Leading Supplier of High-Safety Explosion-Proof Oil Tanks

As a leading provider of explosion-proof oil tanks in China, we engineer and build robust storage systems that clients can trust. Each unit is crafted to minimize the risk of combustion and delivers superior protection during the handling of flammable liquids, thereby supporting safe, efficient fueling activities.

What is an Explosion-Proof Oil Tank?

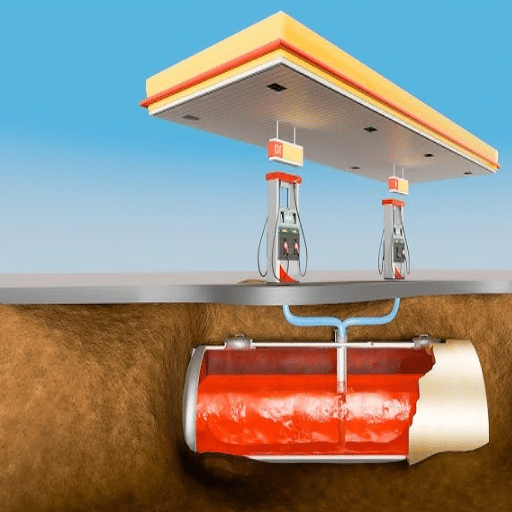

An explosion oil tank is a specialized explosion proof container engineered with advanced technology to safely store flammable substances like gasoline and diesel. Unlike standard tanks, our design incorporates specific materials and structural features that suppress and contain the explosive potential of fuel vapors, making it a critical piece of explosion proof equipment for any site handling explosion oil. It is engineered to withstand internal and external pressures, preventing catastrophic failures and ensuring a safe environment.

Core Features of Our Explosion-Proof Tanks

Our tanks are engineered with state-of-the-art technology and materials to deliver unparalleled safety and reliability.

Advanced Explosion Suppression

Utilizes a specialized alloy barrier material that effectively inhibits combustion, providing superior protection against fire and explosion hazards.

Robust Double-Walled Construction

Features a dual-layer steel structure for secondary containment, preventing leaks and ensuring environmental protection.

International Standards Compliance

Fully certified and compliant with key global safety standards, ensuring regulatory acceptance and your peace of mind.

Key Benefits of Our Explosion-Proof Oil Tank

Choosing our certified explosion proof tank means investing in more than just storage; it's a strategic decision for operational safety and regulatory compliance. Our solutions are engineered to provide tangible, long-term benefits that protect your assets and streamline your fueling processes.

Enhanced Site Safety

Significantly mitigates the risk of fire and explosion, creating a safer working environment that protects your personnel, valuable assets, and local ecosystem.

Operational Continuity

Ensure your operations run smoothly without interruption. Our reliable tanks prevent costly downtime caused by safety incidents or storage failures.

Flexible Application

Our tanks are engineered for versatility, making them the ideal, secure storage solution for gas stations, fleet depots, mining, and construction sites.

Cost-Effectiveness

Achieve long-term savings by reducing potential liability costs and high insurance premiums associated with the risks of storing flammable liquids.

Standard vs. Explosion-Proof Tank: What's the Difference?

- Core Design Purpose: A standard tank is built only for containment. Our explosion proof tank is engineered specifically to suppress and prevent internal explosions.

- Internal Safety Feature: It contains a specialized alloy matrix that absorbs and dissipates heat, effectively quenching any flame front before it can escalate.

- Resulting Safety Level: This inherent safety design meets stricter global certifications, providing a far superior level of protection for handling volatile explosion oil.

How to Choose the Right Explosion-Proof Tank?

- Assess Your Needs: First, determine the required storage capacity and confirm the tank's material compatibility with the specific fuel you need to store.

- Verify Certifications: Ensure the tank complies with necessary industry standards (like UL, API) and meets all of your region's local safety regulations.

- Evaluate Site & Fittings: Consider your installation environment and identify the specific fittings you'll need, such as pumps, gauges, vents, and spill containment.

Comparison Table for the Explosion-Proof Oil Tank

| Parameter | Description | Typical Value/Example |

|---|---|---|

| Capacity | Available storage volume | 10,000L to 50,000L (Customizable) |

| Material | Main tank material | Q235B Carbon Steel, Stainless Steel option |

| Dimensions (L*W*H) | Approximate external size | Varies by capacity (e.g., 6m * 2.5m * 2.5m for 30KL) |

| Wall Structure | Safety construction | Double-walled with interstitial monitoring |

| Explosion-Proof Tech | Suppression method | Aluminum alloy honeycomb barrier material |

| Certifications | Safety & Quality Standards | ISO9001, UL (optional), API |

| Standard Fittings | Included components | Manhole, Fill Port, Vent, Level Gauge, Pump Inlet |

| Working Pressure | Designed operational pressure | Atmospheric Pressure |

Versatile Applications for Explosion-Proof Oil Tank

Retail Fuel Stations

Commercial Fleet Refueling

Mining & Construction Sites

Marine & Port Fueling

Why Choose Our Explosion-Proof Oil Tank

-

Direct-from-Manufacturer Pricing: By eliminating middlemen, we offer a competitive explosion proof oil tank price without compromising on quality.

-

Unmatched Expertise: With years of experience, we possess deep knowledge in the design and production of explosion proof oil tanks.

-

Stringent Quality Control: Every tank undergoes rigorous testing, including pressure tests and weld inspections, to ensure flawless performance.

-

Customized Solutions: We understand one size doesn't fit all. Our engineering team can tailor tanks to your specific capacity, footprint, and fitting requirements.

-

Global Logistics Support: We have extensive experience in international shipping, ensuring your equipment arrives safely and on time.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

From our initial inquiry to final delivery, the entire process was seamless. The tank arrived on schedule and its quality exceeded our expectations. It’s a robust, well-built piece of equipment that we rely on daily for our fleet refueling operations.

Maria Garcia

Logistics Manager

We required a tank with very specific dimensions for our new station. Their team delivered a perfect custom solution at a highly competitive price. The quality is excellent, representing a much better value than sourcing locally. We highly recommend them.

Kenji Tanaka

Project Engineer

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Gas stations are far more than mere thin strips for motor fuel, and they can be magnificent architecture, center-right for […]

Fuel management optimization and operations present significant challenges for fleet operators worldwide. Firms have begun seeking more innovative and more […]

Gas stations are not only complicated but also well-equipped hotels to cater to the daily fueling needs of millions of […]

Hard rock drilling is a special kind of operation that needs the creation and application of tough solutions, very much […]

Understanding Mechanisms, Safety Features, and Efficient Operation Gasoline pumps are an essential part of our everyday lives, yet few would […]

Modern fuel dispenser machines can be recognized as the heart of any modern petrol station, acting as the nucleus that […]

When it comes to investing in a fuel dispenser machine, understanding the cost implications and available options is crucial for […]

Are gas stations a vital daily matter, essentially providing refueling avenues for fuel vehicles? How much do we really know […]

Get Explosion-Proof Oil Tank For Sale

Looking for a reliable and high-quality explosion proof tank? Our expert team is ready to assist you. We provide detailed explosion proof oil tank specifications and competitive pricing to meet your project’s budget and technical needs. Contact us today to secure your assets and ensure operational safety.

Frequently Ask Questions

Q: How does an explosion-proof tank actually prevent an explosion?

A: It uses a special metal alloy honeycomb structure inside the tank. This material absorbs and dissipates heat rapidly, preventing the fuel vapor from reaching its ignition temperature and suppressing the flame front, thus stopping a potential detonation.

Q: What is the main difference between a standard diesel tank and an explosion oil tank?

A: The primary difference is the passive safety system. While a standard tank simply holds fuel, our explosion oil tank is designed with an internal suppression system to mitigate fire and explosion risks inherent with flammable liquids.

Q: Can these tanks be used for liquids other than gasoline or diesel?

A: They are primarily designed for petroleum products. For other chemical storage needs, please consult with our technical team to ensure material compatibility and safety, as different liquids may require different materials and configurations.

Q: What is the typical service life and warranty for these tanks?

A: Our tanks are built for longevity with high-grade steel and protective coatings, designed for a service life of 20+ years. We offer a comprehensive manufacturer’s warranty, details of which can be provided with your quotation.

Q: What are the installation requirements for an explosion-proof tank?

A: Installation is straightforward. It typically requires a flat, stable concrete foundation capable of supporting the tank’s weight when full. We provide detailed foundation guidelines and installation instructions with every purchase.

Q: What aspects of the tank can be customized?

A: As a manufacturer, we offer extensive customization. This includes capacity, dimensions to fit specific site footprints, the number and type of fittings (ports, manholes), and exterior paint color to match your branding.

Q: Do these tanks require regular maintenance?

A: Maintenance is minimal but important. It includes periodic checks of the interstitial space for leaks (on double-wall models), ensuring vents are clear, and inspecting the exterior coating. We provide a full maintenance guide.

Q: How do I get a detailed quote for a specific size?

A: Simply click the “GET A FREE QUOTE” button on this page or contact us via email. Please provide your required capacity, destination port, and any custom requirements for a prompt and detailed explosion proof oil tank price quotation.