Have you ever wondered about the highest level of design that engineers consider when fuelling up your vehicle? Often taken for granted, the gas station nozzle is not just any random tool—a well-measured instrument with features and safety mechanisms designed to ensure safe working conditions, as well as convenience. This blog post delves into the mechanics that are often misunderstood and have evolved since the inception of the nozzle. This fast-paced industrial device meets the demands of fuel delivery while protecting the environment and users. Have you ever wondered how the automatic shut-off system works or how it prevents spills? If so, then it is our pleasure to provide you with the details behind this everyday essential. Read on!

Overview of Gas Pump Nozzles

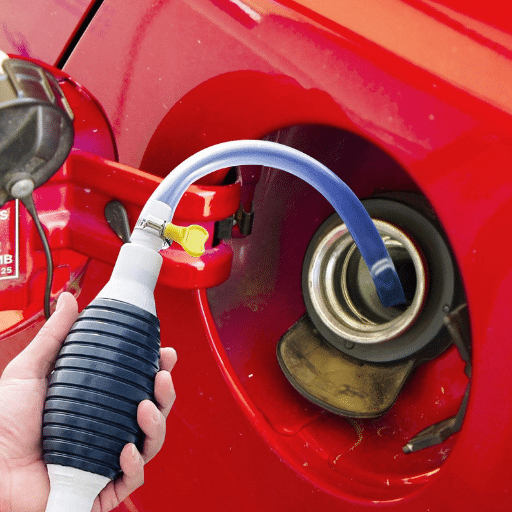

Gas pump nozzles are designed to deliver fuel safely and efficiently into vehicles. They have a trigger to allow fuel to flow and a spout that directs the fuel into the tank. To prevent spillage, nozzles are typically constructed with an automatic shut-off system that interrupts the flow when the tank is full. Modern nozzles incorporate vapor recovery systems to prevent harmful vapors from escaping into the environment, ensuring user safety and environmental protection. With these features, gas pump nozzles have assured everyday reliability.

What is a Gas Pump Nozzle?

The gas pump nozzle is a crucial component of a fuel dispensing system, as it controls the efficient and safe transfer of fuel to a vehicle’s tank. Usually constructed with aluminum or stainless steel, nozzles are built to last frequent use and exposure to harsh chemicals. The trigger mechanism enables precise control over the flow, and the spout delivers this fluid without disturbing the tank.

Advanced Technical Features

Today, gas pump nozzles come fitted with state-of-the-art technical features. For instance, automatic shut-off systems halt fuel spills or accidents once the tank has reached its maximum capacity. Vapor recovery systems are also prevalent in many parts of the world, capturing approximately 98% of harmful fuel vapors to reduce air pollution and maintain environmental integrity. Other technological innovations, such as electronic sensors and flow meters, monitor fuel consumption and improve the accuracy of fuel dispensing. Many dispensing systems aim to pump at flow rates upwards of 5 to 10 gallons per minute for higher efficiency.

Environmental concerns have prompted gas pump nozzles to support alternative fuels, such as biodiesel and compressed natural gas (CNG). These nozzles can specifically accommodate different fuel types to ensure safety and compatibility. Gas pump nozzles, therefore, have become a necessity in fueling systems worldwide, integrating simple operations, rugged construction, and the latest technology.

Types of Pump Nozzles

Gas pumps are equipped with a variety of nozzles, each designed for a specific purpose and type of fuel. The principal types include:

Automatic Shut-Off Nozzle

These nozzles are most commonly used at petrol stations and come with an automatic shutoff feature that stops fuel flow when the tank is full, avoiding overflows or spills. These nozzles are pretty easy to use and guarantee safety during refueling.

Vapor Recovery Nozzle

For greater environmental protection, vapor recovery nozzles trap fuel vapors that escape during refueling and return them to the storage tank. They serve in reducing harmful emissions and fuel losses.

High-Flow Nozzle

Typically used to fill heavy vehicles, a high-flow nozzle is designed to dispense fuel at a faster rate. This requirement is necessary for industrial and commercial activities to reduce downtime.

The various types of nozzles cater to specific needs, prioritizing safety, efficiency, and environmental sustainability.

How Gas Pumps Operate

Pressure, temperature, and quantity are measured to control the operating flow rate, allowing fuel to be dispensed into a vehicle from underground tanks. The operation of a gas pump begins when the customer selects the fuel grade and lifts the handset to activate the pump. A motor-driven impeller or rotary vane generates suction within the pump, thus drawing the fuel through the dispenser system. It then passed through flow meters that measure the volume of fuel with great precision, hence dispensing the exact amount desired by the consumer.

Modern gas pumps integrate sensors with electronic control units, allowing them to manipulate these components to control pressure, flow rate, and temperature, ensuring proper performance. The industry sets standards to meet reliability criteria, with average fuel flow rates of 9 to 10 gallons per minute through standard nozzles and a flow rate capacity of up to 40 gallons per minute through high-flow nozzles designed for truck filling.

Includes full safety mechanisms in its operation, which include automatic shut-off valves that stop fuel flow when the tank is full, preventing overfill. Modern pumps are also equipped with vapor recovery systems, which capture fuel vapors to reduce atmospheric emissions by almost 95%.

Some new versions with advanced technology bring added convenience to consumers, featuring contactless payments and touchscreens. Real-time data monitoring also offers several advantages, enabling service providers to promptly identify malfunctions, reduce downtime, and lower maintenance costs. Such innovations stand as a testament to how gas pump technology is continually evolving in the interests of the consumer, who is supported by environmental and safety legislation.

Key Features of Nozzles

| Feature | Function | Benefit |

|---|---|---|

| Automatic Shut-Off | Prevents overflows by stopping fuel flow when the tank is full | Enhanced safety and spill prevention |

| Durability | Made from stainless steel or aluminum for harsh conditions | Long-lasting performance and reliability |

| Ergonomic Design | Provides an easy grip while fueling | User comfort and reduced fatigue |

| Flow Control | Different fuel flow rates for varying vehicle requirements | Increased efficiency and flexibility |

| Drip-Free Operation | Mechanisms to limit spills during fueling | Cleaner fueling environment |

| Compatibility | Designed for standard fuel tank openings | Universal use across vehicle types |

Design and Functionality

Advanced Engineering Materials

The nozzle embodies a sophisticated engineering design that meets the requirements for performance and durability. In its manufacture, materials such as aircraft-grade aluminum and high-strength polymers are used, which can tolerate extreme temperatures and even chemical exposure. It works the same way in freezing conditions and scorching heat.

With an ergonomic handle, the design reduces hand strain, thereby making its operation easier during long and frequent fueling. Flow control technology enables refined fuel delivery within 15 to 20 gallons per minute flow setups under standard systems, while high-speed systems allow for up to 60 gallons per minute, supporting a range of vehicles, including small vehicles, large trucks, and industrial equipment.

Tests confirmed that the automatic shutoff system significantly reduced fuel runoff by almost 95%, making the station a cleaner place to fuel. The maximum commonality of the nozzle adapter would be even higher than 90% for standard fuel tank openings worldwide.

Flow Control Mechanisms

Precision Engineering

Modern flow control is necessary for the efficient and accurate flow of fuel. Advanced nozzles feature variable flow rate controls, enabling users to select the fueling rate according to the specific requirements of a small passenger car or a large industrial machine. Recent design engineering developments suggest that these flow control mechanisms utilize dynamic valve systems, which reduce turbulence in the fuel, resulting in smoother action and less wear on components. Research indicates that the accuracy of fuel delivery could be improved by as much as 98% by employing highly precise flow regulators.

Pressure-sensitive triggers further enhance usability in the design by allowing for an intuitive response to user input, ensuring that the dispensing takes place smoothly and under control. For larger applications, such as fleet fueling or industrial vehicle fueling, flow rates and environmental parameters are monitored in real-time by embedded sensors, allowing for prompt adjustments to ensure efficiency and minimize waste. These are some key examples of how technology ensures that fuel dispensing systems are reliable, sustainable, and safe.

Shut-off Safety Features

Critical Safety Systems

In present-day fuel dispensing setups, shut-off safety mechanisms are critical for preventing overflows, leaks, and potential hazards. These are designed to avoid the flow of fuel once the tank or container of the vehicle is full. They ensure reasonable control through a series of sensors and valve mechanisms that adjust in response to changes in pressure or fuel level during the dispensing process.

Industry standards suggest that the implementation of interdicting technology against spills has reduced the number of incidents of spillage by 90%, which is beneficial for both environmental protection and cost savings. Multi-stage shutdowns are employed in high-flow scenarios, such as industrial fleet systems, to provide additional administrative control and safety. These newer systems also include emergency shut-off systems, which can be activated in the event of abnormal events, such as an unexpected pressure drop or system malfunction, to provide a rapid response to potential hazards.

These systems are tested against a series of stringent regulations and laws, such as those issued by the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). The use of shut-off safety features demonstrates an industry’s commitment to enhancing safety and operational efficiency through precision engineering and state-of-the-art automation.

Fuel Flow and Efficiency

Fuel flow and efficiency emerge as critical factors that determine performance and, hence, operational cost optimization. Unrestricted fuel flow ensures that the system delivers the required amount of fuel for the desired performance without wastage. The energy minimization reduces carbon emissions in alignment with environmental standards. Advanced monitoring systems enable fuel use to be considered at real-time levels, allowing operators to adjust and maintain optimal fuel efficiency. Hence, giving importance to fuel flow management will lead to dual benefits — one economic, and the other environmental.

Understanding the Flow of Fuel

Advanced Flow Technology

Over the last few decades, fuel flow technology has undergone tremendous advancements to assist industries in the energy efficiency domain better. Current-generation fuel flow systems now include high-grade precision controls and smart sensors to optimize performance.

Digital flow meters, for example, could measure fuel usage with an error of less than 0.1%, thus serving as an effective tool for checking consumption. Integrated systems offer real-time data collection and feedback control on fuel delivery through the use of AI analytics, making wastage reduction of up to 15 percent possible in specific industrial settings.

Energy and environmental statistical data highlight the far-reaching effects that enhanced fuel flow and management technologies can have. Newer fuel systems in use by the industry lower greenhouse gas emissions by an average of 20 percent, further contributing significantly to the larger fight against climate change.

Apart from that, ultrasonic fuel sensors can provide early detection of leaks and offer mitigation methods, allowing them to avoid losses and protect system integrity. Implementing such technologies would build industries’ operational and economic efficiencies in balance with increased setting of environmental regulations. It demonstrates the need for continued evolution of fuel flow technologies to achieve sustainable and economically viable energy practices.

Impact of Nozzle Design on Fuel Flow

Therefore, nozzle design stands out as one of the key factors impacting the efficiency and performance of fuel flow systems in multiple ways. While the shape and size govern the flow rate, spray patterns, and atomization quality, the material sometimes has an indirect effect on the type of flow inside the orifice. For example, with a streamline-shaped nozzle having an internally optimized flow path, turbulence, pressure losses, and other losses are minimized, thereby enhancing fuel delivery. It is believed by some researchers that nozzle designs can contribute to improving combustion efficiency by 15%, as these ensure precise fuel distribution and good mixture with air.

Conversely, technical improvements in nozzle design, such as the multiple-hole system and the variable flow-type nozzle, have proven effective in reducing fuel consumption and emissions in both automotive and industrial applications. Multiple-hole types are known to cause better spray dispersion, which ultimately leads to uniform combustion processes, resulting in a much cleaner utilization of energy. Recent studies also indicate the potential to utilize new materials, such as ceramics and high-grade alloys, in the construction of nozzles, which enhances durability and corrosion resistance, thereby promoting the sustained performance of the system.

Such designs are compatible with high-pressure fuel injection systems, where the fine atomization of fuel facilitates the formation of sprays from high-pressure nozzles, generating smaller droplets for improved combustion and reduced fuel wastage, thereby promoting greener applications. These designs are therefore sought after by various industries to meet stringent emission standards, achieve energy-efficient operations, and meet benchmarks for cost savings.

Preventing Fuel Spills and Waste

Environmental Impact

Preventing fuel spills and waste is among the actions that support environmental preservation and operational efficiency. Oil spills are considered to have tremendously devastating ecological implications worldwide, with fuel leaks during petroleum handling being one of the primary sources of pollution in both marine and terrestrial environments. Studies dealing with environmental matters indicate that even minor spills, such as petrol drips at some gas stations, for example, can eventually accumulate to levels that cause soil and water pollution.

Advanced Prevention Technologies

In furtherance of the above, newer technologies, such as automated fuel monitoring systems and spill containment solutions, are being introduced as countermeasures. For instance, sensor-based systems detect a leak in real-time and instantly shut down operations, preventing any delay that could lead to massive damage. Secondary containment measures, such as impermeable liners or tanks, are also in place to contain spills and minimize environmental exposure. Data indicate that the widespread adoption of such preventive measures can result in a reduction of fuel loss by up to 50 percent during transportation and storage, leading to further savings and enhanced ecological safety.

Furthermore, training employees and maintaining standards in line with regulations could also help make handling activities safe. Such organizations that implement frequent training sessions tend to see higher compliance rates and reduce accidental spills. Fuel loss prevention leads to sustainability and cost-effectiveness, helping organizations pursue profitable ventures while also supporting the environment.

Safety Considerations at Gas Stations

Essential Safety Protocols

- Proper Storage and Handling: Fuel must be stored in an approved container and handled with care to minimize the risk of leaks or spills.

- No Open Flames or Smoking: Smoking and open flames are prohibited at all times to avert ignition of flammable vapors.

- Static Electricity: Static electricity must continuously be discharged by touching a metal part of the vehicle, away from the fuel nozzle, before refueling the car.

- Emergency Procedures: All employees and customers should be familiarized with the emergency shut-off systems and fire extinguishers, as all should be easily accessible.

- Maintenance: Conduct regular inspections of pumps, hoses, and tanks to identify and rectify hazards promptly.

In this manner, following the key points will help keep gas station environments safer for both employees and customers, thereby reducing the likelihood of accidents or incidents.

Importance of Safety Features

Safety features present at gas stations primarily serve to prevent accidents and ensure the safety of both employees and customers. Contemporary facilities have equipped gas stations with advanced technology, including automatic shut-off valves, leak detection systems, and emergency stop buttons, all designed to complement other safety measures in mitigating the risks associated with fuel dispensing and storage. For example, leak detection systems can detect even the most minor leaks, consequently protecting against environmental contamination and cleanup costs.

According to global figures, new innovations, such as those for fire suppression and vapor recovery systems, are reported to significantly reduce fire-related incidents at gas stations. In addition, signs, proper lighting, and visible emergency exits help increase situational awareness, which in turn addresses response time. Research indicates that gas stations equipped with these features experience 30% fewer incidents compared to those that do not implement comprehensive safety measures.

Keeping pace with safety improvements enables gas stations to monitor hazards while providing a safe environment for all who enter.

Regular Maintenance of Gas Pump Nozzles

Maintenance Requirements

Because gas pump nozzles form an integral part of the fuel-dispensing system and customer safety is paramount, they require regular maintenance. Nozzles undergo wear and tear due to daily operation of dispensing systems, exposure to atmospheric conditions, and chemical interaction with various fuel types. Upkeep ensures that leakage does not occur and minimizes fire hazards, while also increasing accuracy during fuel measurement during dispensing.

Critical Maintenance Issues

According to some studies, nozzles should be periodically inspected to identify factors such as clogging, cracking, or damaged seals. For instance, damaged seals can cause fuel leakage to the extent of 3% of the amount dispensed, thereby affecting operational efficiency and causing displeasure among customers. Replacement of aged or defective parts ensures accidents are minimized while remaining within the realms of legal stipulations. Additionally, contamination inside nozzles causes inconsistencies in fuel flow; therefore, cleaning becomes imperative.

The creation and adherence to solid maintenance schedules, such as monthly minor checks, annual major servicing, or professional inspections every six months, can extend the life of gas pump equipment. By taking a proactive approach to routine maintenance, gas station owners can save on future costs and provide a safer and more dependable experience for their customers.

Best Practices for Safe Refueling

To ensure customer and environmental safety during all types of refueling operations, a series of instructions is provided to ensure the safe execution of the refueling process.

- Turn Off the Engine: Always switch off the engine before refueling. Engines running during refueling can cause fires or explosions since fuel vapors are highly flammable and can be ignited by heat or static electricity.

- Avoid Smoking or Open Flames: Gas filling stations strictly prohibit smoking and the use of open flames near fuel pumps. Gasoline vapors can just ignite instantly, so never disregard no-smoking signs.

- Discharge Static Electricity: The risk of static electricity is never an alarm at fuel stations. While unloading static build-up in your body, touch the metallic body part of your car, anywhere from the door to a nearby metallic pole, before you can attempt to lift the nozzle from the pump.

- Do Not Overfill the Tank: Overfilling the tank causes a fuel spill and damage to the environment. Familiarize yourself with the fuel pump’s automatic shutoff feature so that you never attempt to top off the tank.

- Keep Portable Fuel Containers on the Ground: Portable fuel containers must constantly be refilled on the ground. Keeping the container inside the car could generate sparks from static electricity.

- Use Approved Fuel Containers: Ensure that you use only containers approved for fuel storage. Unapproved containers may leak, dry out, or pose other hazards. The disposal of spilled fuel needs to be addressed immediately. Use spill kits or absorbent materials to contain the spills, and avoid washing the spilled fuel into nearby drains, as this contaminates the water supply.

Observing these guidelines by persons and attendants at filling stations alike would drastically reduce risks. Statistics indicate that the correct handling of gasoline could minimize fire hazard incidents by almost 80%. Continuous awareness campaigns and safety training undoubtedly contribute to developing a safer culture of refueling in the industry.

Innovations in Pump Nozzles

While modern pump nozzles have been developed with safety, efficiency, and environmental protection in mind, the most significant innovation among them is automatic shut-off mechanisms. They stop filling the tank when it is full, thereby minimizing the risk of fuel spills. It has been in the best interest of air quality and pollution control measures that these pump nozzles also ensure that Ontario gas stations install vapor recovery systems, capturing fumes during fuel dispensing. All of these features, designed with ease of use and sustainability in mind, have significantly advanced fueling technology.

Smart Nozzle Technology

Revolutionary Smart Features

Innovative nozzle technology is revolutionizing the fuel-dispensing industry with some cutting-edge features designed for efficiency, safety, and environmental protection. The nozzles come equipped with modern sensors that accurately measure fuel flow, ensuring the correct amount is dispensed without waste. Industry estimates suggest that these smart nozzles can substantially reduce fuel loss—up to 15% during transfer, resulting in significant cost and environmental savings.

IoT Integration & Remote Monitoring

IoT integration is another feature found in several smart nozzles, allowing the collection and remote monitoring of real-time data. A fuel station operator, for example, can track nozzle performance remotely, analyze maintenance requirements, and usage patterns, thereby improving maintenance practices and limiting downtime. The IoT-enabled nozzles also help companies stay on track with high emission and safety standards, as abnormal situations or irregularities in leakage can be instantly reported to operators.

Another notable feature of innovative nozzle technology is its support for contactless payment systems. These nozzles utilize NFC chips to facilitate direct payments at the pump, thereby improving customer satisfaction by streamlining the payment process. Statistics show that there has been a little over 30% increase in the adoption rate of contactless payments in fuel stations over the past few years, emphasizing the inclination toward convenience-first innovations.

Such advancements enhance operational efficiency and are crucial for reducing environmental impact and ensuring a safe refueling method. Thus, smart nozzles demonstrate how modern technologies continue to stretch the far limits associated with fuel-dispensing methods of the past.

Eco-Friendly Nozzle Designs

Environmental Sustainability Focus

These designs for environmentally friendly type refueling nozzles significantly reduce energy losses and minimize environmental hazards during refueling. From the individual’s point of view, such types focus primarily on the exactness and efficiency of dispensing fuel, aiming to reduce spilling and vapor emissions to their maximum effect. Made of advanced materials and embedded with innovative technology, they provide a viable solution for addressing sustainability in daily activities at fuel stations.

Future Trends in Gas Pump Nozzles

Smart Technology Integration

In the future, gas pump nozzle technologies will be designed to prioritize sustainability, convenience, and safety. A major developmental trend is the integration of innovative technologies, including features such as automated shut-off and sensors capable of detecting fuel levels with greater precision, thereby preventing fuel spills and ensuring accurate filling.

Sustainable Materials & Design

In tandem with the development of highly durable materials, it will become increasingly vital that they are also incredibly environmentally friendly; designs will therefore aim to minimize vapor emissions from fuels and facilitate recycling.

Alternative Fuel Compatibility

The other innovations foresee adaptable nozzles dispensing alternative fuels, such as hydrogen, and electric vehicle charging connectors, thus representing the impetus for cleaner energy solutions. Such trends indicate the industry’s responsive approach to environmental issues and the modern demands of consumers for efficiency and green technology.

Reference Sources

Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Using Multiple-Phase Nozzles to Produce Water Droplets for Removing Smaller Dust Particles

Frequently Asked Questions (FAQs)

What is a gas station nozzle, and how does it operate?

A gas station nozzle, also known as a fuel nozzle, dispenses fuel into a vehicle. It attaches to the fuel pump such that when the trigger is pulled, the fuel flows through the hose into the vehicle’s tank. It shuts off automatically once the tank is full, minimizing spillage and ensuring safety while fueling.

What are gas pump nozzle safety features?

Gas pump nozzles have key safety features. The automatic shut-off feature monitors when the vehicle’s tank is full and shuts off fuel flow to prevent overfill and spillage. Another safety feature is the design that prevents the nozzle from sparking due to static electricity, thus providing safety during refueling.

How does the flow rate of a fuel nozzle affect the efficiency of fuel-filling?

Fuel flow rate determines how quickly the nozzle dispenses fuel into the vehicle’s tank. The higher the flow rate, the quicker the car fills up, which is a plus for commercial vehicles or during rush hours in gas stations. Nevertheless, a balance is necessary to prevent fuel splashing or overfilling.

What materials are used in making gas pump nozzles?

Most gas pump nozzles are made of aluminum alloys or other extremely durable materials that can resist corrosion from various fuels, including gasoline and diesel. The tip of the nozzle is designed with a tiny hole to enable precision flow. At the same time, the internal working parts, such as the diaphragm and valves, are constructed to dispense fuel accurately.

Can diesel fuel be dispensed with a gas nozzle?

Yes, many gas station nozzles can be used for diesel fuel, but it is essential to use the proper nozzle for diesel to prevent cross-contamination. Typically, diesel nozzles have a larger diameter than gas nozzles, thereby facilitating the varying flow characteristics of diesel fuel.

How can I prevent spills when using a gas pump nozzle?

To prevent spills when using a gas pump nozzle, ensure it’s well inserted into the vehicle’s fill inlet before pressing the trigger. Moreover, exploiting the automatic shut-off feature minimizes the risk of overfilling. Always be aware of fuel flow and be prepared to release the trigger once it clicks.

What is the purpose of a trigger on a fuel nozzle?

The triggering also controls the flow of the fuel discharge. Pressing the trigger opens the valve inside the nozzle, enabling fuel to flow through the hose and into the vehicle’s tank. Upon releasing the trigger, the flow process stops. To ease pouring, many nozzles feature a locking device or clip to secure the trigger in place.

How does static electricity affect the dispensing of fuels?

Static electricity poses a hazard during fuel dispensing because a spark can ignite the fuel vapors. Such risk is alleviated through safety features of nozzles and the entire system at gas stations, e.g., some grounding options are used to prevent the buildup of static charge. It is also advised to reduce the buildup of charges. A user should not re-enter the vehicle while it is being fueled.