Gas pumps are almost everywhere that drivers pass, and few think about the complex engineering that goes into their operation. How does the pump automatically know when to stop dispensing fuel? It is such a simple feature that could be viewed from different angles involving Physics, Design, and Engineering-Knowledge for Safety, Health, and Efficiency. This article shall shed light on how this system works, giving an overview of vacuum sensors, nozzles, and compression forces. You’ll never look at the gas pump the same way again-and it will make you really appreciate how technology makes sure that your fill-up is quick and free of spills.

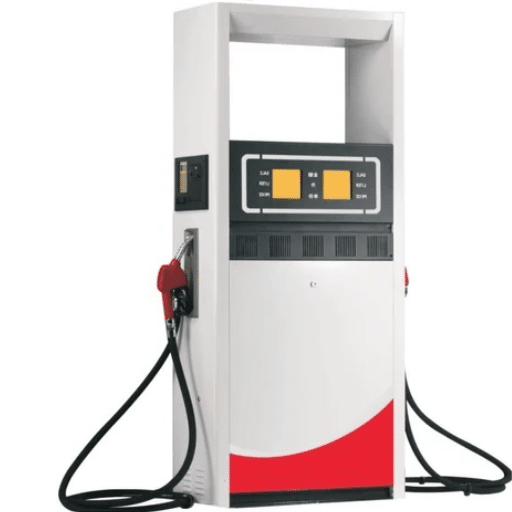

The Mechanics of Gas Pumps

The pumps employ a vacuum sensor, which detects the filling of the fuel tank, thus stopping the fuel from flowing automatically. This system uses the venturi effect inside the nozzle. An interior tiny tube inside the nozzle sucks in air continuously, provided the fuel is flowing into the tank. The rising level of fuel then blocks air flow, and this pressure difference closes the mechanical shut-off valve in the nozzle, causing an instantaneous stoppage in fuel flow to prevent overfilling, thus assuring human safety and avoiding any spills.

How Gas Pumps Work

Modern gas pumps are rather complex systems that provide fuel to vehicles efficiently and safely. These pumps have the motor, pump, hose, nozzle, and flow meter as their main components. The motor drives the pumping mechanism that moves fuel from the storage tank through the underground pipeline to the dispenser. The pump can be either a turbine or a piston pump, so that the flow of fuel can be kept smooth, while the flow meter measures very precisely the amount of fuel that is given, so there is no discrepancy in the billing.

Increasingly advanced technologies have been implemented to mark the safety and functionality of gas pumps. The systems have many incorporating pressure regulators to stabilize flow rates and to avert sudden discharges of fuel. Such systems also contain high-grade filters that separate any debris or contaminants from the fuel before they enter the vehicle; this results in a cleaner engine performance. Some current-generation pumps deploy digital display panels with integrated payment systems to ensure a smooth transaction while detailing cost, type of fuel, and gallons dispensed.

Statistical data illustrate the efficient designs of gas pumps, and for example, high-flow nozzles employed at commercial filling stations crush speeds of refueling times by giving a maximum supply of 60 gallons per minute for big vehicles and trucks. These advances speak well about the intricacies of engineering that keep such systems in maintaining safety, reliability, and customer satisfaction.

Components of a Fuel Pump

Impeller or Diaphragm

The impeller or diaphragm generates the pressure needed to transfer fuel. An electric fuel pump with impellers uses the spinning motion of the blades to push fuel. Diaphragm ones typically operate mechanically: a pulsing motion is used for the same purpose.

Pressure Regulator

Pressure regulation keeps the fuel pressure within acceptable limits. In most passenger vehicles, limits range between 40 and 60 PSI. A higher-pressure application would bear the consequences of a damaged system or even an inefficient process of combustion.

Check Valve

It prevents the fuel from flowing backward into the tank, thereby maintaining system integrity. The invariable pressure that would lie in the fuel lines, thanks to the check valve, ensures consistent engine performance.

Fuel Filter

Whether internally or externally mounted with respect to the pump assembly, this feature ensures that fuel filtering is done for dirt and rust traces. Premium-grade filters are capable of resisting particles up to 10 microns in size to presumably save injectors and combustion chambers from being damaged.

Fuel pump technology advances now also include sensor integration for measuring fuel pressure and flow in real-time. In modern designs, many are expected to last 100,000 miles or so before a replacement is necessary. The fuel quality and operating environment do play a role here. Such components together ensure optimum performance while remaining in line with stringent emission regulations.

Understanding Fuel Flow and Pressure

Fuel flow and pressure determine the engine’s performance, efficiency, and emissions control. The fuel flow refers to the speed at which fuel is delivered inside the engine. Usually measured in terms of liters per hour (lph) or pounds per hour (pph), this rate must be sufficient to supply the necessary amount of fuel to the injectors for combustion. Fuel pressure is the force acting upon the fuel during delivery, which is regulated by the fuel pressure regulator to satisfy engine requirements. Maintaining proper fuel pressure will ensure the formation of droplets in the required form and their ability to mix with air, thereby determining the power output, fuel efficiency, and emissions.

Modern fuel delivery systems rely on a high-pressure pump, accurate flow sensors, and feedback from the ECU for accurate flow and pressure levels. Any variation in fuel pressure leads to a lean or rich mixture, resulting in a reduction in power reduction or pollutant emissions. Such advanced systems attempt to adjust fuel injection quantity in real-time to altitude, temperature, or load changes, ensuring engine reliability and environmental friendliness.

How Do Pumps Know When to Stop?

Modern pumps use their own pressure sensors and control circuits to operate according to the real-time demands of the system. When pressure or flow levels have reached their designed values, the operating condition is withdrawn, i.e., the control system informs the pump to stop running so that over-pressure or energy wastage may be avoided. The efficiency and reliability of the process are ensured, and also protection is offered to system components against excessive pressure or operation when unwarranted.

Automatic Shut-off Mechanisms

Automatic shut-off systems are important features intended to boost operational efficiency and protect the equipment. These mechanisms usually function through integrated pressure sensors, flow meters, or temperature monitors that keep an eye on the present operating state of the system. Upon the attainment of certain parameters like pressure or flow rate, etc., it would activate a stop instruction in the pump. These advanced shut-off mechanisms could be tied into PLCs, wherein certain preset thresholds would dynamically alter the behavior to eliminate undue power or wear on components. In preventing over-pressure, overheating, or cavitation through automatism, the system ensures performance that is reliable and consistent under different applications.

Automatic shut-off technologies have seen an improvement in precision and response time in recent years. For instance, it is found in tests that such systems could identify the tank fill level within a 0.1-gallon margin of error and ensure the fuel flow stopped exactly when the tank reached capacity. Further, modern nozzles are often fitted with fail-safe devices to prevent unintended override, thereby enhancing safety during operation. Reliability is most important where large-scale refueling is being undertaken in high-volume gas stations with several vehicles being refueled air-borne. This greatly lowers human error and increases operational efficiency on a large scale.

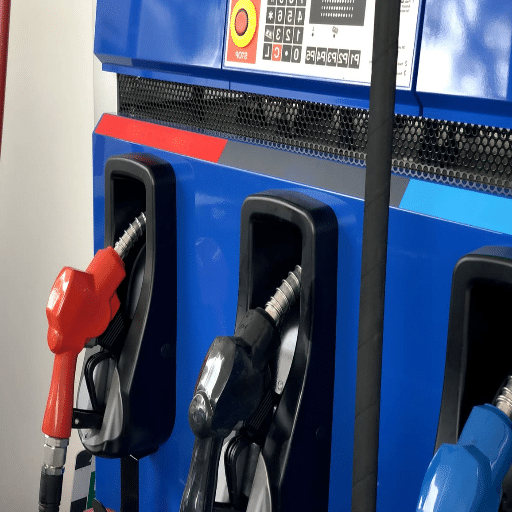

Role of the Nozzle in Stopping Fuel Flow

The nozzle is used in a system to stop and control the flow of fuel, forbidding any further uncertainty in its geometry lest safety and efficiency are compromised. Current fuel nozzles are equipped with auto shut-off mechanisms operating on the Venturi principle or pressure differentials. On filling up the tank, the back pressure in the tank signals the nozzle’s sensing port; this action closes the shut-off valve instantly, ceasing the fuel flow altogether. Such an operation prevents overfilling, spilling of fuel, and other associated risks. Besides the shut-off features, advanced nozzles are generally manufactured from tough materials that offer resistance to high pressures and are calibrated for high precision; thus, wear and tear are kept to a minimum so as to maintain uniform performance under diverse conditions. In integrating those features, the nozzle adds to the operational reliability of the fueling system while embodying standards of safety and efficiency.

Sensor Technology in Gas Pumps

Modern gas pumps employ sensor technology to guarantee accuracy, reliability, and safety during fueling. Flow sensors ensure that the volume of fuel dispensed is measured with utmost precision for accurate billing and to avoid any discrepancies. These can be electromagnetic or ultrasonic in nature and provide high accuracy even in fluctuating pressure and temperature conditions.

Pressure sensors monitor the pressure within fuel lines and thus prevent any possible leaks or failures in the system. These sensors keep providing data to the pump control systems for real-time adjustments, which in turn helps in the safe and efficient delivery of fuel.

Furthermore, vapor recovery sensors enforce environmental regulations by detecting and destroying fuel vapors that would otherwise enter the atmosphere. Industry data suggests that advanced vapor recovery systems may capture 95% of hydrocarbon emissions, diminishing the scope of environmental pollution.

Temperature sensors constitute another vital instrumentation, as temperature variations impact the volume of fuel. Upon keeping track and compensating for such volume variations, these sensors ensure that accurate performance is achieved while protecting the accuracy of the transactions.

Overall, installation of premium sensor technology in gas pumps will spur efficient process management, safety enhancements, environmental protection, and compliance with the standards that will create conditions for a safer and more sustainable fuel infrastructure.

Signs That Your Tank is Full

- Automatic Nozzle Shut-Off: Most gas pump nozzles come fitted with an automatic shut-off mechanism. Once the tank fills to its full capacity, the nozzle will cease to dispense any fuel, preventing overfilling.

- Audible Change in Flow: Any change in the characteristic sound of fuel flow, such as when the splashing or gurgling sounds start fading, indicates that the tank is almost loaded.

- Fuel Backs Up: If fuel starts spilling or backing up at the filler neck, then that’s an ominous indication that the tank is full and dispensing should stop right away.

- Visual Marks (in some vehicles): In case you drive a vehicle whose fuel tank is transparent or visible, then you can watch the fuel come up to the very brim, indicating that the tank is full.

Irrespective of these signs, keep your hand on the pump handle and immediately stop filling in case of spillage to be safe.

Indicators for Gasoline Pumps

Gasoline pumps come along with certain indicators to help users know when to stop fueling to ensure correct operation. A quick recap of the indicators is given below:

- Automatic Shut-Off: Most new generation gasoline pumps have the automatic shut-off system. A sensor detects a pressure change as the tank fills, triggering the pump to shut off delivery of fuel automatically. This acts as the main signal to the user that the tank is full.

- Nozzle Click: When the tank is full, most pumps produce a distinctive “click” from the handle, indicating that the automatic shut-off mechanism has occurred. The user should never try to override this or force more fuel into the tank.

- Fuel Back-Pressure: If you observe random bubbling and splash-back on the fuel near the nozzle, or random fuel back-ups toward the filler neck during the actual refilling of fuel, it is a very strong indication that the tank is near or has already reached full capacity.

- Digital Display Alerts (on some pumps): On some pumps, the display screen can provide alerts and messages such as Tank Full or Dispensing has been automatically stopped.

The operator must watch out for these alerts to put a stop to overfilling, minimize spilling, and dispense fuel as safely and efficiently as possible. It is imperative to follow these basic safety features and never try to trick the automated systems of the pump.

Importance of Accurate Measurements

In various industries, such as fuel systems from the method of manufacture and agriculture, measurements are shipped off to affect efficiency, cost-effectiveness, and safety considerations. The biggest problem with fuel dispensing systems is that the magnifications on the measuring instruments may lead to massive financial gains or losses, given time as a factor. According to reports, an error in the measurement quantity of even 0.5% would lead to millions of dollars in losses every year for large-scale operations of large scale, showing the dire need for accuracy.

Similarly, in industrial manufacturing, measurements that are exact assure quality and adherence to regulatory norms. A deviation in measurement of as little as a fraction of a millimeter can render a product useless, resulting in high levels of wastage and further costs of reworking or recurrences. Improper equipment calibration has been reported as one of the foremost causes of such discrepancies; hence, maintenance and validation of measurement systems should be carried out incessantly.

Measuring water requirements and soil parameters for better crop yield and resource conservation are fundamental data collection requirements in industries such as agriculture. Technologies such as digital sensors and automatic systems have now found wide application in improving measurement accuracy and minimizing human intervention.

Measurement precision is regarded as a safeguard for operational and financial outcomes. Also, the measurement systems guarantee compliance with environmental and safety laws during their lifetime. Advanced tools and best practices for measurement systems are, therefore, indispensable across various sectors.

Common Misconceptions About Pumping Fuel

Filling Up in the Morning Saves Money

This is a very popular belief because it is thought that in cooler temperatures, fuel is denser, and therefore, you are getting more for your money. However, modern fuel storage systems are underground and highly insulated from temperature fluctuations. Studies have shown that the density of fuel remains pretty constant all throughout the day, hence refueling at any time has virtually no significance concerning cost-effectiveness.

Topping Off the Tank Prevents Evaporation Loss

Many think that filling the tank prevents any vaporization and makes the tank full to its capacity. These days, however, vehicles are fitted with highly advanced vapor recovery systems that limit the escape of fuel vapor. In fact, overfilling the tank causes damage to these systems, which requires expensive repairs at a later time. Also, when the fuel gets heated, it expands; this could lead to spillage, resulting in a considerable loss of money and resources.

All Fuel Grades Provide the Same Performance

Another wrong assumption is that there is no difference between fuel grades, and therefore, the use of regular in contrast to higher grades would not affect the performance of the vehicle. Lower octane fuels are fine for most standard engines, but certain high-performance or turbocharged engines specifically require high-octane fuel for anti-knock operation and power output optimization. Wrong-grade usage leads to engine inefficiencies and long-term damage.

Fuel Stations Always Provide the Amount Displayed

Many drivers think that fuel pumps dispense the exact amount shown on the meter. Although a pump must legally be tested and calibrated to exacting standards, wear and tear or poor maintenance may contribute to slight deviations at some gas stations. It is cited by regulatory bodies that about 5% of pumps inspected were found to be inaccurate. Consumers should preferably fuel at stations that keep themselves in good standing through regular inspections.

Turning Off the Engine Below the Fueling Point is Optional

Some say leaving the engine running during refueling poses no real danger; however, it actually leads to a significant risk of fire hazards as fuel vapors might come in contact with the various ignition sources. Therefore, in safety and regulatory guidelines, it is mentioned that the engine must be shut down, as even tiny sparks inside could lead to disastrous accidents.

Understanding these factors helps the drivers learn to decide better on their refueling practice, thus saving money, ensuring safety, and preserving the life of their vehicles.

Safety Features of Gas Pumps

Some safety features modern gas pumps have for refueling minimize hazards. These include shut-off control mechanisms that put a stop to fuel flow once the tank is full to prevent spillages and overflow. Another vapor recovery system absorbs and releases fuel vapors into the environment and toxic fumes. All gas pump units have an emergency stop switch by the attendant or a customer to terminate any operation immediately in case of emergencies. In addition, grounding measures ensure that static electricity does not ignite fuel vapors. Refuelers are conducted safely and efficiently with these safety features.

Preventing Overflows and Spills

Technological advancement in fuel dispensing has greatly reduced the yesterday’s risks of spills and overflows, improving environmental safety and operational efficiency. One of the biggest innovations has included automatic shutoff systems that use the pressure differential to recognize a full tank. The systems then automatically stop the fuel flow, with an accuracy of over 99.9%, according to industry studies. In addition, vapor recovery systems have been developed to capture fuel vapors when vaporizing during refueling, thus reducing emissions and preventing fuel losses.

Recent engineering studies and analyses indicate that double-containment systems have been widely implemented in nozzle designs, which drastically lowers leak chances. Containment systems act as barriers that contain any unintentional fuel discharge into safe reservoirs away from the environment for contamination purposes. Also, most of the fuel nozzles highly potentialized with extra chemical-resistant materials would offer permanence to work reliably over time under extreme conditions.

All these innovations are crucial because just one gallon of gasoline spilled can pollute some 750,000 gallons of water. In this regard, having advanced spill-prevention systems in place helps gas stations comply with environmental laws, gives assurance for the preservation of ecosystems, and potentially reduces cleanup costs. This shows the industry’s commitment to accuracy, safety, and the conservation of natural resources.

Regulations and Standards for Fuel Pumps

The installation and functioning of fuel pumps are under intense regulations and standards that safeguard various considerations like the environment, operational efficiency, and the consumer. An example is the set of regulations imposed by the Environmental Protection Agency in alignment with the Clean Air Act. These rules mandate that fuel dispensing systems be equipped with vapor recovery systems that prevent VOCs from being emitted into the atmosphere during the fueling process. VOCs form a huge factor in smog formation and detrimental air pollution; hence, VOC containment becomes imperative for urban and industrial locations.

International level standards laid down by bodies such as ISO are critical to maintaining harmony and safety. ISO certifications—namely ISO 9001—are put in place to ensure the manufacturing and performance of fuel pumps align with worldwide recognized quality management standards. Non-adherence to such standards would attract operational penalties, raise liabilities, and incur environmental consequences.

According to data from industry analysts regarding fuel movement and metering, a customer’s trust is at stake. Regulations bind fuel dispensing units to strict calibration and testing programs set forth by weights and measures departments. For example, in the United States, devices are required to operate within specified tolerances, ordinarily ±0.3%, to ensure that customers receive the quantity of fuel paid for.

Such commitment is further exemplified by standards like the American Petroleum Institute (API), which aid continuous innovation. These guidelines specify fuel pumps in various respects, including materials, construction operations, and testing procedures, to ensure pump reliability and durability. Design changes since then have incorporated safety features like automatic shut-off and leak detectors that the industry prioritizes in minimizing spills and hazards to workers.

Working within such a regulatory framework, the operators of gas stations and the manufacturers of equipment for fuel dispensing demonstrate their commitment beyond compliance and toward protecting human life and the environment.

Technical Challenges and Solutions

A primary issue of technical nature in fuel dispensing systems is the maintenance of calibration to achieve correct fuel measurement. Increase in wear and tear of components, such as flow meters, may result in certain discrepancies in fuel outflow, which subsequently questions the adherence to laws and regulations and the trust of customers.

Such concerns can be prevented by setting up periodic maintenance schedules and by ensuring that the latest digital calibration systems are used. These systems provide the benefits of performing calibration in real time, plus they support automatic recalibration to minimize the chances of errors while doing so, thus enhancing their compliance with measurement standards and ensuring system reliability.

What Happens When Pumps Keep Pumping?

When pumps are operated constantly outside their rated duty cycle or hypothetical conditions, all sorts of problems can develop. Long operation wears out the mechanical parts like seals, impellers, and bearings, putting them at a higher likelihood of breakdown. Besides, stopping too much could lead to overheating, particularly where the system might otherwise cool down, thus less efficient and energy-wasting. Also, somewhat from a hydraulic view, continuous pumping would be damaging in the sense of undesired cavitation, i.e., bubbles of vapor forming and knocking into internal surfaces, impairing the pump internals. Other than an engineering problem, there is an environmental issue where over-pumping of natural water courses or improper disposal of fluids will trample on sustainability and environmental compliance. Periodic performance evaluation, together with an enforceable safety shutdown, will prove effective in countering the risk.

Addressing Malfunctions in Fuel Pumps

First and foremost, to fix a problem effectively in a fuel pump, I would do a thorough diagnosis to nail the true cause, whether it’s mechanical wear, contamination, or electrical. It is important to ensure that the pump is working within the limits specified by the manufacturer with respect to such operating variables as pressure and flow rates. I would examine the system for any signs of cavitation or any blockages that might restrict performance. Regular maintenance to clean filters, check seals, and inspect connections is fitting, so as it will avoid any recurring problems. Another thing to consider is using automated monitoring systems that will alert you to any abnormality in advance, thereby decreasing downtime and ensuring smooth operation.

Future Innovations in Pump Technologies

Pump technologies are increasingly moving toward efficiency, automation, and sustainability. A key concept is the use of smart sensors coupled with IoT-enabled systems for real-time monitoring of performance and operating parameters like flow rate, pressure, and energy consumption. These systems allow for predictive maintenance by spotting issues before they cause expensive downtime, thus improving operational efficiency.

Another promising concept toward energy savings is the more extended applications of energy-efficient pump technologies like VFDs. VFD is a method that allows the pump to operate such that it can adjust the speed and power consumption of the pump depending on demand, which in turn minimizes energy waste and operational costs. Parallel to motor efficiency, these technologies seek to meet system installations for industrial operations that have achieved strict energy-saving regulations.

Moreover, the utilization of sustainable materials and designs is beginning to get recognition. The new inventions of 3D-printed components and corrosion-resistant materials are made to aid in bettering pump durability while reducing the impact on the environment. The type of energy production mechanisms is being considered. For instance, solar energy can be utilized in pump actions to lessen carbon footprints and strengthen green initiatives. All of these advances make it possible for pump technologies to have a bright future, emphasizing performance, reliability, and sustainability.

Reference Sources

- Key Findings: This study focused on fixed speed for continuous flow pumps in LVADs, emphasizing that most LVADs do not have a speed-adjusting mechanism, a limitation in the management of end-stage heart failure patients with renal failure.

“Proton Pump Inhibitors for Laryngopharyngeal Reflux: What Do We Know?”

- Key Findings: This paper deals with proton pump inhibitors (PPIs) in relation to laryngopharyngeal reflux and management. It informs about the mechanism of PPIs in blocking the final step of stomach acid production.

“Limiting factors for the ability to achieve accurate pressure control in long wells”

- Key Findings: This study examined challenges in getting accurate pressure control in long wells, concentrating specifically on pump rate problems and going from full flow to a complete stop.

Frequently Asked Questions (FAQs)

What causes the gas pump to stop automatically?

The gas pump stops automatically due to a venturi tube system that detects the level of fuel in the tank when it reaches the top of your tank. When the fuel in the tank rises high enough, it closes off the free passage of air through the small pipe, making a vacuum that causes the pump to shut down. This stops the overfilling and can prevent any spills.

How does the gas nozzle stop pumping?

In general, the gas pump is designed to stop pumping when it detects a change in the air pressure inside the tank. When the gasoline level rises so high that it covers the tiny opening in the nozzle, air pressure is affected, causing the gas pump to stop gallons from flowing into the tank so as not to overflow.

Can it stop if the gas tank is not filled?

Till the fuel level reaches the set threshold, the pump will continue to pump gasoline into the tank. The system is designed to keep detecting fuel flow and pressure changes, ensuring the pump does not stop unless the tank is full or you manually stop pumping gas.

What role does air pressure play in this gas pump operation?

Air pressure is the chief operative element of a gas pump. Filling the tank with gasoline removes air from it, which leads to a change in pressure. The pump, so to speak, detects this slight pressure variation to serve as a signal for the valve to shut off the flow of gas. This slight change in air pressure is the only indicator for the nozzle to cease the pouring of fuel once the tank is full.

How do the pumps work to fill my gas tank efficiently?

Pumps grant an efficient and constant gasoline flow-in-the-tank system. They use a combination of suction and pressure to draw fuel from the storage tank, while the venturi tube regulates the flow. The passage of fuel through this narrow tube ensures the smooth, unbroken flow of gasoline till the tank is filled.

What if the gas pump was stuffed after the tank is filled?

Beyond the full tank establishes a spill situation and hazard condition. To remain safe, the pump factors in detecting fuel levels by stopping this flow. It is very important to observe the filling operation and change the nozzle when irregularities occur.

How does a fuel level detection system work inside a pump?

Inside the pump, the fuel level detection system works on a hybrid mechanism of pressure sensors and airflow dynamics. When the fuel progressively rises in the tank, a change occurs in the air pressure that is sensed by the pump. Using this information it shuts off the flow of gasoline for safe and efficient refueling.