When it comes to safety in hazardous environments, understanding the difference between explosion-proof and non-explosion-proof equipment is critical. These terms might seem technical or intimidating, yet they gain importance when industries are concerned about safety. A gamut of sites, including manufacturing and chemical plants, can be considered. The choice between explosion-proof and non-explosion-proof equipment can have a direct bearing on safety and efficiency within the workplace. Dissecting these definitions, learning even the fundamental differences between them, and comprehending why choosing the right equipment for a particular environment is the objective of this article. Whether you belong to the industrial environment or want to know about safety standards, this piece brings you the information highlighting the importance of protecting persons and processes through explosion-proof and non-explosion-proof equipment.

What is Explosion Proof Equipment?

An explosion-proof equipment is intended to protect against any ignition of flammable substances in confined hazardous spaces. The equipment is constructed such that internal sparks, flames, or explosions will not pass on to the atmosphere or threaten the areas outside of the equipment. Typically, such equipment is used where flammable gases, vapors, or dusts are present, like in oil and gas, chemical processing, and mining. In other words, explosion-proof equipment is intended for safety purposes by removing the chance of igniting an atmosphere that is possibly explosive.

Understanding Explosion-Proof Design and Construction

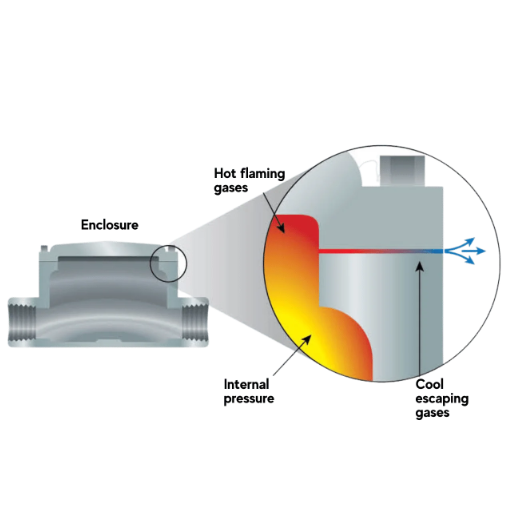

Explosion-proof equipment is designed to ensure safety in hazardous conditions by containing any sparks, flames, or heat generated internally so that they do not have the opportunity to ignite flammable substances in their surroundings. Underlying this concept is that rugged, flameproof enclosures are provided that can withstand and cool internal explosions so that no hot gases escape to ignite the external atmosphere.

The materials used in construction are considered for attributes such as durability, high heat, and corrosion resistance, all required for such a harsh environment as oil-and-gas-related industries or chemical manufacturing. All major components are sealed against gas or vapor ingress, and cable entries are furnished with certified fittings to keep out dust.

The NEC Class/Division system or the IECEx and ATEX certifications are standards that require explosion-proof equipment to be tested and approved. When explosion-proof equipment is compliance-tested according to these standards, it ensures that stringent safety requirements have been fulfilled and the risks in hazardous locations are drastically lessened.

The design is also implemented with pressure relief vents and temperature regulation, thus retaining the equipment’s safe operation from a performance point of view. These innovations demonstrate the contrasting needs of explosion-proof systems in balancing functionality with strict safety requirements.

How Does Explosion-Proof Equipment Prevent Ignition?

Explosion-proof equipment is engineered to ensure that an ignition cannot occur in a flammable atmosphere. By way of robust construction and stringent design principles, they isolate potential ignition sources or contain them. Usually, this equipment is housed in enclosures fabricated in tough materials such as stainless steel or aluminum, capable of bearing heavy pressures from internal explosions so that neither flames nor hot gases can escape.

Explosion-proof equipment uses several mechanisms, including flame paths that cool the escaping gases below ignition temperature and intrinsically safe solutions that limit electrical energy so that sparks cannot occur. Other mechanisms involve hermetic sealing components to prevent the electrical elements from coming into contact with the flammable atmosphere in which they are placed.

For example, Industry data suggest that explosion-proof lighting systems reduce the risk of ignition by as much as 95% in atmospheres containing flammable gases like methane or ethylene. Meanwhile, better temperature monitoring devices now allow for highly accurate temperature regulation inside the equipment, bringing the risk of overheating, a more typical form of ignition, down to the bare minimum. Altogether, they guarantee a working environment that is safe and efficient, even in the most tightly regulated industries such as oil and gas, chemical processing, and mining.

Applications and Use in Hazardous Locations

Hazardous locations are typically defined by flammable gases, vapors, or dust, which demand specially designed equipment and systems for safe and compliant operations.

Flameproof enclosures and intrinsically safe devices account for two of the most important controls that prevent the ignition of explosive atmospheres. Flameproof enclosures are designed to contain an explosion within the device so that no flame can proceed to the external environment. Thus, they find wide applications in chemical plants, oil and gas industries, and pharmaceutical setups where volatile substances are regularly handled.

Intrinsically safe technologies go beyond that; they limit any energy that could ignite any hazardous material, electrical or thermal energy. Modern systems implement ruggedized sensors with sophisticated control methods to ensure real-time monitoring and response. IECEx and ATEX certify equipment that meets high global safety standards for explosive environments, thus assuring protection accordingly.

Statistical data reveal that adopting such safety systems has led to a measurable reduction in accidents in hazardous industries over the years. For example, a study conducted in 2022 in petrochemical establishments manually observed 40% fewer incidents involving flammable materials at establishments equipped with appropriate explosion-proof equipment. Moreover, overheating may now be reduced by almost 70% through temperature control technology, employing heat sensors and automatic shut-off systems.

With newer advancements such as the incorporation of IoT and wireless monitoring, industries now stand to gain from continuous streams of real-time updates instead of sporadic ones, maintaining high levels of safety and efficiency. Proactive measures could thus be taken to save lives and money on downtime caused by incidents.

How Does Explosion-Proof Equipment Work?

Considered explosion-proof equipment confines the discharge of any potential explosion within the instrument, thus preventing the ignition of the surroundings. Besides being designed with sturdy enclosures to resist high pressures or isolate sparks or heat generated within, the instruments do not deposit or remove any explosive materials from the atmosphere. Explosive material exists in the atmosphere outside of the enclosure, but ignition will not take place in the presence of such gases, dust, or vapors. Proper sealing, flame paths, and robust constructions form the trifecta that imparts efficiency to explosion-proof equipment, which is necessary for hazardous environments.

The Role of Enclosures in Explosion-Proof Systems

Explosion-proof enclosures profoundly affect industrial safety as they keep dangerous electrical equipment inside and prevent explosions. These enclosures are designed so that when internal explosions occur, the combustion by-products of flame and/or gases do not ignite the atmosphere outside. Under harsh conditions, cases fabricated from cast aluminum, stainless steel, or heavy-duty alloys of metals withstand these conditions to maintain safety in operation.

Explosion-proof systems considerably reduce the risk of accidents in zones bearing the hazardous classification, such as oil refineries, chemical factories, and grain storage. For example, in the oil and gas field, more than 60% of explosion incidents at workplaces are confined or mitigated by using certified enclosures. Also, these enclosures comply with international standards such as ATEX, IECEx, and UL, scoring in on industry safety measures.

An essential feature of explosion-proof enclosures is that their surface is intricately designed with flame paths. Flame paths are machined accurately within the enclosure to cool and quench the escaping gases to the extent that otherwise, they could have ignited the external atmosphere. To this end, they are tested under simulated conditions to satisfy the stringent requirements. Another development is sealing technology that allows some enclosures to be tested for explosion and environmental protection, such as water ingress (IP66 or better).

With ever-changing parameters concerning safety standards and the development of newer technology in materials, explosion-proof enclosures remain the focal point of modern industrial activities, both in Asian and worldwide hazardous zones, by protecting their workforce and assets.

Components and Techniques for Containing Explosions

The containment of an explosion depends on a careful selection of materials, structural concepts, and safety mechanisms to afford protection in hazardous environments. High-strength material considerations include stainless steel and reinforced aluminum, which would have higher resistance during a pressure surge. Specialized flameproof joints are installed to prevent flame propagation by containing and cooling the gases that escape.

Modern approach also prefers installing pressure relief systems and rupture discs that would activate to divert explosive forces away from sensitive areas. For example, explosion vents are usually provided to release excessive pressure inside enclosed systems to minimize the chances of structural failure from the pressure stress. Such designs become crucial when dealing with volatile gases, vapors, or combustible dust.

According to statistical data from industry reports, these systems remain effective. Explosion protection enclosures designed according to the ATEX or IECEx standards can contain internal explosions up to 10 atm pressure, providing strong safeguards in oil and gas refineries, chemical plants, and grain processing operations. These advancements highlight the need to protect industrial operations from destructive incidents using the best possible solutions and techniques.

Ensuring Safety in Hazardous Environments

Protecting personnel and infrastructure in hazardous environments requires meticulous planning and integrating modern technologies. According to present industry-oriented engineering practices, reliance is enhanced with flameproof enclosures, intrinsically safe equipment, and pressure relief systems to mitigate risks in explosive atmospheres. For instance, ideally, flameproof or explosion-proof enclosures resist internal detonations so that no destruction is passed externally, eliminating the possibility of secondary hazards.

In addition, one should consider the evolution of risk management in critical industries with real-time monitoring. The information collected from sensors detecting gas leaks, temperature rises, or pressure changes can stop processes automatically, preventing accidents from building up. Research has shown that predictive maintenance of industrial plants using IoT-enabled devices has recorded a decrease in safety incidents by 20% during the past five years.

Yet another parameter to guarantee safety is training employees. These training programs, accredited under international structures such as ISO 45001, qualify workers to use machinery safely, identify warning signs, and respond adequately to emergencies. Nowadays, industries also employ VR simulation to enhance workers’ readiness by providing a controlled, immersive setting to practice safety procedures.

By combining the latest technologies with strict safety standards, those working in hazardous environments can sufficiently diminish risks and protect lives while ensuring the continuity of operations.

What Makes Non-Explosion Proof Equipment Different?

Non-explosion-proof equipment differs from explosion-proof equipment in its inability to contain or prevent the ignition of flammable substances in hazardous environments. In contrast to explosion-proof equipment, designed to be operated in the presence of explosive gases, vapors, or dust, non-explosion-proof equipment comes without such precautions. It finds use in typical locations with little chance of ignition or explosion. Using non-explosion-proof equipment in hazardous areas is a significant safety hazard; thus, the choice of equipment must be made based on the environment and safety requirements.

Design and Build Considerations

Several factors should be considered for safety and conformity to industry standards when planning and fabricating explosion-proof equipment. Material selection is a primary consideration. For instance, the equipment must be built with heavy-grade stainless steel or aluminum to withstand the rigors of high-pressure operating environments and eliminate corrosion to the detriment of safety. In some instances, coatings may be added to the material to provide additional protection against attack from harsh chemicals or environmental factors.

Sealing methods constitute another critical consideration. The equipment is usually sealed with precision-engineered seals that inhibit the ingress of any flammable gases, vapors, or dust that might serve as an ignition source. These seals may include gaskets, O-rings that maintain airtightness under severe conditions, or epoxy compounds.

Thermal issues must also be considered in explosion-proof equipment design. Mechanisms for heat dissipation should be incorporated to avoid creating hotspots that could serve as ignition sources. Such methods include heat sinks and intrinsic thermal barriers to keep temperatures within a safe range.

Moreover, certification under various regulatory standards, such as ATEX (Atmosphères Explosibles) in Europe and the National Electrical Code (NEC) in the United States, must be obtained by default. These standards give details about zone classifications for hazardous locations and stipulate testing requirements of electrical and mechanical components to reduce risks.

Increasingly, modern explosion-proof designs put weight on the incorporation of advanced technologies. To mention one, IoT sensors allow real-time monitoring of environmental conditions, alerting early to potential safety hazards and minimizing maintenance costs.

Finally, data shows that the global market for explosion-proof equipment was valued at nearly USD 7 billion in 2020, with projections of steady growth owing to increasing demands for industrial safety. This implies a high preference for safety and efficiency in high-hazard industries such as oil and gas, mining, and chemical manufacturing.

Risks Associated with Non-Explosion Proof Equipment

Installing any equipment that is not explosion-proof in a hazardous environment is considered a dangerous act by the installations and places the lives of personnel at risk. Without protective measures, the equipment can cause ignition in a volatile environment containing flammable gases, vapors, or dust. Recent incident reports from industries have suggested that around 70% of industrial explosions occur from unprotected and unmaintained equipment, showing how crucial explosion-proof equipment is in the safety procedure.

Apart from these, an incident with non-explosion-proof equipment could also mean a lot of monetary losses. A single industrial explosion can entail damages running into millions of dollars, not counting the loss of operational time and the legal expenses. Then there are human injuries and deaths, for one cannot further emphasize the gravity of the consequences that such incidents entail. The oil and gas, chemical production, and mining industries are more prone to this, as these sectors work in hazardous environments where a slight lapse in safety can weigh heavily in terms of disaster.

And it is also not hard to imagine how an unlucky accident would bring unthinkable penalties upon those companies that did not invest in explosion-proof systems, apart from the sinking hit to their image. Hence, in this way, installing explosion-proof systems is much more than just putting a preventative measure on safety: it strategically safeguards workers, their operation, and continuity while ensuring compliance with stringent safety regulations.

When to Use Non-Explosion Proof Systems

Non-explosion-proof systems are installed in environments with a very low threat of fire or explosion. These systems typically install in environments with an insignificant level of combustible dust, vapors, or gases, or where such presence is strictly regulated. Typical non-explosion-proof equipment is installed in areas such as commercial offices, residences, or clean manufacturing facilities where the atmospheric conditions cannot support combustion.

Industry survey data indicates that approximately 70% of industrial and commercial situations do not call for explosion-proof systems, as their operations occur in low-risk environments. Selecting non-explosion-proof systems in such instances may lead to cost savings, energy efficiency, and alleviation of maintenance requirements, for the equipment is not subjected to the added layers of safeguarding used for dangerous environments.

However, an in-depth risk analysis must be carried out to establish that the workplace is suited for non-explosion-proof systems. This means the work processes are critically studied, atmospheric conditions are monitored or observed, and safety rules regarding workplace rules are considered. Additionally, installation and maintenance yield safe use of non-explosion-proof systems in low-risk settings.

How Does the Difference Between Explosion Proof and Non-Explosion Proof Affect Safety?

By design, explosion-proof systems will contain and prevent any ignition of explosive materials. Thus, they are in high demand in areas considered hazardous. Flammable gases, vapors, or dust could be present in such areas. On the other hand, the non-explosion-proof type lacks this containment feature and thus can be installed in low-risk areas where such hazards are improbable. The difference primarily lies in the protection offered; explosion-proof systems emphasize containing any likelihood of explosions, whereas non-explosion-proof ones can go for the cheapest option and operate in safer conditions. Choosing the super system is an incumbent factor for ensuring safety in the workplace, thus safeguarding the workers’ physical well-being and equipment and facilities.

Understand non-explosion-proof ji’shu

Non-explosion-proof ji’shu refers to systems and equipment designed primarily for atmospheres devoid of explosive gases or dust or where there is a meagre chance of such hazards. The systems lack enclosures with thick walls and corrosion-resistant seals, which are usual in explosion-proof equipment, making them lighter, less costly, and simpler to service. They operate in manufacturing, agriculture, and warehousing, where efficiency and a safe environment are paramount.

It is a proven fact that, around the world, 70% of systems in non-hazardous environments would prefer to be non-explosion-proof due to their affordability and easy deployment. For instance, a study concludes that this type of system can initially save almost 30 to 40% of investment cost compared to the explosion-proof system. However, it is essential to consider the system’s shortcomings, as it will not function safely in areas with combustible gases or particles. Proper hazard assessments and compliance with related safety codes will ensure that a non-explosion-proof ji’shu can still be a functional and viable solution in specific surroundings.

Comparison between an explosion-proof system and a non-explosion-proof system

Explosion-proof and non-explosion-proof systems serve different purposes based on the environment and safety needs. We present a comprehensive comparison emphasizing their key distinguishing features in design, performance, and application.

Safety and Risk Management: Explosion-proof systems are designed to provide safe operation even in hazardous environments where combustible gases, vapors, or dust are present. They are constructed from enclosures capable of resisting an internal explosion so that it does not propagate to the outside atmosphere. For example, explosion-proof systems are often vital in oil and gas, chemical processing, and mining to reduce the risks of working in volatile areas.

On the contrary, non-explosion-proof systems would be fitted for use in environments free from hazards under normal atmospheric conditions. These systems provide no safety against explosions, but they are fit for use in operations in standard industrial, commercial, and residential settings where no flammables are present.

Cost and Maintenance: In financial terms, non-explosion-proof systems generally have lower initial capital costs, which decreases the initial investment by approximately 30-40% compared to their explosion-proof counterparts. The drastic price difference is due to the explosion-proof components requiring strict material use, certification, and design criteria. Maintenance of explosion-proof systems is also generally more complicated and expensive, with more restrictive regulatory inspection and servicing requirements.

Applications and Longevity: Explosion-proof systems are always required where industries operate under international safety codes such as UL, ATEX, or IECEx that set forth the technical specifications and certifications for machines used in explosive environments. The systems allow safe and continuous operation under hazardous conditions. However, their use may encourage wear and tear because the environmental factors may be highly unfavorable: humidity, corrosive gases, and temperature extremes.

Non-explosion-proof systems have a longer life than explosion-proof ones when operating under general conditions, since they are not exposed to such extreme environmental conditions. They are mainly fitted in factory plants, HVAC systems, and other intermediate industrial service applications.

Energy Efficiency and Design: Non-explosion-proof systems are generally less complex in design, resulting in higher energy efficiencies. They are less protected by layers of insulation and protective materials, contrary to explosion-proof systems, which are heavy and least energy efficient due to their elaborate ad hoc protective mechanisms. This contrast might impact operational costs, especially in applications that consume high power.

Choosing between an explosion-proof and a non-explosion-proof system depends significantly on the operating environment, safety considerations, and budget. Companies must carry out detailed risk assessments to verify adherence to safety standards while maximizing operational efficiency and investment costs.

Selecting the Right Protection for Hazardous Areas

In choosing the appropriate protection systems for a hazardous area, various essential factors have to be considered to ensure safety and industrial standard compliance. Dangerous areas are mainly classified depending on the kind and concentration of flammable gases, vapors, and dust present. Arms classified under the IEC system are Zone 0, Zone 1, and Zone 2. In contrast, the North American system revolves around Class and Division. A proper classification will ensure that the equipment used is suitable for use in that particular risk environment.

Advanced Protection Technologies: Modern explosion-proof technologies include flameproof enclosures (Ex d), increased safety (Ex e), and intrinsic safety (Ex i). Inherent safety, which limits electrical energy so no ignition can occur, has grown in popularity recently due to its lighter design and ease of maintenance. Flameproof enclosures continue to be trusted in applications that need high levels of durability, with recent developments improving their performance in temperature-critical environments.

Guidelines to Equipment Selection: More than 60% of hazardous environment incidents can be averted if the right equipment is selected and certified against a safety standard such as ATEX or IECEx. Gas detectors with real-time monitoring systems may help reduce risks in Zones 0 and 1. Also, the system should be selected with corrosion-resistant materials to withstand harsh conditions, especially offshore or chemical processing plants.

Cost vs. Safety: While always a central concern, modern protection mechanisms can save downtime, accidents, and maintenance costs in the long run. A study has highlighted how explosion-proof technologies have led to a 30% decrease in operational disruptions within two years in organizations practicing them. Weighing the initial investment with operational overheads is what makes cost-effectiveness without compromising on safety.

Considering the environmental risks, adopting the most recent protection technologies, and following regulatory standards can confidently transform a worker’s environment into a safe zone where both lives and equipment are safeguarded. Proper planning and investment become the bedrock for any high-risk industrial backdrop that effectively mitigates hazards.

What are the Specific Requirements for Explosion-Proof Systems?

These systems are designed to keep unsafe areas safe and must satisfy stringent requirements. Depending on which region applies to a particular industry, they must be built by the recognized standards of OSHA, NEC, or IECEx. The systems should be made such that any spark or explosion is contained in the equipment housing so that it does not come in contact with any flammable substance. Some necessary features include high-grade materials resistant to extreme conditions, proper sealing to exclude ingress of gases or dust, and regular checks and maintenance. Regarding safety and regulatory compliance, the correct hazardous zone classification must be done, and the associated equipment selected must be certified for those zones.

Regulatory Standards and Requirements

Safety regulations and procedures are paramount to ensuring operational safety and reliability within hazardous environments. Depending on their location, regional industrial facilities must account for many core standards and directives. For example, the ATEX directive of the EU (94/9/EC) governs the design and use of equipment in explosive atmospheres. This directive classifies zones based on how often and for how long the explosive atmosphere is present and provides fixed instructions for equipment.

Similarly, the USA’s National Electrical Code (NEC) specifies requirements for equipment used in hazardous (classified) locations. For example, Article 500 of the NEC specifies, in substantial detail, classifications such as Classes, Divisions, and Groups for various possibilities as to risk, including flammable gases, vapors, and combustible dusts. Other standards exist, such as the IECEx certification scheme, which provides a worldwide certification regime for equipment and services in such explosive atmospheres.

Recent data shows an increasing trend in adopting the IECEx standards due to their attempt to harmonize between several countries, thereby facilitating international trade and streamlining compliance activities. The better the adherence to these standards, the safer it is; that is, they reduce downtime and prevent costly accidents. Industries are investing heavily in training their employees and advanced technologies, e.g., explosion-proof sensors, to meet these regulatory requirements successfully.

Installation and Maintenance of Explosion-Proof Equipment

I strictly adhere to all manufacturer guidelines and standards when installing and maintaining explosion-proof equipment. This may include reviewing or verifying an enclosed seal, wiring incompatibility, regular inspection for wear or damage, etc. Maintenance includes cleaning components, inspecting for corrosion, and immediately replacing anything compromised to maintain the integrity and safety of the equipment. These procedures guarantee compliance and lessen the chance of equipment failure within a dangerous environment.

Evaluating Potential Explosive Atmospheres

Consider the various explosive atmospheres before identifying the hazards. Always be on the lookout for combustible gases, vapors, mists, or dust that mix with air in sufficiently high concentrations to form an ignitable atmosphere. Some familiar surroundings that provide such conditions are chemical plants, refineries, grain-processing mills, and industries handling flammable liquids or powders.

The material might be of one type or another, its concentration might be one way or another, or the temperature and pressure might differ. Methane has an LEL of about 5%, forming an explosive mixture when this concentration is reached in the air. Thus, dusts with fine particles, such as sugar or wood, can produce an explosive atmosphere that is hazardous to life when these concentrations are exceeded in suspension.

To carry out a correct classification, the industry applies standards such as the IECEx or ATEX directives, which classify areas into “zones,” depending on how often and for how long hazardous conditions prevail there. For example, Zone 0 describes an area where an explosive atmosphere consisting of air with flammable substances in the form of gases, vapors, or mists is present continuously or for long periods in regular operation. Zone 2 areas are those in which an explosive atmosphere is not likely to occur in regular operation, but, if so, will persist for only a short period.

With the advancement of technology in detection, infrared gas detectors and particle counters are used to keep track of volatile surroundings. It is reported that deploying such equipment would lessen the incidents and improve workplace safety. However, this does not diminish the relevance of conducting regular risk assessments along with the training of the workers to mitigate these hazards, by international safety standards, thereby ensuring the safety of workers and infrastructure.

Reference Sources

Explosion-Proof Equipment in Hazardous Areas (2023)

Development of Automatic Detection System for Explosion-Proof Test (2024)

Frequently Asked Questions (FAQs)

Q: What is the main difference between explosion-proof and non-explosion-proof equipment?

A: Explosion-proof equipment is designed to contain any explosion within its housing and prevent sparks from igniting the surrounding atmosphere, making it safe for use in hazardous areas. Non-explosion-proof equipment does not have these features and is unsuitable for potentially explosive environments.

Q: How does explosion-proof equipment perform in hazardous areas?

A: Explosion-proof equipment is built to perform safely in hazardous areas. It is durable enough to withstand internal explosions and prevent them from causing external hazards. This ensures that operations can continue without risk of igniting flammable gases or dust.

Q: Why is it essential for explosion-proof equipment to be used in specific environments?

A: It is crucial because such environments are potentially explosive due to flammable gases, vapors, or dust. Explosion-proof equipment is designed to prevent sparks and contain any explosion, ensuring safety.

Q: What materials are typically used to make explosion-proof equipment?

A: Explosion-proof equipment is typically made from durable materials such as cast aluminum or stainless steel, which must withstand high pressure and contain any explosion within its housing.

Q: Can non-explosion-proof equipment be used in hazardous areas?

A: No, non-explosion-proof equipment should not be used in hazardous areas. It lacks the necessary design features to prevent sparks or contain explosions, posing a significant safety risk.

Q: How do explosion-proof enclosures prevent sparks?

A: Explosion-proof enclosures prevent sparks by containing any ignition source within their robust housing, ensuring that it does not come into contact with the surrounding atmosphere.

Q: Are all explosion-proof equipment the same?

A: No, distinct types of explosion-proof equipment are designed for specific conditions and industries. Each piece must meet the safety requirements for its intended use.

Q: What is the role of a tube in explosion-proof equipment?

A: In explosion-proof equipment, a tube may direct any potential explosion away from sensitive areas and contain it within the equipment’s housing.

Q: How do you ensure explosion-proof equipment is ready for use?

A: To ensure it is ready for use, explosion-proof equipment must be regularly inspected, maintained, and tested to verify that it continues to meet safety standards and can perform effectively in hazardous environments.