Fuel dispensers are an essential subject in an industrial energy environment. They stand as the primary linking device between fuel storage and the respective consumers of that fuel, who keep their daily lives going. The fundamental component, behind the machinery, which is often overlooked, is the base for the fuel dispenser. Though it appears to be a smaller element, the base provides the operations stability, precision, and durability. The article deep dives into the essential place of fuel dispenser bases under fuel dispenser parts, including designs, uses, and importance. You will have a fuller appreciation of how this base member ultimately contributes to the efficiency and reliability of fuel systems worldwide.

Introduction to Fuel Dispenser Bases

Fuel dispenser bases form the foundation of fueling systems, thus imparting stability and accurate performance during operations. Their primary function is to provide a firm base for the dispenser unit, considering environmental factors such as vibrations and uneven ground. These bases, being designed for the long haul, are created from strong materials to withstand heavy wear and tear and, in doing so, prevent structural problems over time. By remaining strong and providing a steady framework, the fuel dispenser base stands in for industry and is necessary for the worldwide development in efficiency and safety of fuel dispensing systems.

Definition and Purpose

Fuel dispenser bases are an integral part of fuel systems since they provide the foundation on which the system relies for operational reliability and efficiency. These bases are supposed to anchor the dispenser units securely, compensating for vibrations, uneven surfaces, and external forces from the environment. These days, the dispenser bases are built with high-strength materials such as reinforced concrete or heavy steel, and their finishes can withstand wear and tear, corrosion, and adverse weather situations.

In addition, they follow engineering standards that provide a certain degree of functional durability and environmental safety. Research has found that improper installation or use of substandard materials in dispenser bases may result in structural failure, leakage, hazards, etc., thus increasing maintenance costs. Data shows that investment in a good base will increase the service life of fuel dispensers by up to 20% while reducing downtime. They ensure safe fueling operations, uphold regulatory standards, and guarantee uninterrupted service for customer satisfaction.

Importance of Fuel Dispenser Systems

Fuel dispenser systems are pivotal in ensuring efficient and safe customer delivery. Technological developments have been incorporated to raise functionality and reliability meaningfully. For example, in the current era, one can implement digital monitoring to provide real-time tracking for fuel flow rates, inventory levels, and dispenser performance, thus reducing collisions and operational losses.

According to industry statistics, upgrading to highly precise fuel dispensers with good metering accuracy could reduce measurement errors by 0.3%, saving thousands of dollars yearly for any high-volume-fueling station. Furthermore, implementing superior materials such as corrosion-resistant alloys and polymers in the dispenser’s manufacturing greatly improves the equipment’s lifespan, with specific models capable of performing efficiently for more than ten years, almost without any maintenance.

The customer experience at the fuel pump has been transformed through contactless payments and IoT-enabled communications, with dual benefits of faster transaction flow and data security that is in sync with evolving consumer expectations. That way, state-of-the-art fuel dispenser systems will provide efficiency of operations, cost savings, and ultimately, higher service quality standards.

Overview of Components

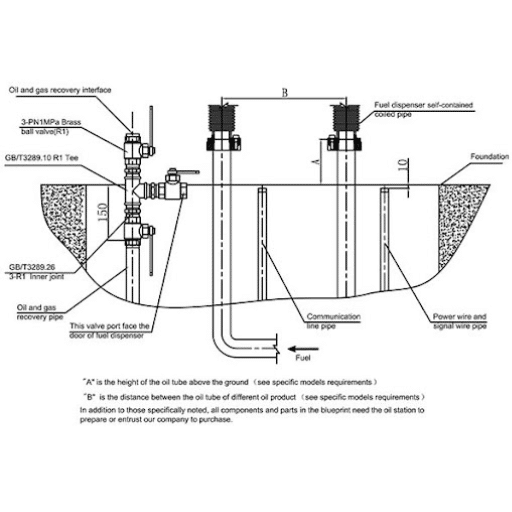

The fuel dispensing system encompasses several key components that work together to ensure accurate, efficient, and safe fuel delivery.

Pump and Motor Unit: The pump removes fuel from underground storage tanks, while the motor powers the pumping mechanism to ensure a smooth and consistent flow. Advanced systems typically use variable-speed pumps for energy efficiency.

Metering Mechanism: The metering mechanism ensures the accurate measurement of fuel being dispensed. Contemporary fuel dispensers employ electronic metering systems with high accuracy, thereby eliminating errors or inconsistencies that may occur.

Hoses and Nozzles: These transfer fuel from the dispenser to the vehicle. Nozzles with automatic shutdown prevent overfilling and spilling, making the scenario safer and more convenient for the user.

Display Unit: The display unit displays real-time information on the quantity and price of dispensed fuel. Modern dispensers prefer an LCD digital display that offers an interface within the user’s reach and is customizable.

Payment Systems: The options for contactless and card payments now form an essential part of fast transactions and areas for data security, as expected by today’s consumer.

Control Systems and IoT Integration: Technological improvements have led to the incorporation of IoT-enabled components for fuel level monitoring, diagnostics, and remote management to maximize operational efficiency and reduce downtime.

These components collectively define the reliability, performance, and customer experience that define a fuel dispenser system, emphasizing function and innovation.

Types of Fuel Dispenser Bases

Generally, fuel dispenser bases can be divided into two major types:

Above-Ground Bases: These bases are placed above the surface area, thus making maintenance and installation easier. A common location where Above-Ground Bases are found is one in which excavation is impossible.

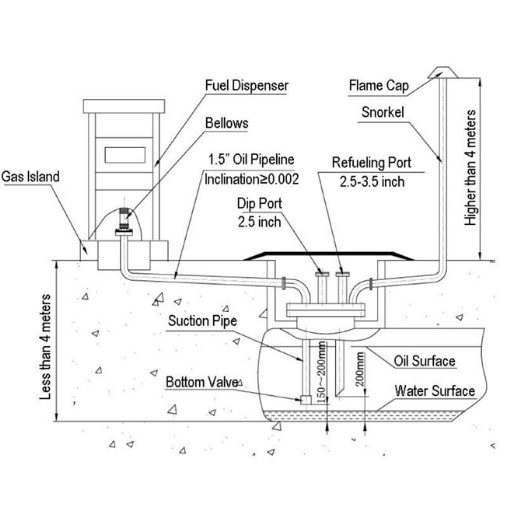

Below-Ground Bases: These are more avant-garde, fitted beneath the surface, and generally safer than their above-ground counterparts. They are primarily installed in industrial zones with heavier traffic to minimize obstructions.

The site’s specific installation requirements guide selecting one or the other type, thus providing flexibility and convenience.

Standard Fuel Dispenser Bases

Standard fuel dispenser bases provide fuel dispensers stability, durability, and functionality simultaneously in varying and extreme environments. The bases are designed to bear the dispenser’s load, keep it aligned, and resist environmental conditions such as temperature change, vibrations, and chemical attacks. Modern dispenser bases are manufactured using sturdy materials such as reinforced concrete, corrosion-resistant steel, or composite materials. The concrete bases are favored for their toughness against heavy loads and thus would be best for large fuel stations. Age resists wear and tear among steel bases, while composites weigh less and resist corrosion.

Ensure that the design considerations comply with safety and environmental standards. For example, containment mechanisms may be integral to many of these bases, stopping fuel spills from contaminating the environment. In addition, being portable and easy to install, modular installations have recently become the preferred option for replacing and maintaining.

Depending on the type of dispenser, the standard size dimensions of the fuel dispenser base may vary. Usually, such bases range from 4 feet to 6 feet in width and length, and the height can be anything between 6 inches and 12 inches. Specific bases are technically advanced in other respects and include an anchoring system that helps keep them stable even when confronted with seismic conditions.

Fuel dispenser budgets for disparity are essential in minimizing downtime at fueling stations. By providing applications for stability and security, the bases also pay attention to extending dispenser life and smooth operations to ensure transfusion to customer satisfaction.

Custom-Designed Bases

Custom-designed fuel dispenser bases are fabricated to suit any fueling environment’s requirements, ensuring utmost functionality and durability. Bases are fashioned with precision from reinforced concrete, steel, or composite blends to provide better load capacity and resistance to environmental parameters. For instance, advanced concrete bases may have compressive strength ratings exceeding 4,000 PSI, making them very durable in high-traffic areas of any fueling station.

On the other hand, customization allows for accommodating safety and operational features. For example, they could include conduits embedded within the base for electrical wiring, drainage for spill management, and an anti-corrosion coating to preserve the base in coastal or chemically exposed areas. The latest advancements in base design also feature vibration-dampening elements or shock absorbers to reduce mechanical wear and tear due to constant dispenser usage.

Stations with custom-built bases have 30% fewer maintenance-related disruptions, which translates to better operational efficiency. With their site-specific design, these bases enhance dispenser performance while ensuring that local regulations and industry standards are met.

Material Considerations

Selection of materials for custom bases is key to ensuring durability, stability, and performance. Due to its ability to sustain substantial forces exerted upon it by construction, environmental, and temperature conditions, high-strength reinforced concrete is given precedence. Moreover, corrosion-resistant steel is supposed to be used in the structure. In that case, its strength, integrity, and durability get significantly enhanced, particularly in regions where humidity is high or de-icing salts are applied frequently.

Recent literature has highlighted the need to use sustainable materials to lessen the environmental impact of any construction project. For instance, recycled aggregates in concrete can reduce carbon emissions by around 20%. Geopolymer concrete uses industrial wastes such as fly ash or slag while providing high performance and reducing greenhouse gas emissions.

Other measures include coatings and sealants that protect the bases from wearing out over time. For example, epoxy-type coatings are highly resistant to chemicals and abrasion, ensuring a long service life for the infrastructure. Hence, the selection and installation of base materials with proper quality control measures meet the best industry requirements, giving exceptional performance under harsh operational conditions.

Installation and Maintenance of Fuel Dispenser Bases

Installation: Properly installing fuel dispenser bases ensures that the bases achieve their long-term performance and reliability. One should first choose or locate a position with the ground surface level, as an uneven surface will cause an uneven distribution of loads. Use an excellent mix of concrete or pre-fabricated concrete materials designed to hold heavy loads and withstand environmental conditions. The base should be installed with the correct dimensions and reinforcements to accommodate the dispenser and ancillary equipment. These considerations, if followed, ensure that the growth adheres to set standards and local regulatory guidelines deemed safe.

Maintenance: Routine maintenance keeps fuel dispenser bases intact and in good working condition. Periodic inspections for the presence of wear, cracks, or chemical damage are of paramount importance. This should also be done with the repair, should any degradation be noted. Clean the surfaces with dirt, debris, and residues of chemicals periodically. Applying protective coatings such as epoxy or polyurethane maximizes resistance to abrasions and environmental degradation. Continuous monitoring and timely maintenance will keep the base in good condition for safe and efficient operation.

Installation Procedures

Installation is critical for base durability and serviceability. Firstly, the surface preparation must be meticulously done; it has to be clean, dry, and devoid of contaminants like oil, grease, or debris. A textured surface is mainly recommended to achieve good adhesion. Checking the moisture levels is equally important, to be within the right range so that blistering or peeling does not occur during or after installation.

For concrete bases, movement needs to be allowed by providing for control joints, which should help prevent cracking and consequently keep coatings intact. Protective coatings and overlays should be applied as even thin layers, according to the manufacturer’s recommendations for layer thickness and time to cure. Temperature and humidity are essential factors in installation; for example, most materials should be applied at a temperature of 50°F to 85°F with relative humidity below 60%.

Recent studies stress the use of modern materials like high-solids epoxy systems, which are more durable, chemically resistant, and quicker to cure. Reinforcing critical areas with fiberglass and other tensile ingredients may further enhance strength, especially under heavy loading. For the safety of the workers and the environment, always wear PPE, ensure good ventilation, and observe all safety protocols during work.

Common Maintenance Practices

Maintenance is necessary to ensure the longevity and performance of structures and equipment. One widely accepted maintenance procedure is scheduled inspections to catch early signs of wear or damage. An example would be ultrasonic thickness testing in tanks or pipework, which accurately measures the thinning of materials over time, thereby preventing expensive failure.

Cleaning is yet another crucial maintenance item, especially for surfaces exposed to corrosive environments. Experts recommend using non-abrasive cleaners and thoroughly rinsing away any residues that can promote corrosion. For instance, marine structures are washed off regularly to ensure that salt deposits do not speed up rusting.

Lubrication of moving parts is equally important in reducing friction and preventing mechanical failures. Studies show that 50% of bearing failures occur because of improper lubrication. Consequently, it is essential to ensure lubricants are those recommended by manufacturers and are applied according to suggested intervals.

Thermal imaging may indicate a recent trend in electrical maintenance: detecting hot spots caused by overloads or defective connections before they shut down the operation. Filter replacement and coil cleaning also provide further energy savings and extend the lifespan of an HVAC system.

These maintenance practices improve performance, reduce downtime, protect assets, and ensure safety compliance across industries. Following the progress of maintenance technology, such as predictive analytics and automated monitoring systems, will provide opportunities for streamlining operations and rendering proactive care.

Signs of Wear and When to Replace

Detecting early signs of deterioration in equipment averts being saddled with huge repair bills and unwarranted downtime. Unusual sounds, decreased performance, overheating, and visible damage in the form of cracks or corrosion are common indicators. In HVAC, worn-out belts, dirty filters, or unusual airflow are signs that some components must be serviced or replaced. Studies show that working with worn-out equipment can lower efficiency by as much as 30%, causing extremely high electricity costs and posing a serious hazard potential as time passes.

When establishing replacement time, performance indicators, maintenance history, and expected life span are also considerations. For instance, industrial motors and pumps are generally designed to run 10-15 years, depending on actual usage and environment. Regular inspection monitoring using vibration analysis or thermal imaging can help identify when equipment is about to exceed its service life. Acting on warning signs promptly will avoid sudden failures, hence increasing reliability and productivity for any business platform.

Gas station pedestal safety precautions

Inspect Regularly: Inspecting the pedestals to detect any signs of wear, damage, or corrosion helps maintain structural integrity and prevent accidents.

Secure Connections: Ensure all electrical connections and fuel lines are secured to prevent leaks, sparks, or fire hazards.

Clear Obstructions: Keep the area around the pedestals clear of clutter and inflammables, which could prevent escape.

Label Clearly: All explanations, controls, switches, and emergency shut-off buttons should be labeled and accessible in an emergency.

Integrate Proper Lighting: Ensure adequate lighting for use and maintenance in and around the pedestal-way during daytime hours.

Following these suggestions will allow gas stations to keep a safe environment for maintenance staff, customers, and equipment.

Gas station pedestal regulatory compliance

Compliance-wise, gas station pedestals would require adherence to all safety guidelines, such as proper grounding of equipment, clear labeling, and sufficient lighting. Further, the immediate area around the pedestal must be kept hazard-free and comply with applicable local and national standards for safety and maintenance. Of course, my first concern would be constantly inspecting and updating to comply with all regulations.

Gas station pedestal emergency procedures

This emergency plan for gas station pedestals shall prioritize the safety of the persons working at the plant, customers, and the environment. The main protocols to be observed include: immediately cutting any possible power supply to the pedestal in case of an accident, malfunction, or hazard as a precaution against electrical fires or other dangerous developments. Buttons and switches for emergency shutdown should be prominent and marked to eliminate any delay. The presence of fire suppression systems and proper training of all staff in using fire extinguishers for the rating of gasoline and electrical fires is also reasonably necessary. It has been recorded that gas station fires cause thousands of incidents annually, most due to the improper handling of flammable materials or mechanical failures. The community can be educated on avoiding ignition sources, such as smoking and leaving engines running at the pedestal, to lessen the risk.

Another consideration of the emergency plan is spill containment. Spill response kits containing absorbent materials and protective gear shall be readily available immediately. Staff shall be trained at least once to deploy these kits fully. A drainage system around the pedestal must be ensured so fuel spills do not contaminate the local water supply.

Evacuation procedures must be well thought out and widely disseminated through drills and signs. Together, these best practices ensure that any untoward incident outside a gas station pedestal is handled promptly with the least risk to the public and the environment. Regular inspections also ensure that these abide by state and federal criteria, such as those posed by NFPA and EPA.

Gas Station Pedestal Safe Operation Best Practices

Maintenance and Inspection: Periodic checks are needed to ensure the proper functioning of gas station pedestals. Look for fuel leaks, worn-out parts, corrosion, or other apparent damage. Carry out routine maintenance as the manufacturer recommends and as per industry safety practices to reduce the risk of operations.

Proper Staff Training: All personnel required to handle gas station pedestals must be formally trained on the standard operating procedures, safety procedures, and emergency response measures. A comprehensive understanding of how the equipment functions, including all possible hazards, will ensure that the issues are handled correctly and promptly.

Leak Detection Systems: Utilize advanced leak detection systems covering tanks, pipes, and dispensers. This ensures that minor leaks get detected and a spill does not lead to heavy environmental pollution and financial damages. The systems should be tested regularly and calibrated.

Emergency Shutoff Systems: Gas station pedestals must be equipped with emergency shutoff systems that are easily accessible and conspicuously marked. The systems must be tested periodically to ascertain their proper operation, and personnel must be regularly trained in their use in emergencies.

Compliance with Regulatory Standards: All relevant standards, such as NFPA, EPA, etc., should be complied with without compromise. Records must be maintained for proper documentation, incidents reported promptly, and the facility must ensure that all safety and environmental guidelines are maintained.

This way, the gas stations will efficiently reduce all risks, safeguard the environment, and provide a safe environment for all employees and customers.

Future Trends in Fuel Dispenser Base Technology

Some of the trends developed in the technology of fuel dispensers for the base include greater efficiency, sustainability, and enhanced user experience. Digital payment systems through automatic advancement transact seamlessly, whereas automated touchless interfaces stand to increase convenience and hygiene. Furthermore, supporting alternative fuels such as EV charging and hydrogen refueling will be essential as the demand for clean energy solutions grows. All advanced monitoring systems with IoT technology will be installed in these new ones for maintenance, fuel usage, and operational safety. The developments will allow adaptation to the fast-changing energy needs while going down the route of conscientious environmental conscientiousness and customer satisfaction.

Innovations in Material Science

Material science drives fuel dispenser base technology breakthroughs toward greater durability, efficiency, and sustainability. Present-day materials like composites, high-strength polymers, and corrosion-resistant alloys substitute for traditional steel and concrete. For example, high-performance polymers keep weights down in contrast to the steel and concrete materials they replaced, thereby saving transportation and installation costs.

Meanwhile, nanotechnology-related techniques have generated coatings resistant to wear, corrosion, and chemical degradation, thus extending the life of the base materials in adverse environmental settings. According to reports, advanced composites have a service life about 30% longer than the traditional ones, minimizing maintenance costs and lessening the environmental impact.

The sustainability aspect comes next, with recyclable materials and bio-based polymers entering the picture. In other words, these clean alternatives chip away at carbon footprints even as they continue to perform just as well, thus directly relating to global efforts to restrict emissions and promote green technology. So, blending these innovative materials from the fuel dispenser industry will pave the way for building an efficient and highly sustainable technology.

Integration with Smart Technology

Innovative technology is transforming the fuel dispensing industry by adding features to augment user interaction, operational efficiency, and security. Fuel dispensers are now equipped with touch screens, IoT connectivity, and the option for a mobile payment system for smooth and customer-friendly interactions at the fuel station. Recent market data suggest that over 60% of new fuel dispensers come with integrated payment systems that allow contactless payments, a growing demand for convenience-type solutions.

Indo-Big dispensers provide operational monitoring by obtaining and feeding back real-time data on fuel levels, maintenance issues, and transaction trends, thereby minimizing downtime. Moreover, advanced cybersecurity protocols are embedded as a protective mechanism against breaches, highlighting the rise in significance of digital safety considerations.

Innovative technology serves environmental aims and station operators, with automated systems deployed for fuel allocations, emission monitoring, and promoting environmentally friendly endeavors such as biofuel blending. Such developments impel bright fuel dispensers to become a stepping stone for modern-day sustainable energy infrastructure.

Environmental Considerations

In essence, bright fuel dispensers address environmental issues by reducing carbon footprint and promoting sustainable energy practices. Worldwide transportation contributes approximately 25% of CO2 emissions in the atmosphere; hence, fuel efficiency checks and stringent emissions monitoring must be considered. The smart dispenser with sensors and automated systems can check emissions in real time, allowing an operator to identify ways in which inefficiencies can occur so these can be rectified and fuel usage optimized.

Many intelligent systems will also work with alternative fuels like biofuels or hydrogen, which emit fewer greenhouse gases than fossil fuels. For instance, biodiesel blends could reduce carbon emissions up to 74% over their lifetime. Support is also given to sustainable practices that enable renewable energy integration into fueling stations, such as solar or wind energy powering the operations.

Using futuristic technologies, bright fuel dispensers are paving the way towards a cleaner future while assisting industries in becoming greener and more environmentally friendly in their energy choices. These improvements, along with the Paris Agreement, are heating emissions reduction globally.

Reference Sources

2. Design and Implementation of RFID-based Fuel Dispensing System

3. Human Reliability Analysis by Cognitive Approach for Unloading Process In an ALDS (Auto LPG Dispensing Station)

Frequently Asked Questions (FAQs)

How is energy technology integrated into fuel dispenser bases?

Energy technology plays a crucial role in enhancing the efficiency and functionality of fuel dispenser bases. These bases are often equipped with advanced energy management systems that ensure optimal performance during fuel dispensing. The integration of innovative technology allows for real-time monitoring and data collection, which can improve the accuracy of fuel measurements. Additionally, the use of energy-efficient components minimizes waste and promotes sustainability. As the industry evolves, incorporating renewable energy sources and innovative technologies will likely become more prevalent in fuel dispenser operations.

What is the role of a submersible pump in fuel dispenser bases?

A submersible pump is essential in fuel dispenser bases as it transfers fuel from the underground oil tank to the dispenser. This type of pump is designed to operate underwater, ensuring it can efficiently move fuel without cavitation or air locking. The submersible pump’s design allows for quiet operation and minimal maintenance, vital for maintaining a reliable fuel supply. Using such pumps, fuel dispensers can achieve higher flow rates and improved dispensing accuracy. Moreover, submersible pumps often have safety features to prevent leaks and spills, enhancing environmental protection.

What is the significance of solenoid valves in fuel dispensing operations?

Solenoid valves are integral to fuel dispenser bases’ functioning as they control fuel flow through the system. These electrically operated valves can open or close rapidly, allowing for precise control over the dispensing process. Operators can use solenoid valves to ensure that the maximum fuel volume is dispensed accurately and safely. They also play a critical role in preventing backflow, which can lead to contamination of the fuel supply. The reliability and responsiveness of solenoid valves make them a vital component in modern fuel dispensing technology, contributing to overall system efficiency and safety.

How do computer systems enhance the use of fuel dispensers?

Computer systems significantly enhance the use of fuel dispensers by integrating various functions into a single platform. These systems can monitor fuel levels, track sales, and manage inventory, providing real-time data to operators. Moreover, advanced computer systems enable automated transactions, reducing customer wait times and improving the overall user experience. Using encoders and other instrumentation, these systems can ensure that the precise fuel volume is dispensed, maintaining high accuracy. The incorporation of computer technology also facilitates remote diagnostics and troubleshooting, further improving operational efficiency.

What safety features are associated with explosion-proof fuel dispenser bases?

Explosion-proof fuel dispenser bases are designed with safety as a top priority, especially in environments where flammable vapors are present. These features include robust construction materials that can withstand high-pressure conditions and prevent ignition sources from causing explosions. Additionally, explosion-proof designs often incorporate safety valves and mechanisms that can automatically shut down operations in case of a fault. Using specialized components, such as explosion-proof solenoid valves and connectors, ensures the system operates safely. By implementing these safety measures, operators can mitigate risks and ensure compliance with industry regulations.

What types of oil pumps are commonly used in fuel dispenser bases?

Various types of oil pumps are utilized in fuel dispenser bases, each serving specific operational needs. Gear pumps, diaphragm pumps, and centrifugal pumps are among the most common types used for fuel transfer. Gear pumps are known for their efficiency and ability to handle high-viscosity fluids, making them ideal for certain oil types. Diaphragm pumps offer excellent precision and are often used in minimal leakage applications. By selecting the appropriate oil pump, operators can optimize performance and ensure the dispensing process runs smoothly and efficiently.