Top Container Filling Station Manufacturer in China

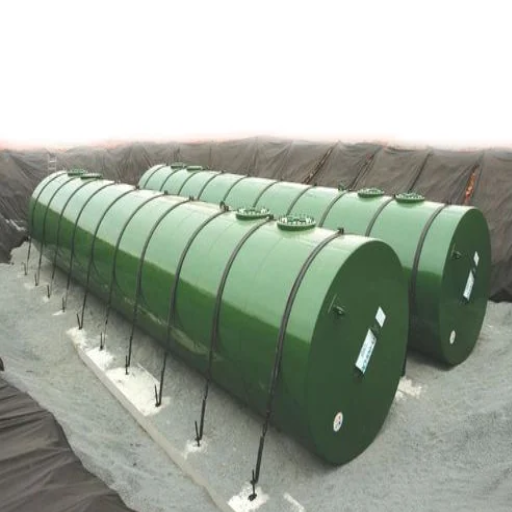

Container filling stations are self-contained units engineered for the storage and dispensing of various liquids, primarily fuels. Constructed within standard shipping containers or similar modular structures, they integrate essential components like storage tanks, pumps, meters, dispensers, and safety systems. These versatile stations provide a mobile and rapidly deployable fueling solution, eliminating the need for extensive on-site construction. They are widely utilized in diverse applications such as construction sites, remote industrial operations, agricultural areas, emergency response scenarios, and logistics hubs, offering efficient and flexible liquid handling capabilities.

What Are Container Filling Stations

Container filling stations are self-contained, integrated systems specifically designed for the storage and dispensing of various liquids, particularly fuels. These units are built within standard shipping containers or equivalent structures, incorporating all necessary components such as storage tanks, pumping equipment, metering systems, and safety features. Engineered for mobility and ease of setup, they provide a flexible and readily deployable solution for liquid handling in a wide range of locations. Essential infrastructure for demanding applications like remote sites, construction projects, logistics centers, and disaster relief efforts, they offer a practical approach to secure and efficient liquid supply.

Functions of our Container Filling Station

Our advanced Container Filling Stations offer integrated functions for efficient and flexible liquid handling.

Mobile Fueling Solution

Provides the ability to deliver fuel directly to remote sites or temporary locations, enhancing operational flexibility and reducing transit time.

Integrated System

Combines secure storage tanks, dispensing pumps, metering, and safety systems within a single, compact unit for streamlined operations.

Rapid Deployment

Designed for quick setup and relocation, making them ideal for emergency response, construction projects, and dynamic operational needs.

Key Advantages Of Container Filling Station

Container Filling Stations offer significant benefits for liquid handling operations, providing flexible and efficient solutions in various settings.

High Mobility & Adaptability

Provides the flexibility to deploy fuel storage and dispensing capabilities quickly to remote or temporary sites as operational needs change.

Self-Contained & Integrated Design

Combines all essential components like tanks, pumps, and dispensers within a single unit, simplifying logistics and minimizing on-site construction work.

Rapid Deployment & Relocation

Enables fast setup and transfer, significantly reducing installation time compared to traditional fixed stations and supporting dynamic project requirements.

Reduced Site Preparation

Requires minimal groundwork and infrastructure compared to permanent facilities, leading to lower costs and faster activation on diverse locations.

How Does a Container Filling Station Work?

- Liquids are held in secure tanks integrated within the container structure, providing contained storage ready for dispensing on demand.

- Pumps move the stored liquid through metering and filtration systems to ensure accurate volume tracking and maintain product quality during transfer.

- The liquid is then dispensed through dedicated nozzles or connection points, managed by control systems for safety, flow rate, and transaction monitoring.

How to Choose the Container Filling Station for Your Application?

- Determine the type and quantity of liquid you require to store and dispense, evaluating factors like density, needed capacity, and dispensing speed.

- Consider the intended installation site, including accessibility, available space, power supply options, environmental conditions, and local safety standards.

- Evaluate necessary features such as integrated monitoring systems, security access controls, specific filtration requirements, and compatibility with existing equipment.

Comparison Table For Container Filling Station Specifications

| Parameter | Description | Parameters |

|---|---|---|

| Storage Volume | Total capacity for liquid storage | Variable (e.g., 10,000 - 60,000+ Liters) |

| Container Dimensions | Size based on standard ISO shipping container standards | 20 ft, 40 ft, or custom sizes available |

| Dispensing Rate | Flow rate capabilities of the integrated pump and meter | Variable (e.g., 40 - 100+ Liters per minute) |

| Number of Dispensers | Quantity of dispensing nozzles or connection points | Single, Dual, or Multiple options |

| Fuel Compatibility | Types of liquids suitable for storage and dispensing | Diesel, Gasoline, Jet Fuel, Water, or specific chemicals |

| Integrated Equipment | Included components like pumps, meters, filters, safety | Pumps, Flow Meters, Filtration, Safety Valves, Control Panel |

| Power Source | Method used to power the station's systems | Grid Connection, Diesel Generator, Solar (optional) |

| Safety Systems | Built-in features for safe handling and containment | Leak Detection, Overfill Protection, Emergency Shut-off, Fire Suppression |

| Operating Environment | Conditions the unit is designed to withstand | Specific Temperature Ranges, Weather Protection, Hazardous Area Zones |

| Mobility | Features facilitating transport and relocation | ISO Container Corner Castings, Forklift Pockets (optional) |

Top Applications of Container Filling Station

Construction Sites

Remote Operations & Mining

Emergency Response & Disaster Relief

Logistics & Transportation Hubs

Why Choose Our Container Filling Station

-

Exceptional Portability & Flexibility: Engineered within standard container frames for easy transport via road, rail, or sea, allowing rapid deployment to various sites as needed.

-

Quick Setup & Operational Readiness: Designed for fast connection and commissioning, enabling immediate liquid storage and dispensing capabilities with minimal on-site assembly.

-

Integrated & Comprehensive System: Combines secure storage tanks, pumping, metering, and safety features in a single unit, providing a complete and efficient liquid handling solution.

-

Durable Construction for Demanding Sites: Built with robust materials and protected within the container structure to withstand harsh environmental conditions and ensure reliable performance.

-

Reduced Infrastructure & Civil Work: Requires less extensive site preparation and permanent infrastructure compared to traditional fixed stations, lowering costs and speeding up implementation.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

“Our Container Filling Station was a game-changer for our remote project. It arrived ready to go, and setup was incredibly fast. Having reliable fuel access directly on site cut down on logistics headaches significantly. It’s durable, easy to operate, and has proven essential for keeping our machinery running efficiently without downtime.”

David Kim

Site Manager

“We needed a flexible fueling solution for a temporary distribution center, and the Container Filling Station was perfect. Its self-contained design made deployment seamless. The integrated pumps and metering are accurate and dependable. It truly provided a rapid and efficient way to manage fuel for our fleet on location.”

Maria Garcia

Operations Coordinator

Discover the Power of Container Filling Station

What is the purpose of a container filling station?

The primary purpose is to provide a portable, self-contained solution for storing and dispensing various liquids, especially fuels, in locations where traditional fixed fueling infrastructure is unavailable or impractical. They are ideal for construction sites, remote areas, emergency response, and temporary events, offering flexible and rapid deployment capabilities for efficient liquid supply.

How does a container filling station work?

A container filling station operates as a fully integrated system. Liquid is securely stored in tanks housed within the container. When dispensing is required, an electric or diesel-powered pump draws the liquid from the tank, pushes it through filters to remove impurities, and then through a calibrated meter for accurate volume measurement before it is delivered via a dispensing nozzle or connection point.

Can you fill up petrol cans at container filling stations?

While primarily designed for refueling vehicles or equipment with larger tanks, some container filling stations may be configured with features like a separate dispensing point or nozzle specifically for smaller containers like petrol cans, provided it complies with safety regulations and is equipped for such a function. Safety protocols for static electricity and spill containment are critical.

How long does it take a container filling station to refuel?

The refueling time depends significantly on the dispensing rate of the station’s pump and the volume of the receiving tank. High-capacity pumps designed for commercial or industrial use can dispense fuel much faster than standard retail pumps. Therefore, a large vehicle might take several minutes, while a smaller tank would be much quicker, contingent on the equipment’s flow rate.

How do you maintain a container filling system?

Maintaining a container filling system involves regular inspections of the tanks, pumps, hoses, and dispensing equipment. Key tasks include checking for leaks, cleaning or replacing filters, calibrating meters for accuracy, testing safety systems (like emergency stops and leak detection), ensuring proper grounding, and inspecting the container structure for integrity and corrosion. Following manufacturer guidelines and safety standards is essential.

How to set up a container filling station?

Setting up a container filling station involves transporting the unit to the desired location using appropriate lifting equipment (like a crane or forklift). The site must be level and suitable for containment in case of spills. Once positioned, the station needs to be connected to a power source (grid, generator, or solar) and properly grounded. Tanks are filled, systems are calibrated and tested, and safety procedures are established before operation begins.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Gas stations are common in our daily lives, whereas the design details are often overlooked—until we question them. These are […]

The high-pressure pump at gas stations is a powerhouse, refueling cars and getting things in motion. But emergencies can arise […]

Making Smart Investment Decisions for Operational Excellence and Customer Satisfaction 🚀 Transform Your Fuel Station Success In retail fuel operations, […]

Taking an important step to keep gas stations working efficiently, undersoil oil tanks generally go unnoticed by the average customer. […]

Gas stations are a staple of modern infrastructure, yet their design often goes unnoticed as we come and go in […]

The idea of gas stations is changing in the land of Connecticut, as it is starting to infuse some elements […]

Gasoline is a very important product for the modern world as it fuels the transportation system and, more or less, […]

The evolution of transportation has been creeping at a good pace, with the filling stations assuming a crucial role in […]

Mobilize Your Fueling with Container Stations

Enhance your operational efficiency with our innovative container filling stations. Engineered for rapid deployment and reliable performance, these self-contained units provide essential liquid storage and dispensing wherever you need it. Experience unmatched flexibility for construction, logistics, and remote sites. Ensure secure, efficient liquid supply for your critical operations. Contact us today to learn how our cutting-edge container solutions can optimize your workflow!

Frequently Ask Questions

Q: What is a container filling station?

A: A container filling station is a modular, self-contained unit typically built within an ISO shipping container, designed for the secure storage and dispensing of liquids like fuels. It includes tanks, pumps, meters, and safety systems, offering a portable and flexible fueling solution.

Q: What types of liquids are suitable for container filling?

A: Container filling stations are engineered to handle various liquids, most commonly diesel, gasoline, and jet fuel. Depending on the specific design and materials, they can also be adapted for storing and dispensing other fluids like water, lubricants, or certain chemicals, facilitating diverse container filling needs.

Q: How do container filling stations differ from filling containers at petrol stations?

A: Unlike filling containers at petrol stations, which are fixed retail locations, container filling stations are mobile and can be deployed directly to specific sites like construction zones or remote areas, providing dedicated, on-site fuel access tailored to operational needs.

Q: Where are container filling stations typically used?

A: Container filling stations are widely used in industries requiring flexible or temporary liquid dispensing, such as construction, mining, agriculture, emergency services, logistics, and remote power generation sites, where establishing permanent infrastructure is impractical.

Q: What safety features are included in container filling stations?

A: Safety features for container filling stations commonly include double-walled tanks for spill containment, emergency shut-off buttons, overfill prevention systems, grounding points to prevent static discharge, fire suppression systems, and secure locking mechanisms.

Q: What regulations apply when using a container filling station to fill containers?

A: When you fill containers using these stations, you must comply with local environmental regulations for spill prevention, fire safety codes, hazardous material handling standards, and potentially specific industry regulations governing fuel storage and dispensing.

Q: What are the benefits of using a container filling station compared to permanent infrastructure?

A: Key benefits of using a container filling station include rapid deployment, mobility, reduced need for extensive site preparation, integrated systems, and the ability to easily relocate the station as operational needs change, offering significant time and cost savings.

Q: How to set up a container filling station?

A: To set up a container filling station, you typically transport the unit to a level, secure site using a crane or heavy-duty forklift. Connections for power and dispensing are made, tanks are filled, and safety checks are performed. The integrated design streamlines setup compared to building from scratch.