Due to the safety and efficiency in working conditions, drivers are allowed to bring their vehicles to get refueled easily in the presence of a sophisticated network of equipment. From underground storage tanks to fuel dispensers that offer precise measurements and advanced monitoring systems, all components need to ensure proper functioning with safety regulations and to give the customer a smooth experience all along. The blog will be discussing the essential components of tank station equipment, with an aim to understand their function, technological updates on them, and a little bit on the major importance of their proper maintenance. Whether you are a station owner or operator or just someone working in the industry, this complete guide will provide you with the facts required to optimize and understand these critical systems.

Overview of Tank Station Equipment

A tank station facility contains critical equipment that safeguards the storage, dispensing, and monitoring activities and assures the safe and efficient handling of various fuel products. Important types of equipment are storage tanks to store fuel securely from contamination, pumps and dispensers to transfer fuel, and monitoring systems for inventory checks and leak detection. These are endowed with safety features, overfill prevention devices, and emergency shut-off devices that guard against violations of safety standards and thereby protect the environment. These systems work in unison to ensure the smooth functioning of tank stations. Hence, proper maintenance and periodic inspections are necessary to ensure that this equipment meets functional requirements and industry standards.

Definition and Importance of Station Equipment

Essential station equipment refers to infrastructure and tools necessary for storing, transferring, and monitoring fuel or hazardous materials in any facility, be it at a gas station or an industrial setting. Station equipment comprises such things as storage tanks, pumps, dispensers, pipelines, and monitoring systems that together maintain the materials in a controlled, safe manner. Station equipment is important because it ensures safety throughout the operations, safeguards against environmental pollution, and serves legal purposes. Some examples would be the newer systems of leak detection that prevent spills and leaks, overfill prevention devices, or the automatic tank gauges that minimize inventory errors and on-the-job human errors. In an ever-evolving field, it continues to emphasize maintenance and modernization, and this again is where the very best of high-quality station equipment, by reducing hazards during operation to a minimum and protecting the environment, meets its mark.

Types of Gas Station Equipment

Gas station equipment covers almost every tool and system designed for smooth and safe interplay. These include:

Fuel Dispensing Systems

To dispense the fuel into the customer’s vehicle, the system: fuel pumps, nozzles, and hoses. Being modernized, the dispenser usually holds an electronic payment system, data tracking features, and vapor recovery mechanisms, which keep the environment safe and also help the outlet run in an efficient manner.

Storage Tank Systems

Storage tanks, both underground and above-ground, keep petroleum products. The system thereby uses advanced leak detection processes with corrosion-resistant materials to be really durable and safe. Very often, the accessories like manhole covers, fill caps, and monitoring devices are attached for ease of maintenance.

Monitoring and Control Systems

An automatic tank gauging (ATG) system forms the heart of inventory management and compliance, offering continuous updates on fuel levels, densities, and temperatures. On the other hand, POS systems streamline transaction processing in fuel stations, whereas the station control software serves as the centralized management platform for equipment and operations.

Environmental and Safety Equipment

In terms of environmental safety, spill containment systems, vapor-recovery units, and fire-suppression systems come into play. These are mechanisms to mitigate risks with accidental leaks, harmful emissions, and fire hazards.

Maintenance Equipment and Accessories

This includes equipment for cleaning, calibration, and routine maintenance, such as squeegees, air vending machines for tire inflation, and oil recycling stations. Maintenance keeps the equipment in good working order, increases its longevity, and ensures it performs well.

Important Note: Equipment sets play a vital role in maintaining operational integrity in a gas station; conscious investments in good equipment and good standards must be upheld in consideration of such.

Key Components of Fuel Stations

Fuel stations are complex systems composed of various critical components that ensure safe and efficient operations. In other words, these are:

- Fuel Dispensers and Pumps: With these devices, fuel is transferred to vehicles from underground storage tanks. Modern dispensers feature precision metering systems and safety functions to automatically shut off when the tanks are full to prevent spills.

- Underground Storage Tanks (USTs): They keep fuel in large quantities safely underground. They are built with corrosion-resistant materials and have a monitoring system to detect any leakage so as to comply with environmental regulations.

- Vapor Recovery Systems: These systems recover fuel vapors that escape during dispensing or storage operations. In preventing VOC releases and pollutant emissions, vapor recovery systems help to protect the environment and improve air quality.

- Payment Terminals and Software: Being on the digital side of the payment systems are terminals at the pump-pay and cloud-based management software alternatives that manage transactions and inventory tracking. These technologies ensure that the customer experience goes smoothly and that the station works at its optimum level.

- Canopies and Lighting: Structurally, canopies provide shelter for customers and equipment, as the lights are installed to provide adequate visibility for safety throughout night operation.

When these components are integrated with good design and maintenance, the station will comply with industry standards, provide enhanced customer gratification, and stand for safety and environmental protection.

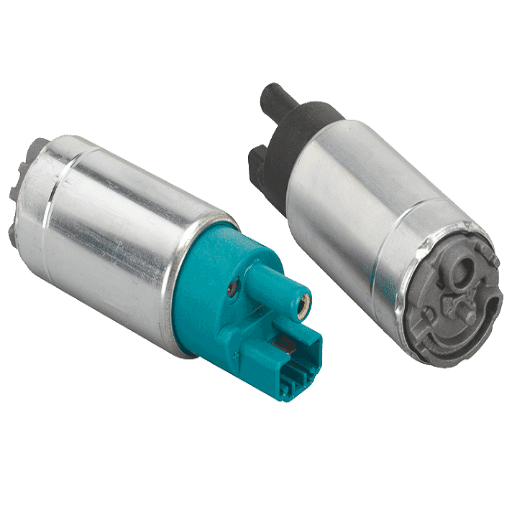

Fuel Pumps and Their Mechanisms

Fuel pumps are of utmost importance in establishing the fuel transfer between storage tanks and vehicles. Upon activation, modern-day pumps can operate electrically or mechanically to draw fuel upwards and dispense it efficiently through special nozzles. The core components in such an arrangement allow the motor of the pump to produce the required pressure while sensors measure the volume of fuel dispensed. Along with safety features that include automatic nozzle shut-off to avert overfilling, these provide for the safe and precise operation of fuel metering. Fully compliant with environmental regulations and trustworthy, systems that adhere to an uncompromising base level of quality will not fail you with their accuracy and reliability.

Types of Fuel Pumps

Fuel pumps have several main categories, which differ in terms of design and application:

| Pump Type | Operation Method | Key Features | Best Application |

|---|---|---|---|

| Mechanical Fuel Pumps | Work with the engine’s drive system using diaphragm and springs to create vacuum | Simple design, low cost, suitable for low-pressure systems | Older vehicles or low-pressure fuel demand systems |

| Electric Fuel Pumps | Electric motor pressurizes fuel and feeds it to the engine at steady pressure | Efficient, higher pressure capability, equipped with sensors and control electronics | Modern vehicles with fuel-injection systems |

| Turbine Fuel Pumps | Impeller spins and moves fuel smoothly | Quiet operation, smooth performance, higher fuel flow rates | High-performance vehicles under extreme conditions |

Mechanical Fuel Pumps

These types of pumps were widely used in older vehicles or in systems at low pressure. Mechanical fuel pumps work with the engine’s drive system. They utilize the action of a diaphragm and springs to produce a vacuum for sucking fuel from the tank into the carburetor. Their simplest form uses a low-cost working method and is suitable for low fuel-demand-based systems.

Electric Fuel Pumps

Modern vehicles use electric fuel pumps that are more efficient and capable of delivering fuel at the higher pressure required by fuel-injection systems. An electric motor within or near the fuel tank pressurizes fuel and feeds it to the engine at a steady pressure. Some advanced models are equipped with sensors and control electronics that help control performance and enhance fuel efficiency.

Turbine Fuel Pumps

Turbine fuel pumps represent a variety of electric pumps in which an impeller spins and moves the fuel. This evolution allows for quiet operation and smooth performance. They gain use in high-performance vehicles as they allow higher fuel flow rates under extreme conditions with due precision.

Selection Criteria: Each pump type corresponds to a landscaped requirement where pressure and flow rates are to be met while considering general compatibility with the vehicle’s fuel-delivery system.

Installation and Maintenance of Fuel Pumps

The fuel pumps should be installed and maintained properly to ensure optimum use and a necessary life span. Usually, the working of installation requires enforcing all the instructions and recommendations of the manufacturer, which usually includes making sure the fuel pump will be compatible with the vehicle’s fuel delivery system and making sure the installation is such that the pump will not be subjected to vibrations. Inspect fuel lines for clogging or damage before installation, and replace old parts like fuel filters so that any debris entering the pump is prevented.

Maintenance involves regularly checking the fuel pump for leaks, unusual noises, or varying performances that indicate wear or malfunction. Periodic cleaning of the fuel injectors and usage of recommended fuel types assist in maintaining the best condition of the fuel pump. The fuel filter should be replaced as per the recommendations to avoid impediments to pump operation from contaminants. Problems should be noticed, followed by troubleshooting; first, checking all electrical connections and using diagnostic tools to check fuel pressure.

Following these directions ensures the reliability and durability of the fuel pump while reducing the chance of costly repairs or replacements.

Innovations in Pump Technology

In the modern day, pumps are developed focusing on high efficiency, durability, and flexibility for varied types of operations. Smart pumps integrated with sensors and IoT connectivity are a major advancement in this domain. After monitoring pressure, flow rate, temperature, and other parameters in real-time, maintenance can be predicted, greatly reducing downtime. Besides that, with progress in materials science, wear-resistant technological advancements have produced ceramic and composite material components that increase pump life, particularly in harsh environments.

Key Innovations Include:

- Variable Speed Drives (VSDs): Optimize energy use by varying pump speed depending on demand, reducing operational costs and addressing sustainability issues

- Magnetic Drive Pumps: Eliminate mechanical seals for leak-proof operations with minimal maintenance requirements

- Additive Manufacturing (3D Printing): Reinforces pump design through rapid prototyping and customized parts for specific industrial solutions

- Smart Monitoring Systems: IoT-enabled sensors for real-time monitoring and predictive maintenance

- Advanced Materials: Ceramic and composite components for increased durability in harsh environments

These innovations are turning the entire pump technology around so that it remains strong and efficient in addressing modern challenges.

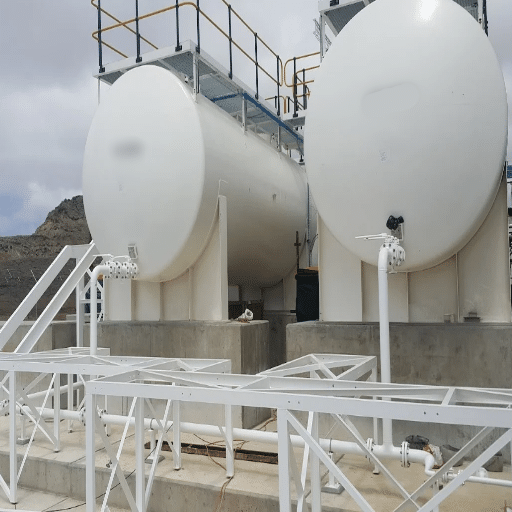

Storage Tanks: Safety and Compliance

For storage tanks, safety and compliance pertain to leakage prevention, contamination control, and accident prevention while following industry safety regulations. Inspections are crucial in spotting structural weaknesses; ventilation is necessary to avoid the build-up of dangerous vapors, while corrosion must be prevented, with coatings or suitable materials used for this purpose. Compliance involves adherence to standards imposed by agencies such as OSHA, EPA, or API, which specify requirements for design, maintenance, and spill prevention. Safe and compliant operations are further achieved through proper record-keeping and employee training.

Types of Fuel Storage Tanks

Classification of fuel storage tanks considers their design, material, and application so as to satisfy industry needs and ensure their safety. Three main types of fuel storage tanks are used these are aboveground storage tanks (ASTs), underground storage tanks (USTs), and double-wall storage tanks.

Aboveground Storage Tank (AST)

These are tanks installed on or above the earth’s surface. Commonly used for storage of gasoline, diesel, or other fuels in industrial, commercial, and agricultural activities, they are easy to inspect, maintain, and relocate, but may require certain precautions to prevent environmental contamination due to leaks.

Underground Storage Tanks (USTs)

In the case of underground storage tanks, they lie beneath the ground and are mainly used for long-term storage of fuel, especially in areas with limitations of space. However, their use poses increased accidental risks of fires, subjecting them to stringent environmental legislation requiring constant monitoring for any leakage arising from corrosion or structural failure.

Double-Walled Storage Tanks

Double-walled tanks apply a principle of containment with two tanks side by side, thus providing an extra layer against spills and leaks. One should definitely consider using double-walled tanks in areas requiring environmental protection, and some jurisdictions require them for enhanced safety and compliance.

Key Insight: Fuel storage tanks of each type are designated for particular purposes and come with strict regulations to maximize environmental care and to improve operational safety.

Regulations and Safety Standards

Since environmental protection and operational safety are imperative, high-standard regulations and safety codes are there for fuel storage tanks. These usually come under various layers of jurisdiction of federal, state, and local laws. For example, to control petroleum leaks, the U. S. Environmental Protection Agency (EPA) regulates USTs under the Resource Conservation and Recovery Act (RCRA), thereby imposing stringent requirements concerning testing, corrosion control, spill containment, and recordkeeping. Conversely, ASTs have to follow other standards, such as those issued by the American Petroleum Institute (API), which include API 650 for construction and installation.

In places deemed environmentally sensitive, state and regional agencies can impose more requirements, such as secondary containment systems and continuous monitoring technologies. Consistent with this, OSHA HCS also applies to safety at the workplace during fuel handling, and tanks need to be labeled properly with fire systems in place. Regular inspections and maintenance of these regulations are thus needed to combat environmental risk while protecting public safety.

Monitoring and Maintenance Practices

For operational safety, regulatory compliance, and environmental protection, monitoring and maintenance of fuel storage sites are crucial. Routine inspections generally look for potential leaks and corrosion or structural damage occurring to important components such as tanks, pipelines, and valves. Advanced monitoring systems such as automatic tank gauges (ATGs) and various leak detection systems can be used for enhancing real-time monitoring and early detection of issues. Maintenance involves cleaning of tanks, replacement of parts that have become worn or defective through use, and inspection of secondary containment systems against potential contamination. Should maintenance be carried out by reference to recognized standards or codes, such as those common to the EPA and API? This will ensure that the system remains operational and safe at all times. Keeping personnel trained on current techniques while also maintaining comprehensive maintenance and inspection records is essential for a monitoring program worth its salt.

Fuel Nozzles and Dispensing Systems

The importance of fuel nozzles and dispensing systems in efficient and safe fuel delivery cannot be understated. These systems should guarantee correct fuel measurements, prevent spills, and minimize vapor emissions. During inspections, focus should be on checking nozzle integrity, flow rates, and the operation of automatic shutoff devices. Safety and compliance are maintained by following guidelines from organizations such as the EPA and the NFPA. It is also important that dispensing systems are properly calibrated to distribute the fuel accurately and do not waste it. Maintenance at scheduled intervals, along with timely repairs of worn or damaged parts, is also essential to ensure very long-term and reliable operations.

Types of Nozzles for Different Fuels

Fuel nozzles are various components designed for certain types of fuels. They ensure the safe and efficient transfer of these fuels. The following outlines the chief types of nozzles for different fuels:

| Nozzle Type | Key Features | Special Characteristics | Primary Use |

|---|---|---|---|

| Gasoline Nozzles | Corrosion-resistant with automatic shutoff | Vapor recovery systems to reduce emissions | Standard gasoline vehicles |

| Diesel Nozzles | Larger diameter for higher flow rates | Magnetic or keying means to avoid misfueling, strong construction for thick viscosity | Larger vehicles and equipment |

| Biofuel Nozzles | Materials compatible with alternative fuels | Better seals and coatings resistant to chemical characteristics | Ethanol blends and biodiesel |

| Kerosene and Jet Fuel Nozzles | Special design for controlled flow rates | Grounding cables to prevent static discharge | Aviation and kerosene applications |

Gasoline Nozzles

These are usually corrosion-resistant and are equipped with an automatic shutoff to prevent overflows. Vapor recovery systems are commonly installed to reduce vapor emissions at the time of fueling in accordance with environmental legislation.

Diesel Nozzles

Diesel nozzles offer a larger diameter for higher flow rates of fueling larger vehicles and equipment. They are usually made to higher durability and often feature strong construction against the thicker viscosity of diesel fuel. Some may even employ magnetic or keying means to avoid misfueling.

Biofuel Nozzles

Biofuel nozzles, or ethanol blends or biodiesel, are constructed with materials compatible with such alternative fuels so as not to degrade. They must comply with regulations and generally incorporate better seals and coatings resistant to the chemical characteristics of biofuels.

Kerosene and Jet Fuel Nozzles

Kerosene or aviation-fuel-type nozzles have special design features to control flow rates and minimize spillage. Special safety features, such as grounding cables, are incorporated at aviation fuel nozzles to prevent static discharge from occurring during the fueling operation.

Selection Principle: It has been said: choosing the right style of nozzle for a particular fuel and use demand is what keeps the fuel-dispensing system safe, efficient, and compliant.

Design Considerations for Fuel Dispensing

The above lines provide that the fuel dispensing systems must be designed with utmost concern for safety, efficiency, and compatibility. An increasing degree of considerations includes the following issues:

- Material Compatibility: Nozzles, hoses, and some other components must be constructed from materials capable of resisting the chemical and corrosive nature of the fuel being dispensed; generally, gasoline, kerosene, or diesel. These measure guarantees permanent durability and safe operation after some time.

- Flow Rate Optimization: The fuel nozzle flow rate should be properly calibrated to suit operational needs so as to minimize spillage or overflows. In the case of very high-capacity usage, such as aviation fuel, flow rates ought to offer a good compromise between speed and safety, reducing the risk of static discharges.

- Safety Devices: Integration of safety features like automatic shut-off valves, grounding cables, pressure relief systems, etc., to stop any leakages of the fuel, release of vapors, and any identified fire hazard.

- Regulatory Compliance: The dispensing equipment must be constructed in accordance with standards set by bodies such as the National Fire Protection Association (NFPA) or the Occupational Safety and Health Administration (OSHA). The adherence to environmental safeguards and operational standards thus remains the concern of the devices.

- Environmental Considerations: In modern-day fueling designs, the incorporation of vapor recovery systems to reduce emissions and to lessen any potential adverse effects on the environment has become a norm. The closed-loop system and contain ment designs further guarantee the safety of the surroundings from contamination.

- Ease of Maintenance: Systems should allow easy maintenance and part replacements with minimal downtime. Follow up on good maintenance procedures to keep equipment reliable for a long time.

When these design considerations are met, the fuel dispensing systems balance well on the pedestal of performance, safety, and environmental concern.

Impact of Nozzle Technology on Efficiency

Optimizing the efficiency of a fuel dispensing system involves nozzle technology. The high-tech nozzles allow precise control over fuel flow rates to ensure minimum spillage and evaporation losses during the refueling process. They automatically shut off when overflow might occur, thereby providing safety and conserving fuel. On the newer side, the nozzles can also adjust flow rates as per vehicle specifications, ensuring quicker refilling without the loss of precision.

Moreover, innovations in material science and nozzle design also cut down on wear and tear. Hence, the nozzle has a prolonged operational life and also needs much less maintenance. Some nozzles utilize vapor recovery systems that catch vapors from fuel, which would otherwise evaporate to the atmosphere, thus reducing environmental impact and emissions. The inclusion of the latest advances has allowed nozzle technology to provide great operational efficiency while also complementing sustainability goals in fuel dispensing systems.

Piping Systems in Fuel Stations

Fuel stations use piping systems to move fuel safely and efficiently from storage to dispensing areas. Their materials are chosen to ensure high durability and resistance to corrosion. Examples are reinforced steel and high-density polyethylene (HDPE). Good piping design goes beyond technical considerations; it must also include leak detection, should any such incident occur, to avoid contamination of the environment and the risk of failing regulatory compliance. Double-walled pipes are often selected for further leak protection. The concept underlying these systems is to provide safe working environments and minimize the hazards arising from fuel handling.

Overview of Piping Systems

In various industrial sectors, the piping works as a service infrastructure for safe and efficient transport of any liquid, gas, or other material. These systems are designed to comply with the highest safety and durability standards, being analyzed for characteristics such as pressure, temperature, and fluid composition. Depending upon the substances being transferred, the materials used for piping systems may be steel, copper, or a special marriage of polymer-aided HDPE.

Rigorous monitoring systems, including pressure sensors and flow meters, may also be added to modern piping systems in order to provide reliability and to ensure environmental protection. Leak detection systems, such as a double wall with interstice monitoring, are commonly employed to reduce the risk of fluid discharge leading to environmental contamination. People caring about safety and efficiency across industries stand behind these regulations, like API, ASME, and ISO standards, enabling piping systems to function on an environmental benchmark.

Material Choices for Piping

Choosing suitable piping materials for any system is a critical step that guarantees operational efficiency, structural integrity, and adherence to industrial and environmental standards. The following are some common materials:

| Material Type | Key Properties | Applications | Limitations |

|---|---|---|---|

| Cast Iron | High strength, cost-effective, suitable for high pressure and temperature | Oil, gas, water transport in industrial processes | Requires proper coating or lining against corrosion |

| Stainless Steel | Corrosion-resistant, highly durable, handles extreme temperatures | Chemical processing, food and beverage industry | Higher cost compared to other materials |

| PVC (Polyvinyl Chloride) | Lightweight, non-conducting, non-corrosive, inexpensive | Sewage, drainage works under low pressure | Cannot be used in high-temperature applications |

| Copper | Corrosion-resistant, reliable for water systems | Water supply systems | Expensive for large projects |

| HDPE (High-Density Polyethylene) | Flexible, impact-resistant, chemical-resistant, seamless installation | Gas and fresh water distribution | Limited high-temperature capability |

| Alloys and Specialty Metals | Resistance to heat, pressure, and corrosive media | Specialized high-performance scenarios | Higher cost, specialized installation required |

Cast Iron

With unusually high strength and great cheapness, this material has been extensively used in all industrial processes requiring service at high pressure and temperature. It may be used for transporting oil, gas, or water, but it requires proper coating or lining against corrosion.

Stainless Steel

It is corrosion-resistant and very durable; stainless steel can be used in systems with corrosive agents or with very extreme temperature levels-could be a chemical processing plant or an industry for food and beverages.

PVC (Polyvinyl Chloride)

PVC is a lightweight polymer that is also non-conducting and non-corrosive. It is sewage and drainage works under low pressure, thus making it cheap. It cannot, however, be employed in high-temperature applications since it is inherently limited by temperature.

Copper

Since it is corrosion-resistant, copper is used in water supply systems; otherwise, copper is very expensive to employ in large projects.

HDPE (High-Density Polyethylene)

Because HDPE provides flexibility, resistance to impact, and chemical resistance, it is predominantly used for gas and fresh water distribution. Its installation techniques are practically seamless, and thus, it is considered to be costly to maintain. This is why it continues to be used for all contemporary infrastructure.

Alloys and Specialty Metals

For more specialized scenarios, nickel-based alloys, titanium, and duplex stainless steel are used as they offer resistance to heat, pressure, and corrosive media.

Selection Criteria: Each material has advantages and limitations; thus, the detailed analysis of its intended application is of utmost importance to meet functional, regulatory, and budgetary factors. When selecting a material, the type of fluid being conveyed, operating temperature, operating pressure, environmental exposure, and expected service life must all be considered to ensure that the piping system offers the target value in terms of safety and performance.

Critical Role of Piping in Fuel Delivery

Pipelines are crucial for the fuel that needs to be safely and efficiently distributed to industrial, commercial, or residential applications. The pipeline systems are intended to transport various volatile hydrocarbons while conforming to stringent safety and environmental standards. Depending on the conditions encountered during the delivery of fuel, this generally involves, among others, high pressures and very high temperatures that can be highly corrosive. Carbon steel is the usual option for strength, stainless steel for corrosion resistance, and composite materials for chemical resistance, combined with weight reduction.

For reasons of fluid viscosity, flow rate, and pressure drop, amongst others, designing a piping system entails numerous critical factors to provide for maximum efficiency and minimal risks. On top of this, in modern systems, we generally consider the option of incorporating various advanced monitoring technologies, such as pressure sensors and leak-detection systems, to monitor operational integrity. In addition, operations can be further protected through adherence to regulatory avenues such as API (American Petroleum Institute) standards or ASME (American Society of Mechanical Engineers) standards.

The installation, maintenance, and inspections of a piping system serve as safeguards against leakages, ruptures, or any other type of system failure that could give rise to environmental hazards or safety incidents. Hence, piping systems should be considered fundamental infrastructure for the reliable and controlled movement of fuels while mitigating risks associated with the handling and transportation of the same.

Modular Solutions for Fuel Stations

The solutions that are modular in nature for fuel stations are pre-engineered sets made to expedite construction, reduce installation time, and maintain consistent quality. These systems could include prefabricated components for storage tanks, piping, and dispensing units, which are, in turn, produced off-site and delivered for assembly works. By reducing on-site construction, this approach curtails labor cost, project timeline, and increases safety, minimizing the times that works are done in potentially hazardous environments. Furthermore, these modular solutions can be worked upon for augmentation or upgrades with little interruption to the existing operations. Being Industry code-compliant, such solutions guarantee reliability and protection of the environment while making them an excellent choice for the contemporary development of fuel stations.

Benefits of Modular Equipment

As a result of the advantages offered by the modular equipment, there is efficiency, quality, and cost-effectiveness in the transformation of industries. The first and foremost advantage is the steep reduction in total construction time. Because modular components are pre-engineered and fabricated off-site, the general trend is for concurrent progress of works, thereby cutting at least 30-50% of time as compared to the conventional procedure. Fewer disturbances are imposed on the site, quality is maintained equally in all respects, and components are fabricated in an environment-controlled manufacturing setting.

Time Efficiency

Modular components reduce construction time by 30-50% through off-site fabrication and concurrent progress of works, minimizing site disturbances.

Scalability

Modular systems allow accommodation of additional technologies or processes with minimal disruption, enabling businesses to modify operations without complete replacements.

Cost Efficiency

Optimizes material usage, reduces waste, minimizes labor costs through consolidated construction, and ensures better quality control with less rework.

Environmental Benefits

Minimal construction emissions and waste through controlled production processes, with many designs integrating energy conservation technologies.

Quality Control

Components fabricated in environment-controlled manufacturing settings ensure consistent quality and reduced defects.

Industry Compliance

Certified under stringent industry standards, ensuring operational reliability and sustainable, environmentally friendly solutions.

Scalability is another benefit that is applied to the present systems for modular treatments. Being modular allows for the accommodation of additional technologies or processes with minimal disruption. These settings allow businesses to modify their operations not with full replacements or complete retrofits themselves.

From another perspective, cost efficiency comes into play. Modular design optimizes material usage, reduces waste, and minimizes labor costs on account of consolidated construction work. Besides, prefabrication would allow greater quality control, and less rework means more savings in the long run.

Lastly, the environmental objectives are borne out altogether. Construction emissions and garbage are minimal due to a controlled production process, while many designs also integrate energy conservation technologies. Having been certified under stringent industry standards, they thus stand for operational reliability and sustainable solutions, and environmentally friendly ways to meet the modern infrastructure needs.

Examples of Modular Station Equipment

Modular equipment examples found in any station are pre-assembled electrical control panels, skid-mounted pumping systems, modular power distribution units, and transportable communication shelters. Modular means these components are made with consideration of flexibility and scalability so they could be put together or taken apart quickly, transported and deployed swiftly, and functionally meet operational requirements.

Future Trends in Modular Fuel Stations

Advances in sustainability, technology, and adaptability dictate the future of modular fuel stations. The key trend includes integrating renewable energy technologies such as solar panels and energy storage to maximize independence on grid power sources and to minimize carbon footprints. Alongside the support of alternative fuels, there are ongoing arguments for EV charging stations and hydrogen refueling infrastructures’ incorporation within modular considerations.

Emerging Trends:

- Renewable Energy Integration: Solar panels and energy storage systems for grid independence and reduced carbon footprint

- Alternative Fuel Support: EV charging stations and hydrogen refueling infrastructure incorporation

- Digitalization: IoT-enabled remote monitoring systems, advanced analytics, and contactless payment solutions

- Rapid Deployment: Prefabrication methods for quick setup in remote or poorly served areas

- Enhanced Customer Convenience: Smart technologies and automated systems for improved user experience

- Environmental Focus: Greener technologies aligned with sustainability goals

Digitalization is an important driver, following the incorporation of IoT-enabled remote monitoring systems, advanced analytics, and a range of contactless payment solutions to benefit operations and facilitate customer convenience. At the same time, modular fuel stations are increasingly designed for speedy deployment in remote or poorly served areas, with the aid of prefabrication methods that reduce construction times and costs. These trends set a bilevel, tied to the ongoing needs of a greener, technology-infused present-day transportation ecosystem.

Summary and Key Takeaways

The comprehensive understanding of tank station equipment is fundamental to ensuring safe, efficient, and compliant operations in the fuel industry. From underground storage tanks and sophisticated fuel pumps to advanced monitoring systems and modular solutions, each component plays a critical role in the overall functionality of fuel stations.

Critical Points to Remember:

- Proper selection and maintenance of fuel pumps (mechanical, electric, and turbine types) ensures optimal performance and longevity

- Storage tanks must comply with strict safety standards and regulations from agencies like EPA, OSHA, and API

- Advanced monitoring systems such as ATGs provide real-time data for inventory management and leak detection

- Fuel nozzles must be matched to specific fuel types to ensure safe and efficient dispensing

- Piping system materials should be selected based on operational requirements, including pressure, temperature, and chemical compatibility

- Modular solutions offer significant advantages in construction time, cost efficiency, and environmental impact

- Future trends emphasize sustainability, digitalization, and support for alternative fuels

Conclusion

Industry Best Practices: The success of tank station operations depends heavily on the integration of quality equipment, adherence to safety regulations, and commitment to regular maintenance and inspections. Station owners and operators must stay informed about technological innovations, regulatory changes, and industry best practices to maintain competitive, safe, and environmentally responsible operations.

As the fuel industry continues to evolve with new technologies and stricter environmental regulations, the importance of understanding and properly maintaining tank station equipment cannot be overstated. Whether you’re establishing a new facility or upgrading existing infrastructure, investing in high-quality equipment, implementing robust monitoring systems, and following industry standards will ensure operational excellence, environmental protection, and long-term business success.

Final Perspective

The tank station equipment industry represents a critical infrastructure sector where safety, efficiency, compliance, and environmental stewardship converge. By implementing the knowledge, technologies, and best practices outlined in this comprehensive guide, station operators can build resilient, profitable, and sustainable operations that serve their communities while protecting the environment for future generations. Continuous learning, adaptation to new technologies, and unwavering commitment to safety standards are the cornerstones of success in this dynamic industry.

Reference Sources

“Construction of Digital Twin System for Intelligent Mining in Coal Mines”

Frequently Asked Questions (FAQs)

What importance does tank station equipment have in fuel retailing?

Tank station equipment is the critical aspect of fuel retailing that enables the actual dispensing of fuel, safely and efficiently. From fuel pumping to storage of fuels, each equipment has its own factors based on which they combine to give customers a solution-free service while adhering to safety and environmental regulations.

How do fuel pumps and dispensers work at a gas station?

Fuel is transferred from underground storage tanks to the vehicle through pumps or dispensers at the gas station. These devices have a nozzle that starts and stops the flow of fuel; some may also give options for payment or provide loyalty information to enhance the customer experience.

What features does modern-fit gas station equipment offer?

Modern gas station equipment is usually equipped with more advanced dispensers with digital interfaces, real-time data monitoring, and safety features such as vapor recovery systems. This increases the efficiency and ensures compliance with environmental laws and regulations.

How can a fuel management system assist in aiding the service station operator?

The fuel management system allows for real-time monitoring of the inventory fuel and fuel levels by the service station operators. It also helps reduce waiting times for customers by enabling operational efficiency and providing insights into decision-making for supply chain management.

What are the payment options at a fuel station?

Payment options available at fuel stations included the traditional credit or debit card, mobile payments, and contactless payment solutions. These payment options ensure customer satisfaction through convenience and security during transactions.

What is the role of the tank gauging system in a fuel station?

Tank gauging systems are used to check the fuel quantity in storage tanks and ensure that safety regulations are complied with. Real-time data provided by these systems helps fuel retailers in inventory control, preventing possible contamination of the environment.

How to open a successful gas station?

To ensure success with a gas station, the operators should install the finest station equipment and implement effective customer loyalty programs while offering a customer-friendly operational interface. Meanwhile, knowing what exists as a competitive edge in the global gas station equipment market can assist one in retaining customers.

What safety precautions apply to gas station equipment?

Safety precautions for gas station equipment include the installation of leak detection systems, adhering to tank monitoring procedures, vapor recovery technologies, etc. These measures protect the environment and ensure the safety and security of all clients and personnel at the service station.