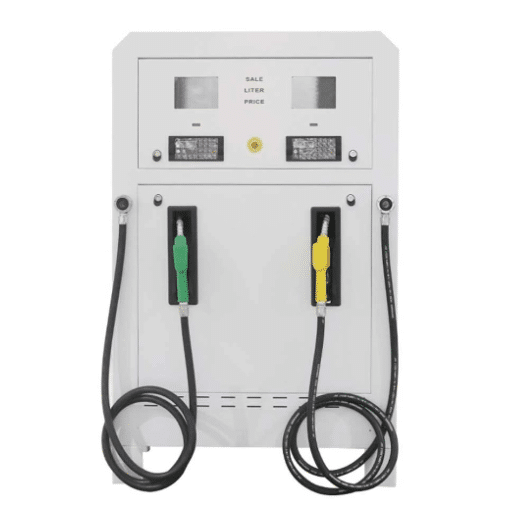

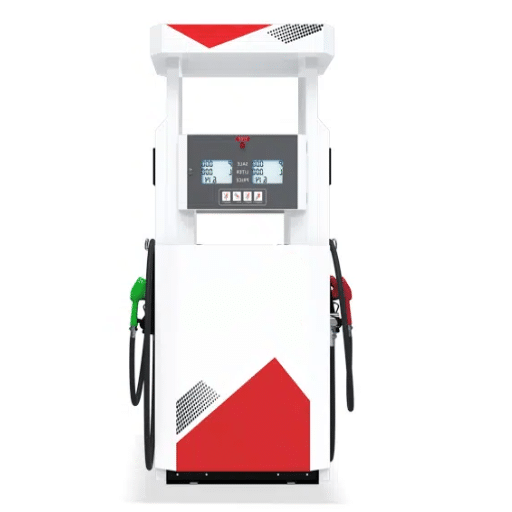

Fuel dispensers are classified based on their use, function, and type of fuel. Below, you will find some essential types of fuel dispensers with their key features.

Suction Fuel Dispenser: Suction fuel dispensers are typically installed in small to medium-sized fuel stations. These units directly draw fuel from the storage tank via vacuum pumps. They are generally cheaper and simpler in construction, thus making them very suitable for low-throughput installations.

Submersible Fuel Dispensers: Submersible pump fuel dispensers operate on the principle of installing a submersible pump inside the storage tank. These are suitable for high-volume stations because they enable a faster fuel flow rate, resulting in quicker fuel refilling for customers. Submersible systems require a great deal of care regarding safety measures due to the interface between the pump and the fuel.

High-Flow Dispensers: As the name suggests, high-flow dispensers deliver fluids at a high flow rate, significantly higher than those of standard dispensers, which are designed specifically to fuel heavy vehicles and industrial equipment. High-flow systems represent one of the many facets of an infrastructure that needs to serve truck stops, airports, or marine fuel stations in the quick and timely refueling of vehicles. For example, the flow rate of these pumps can exceed 130 L/min, rendering refueling extremely efficient compared to a standard dispenser.

Multi-Product Fuel Dispensers (MPD): These dispensers dispense two or more fuel types, such as gasoline, diesel, ethanol blends, or biodiesel, from a single unit. They are pretty standard in contemporary retail fuel stations, as they save floor space and offer customers flexible options for the types of fuel they wish to purchase. This system is usually equipped with advanced metering and pricing methods for different products.

Alternative Fuel Dispensers: As the world’s attention shifts toward sustainability, alternative fuel dispensers are gaining increasing prominence, particularly those dispensing CNG, LPG, and hydrogen. More specifically, hydrogen-based dispensers require a highly specialized design to safely manage the gas at very high pressures, generally exceeding 700 bar in automotive applications.

Mobile Fuel Dispensers: Mobile fuel dispensers are specially designed for transportation fueling, providing portable on-the-go refueling solutions. Often, those serving construction, agriculture, and far-flung locations offer freedom through self-contained systems with pumps, storage tanks, and power sources that should also allow for storing or delivering fuel.

Each type of dispenser is suited to meet very different needs and operational requirements that evolve with technological advancements and changing fuel requirements. Modern configurations feature real-time monitoring systems, secure cashless payment methods, and enhanced security measures that comply with industrial and environmental standards.

Key Components of Fuel Dispensing Equipment

Modern fuel dispensing equipment is equipped with a wide range of advanced components to achieve efficiency, safety, and convenience. A few critical components and their functionalities are:

Metering Unit: Considered as the belly of the dispenser, the metering unit measures the legitimate volume of fuel delivered. Advanced metering systems use positive displacement or turbine technology for utmost accuracy, sometimes allowing an error of ±0.2%. Many of the meters currently available have an electronic calibration system attached to ensure accuracy over time.

Fuel Pumps: The pumps are designed mainly to transfer fuel from the storage tanks to the nozzle. The use of submersible and suction pumps is quite common, with submersible ones offering a higher flow rate and greater energy efficiency. These pumps will be controlled by pressure control mechanisms to maintain a constant flow delivery, even at peak demand.

Nozzle: Dispensing nozzles enable the safe and smooth flow of fuel into the vehicle’s tank. Modern nozzles are made with an automatic shutoff system to prevent overfilling, splash-back, and spillage. Advanced nozzles can also be equipped with vapor recovery systems to cut down emissions and comply with environmental regulations.

Hoses and Couplings: The reinforced hose provides the necessary flexibility and durability to transport fuel from the pump to the nozzle. Couplings and fittings secure areas in locations to prevent leaks and are usually tested to meet internationally accepted safety standards, such as UL or ISO.

Electronic Control System: A centralized electronic control system is used to monitor and control all activities on the dispenser. With fuel flow data being captured in real time, systems can be diagnosed and maintained remotely. Increasingly, with cloud-based connectivity, systems are being used for fleet management and inventory tracking.

Payment Systems: Secure payment systems embedded in the advanced fuel dispensers offer multiple payment options, including credit cards, RFID, and mobile payment apps, allowing users to pay without using cash. The system’s feature is encrypted communication and meets the PCI DSS (Payment Card Industry Data Security Standards) for securing financial transactions.

Filters and Strainers: Filters and strainers filter out impurities such as dust, dirt, or water from the fuel to maintain its quality and protect internal components. Filters with good performance will significantly reduce maintenance costs and also increase the equipment’s lifespan.

Safety Mechanisms: Integrated safety mechanisms, such as emergency shut-off valves and fire suppression systems, help prevent hazards. Dispensers are often made using materials of high commendation for corrosion resistance and static electricity, ensuring they meet safety protocols.

These components work together seamlessly to fuel up while efficiently and safely adhering to current standards of environmental sustainability and operational excellence.

Importance of Quality in Fuel Dispensing Systems

Quality in fuel dispensing systems serves as a guarantee of operational efficiency, regardless of safety, environmental considerations, and customer satisfaction. Leakage of fuel ultimately causes ecological damage and incurs significant costs for cleanup, making systems with the highest standards worthy investments. Industrial reports estimate the annual losses of fuel due to leaks in the millions.

Modernity, equipped with a precision metering system and advanced filtration technologies, dispenses fuel accurately into the dispenser, ensuring contaminant-free fuel. For example, various studies have shown that returning filtration purposes with better systems highly decreases the particulate levels present in the fuel, thereby protecting engines and equipment from deterioration. Precision metering ensures that customers pay only for the quantity of fuel they receive, thus building customer trust and commercialization.

In addition, new materials such as corrosion-resistant alloys and anti-static materials have been developed to prolong the life of dispensing equipment, reducing maintenance costs and down times, and thus becoming cost-effective for businesses over time. These high-quality components also help in complying with the increasingly stringent environmental and safety regulations worldwide.

By prioritizing quality, fuel retailers and industrial operators can confer advantages in performance, cost, and user experience, ultimately securing a safer and more sustainable footing for the future.

The Role of Manufacturers in the Fuel Industry

The fuel category needs manufacturers, designers, and assemblers of equipment and components for storage, transportation, and dispensing. They must ensure these products comply with stringent safety and quality standards to carry out their reliable and environmentally friendly operations. With innovations, manufacturers promote and install new technologies that increase efficiency while reducing emissions and satisfying newer regulations. Therefore, manufacturers are enhancing the movement towards sustainability and streamlining operational performance for both fuel retailers and industrial operators.

Leading Fuel Dispenser Manufacturers Worldwide

Producing fuel dispensers created a global role in sustaining fuel supply lines. Some manufacturers stand out for offering innovative solutions that consider both durability and environmental friendliness. Here are some of the foremost players in the market:

Gilbarco Veeder-Root is globally recognized as a pioneer in the field of fuel dispensing technology. While offering the entire portfolio of fuel dispensers, point-of-sale systems, and payment solutions, it envisions systems that help site operators increase operational efficiency as well as consumers enjoy their purchases. The products henceforth serve the region with high-speed refueling, environmental monitoring systems, and manual control systems, assisting on-air toward sustainable fuel dispensing.

Wayne Fueling Systems: The company offers an excellent setup of fuel dispensers that demonstrate technological advancements, recognized for their reliability and performance. Promoting integrated systems, Wayne Fueling Systems also endorses easy-to-use interfaces and payment modules. The company is a leader in green technology, reducing its carbon footprint and promoting solutions that enable the growth of alternative fuels to support sustainable operations.

Tatsuno Corporation is a well-established Japanese company that produces high-quality fueling equipment, including dispensers and flow meters. Quality, precision, and durability with a worldwide view define the products of Tatsuno. The company also provides alternatives to traditional fuels, such as compressed natural gas (CNG) and hydrogen, to meet the evolving sustainability needs of the industry.

Dover Fueling Solutions: Dover Fueling Solutions (DFS) provides advanced fuel dispensing solutions, with a focus on automation and digital capabilities. The implementation of IoT and cloud-based technology enables real-time data monitoring and analytics, streamlining fuel station management. Safety and international compliance, being at its core, ensures efficiency and reliability within the product spectrum of DFS.

Scheidt & Bachmann: Scheidt & Bachmann stands at the forefront in manufacturing fuel dispenser systems and integrated payment solutions. With its innovative approach, it considers the customer with systems that guarantee swift and secure transactions at the fuel station. Furthermore, Scheidt & Bachmann’s dispensers accept a variety of fuels, including both conventional and renewable ones, thus catering to today’s energy trends.

These companies, along with other manufacturers, are helping to sustain the growing demand for efficient, safe, and environmentally friendly fueling solutions, ensuring the success of fuel retailers and industrial operators in the transition to a new energy landscape.

Manufacturing Processes for Fuel Dispensers

Manufacturing fuel dispensers is a complex manufacturing process that involves engineering, precision machining, and rigorous quality control to ensure reliability and safety. In the design and development process, manufacturers create detailed schematics on a computer. These designs are created by global safety and environmental standards, as well as the specific requirements and expectations of fuel retailers.

Finalized designs are then built, with pump systems, flow meters, and dispensing nozzles constructed from materials intended to ensure durability. CNC machines are often used to manufacture parts that require high precision, while 3D printing technology is increasingly being applied for creating prototypes and smaller parts for testing.

Dispenser components are joined during assembly to form a single, integrated unit, ensuring correct alignment and optimal operation. The electronics and software systems are installed to provide capabilities such as digital displays, payment systems, and fuel monitoring technology for dispensers of alternative fuels, including CNG, LNG, or hydrogen. Special high-pressure components are used to meet the varying requirements.

After all these methods, the final inspection is done, and emergency tests are performed. This includes performance tests, leak detection, and calibrations with federal requirements; for example, the flow meter is verified for calibration using high-precision equipment. Industry sources indicate that in more than 90% of cases, flow meter calibration results in an error of less than 0.2%, thereby ensuring that fuel is delivered reliably and consistently to consumers.

As eco-friendly processes are being adopted by many manufacturers, such as the use of recycled materials and energy-efficient production methods, some organizations have reported reductions in manufacturing emissions of over 15% after restructuring their supply chains and installing renewable energy sources on their factory sites. Lean manufacturing is further considered to reduce waste and enhance efficiency within the production facility.

Fuel dispenser manufacturers continually evolve their manufacturing techniques and technology to meet the growing demand for performance, precision, and sustainability from consumers and the industry. These advances continue to support the development of fuel systems while promoting environmental goals.

Evaluating Manufacturer Support and Services

In checking manufacturer support and services, certain critical factors can be directly linked to the customer experience and operational efficiency. The availability of warranty programs for a full duration is one such factor. This provision protects customers from unexpected breakdowns or instances of confirmed defects. Generally, manufacturers who are willing to offer an extended warranty period likely have confidence in their product quality and a considerable concern for customer satisfaction.

Another important aspect is the availability of technical support and maintenance services. The top-end manufacturers offer customer support through hotlines that are operational 24 hours a day, seven days a week, online troubleshooting guides, and visits by service engineers to their clients’ premises. According to industry data, 83% of customers prefer manufacturers that have readily available support resources and guarantee quicker response times, potentially reducing downtime.

Another aspect is the availability of training programs to enhance the product’s usefulness for equipment operation and maintenance. Several training modules are offered free of charge or on a subscription basis to help customers maximize the value of their systems. An example may be nifty platforms for training and interactive live sessions in real-time.

Furthermore, manufacturers with a vast global network of service centers and spare parts availability demonstrate their ability to service various markets efficiently. Localized support cuts at least 50% of repair times, allowing smoother operations in all ensuing high-demand applications.

When considered alongside these criteria, the company can make a good assessment of the manufacturer that will fit their operation and establishment in service.

Innovations in Fuel Dispensing Technology

Modern dispensing technologies have brought significant improvements in efficiency, accuracy, and compliance with environmental regulations. One of the advancements might be considered on a payment basis: the introduction of an online payment system for faster transactions and the elimination of human error. Precise measurements using new flow meter techniques ensure that less fuel is wasted, eliminating any disputes. Another environmental aspect that led to the development of the so-called vapor recovery systems is their control of emissions during fueling. These technologies must ensure a good user experience, operational efficiency, and environmental compliance.

Advancements in Pump and Nozzle Design

Sales and payment systems have undergone significant changes to make the customer’s experience more efficient and safe. The design has undergone several ergonomic enhancements to reduce operator fatigue during prolonged use. Automatic shut-off systems have been fine-tuned to minimize the possibility of fuel spilling, making the station slightly safer to work in.

High-flow nozzles have become popular in the commercial and industrial sectors, reducing refueling time for larger trucks. The nozzles are ensured for measurement accuracy even at high flow rates. The recent advances in material technology have made lighter composites available for nozzles and hoses. This has increased durability and resistance to wear, while also making them easy to carry.

The introduction of innovative technology has led to the implementation of state-of-the-art monitoring systems within pumps and nozzles. These measure real-time fuel flow rates, provide real-time performance feedback, and offer integration options with mobile apps to enhance the user interface. For instance, pumps are equipped with digital displays that offer detailed fuel data, enabling customers to monitor costs and consumption with precision.

According to data derived from case studies of advanced industrial applications, improved nozzle designs have led to measurable reductions in fuel loss and emission levels. Nozzles with advanced sealing mechanisms block the escape of fuel vapors, in line with the global environmental standards, including those specified by the EPA and EU Stage V. In a nutshell, these innovations provide much-needed impetus for reducing the ecological footprint of fueling operations, all while ensuring they perform at peak efficiency.

Integration of Smart Technology in Fuel Dispensers

Innovative and modern technology in fuel dispensers is set to pivot the fueling industry with enhanced operational efficiency, security, and user experience. Nowadays, fuel dispensers incorporate advanced Internet of Things (IoT) sensors and real-time data analytics, enabling the assessment of fuel level monitoring, vehicle information tracking, and resource management. For instance, a connected system can alert and inform operators about the maintenance needs or failures of specific equipment, thereby minimizing downtime and operational costs.

Since consumers demand convenience and hygiene, contactless payment systems have become the norm in fuel dispensers. RFID, NFC, and mobile payments can streamline pump-side transactions, reducing the time spent waiting to download at fuel stations. Research shows an increase in consumer satisfaction, and 65% of consumers choose to go to filling stations equipped with these newer features.

In addition to being environmentally sound, these systems also enhance environmental compliance. Equipped with precise metering systems and leak detection sensors, bright dispensers ensure accurate fuel delivery and help prevent environmental hazards. Industry information suggests that fuel loss at dispensing operations might have been reduced by up to 15% with systems installed with advanced monitoring and sensor technologies.

Innovative technologies are, thus, changing the overall standard of infrastructure and operations of the fuel dispenser, with the ultimate goal of endorsing a top-line, sustainable, and customer-oriented industry.

Future Trends in Fuel Dispensing Equipment

Fuel dispensing equipment utilizes new and emerging technologies to enhance efficiency, sustainability, and customer convenience. Alternative fuel sources such as electric vehicle charging points and hydrogen filling stations are on the rise. With the global EV market expected to register a CAGR of 23.1% from 2023 to 2030, the present-day manifestation of evolving consumer demand is the integration of fast EV charging solutions within traditional fuel stations and vice versa.

Operation optimization using IoT and AI is another relevant trend. IoT-connected fuel dispensers provide real-time data on fuel levels, equipment status, and potential operating mode requirements for maintenance, resulting in reduced downtime and optimized efficiency. For example, utilizing AI-powered predictive maintenance systems would enable the analysis of operational patterns that predict malfunctions, thereby reducing repair costs by as much as 30%.

Also relevant here is sustainability, particularly in forms that aim to reduce carbon emissions and promote eco-friendly working conditions significantly. The development of biofuel-compatible dispensers and vapor recovery systems shows that the industry is moving towards greener solutions. As biofuels are expected to experience an exponential rise in the global market, reaching around $245.6 billion by 2030, dispensing technologies must be updated to dispense biofuels safely and efficiently.

Finally, the rise of contactless and smartphone payments is set to transform vendor experiences, thereby fueling the need for dispensers to be equipped with digital frontends that integrate with mobile apps, allowing users to pay and access loyalty programs with ease. When doing this, they become very convenient, engage customers, and strengthen the ongoing transition to digital in retail and services.

The fuel dispensing industry has thus entered a dynamic phase today, where technological innovation and sustainability align to address an energy landscape that changes rapidly yet demands efficiency and environmental consciousness.

Choosing the Right Fuel Dispenser Manufacturer

When selecting the proper fuel dispenser manufacturer, choose one with a proven track record of reliability, quality, and innovation. They should maintain industry standards and provide good customer support, including services for maintenance and warranty coverage. They should also stand for sustainability and energy efficiency, as these are basic modern operational and environmental considerations. Ensure they offer solutions that are customizable to your specific business needs, making them both functional and cost-effective within your budget.

Factors to Consider When Selecting a Supplier

Several key factors must be considered when establishing a strategic and successful supplier relationship that benefits both parties.

Quality of Products and Services: The supplier’s products or services must necessarily meet or exceed the standards applied by your business. Anything less in quality will prompt inefficient operation and customer dissatisfaction. To illustrate, over 60% of product buyers rank quality as their top consideration when selecting vendors.

Pricing and Cost Structure: Price is a primary consideration in selecting suppliers, but it should not come at the expense of either reliability or excellence. Calculate the total cost of ownership (TCO), which should include not only the product cost but also logistics, maintenance, fees, and other relevant expenses. A little bit of compromise will aid in long-term profitability and sustainability.

Reliability and Delivery Performance: Ensure uninterrupted business operations with timely and reliable deliveries. Better still, examine supplier records of on-time performance and associate with suppliers that can meet cast-iron deadlines while maintaining product standards. Ensuring deliveries are reliable is another effective way to move forward, especially for just-in-time (JIT) industry models.

Technological Capability and Innovation: With new technology, suppliers can better serve their customers with more efficient, scalable solutions. For example, suppliers with automated inventory systems and state-of-the-art manufacturing operations cut lead times and improve accuracy.

Sustainability and Ethical Practices: Environmental responsibility and ethical sourcing are among the key considerations in today’s business landscape. More than 70 percent of consumers value sustainability in the companies they support. Choosing suppliers with a conscious environmental policy and an ethical supply base would serve to run your operation in parallel with such ideals, while also enhancing your reputation.

Customer Support and After-Sales Service: A good customer relationship resolves problems as soon as they arise. Try to find those suppliers that offer after-sales service, including technical support, easy return policies, and warranties that ensure smooth operation.

Scalability and Customization Options: Procurement of any supply is demanding; nonetheless, this requirement will continue to evolve and change over time. Suppliers should, therefore, be able to offer scalable solutions that are flexible and can be customized to meet your particular requirements. This adaptation will keep you prepared for any changes that will affect your market or operation.

Financial Stability and Credibility: By partnering with financially sound suppliers, an organization minimizes risk. When analyzing the financial health of your suppliers, consider factors such as credit ratings, annual reports, and market reputation (brand name recognition) to ensure they can consistently meet your demands.

When weighing all these factors, companies can select suppliers who not only deliver on cost and quality but also innovation, reliability, and shared values, ultimately benefiting from their long-term partnership.

Case Studies: Successful Partnerships with Dispenser Manufacturers

Case Study 1: The Quest for Efficiency

A mid-range beverage company partnered with the dispenser manufacturer known for its avant-garde technology. Upon setting up their automated dispensing systems, the beverage company achieved fast-line production, resulting in a 25% increase in production within six months. The new system reduced manual errors, enhanced precision in liquid measurements, and reduced waste by almost 18%. The partnership created further operational efficiencies and cost reductions, enabling a renewed focus on product innovation.

Case Study 2: Sustainable Collaboration

A global fast-food chain wed with a dispenser manufacturer specializing in environmentally friendly solutions. The focus of the partnership was to develop dispensers that utilized recyclable materials and consumed minimal energy during operation. Over three years, the chain was able to reduce its annual carbon footprint by 15% and save millions of gallons of water, thanks to the implementation of optimized dispensing systems. The environmental improvements were acknowledged in industry publications, which helped build the brand’s reputation among environmentally conscious customers.

Case Study 3: Tailored Solutions for Market Expansion

The pharmaceutical company sought a dispenser manufacturer that could tailor solutions to their diversified product lines. The selected manufacturer designed a novel dispensing system suitable for both liquid medicines and viscous substances. This versatility enabled product launches in various markets, fueling a 40% revenue surge within a year and thereby increasing market penetration. The partnership highlighted the necessity of marrying technical competence with the peculiar requirements of a growing industry.

These varying case studies demonstrate the significant positive impact of collaborating strategically with dispenser manufacturers. From improvements in sustainability to gains in operations and market innovation, businesses can achieve remarkable outcomes when they nurture their partnerships towards a shared set of goals and values.

Importance of Specialization in LPG and Diesel Solutions

LPG and diesel solutions constitute a critical area for specialization, given the distinct requirements of modern industries in terms of energy efficiency, environmental norms, and operational efficiencies. After LPG enjoys a reputation for being a clean-burning fuel compared to other fossil fuels, beneath its fumes lie lower emissions of potentially harmful particulates and carbon dioxide. Hence, LPG has been singled out as a preferred energy source in sustainability-conscious environments, including manufacturing, agriculture, and commercial transportation.

Diesel fuels heavy machinery, long-haul transportation, and industries with high energy intensity. The specialization in advanced diesel technology led to the arrival of ultra-low sulfur diesel (ULSD) and biodiesel blends. According to the latest data, sulfur emissions have decreased by 90%, thereby ensuring improved air quality. Advanced diesel engine technology is now capable of meeting the stringent worldwide emission requirements under Euro 6, providing higher fuel efficiency while reducing environmental emissions.

Specialized solutions enable firms to utilize customized equipment and maintenance services tailored to their specific energy requirements. For example, dual-fuel installations that combine diesel and LPG attract considerable attention because they offer a guarantee of fuel savings without compromising performance. With fluctuating fuel prices and growing global movements toward green energy, expertise in LPG and diesel solutions would potentially give companies an edge in optimizing their fuel usage and meeting regulatory compliance with ease.

Concentrating on the innovation and application of such technology would enable an organization to remain competitive, keep operating costs low, and strive toward sustainability goals on a global scale.

The Global Market for Fuel Dispenser Manufacturers

Due to the ever-increasing demand for fuel, advances in fueling technology, and the rising adoption of alternative fuels such as LPG and CNG, the global fuel dispenser manufacturers market is experiencing growth. Key regions driving market growth are North America, Europe, and the Asia-Pacific. There is a prominent emphasis on environmentally friendly and energy-efficient dispensing systems. Manufacturers are primarily focused on innovating to comply with environmental regulations and enhance operational efficiency, positioning themselves for future solutions that address the diverse needs of the energy sector.

The Impact of Chinese Manufacturers on the Market

Chinese manufacturers have emerged as dominant players in the global arena, leveraging low prices, high production volumes, and technological advancements to operate at a rapid pace. Supported by the Chinese government in innovation and industrial growth, China has become a manufacturing hub for energy, automotive, and electronics. Industry data indicate that Chinese companies hold a significant share of the global exports in these industries, with machinery and equipment being among the major contributors.

One of the impacts thrust by these manufacturers is their cost competitiveness. Chinese companies, by ensuring their supply chains are well-optimized and working to achieve economies of scale, have succeeded in offering high-quality products at relatively lower costs, forcing intense competition worldwide. On the other hand, the integration of innovative technologies into manufacturing processes enables Chinese companies to achieve greater efficiency and enhanced precision in production. The adoption of automated and AI technologies has thus leveled the playing field for Chinese manufacturers worldwide, making them top innovators in the global industrial setting.

Meanwhile, the rise of green technologies in China’s manufacturing sector demonstrates the country’s dedication to sustainability. With investments being made into renewable energy solutions, such as solar panels and electric vehicle components, Chinese manufacturing firms are at the forefront of clean energy globally. Data shows that China produces more than 70% of the world’s solar panels, emphasizing this country’s leadership in green manufacturing.

In general, the far-reaching influence of Chinese manufacturers is shaping the trends of the world market. Being able to adjust quickly to changing demands, these manufacturers remain a force in shaping the contours of global manufacturing, helped by aggressive government policies and an innovation orientation.

Market Predictions and Opportunities for 2025

Prospective changes in global manufacturing by 2025 are being driven by technological advancements, the sustainability agenda, and shifting geopolitical factors. Increasing automation and the use of artificial intelligence will be among the key trends driving improvements in efficiency and reducing production costs. Meanwhile, industries should be increasingly guided towards sustainable practices, and topics such as renewable energy and recyclable materials will take precedence in addressing environmental concerns.

For Chinese manufacturers, opportunities lie in continuing to drive innovation in clean energy technologies, ranging from solar panels to components for electric vehicles. Furthermore, internal supply-chain restructuring in a near-shoring manner is likely to incentivize companies to achieve geographical diversification in their operations, thereby fostering avenues for strategic partnerships and collaboration between Chinese and non-Chinese players. Moreover, innovations in Industry 4.0 technologies must mature in parallel to provide a brand-new toolkit for manufacturers to optimize production and engage in newly created markets.

With evolving consumer demands, manufacturers will face other opportunities from data-driven strategies, concerning personalized products and digital experiences. Generally speaking, the cardinal will need to adapt to these upcoming trends to remain competitive in the global manufacturing landscape by 2025.

Challenges Facing Fuel Dispenser Manufacturers Today

The biggest challenge facing fuel dispenser manufacturers today is the adaptation to alternative fuel sources such as EVs and hydrogen. This transformation demands innovation in the fuel infrastructure and diversification of product offerings. Environmental regulations are further imposing greater sustainability and energy efficiency requirements on our technology and solutions. At the same time, increasing raw material prices, supply chain disruptions, and heightened competition necessitate the adoption of intelligent production methods and investment in R&D to remain competitive.

Reference Sources

Frequently Asked Questions (FAQs)

What are the key features of fuel dispensing equipment?

Fuel dispensing equipment is designed to provide fuel effectively and safely. Key features include advanced technology for accurate measurement, durable fuel nozzles for various fuel types, and self-service capabilities that enhance user convenience. Many manufacturers incorporate management systems to monitor fuel distribution and ensure compliance with industry standards.

How do I choose a reliable fuel dispenser manufacturer?

Choosing a reliable fuel dispenser manufacturer involves researching their reputation, product quality, and after-sales support. Manufacturers based in Wenzhou, for instance, are renowned for their robust production capabilities, which include CNC punching and laser cutting techniques. It is advisable to look for providers that offer comprehensive solutions, including installation and maintenance services.

What types of fuel can be dispensed using these devices?

Fuel dispensers are versatile devices that can dispense various types of fuel, including gasoline, diesel, kerosene, and LPG. Different models may be tailored to handle specific fuels, and it’s essential to choose an appropriate dispenser based on the fuel type needed for your operation.

What is the role of management systems in fuel dispensing?

Management systems play a crucial role in fuel dispensing by allowing real-time tracking of fuel distribution and inventory management. These systems enable operators to maintain efficient operations, minimize losses, and ensure that underground storage tanks are correctly monitored and maintained.

Are there different models of fuel dispensers available?

Yes, there are various models of fuel dispensers available in the marketplace. Manufacturers often offer custom designs to meet specific requirements, whether for a fuel station or industrial zone. It’s essential to evaluate the features and capabilities of each model to determine the best fit for your specific needs.

What technologies are used in the manufacturing of fuel dispensers?

Fuel dispenser manufacturing involves advanced technologies, including CNC punching for precision parts, laser cutting for creating complex shapes, and electrostatic spraying for durable finishes. These technologies ensure that the equipment produced is of high quality and meets industry standards.

How can I ensure the durability of my fuel dispenser?

To ensure the durability of your fuel dispenser, it is essential to choose a reputable equipment manufacturer that uses high-quality materials and advanced manufacturing processes. Regular maintenance and timely servicing can also help prolong the dispenser’s life and maintain its optimal performance.

What should I know about self-service fuel dispensers?

Self-service fuel dispensers enable customers to dispense fuel independently, eliminating the need for assistance from station staff. These dispensers are equipped with user-friendly interfaces and safety features to enhance the customer experience. When considering a self-service option, ensure that the equipment complies with relevant safety regulations and provides clear, easy-to-follow instructions for users.