If we take efficient transfer of fuel or any other liquid from one place to another, transfer pumps are among the most important tools required by many industries. Be it for refueling machinery and means for agricultural use, or for industrial applications, time is what transfer pumps save, whereas waste causes it. In this guide, go into the realm of transfer pumps, with an emphasis on fuel and electric transfer pumps. The article aids you concerning whether to make decisions for these essential tools by first describing what they are and how they operate, what they are used for, and the pros that accompany them. It will be an easy-to-follow guide to see how transfer pumps can ease your work and satisfy your specific needs for liquid transfer.

Understanding Transfer Pumps

Transfer pumps are meant to efficiently and safely move liquids from one place to another. They are usually instrumental in fuel transfers, water management, or industrial operations. Having a pump for transfer purposes makes things easier with bulk transfer, saving on time for both the manual effort involved. Coming in several types, including fuel transfer, electric transfer, one may find the kind that suits their needs concerning either liquid or flow rate.

What is a Transfer Pump?

A transfer pump is a versatile device designed to efficiently and reliably move liquids from one place to another. Some of the main applications include fuel transfer, water removal, chemical handling, and distribution of oils or other liquids.

Depending on the aspect, the following are the criteria for choosing a transfer pump: type of liquid being moved, flow rate, and power source. For example:

- Flow Rate: Transfer pumps are rated by their flow rate, in GPM (gallons per minute) or LPM (liters per minute). Higher flow rates are suited for moving large volumes of liquids, while small flow rates are required for finer work.

- Power Source: Transfer pumps are available mostly in manual, electric, and gas. Electric transfer pumps find their place for indoor use and controlled environments, whereas the tasks can be readily handled by gas pumps in distant areas.

- Liquid Compatibility: Different pumps are built for different liquids, such as fresh water, saltwater, fuels, or chemicals. An incorrect pump type in use could prove detrimental or hazardous.

Thanks to more advanced technology, transfer pumps come with new levels of automation, with features such as automatic shut-off, corrosion-resistant material, and variable speed settings. For example, fuel transfer pumps are constructed with explosion-proof motors and heavy-duty hoses to meet safety requirements, whereas water transfer pumps emphasize lightweight designs to encourage portability.

Nowadays, it is seen that transfer pumps can save a large amount of time and effort in conveying liquids. On one hand, the electric transfer pumps can work up to 12 GPM for residential works, on the other, the industrial grade ones go as far as 300 GPM for huge operations. This makes transfer pumps indispensable equipment on both small and large scales for various other uses.

Types of Transfer Pumps

Transfer pumps are of different kinds, with each type meant for a specific kind of application. Let us look at some of the most common types with their identifying characteristics:

1. Centrifugal Transfer Pumps

These pumps are widely used because of their ability to transfer great volumes of liquid. Centrifugal pumps work on the principle of imparting kinetic energy to the fluid by rotating impellers, thus moving it. For instance, such pumps are used in irrigation, water supply, or industrial fluid transfer. Large systems operate at flows ranging from 50 GPM to over 5,000 GPM.

2. Submersible Transfer Pumps

These pumps, as the name says, are meant to operate while being completely submerged in a liquid and are very good for draining flooded areas, water tanks, or wells. They are very economical to use and possess a high durability rating, while some have motors sealed to prevent any damage caused by exposure to liquids. The transfer rate of these pumps often falls into a range from around 20 GPM for small residential models to over 1,000 GPM for bigger industrial applications.

3. Diaphragm Transfer Pumps

Generally capable of handling viscous or abrasive liquids, diaphragm pumps can transfer high-viscosity fluids, slurries, or liquids with solids. The pumps are common in industries such as chemicals, food, and wastewater. Flow rates vary widely, depending on the application; however, many range from 1 to 20 GPM.

4. Utility Transfer Pumps

These are portable, lightweight utility pumps meant for quick jobs such as draining pools, basements, or aquariums. The pump is self-priming in many cases and delivers suction rates from 5 to 50 GPM, depending on its size and purpose.

5. Fuel Transfer Pumps

These pumps are safe and efficient for fuel handling and, in the most common usage, serve automotive, agricultural, and industrial sectors. Fuel transfer pumps are designed to handle gasoline, diesel, kerosene, and other fuels, with flow rates typical in standard models varying between 10 GPM and 50 GPM.

6. Peristaltic Pumps

Peristaltic pumps operate by forcing liquid through by squeezing a flexible hose with either rollers or shoe-shaped dispensers. They work well for chemical dosing and handling sensitive or corrosive liquids. Frequently, such applications are for pharmaceutical or laboratory work, with flow rates as low as milliliters per minute up to 70 GPM at the industrial level.

Key Takeaway: Choosing the transfer pump that best fits the user’s liquid transfer needs guarantees maximum performance for them, be it domestic, commercial, or industrial.

Applications of Transfer Pumps

Transfer pumps, indeed, being very versatile, find use in several industries owing to their ability to efficiently transfer liquids from one place to the other. Some of the common applications include:

Industrial Uses

Transfer pumps are used in chemical processing, oil and gas, and wastewater treatment. They do so while safely handling corrosive, viscous, or hazardous liquids, working toward productivity and safety standards.

Agriculture

Farmers need transfer pumps for irrigation, to transfer water into fields, and for the application of fertilizers or pesticides.

Construction

On a construction site, these pumps are used to dewater flooded areas, carry concrete slurry, or transport liquids that are part of the building operations.

Residential and Commercial Use

Used in a variety of situations for water transfers, draining ponds, or maintaining fountains, transfer pumps are commercial applications for the HVAC system, water fountains, and other fluid distribution tasks.

Marine Applications

Transfer pumps serve a critical role in marine areas on all vessels for bilge pumping, fuel transferring, or wastewater transferring.

In accommodating an extensive range of applications, transfer pumps have become a key and enabling device across the industries.

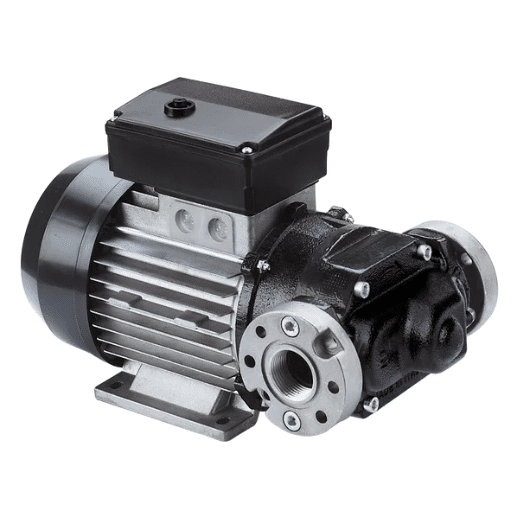

Fuel Transfer Pumps

A fuel transfer pump is a particular type of equipment established to move fuel from one place to another efficiently, e.g., from storage tanks to vehicles, machinery, or equipment. They are necessary for ensuring a steady supply of fuel in areas such as agriculture, construction, and transportation. These pumps allow the transfer of fuel in a safe and timely manner, sometimes featuring easy-to-use controls for simple operation. Durability and efficiency are key attributes of a pump, as this allows them to handle different fuel types such as diesel, gasoline, and kerosene while keeping spillage and contamination to an absolute minimum.

Features of Fuel Transfer Pumps

Some of the smart features incorporated into fuel transfer pumps to extend the functionality and enhance their reliability in various applications include:

Versatility and Compatibility

The pumps in general handle a large array of fuels such as diesel, gasoline, kerosene, and biodiesel blends. Most of these models also suit different vehicles and machinery for storage tanks of the same sort, thus providing for cross-industry adaptability.

High Efficiency and Flow Rates

These fuel transfer pumps offer high flow rates, mostly 10 to 50 gallons per minute (GPM), able to facilitate quick and efficient fuel transfer. This becomes a time-saver in the operative world, particularly in hard-working environments like those of construction and agriculture.

Durable and Weather-Resistant Construction

These pumps, built with extremely sturdy materials such as aluminum or stainless steel, are highly resistant to weather conditions, corrosion, and wear. They can serve you longer, even under the cover of frequent operational use.

Ease of Use and Safety

Features such as automatic receptors, digital displays, and units functioning with little complexity make the pumps very user-friendly and help prevent overflow and spilling. Other safety features include thermal protection and explosion-proof motors.

Portability and Power Options

Fuel transfer pumps come in portable models, providing several power options such as electrical, battery, or operation-induced power. Such consideration provides users with the ability to execute the transfer in distant areas where a direct power source may not be present.

The above set of features guarantees fuel transfer pumps to be a robust and efficient method of managing fuel supply in varied industries.

Choosing the Right Fuel Transfer Pump

Choosing a fuel transfer pump involves a host of considerations according to your operational needs. The first thing to consider is the type of fluid you are transferring, as not all pumps transfer every fuel type. That is to say, gasoline, diesel, and kerosene may require pumps made of different materials that do not corrode or get damaged upon contact. The next thing to consider would be flow rate. If you are operating high-volume operations, it is best to use pumps that transfer faster, while slower pumps can be used in a precision-controlled manner for smaller jobs.

Another consideration is the power supply: electric, battery, or manual, depending upon the availability of power on-site. Portability comes next: if a lightweight, mobile setup will cater to your application, great, but if not, a fixed one would have to do. And, of course, compatibility with any existing fuel storage tanks or systems must be looked at.

Safety features should be the foremost on the list. Consider pumps that come fitted with thermal protection devices or have explosion-proof designs or automatic shut-off functions. And finally, on the matter of durability, ensure that pumps made of tough materials like cast iron or stainless steel, which can withstand harsh conditions and prolonged use, are considered.

Important: By considering these points, one can pick a fuel transfer pump suitable for the demands for efficient and reliable fuel management.

Applications of Fuel Transfer Pumps

Fuel transfer pumps hold a critical value in industries as well as situations, requiring safe and efficient fuel handling. Some standard applications account for the refueling of vehicles, machinery, and equipment involved in agriculture, construction, and transportation activities. At the same time, it is good for the transfer of diesel, gasoline, or other fuels at a fuel station, or marine dock, or an industrial site. They are also useful in storage tank management, where fuel moves between tanks or to a generator with absolute precision. Their versatility enables them to perform any task for which they are designed, and their high efficiency sustains multiple industries in maximized operating conditions.

Electric Transfer Pumps

Electric transfer pumps serve the useful purpose of transferring fluids, such as fuel, oil, or water, from one place to the other, promptly and safely. Electric transfer pumps run from electricity, which guarantees a steady supply of power and performance. These pumps best find their application in situations wherein the clean transfer of liquids is exemplary, requiring some degree of precision and reliability. Among other things, they are commonly used to fuel vehicles, traverse liquids for industrial processes, and deal with storing systems of liquids. Indeed, the ease of operation and flexible design of these types of pumps make them a worthy candidate for nearly every industry.

Advantages of Electric Transfer Pumps

Electric transfer pumps carry many advantages that make them crucial in numerous industries. One of them is their high efficiency-any pump that can transfer large volumes of liquids with rather less consumption of energy will surely become a cost reducer in the admitted industry. Modern electric transfer pumps with their advanced motors and state-of-the-art precision engineering can deliver flow rates with greater accuracy and enhanced performance even in harsh conditions.

Another advantage of these pumps is their clean mode of operation. Thus, these pumps are greener to use since they do not emit any harmful carbon emissions into the environment as opposed to their fuel-activated counterparts, giving the industry the option to lessen its ecological footprint. For example, electrical pumps would also provide efficient irrigation in agriculture without imposing air pollution on the area.

Durability also stands out as a feature. Most electric transfer pumps are made from corrosion-resistant materials, which render them suitable in adverse conditions or with liquids containing chemicals. With this, many of these pumps also encompass certain safety features, such as automatic shut-off to prevent overheating or overloading.

Based on industry reports, electric transfer pumps are gaining tremendous popularity in market sectors like manufacturing, automotive, and construction, with growth in the industry estimated at about 5-6 percent annually. This trend upholds their commitment towards reliability and versatility in harmony with green solutions affecting the working operations.

How Electric Transfer Pumps Work

An electric transfer pump draws the liquid through the inlet hose, channels it through a pump chamber, and discharges it through the outlet hose. The motor creates rotary motion, which imparts movement to the impeller or diaphragm of the pump that, in turn, moves the liquid. These pumps may be used to carry water, fuel, chemicals, etc., hence serving as a useful tool for a vast number of industries.

Modern electric transfer pumps apply the best of technologies aimed at improving the operating performance and efficiency of the pump. For instance, many of these pumps are fitted with variable speed controls, according to which one may cause the change of flow rate with the exactitude required for the particular application. Hence, this control leads to less energy consumption and promotes sustainability.

The industry also recently gathered that the world electric transfer pump market had actually reached the valuation of roughly $4.5 billion in 2022, while projections feel the growth will continue further at a CAGR of around 5.4% through to the year 2030. The growth is due to the ever-rising concerns of needing portable, high-capacity pumps in the oil and gas, agriculture, and manufacturing industries.

Innovations such as self-priming and corrosion-resistant pumps have further enhanced applications in more negative environments. These developments, therefore, gradually contribute to safer handling of a variety of fluids while ensuring better operational reliability, driving the electric transfer pumps toward becoming the backbone of modern industrial applications.

Common Uses of Electric Transfer Pumps

Electric transfer pumps, with their versatility and efficiency, can be applied in just about every industry imaginable. Perhaps their most widespread application is in the oil and gas industry. Here, these pumps assure the smooth flow of crude oil, refined products, and fuel through pipelines and storage systems. Since they are designed for moving huge amounts of liquid, they remain very essential in this industry.

The other great application involves agricultural irrigation systems, moving water into fields, and chemicals for agriculture. Focused on accuracy and reliability, these hygienic pumps are needed for sustaining high-yield farming practices.

Manufacturing also relies on electric transfer pumps for chemical transport, coolant transport, and transport of other liquids required for their production operations. For example, they transfer oils and lubricants in automotive plants or enable the fluid transfer processes that take place in chemical plants.

Electric transfer pumps also find applications in wastewater treatment plants, where they assist in transferring and managing water and sludge for better wastewater treatment and compliance with environmental standards.

As per industry experts, the global electric transfer pump industry is witnessing steady growth, backed by developments in energy efficiency and increased demand across these sectors. Increased demand fosters even more growth through the increased acceptance of newer features like variable speed controls, which add to the flexibility and energy savings in any industrial setup.

Flow Rate and Performance

Flow rate and performance are crucial in determining the efficiency of electric transfer pumps. Flow rate marks the amount of fluid a pump can move in a given amount of time, generally GPM or LPM. High-performance pumps are those designed to meet application requirements such as fluid type, system pressure, or desired flow rate. Highly efficient pumps can be adjusted during operation; for example, they have variable speed controls to reduce energy consumption and ensure reliable, cost-effective operation.

Understanding Flow Rate

Because of high degrees of accuracy and precision in measurement, flow rate is critical to technical considerations, or the safety and efficiency prerequisite of a wide range of applications in water management, manufacturing, and chemical processing. It is customary to measure flow rate in gallons per minute or liters per minute, whatever. Any inaccuracy in measurement can result in serious operational issues or lead to energy inefficiency.

Some of the new methods bringing advancements to flow-metering technology are ultrasonic and electromagnetic flow meters that can measure flow stream rates with a high degree of accuracy, even under high pressure or fluctuating conditions. For instance, ultrasonic flow meters are capable of measuring with a ±1% accuracy of the reading, providing the best possible information in cases where accuracy is paramount. Also, studies have revealed that a reduction in energy used for pumping systems by 40% can be achieved by optimizing systems according to flow rate, presenting a huge opportunity for cost saving. With the advent of high-tech measuring techniques and continuous monitoring of flow rate, industries will be able to improve their efficiency and, at the same time, guarantee sustainability.

Factors Affecting Flow Rate

There is a multitude of factors that determine flow rate, and a good knowledge of these variables helps in designing better fluid systems. One major determinant is the viscosity of the fluid, which dictates how easy or difficult it is for any fluid to pass through a pipe. High-viscosity fluids, like oil or syrup, tend to flow slowly due to a high degree of internal friction; on the contrary, fluids having low viscosity, like water or gases, flow with ease. Another point to notice is Temperature: heating or cooling can modulate the viscosity of the fluid and so enable more or less flow.

Changes in the diameter and length of a pipe also have drastic implications for flow. According to the Hagen-Poiseuille equation, the flow rate is proportional to the fourth power of the radius of the pipe; even the smallest change in diameter affects a lot. Flow through longer pipelines encounters higher frictional losses, thus lowering the flow rate and increasing energy demand to maintain desired levels.

Pressure differences dictate flow rates. As high-pressure fluids follow the way of least resistance to low-pressure spots, flows are faster whenever the inlet pressure is substantially different from the pressure at the outlet. The need to maintain such pressure differences, however, requires powerful pumps.

System fittings and components, such as valves and elbows, also impede flow, causing energy dissipation. Studies show that the use of streamlined designs coupled with minimizing pipe bends can contribute to an increase of about 20% in flow efficiency.

Lastly, the presence of sediment or particulate matter in the fluid would affect the flow characteristics. Particulates settle and deposit on the inner walls of the pipe, gradually choking down the effective diameter and hindering flow. Systems may be installed for filtration, alongside regular maintenance, to alleviate this problem and maintain good flow rates while extending the lifetime of the system.

Key Insight: Thus, knowing these factors and using pinpoint measurement tools empowers an industry to optimize flow systems such that energy consumption is cut back and, instead, operational costs are slashed.

Maximizing Flow Efficiency

Maximizing flow efficiency in industrial systems requires advanced technologies, strategic system design, and periodic maintenance. Recent advancements in flow meters, including the ultrasonic and electromagnetic types, have ensured accurate, non-invasive monitoring and the ability to detect inefficiencies in real-time. For example, studies say that energy consumption can be reduced by 20%, as smart sensors monitor flow rates and adjust system operation to maintain optimal function.

In addition, upgrading pipes and tubes to high-performance standards and corrosion-resistant materials such as stainless steel and polyethylene also enhances efficiency by way of less wear and lower internal friction. CFD modeling provides the dynamic simulation that enables industries to predict flow behavior and fine-tune system configurations before implementation.

Maintenance data reveal how important it is; if blockages in pipelines or leaks or biofilm buildup are not attended to, some industries have even seen efficiency drop by as much as 30%. Implementing predictive maintenance strategies supported by IoT-enabled devices for condition monitoring would keep equipment running at top efficiency and guard against surprises.

Thus, advanced technology complemented by data-based approaches truly optimizes flow efficiency to save resources, mitigate environmental impacts, and sustain the final operations.

Specifications and Horsepower

The characteristics and horsepower of machinery will vary according to its classification and purpose. For example, an industrial-grade pump normally ranges from 1 HP to 500 HP, depending on the operations and output required. Some other important specifications to consider are maximum flow rate, operating pressure, and energy efficiency ratings. Selecting the right horsepower combines the flexibility of optimum performance at the lowest cost with reliability. Always follow the manufacturer’s instructions to adjust the equipment to suit operational demands.

Importance of Horsepower in Transfer Pumps

Horsepower plays an important role in the working capacity and efficiency of transfer pumps. The correct horsepower will ensure that the pump can perform the required volume and pressure of fluid transfer without putting undue overload on the motor. Pumps ranging from 1 to 10 HP may suffice for smaller operations, but industrial-sized applications will require higher horsepower, sometimes even over 100 HP. The greater the horsepower of the pump, the higher the flow rate and pressure it is able to develop, but energy consumption also rises. In view of this, it is important to choose a pump with the right horsepower to prevent energy wastage and wear and tear. In determining the correct horsepower, factors such as fluid type, distance, elevations, and flow requirements should be taken into consideration, together with specifications laid down by the manufacturer.

Determining the Right Horsepower

The first step towards determining an adequate horsepower for my pump is to determine the specific requirements of the application. Factors I consider include the fluid being handled, the distance it has to travel, the elevation changes, and the flow rate being demanded. By measuring these factors together with the manufacturer’s specifications, I can select a pump of horsepower that will work efficiently in my application, yet with minimal energy consumption and premature wear.

Comparing Specifications

To put it concisely in answering the above questions, it crucially undertakes several steps when determining the correct horsepower rating for a particular pump, as per expert advice:

- Fluid Type and Viscosity: Recognize the specific fluid being pumped. The heavier the fluid, the more horsepower is required to effectivity move it.

- Total Dynamic Head (TDH): Calculates all elevation changes, friction loss inside the pipes, and pressure requirements. This calculation ensures that the pump creates enough force to overcome the system resistance.

- Flow Rate: The flow rate in gallons per minute (GPM) needs to be defined as per your applications. Usually, a greater flow rate requires more horsepower.

Once these parameters are matched, a cross-reference with performance curves of pumps manufactured by some of the top manufacturers can ascertain the horsepower to be selected. Always work towards efficiency so there can be a good balance between actual working cost and electricity cost; because of this balancing, the pump shall either never be over-sized or over-heated.

| Application Type | Typical Horsepower Range | Flow Rate (GPM) | Best Use Case |

|---|---|---|---|

| Residential | 1-3 HP | 5-25 GPM | Pool drainage, small water transfer |

| Commercial | 3-15 HP | 25-100 GPM | HVAC systems, building water management |

| Agricultural | 5-50 HP | 50-300 GPM | Irrigation, livestock watering |

| Industrial | 25-500 HP | 100-5000+ GPM | Chemical processing, large-scale operations |

Reference Sources

“Review of research on intelligent diagnosis of oil transfer pump malfunction”

“Pump research and development: past, present, and future—an American perspective”

“Review of research on the three-dimensional transition process of large-scale low-lift pump”

Frequently Asked Questions (FAQs)

What are fuel transfer pumps, and how do they work?

Fuel transfer pumps are devices that transfer fuel from one place to another-from storage tanks to vehicles or machinery. This pump uses a motor or engine to create suction for fast and efficient transfer of liquids. Many models, like the automatic fuel transfer pump, come with flow control systems that maintain safe, steady discharge of fuel.

How do I choose the right transfer pump for my needs?

Choosing the right pump depends on several factors, such as the kind of fluid you are transferring, the flow rate, and the power source. Battery-powered or cordless transfer pumps, for example, allow for portability. Before purchasing, look at the horsepower, the style of nozzle, and the extraction suitability-it should really fit the bill.

Where do I buy transfer pumps online?

You can buy transfer pumps over the Internet by many retailers and specialized shops. Many websites offer a wide range of selections that include portable fuel transfer pumps as well as battery-powered ones. Keep reading the blogs about shipping options so that you know what is to come after an informed purchase.

What is the maximum flow rate from a typical transfer pump?

The maximum flow rate of transfer pumps varies with models and design. In general, transfer pumps are capable of giving a variation of flow rates of some gallons per minute up to 100 gallons per minute plus. It is important that the user chooses the pump that perfectly matches the customer’s flow requirements for sufficient fuel transfer.

Are there automatic fuel transfer pumps?

Yes, they exist in many varieties as automatic fuel transfer pumps. These are meant to simplify the transfer process by stopping automatically when the tank is full, avoiding any spilling and overflow. Another interesting feature in these pumps is having the flow control built in and a digital display that helps operators do their job more accurately.

What materials are generally used for transfer pumps?

Transfer pumps are generally constructed from materials such as stainless steel, plastic, or aluminum. Of course, the choice of material will determine the service life of the pump and affect its suitability for a variety of liquids. For example, pumps intended for corrosive liquids use special materials that do not react chemically with the substances.

Is it safe to transfer hazardous materials with these pumps?

It can be safe to use transfer pumps for hazardous materials if the pump is suitable for those hazardous materials. Always check the specifications of the manufacturer and be sure the pump has safety features such as explosion-proof motors and sealing to prevent any leaks.

What features should I look for in a portable fuel transfer pump?

While looking for a portable fuel transfer pump, take into account the flow rate, battery-powered capabilities, ease of carry, and design of the nozzle to ensure it discharges effectively. One should also consider the safety features of the pump that will guarantee user safety during operation.