Device fuel dispenser systems are very important in the fuel retail and distribution industry, and they are the main factors in making the delivery of fuel efficient, correct, and safe. Modern fuel dispensers can do much more than just dispense since they are capable of managing multiple products, integrating advanced payment and inventory monitoring technologies, among other things. This piece of writing unveils the necessary management practices and cutting-edge equipment that are the backbone of effective fuel dispensing operations. The guide will provide practical insights for the professionals in the industry who want to stay in the over-competitive market today, regardless of whether it is system performance optimization, regulatory standards compliance assurance, or innovative solutions integration for a better customer experience.

Understanding Fuel Dispenser Systems

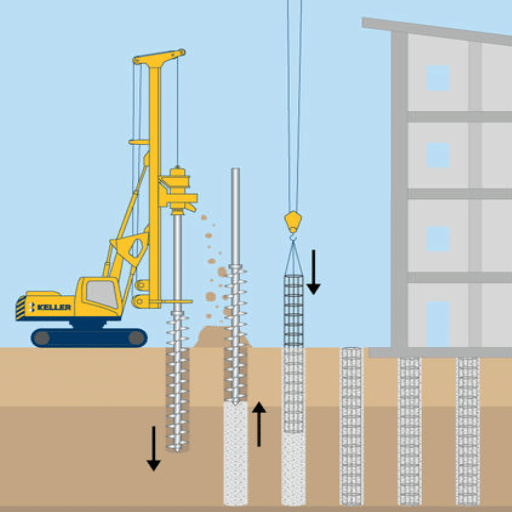

Fuel dispenser systems are essential to the process of accurate, efficient, and safe delivery of fuel to vehicles. A typical system would comprise, among others, a pump, a flow meter, a nozzle, and electronic control units that work together. A pump lifts fuel from the tank, and a flow meter tracks its volume with precision. Nozzles control the amount of fuel being dispensed, and advanced electronics handle transaction data as well as operate everything smoothly. Regular maintenance, calibration, and following safety guidelines are necessary for the best operation and the meeting of industry norms.

What are Fuel Dispensers?

Fuel dispensers are intricate and sophisticated devices that ensure the liquid fuels at the gas stations are distributed swiftly, taking care of any safety measures in the process. They are the main machines the oil and gas industry uses, and they come alongside the technology and engineering that are very advanced to provide accurate and reliable service. Today’s fuel dispensers are made up of various main parts like hydraulic systems, vapor recovery mechanisms, and computerized control interfaces. The combination of these systems is vital for fuel delivery management, monitoring of usage, and compliance with strict environmental and safety regulations.

Market Growth: Worldwide figures reveal a market rise in fuel dispenser technologies brought about by the increasing demand for giving up fossil fuels and using CNG, LNG, and biofuels instead. For instance, one of the latest developments in innovation has been the introduction of high-speed dispensers that are up to 40 gallons per minute fast for commercial applications, besides the already existing integrated payment systems that now offer secure and fast transactions as well as greater user comfort and higher operational efficiency in the process.

Fuel dispenser design is almost entirely dictated by environmental issues. Typically, vapor recovery systems are added to the pumps to capture and reduce the amount of pollution that would otherwise be released into the atmosphere during the process of fuel transfer, thus complying with regulations such as those implemented by the Environmental Protection Agency (EPA). IoT-connected dispensers also allow the user to monitor the system in real time and perform maintenance based on predictions, thus eliminating downtime and increasing operational efficiency. The trend toward automation and digitalization in fuel dispensers has been marked by their rapid adaptation to be in tune with future trends in mobility and sustainability.

Components of Fuel Dispensing Systems

The various components that make up fuel dispensing systems interact with one another in a way that guarantees efficient and safe fuel transfer.

Fuel Pump

The main component responsible for pumping the fuel from the storage tank to the nozzle is at the center of it all. The modern fuel pumps usually come with cutting-edge technology to control the rate of flow and air pressure, which reduces the chance of spilling and guarantees accuracy.

Metering System

The one that ensures the accurate measurement of fuel dispensed. These systems that use advanced flow meters like positive displacement or ultrasonic meters give precise readings for regulatory compliance and consumer trust maintenance.

Hoses and Nozzles

The main parts of the delivery system and are built to endure the different kinds of fuel and to stop leaks and spills. Nozzles generally have automatic shut-off devices to avoid filling beyond the intended limit.

Electrical Control System

Made up of hardware components such as relays, switches, and sensors, which are connected to the software that oversees and controls the dispensing processes. The Internet of Things feature is that these systems are also used for data analytics to further improve their performance.

Filtration System

Preserves the quality of the fuel by taking off impurities before it goes through the nozzle. The combination of these components results in a setup that gives first priority to safety, functionality, and environmental compliance in the present-day fuel dispensing systems.

How Fuel Dispenser Systems Work

The functioning of fuel dispenser systems relies on the intricacy of mechanical and electronic components that work in conjunction with one another to guarantee precise and speedy fuel transfer. The operation starts with a submersible or suction pump that pulls the fuel out of an underground storage tank. The system then utilizes highly accurate flow meters to measure the volume of the fuel according to the movement of gears or pistons within the meter, thus providing very precise dispensing.

The fuel subsequently passes through a filtration system, which eliminates the impurities and particulate matter that may compromise quality and engine durability. During this, electronic sensors along with software are managing the flow, so delivering it at a constant rate while also stopping the excess dispensing. Dispensers that are such advanced have IoT capabilities, which allow them to be monitored and diagnostics done on the spot, even with data analytics for a performance-optimized system.

The nozzle at the dispensing point is equipped with an automatic shut-off device that is activated when the tank level gets close to full, so it prevents spills and accidents. Besides these, the systems have vapor recovery devices that suck in and thus cut down the harmful emissions, so they go absolutely by the laws regarding pollution and safety. The combination of strong mechanical operation with state-of-the-art technology leads to the creation of fuel dispenser systems that are world-class in terms of precision, reliability, and conformance with global industry standards.

Types of Fuel Dispenser Systems

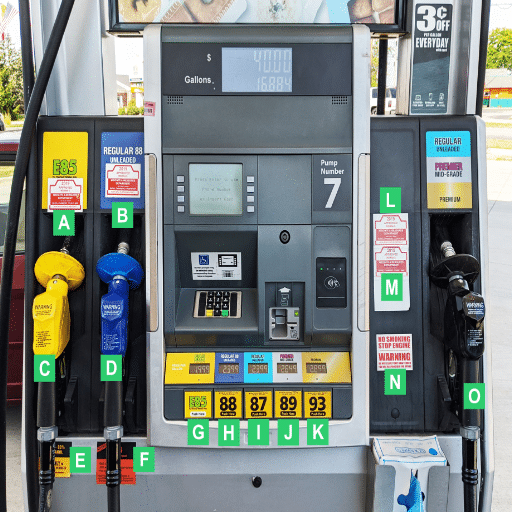

Fuel dispenser systems are usually grouped into two main categories depending on how they operate:

| System Type | Description | Key Features | Best Use Case |

|---|---|---|---|

| Single-Hose Dispensers | Systems that consist of one hose for each kind of fuel | Specific fuel dispensing, prevents fuel mixing | Facilities requiring precise fuel control |

| Multi-Hose Dispensers | Can accommodate different grades of fuel with different hoses for each grade | Multiple simultaneous services, quick customer service | Busy areas with diverse customer needs |

All kinds are made to comply with the industry regulations regarding safety, precision, and environmental friendliness.

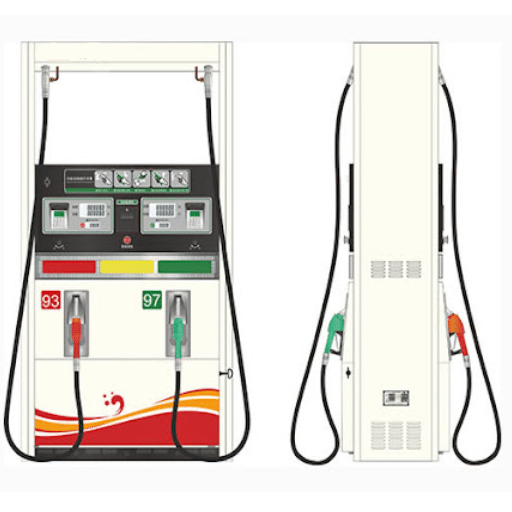

Traditional Fuel Dispensers

Fuel dispensers of the traditional type are the fueling stations’ very core, providing accurate amounts of gasoline, diesel, or other fuels in a manner that is both efficient and safe. To achieve this, they are made up of a combination of mechanical and electronic parts comprising metering pumps, nozzles, and flow meters, ensuring that the fuel is delivered without any errors. Besides that, they frequently have integrated vapor recovery systems so as to minimize the effect on the environment and to be in line with emissions regulations.

Dispen-sers of modern type have been coming along with the advancements of technology that add to the traditional models with digital displays, payment terminal integration, and automatic calibration mechanisms. All these upgrades are aimed at making the user experience and operational efficiency better. Traditional dispensers still provide a reliable option for station operators, especially in locations where infrastructure makes it hard to apply advanced fueling technologies. Their robustness, low maintenance, and adherence to safety standards in the industry make them a vital aspect of the fuel distribution systems in the world.

Smart Fuel Dispensing Equipment

Smart fuel dispensing devices combine high-tech features to make fuel distribution more accurate and efficient. Moreover, these systems usually empower the operators with monitoring capabilities, prevent losses, and improve performance through real-time alerts, IoT connections, and cloud data analytics. The measures, such as automatic shut-off valves, RFID-based customer recognition, and mobile payment integration, give the users both safety and comfort. The modern solutions also comply with rigorous regulatory standards, thereby providing dependable compliance with less maintenance downtime. In conclusion, the application of smart dispensing systems shows that the fuel management sector is strategically shifting towards a digitally-driven approach to meet the growing global demands for efficiency, scalability, and sustainability.

Mobile Fuel Dispenser Systems

Mobile fuel dispenser systems are small, powerful, and efficient devices that give fuel on the spot and are mostly used in the construction, agriculture, and logistics industries. The integration of sophisticated pumping mechanisms, flow meters, and hose reels in a mobile or portable unit usually allows for accurate fuel dispensing. Mobile dispensers have various features like real-time fuel monitoring, automatic tracking systems, and multiple payment choices that are all aimed at achieving accuracy in operations and simplifying fuel management.

Fuel dispensers have several benefits, and one of them is the quick refueling process. The design of these machines meets the requirements of the industry, thus assuring a smooth supply chain and use up to the point of consumption. The systems are indeed state-of-the-art, with some even coming with IoT technologies that include remote monitoring, fuel inventory management, and security features. In this way, mobile fuel dispenser systems become effective for those companies that need fuel solutions to be efficient, power scalable, and can fit into the changing operational environment.

Fuel Dispensing Solutions

The latest fuel dispensing solutions are engineered to maximize efficiency, safety, and accuracy throughout the fuel distribution process. Usually, these systems comprise high-tech flow meters to deliver exact measurements, filtration units to provide clean fuel, and automated control units for hassle-free operations. They fit into different places, ranging from big factories to small shops, and they can deliver fuel in a dependable and scalable way. Companies can decide on the systems that best fit their needs and, at the same time, be compliant with environmental and safety regulations through choices such as mobile or stationary units.

Mechanical vs. Electronic Fuel Dispensing

Mechanical Fuel Dispensers

Mechanical fuel dispensers use analog technology, and their operations depend on the rotation of gears and the movement of the measuring components, which makes them perfect for areas with no electricity or where the power supply is not reliable.

Advantages: Their simplicity of construction makes them easy to maintain, very durable, and resistant to bad weather conditions.

Disadvantages: They generally do not possess such high precision and data logging features as electronic dispensers.

Electronic Fuel Dispensers

Electronic fuel dispensers employ digital technology to improve accuracy, provide user interface options, and enable features like automatic transaction reporting, remote supervision, and syncing with fuel management systems.

Advantages: Offer excellent control and data access for operations that require tracking and reporting in detail.

Disadvantages: Need a stable power supply and are typically more costly in terms of purchase and maintenance.

The selection of a mechanical versus an electronic system is largely dependent on the operational priorities, budget limitations, and app-specific environment wherein the mechanical systems are made of basic, durable applications, while the electronic systems are modern, data-driven ones.

Innovative Solutions for Fuel Dispensing

Automated Fuel Management Systems

Automated fuel management systems are a huge step forward in the use of technology for fuel dispensing. RFID tags, Internet of Things (IoT) integration, and cloud-based software are some of the technologies that these systems use to their full advantage to facilitate fuel dispensing operations. These systems make the processes easier to manage and provide accurate monitoring of fuel consumption, which, in turn, leads to less human error and more efficient operation overall. The movement of fuel is controlled by RFID tagging, and data monitoring is done in real-time through IoT and cloud platforms, allowing the operator to not only know the fuel levels but also to detect anomalies and to create comprehensive reports that facilitate the making of informed decisions.

Contactless and Mobile Payment Systems

The next big thing in fuel dispensing solutions has been the integration of contactless and mobile payment systems into the process. These applications reduce waiting times at gas stations by allowing customers to refuel faster. Operators and consumers enjoy the benefit of a quick, easy, and secure payment processing through the use of mobile apps and NFC (Near Field Communication) technology. In addition, the integration with loyalty programs not only helps in customer retention but also provides knowledge about consumer patterns.

Green and Sustainable Dispensing Technologies

Sustainability is still a very important area, and green dispensing technologies are gradually taking over the industry with their innovations. The use of biofuel-compatible dispensers, vapor recovery units, and energy-saving designs is becoming more widespread as a means to reduce the negative impact of the industry on the environment. These measures are in line with the regulations designed to lower the production of pollutants and the usage of resources while keeping the efficiency of operations at a high level. Such technology implementation not only supports the ecological targets but also provides the professionals in the industry with the benefit of the operating cost reductions, which are in the long run.

Industry Transformation: The fuel dispensing industry is embracing change and will be going the integrated technology way. No doubt technology-led organizations are going to have an edge over the traditional ones, though with a few hiccups, in the transition from traditional to modern operations in a fully efficient manner.

Risk Management in Fuel Dispensing

Risk management that is efficient in fuel dispensing is a vital factor for the safety, compliance with regulations, and effective operations. The major risks are the malfunctions of the equipment, leaks of fuel, emissions of vapor, and fire; these can all lead to environmental destruction, financial losses, and health hazards. Some of the preventative actions that include the regular maintenance of equipment, the use of advanced leak detection systems, and strict inspection protocols are the main contributors to the reduction of these risks.

Being compliant with laws set by the industry, including those of the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA), is a decisive factor in risk management. The use of vapor recovery systems and following the guidelines for storage tanks are some very common measures that are taken to avoid the release of dangerous emissions and the pollution of aquifers. Moreover, training programs for employees contribute significantly by making them capable of dealing with emergencies and thereby helping in the reduction of accidents.

Modern innovations like automatic surveillance systems and Internet of Things (IoT) connections are making it possible to have better management of the fuel and equipment through real-time tracking, which will be very helpful in the fast identification and fixing of potential problems. A strong safety culture and a proactive approach towards predictive maintenance will not only minimize the liabilities but also ensure the long-term sustainability of the operations.

Product Innovations in Fuel Dispensing

Modern fuel dispensing technologies give priority to efficiency, accuracy, and environmental safety. Along with high-flow nozzles, which have now become commonplace in the industry, fuel transfer rate has been improved, thus causing the operation to be done faster and more smoothly. Digital meters equipped with sophisticated calibration systems guarantee the measurement of fuel to be very precise, hence reducing errors and possible losses. Besides, vapor recovery systems help to prevent the emission of harmful gases during the dispensing process, thus complying with the strictest environmental laws. The mentioned technological improvements are not just about performance but sustainability and quality of operations.

Latest Trends in Fuel Dispensing Equipment

IoT-Enabled Systems

The fuel dispensing technology is changing very fast to fulfill the needs of modern operations, the environment, and consumers. One of the major trends is the integration of IoT-enabled systems that provide real-time monitoring and predictive maintenance capabilities. The data collected from these systems is analyzed to make sure that the equipment is performing optimally, neglected periods are minimized, and overall efficiency is increased.

Contactless Payment Systems

Another important development is the universal use of contactless payment systems, which are not only a customer convenience but also an improvement in transaction speed without compromising security.

Environmental Compliance Technologies

Environmental compliance is still one of the major factors influencing technological innovation. Fuel dispensers now have vapor recovery and leak detection systems, which are very effective in preventing environmental pollution and thus meeting the government regulations.

Alternative Fuel Infrastructure

In addition, there is a move towards hydrogen and electric vehicle (EV) charging infrastructure, which shows the sector’s commitment to the alternative energy market, which is still in development. These innovations serve as pointers to manufacturers’ readiness to provide cutting-edge, eco-friendly, and customer-friendly fueling solutions.

Eco-Friendly Fuel Dispenser Solutions

Eco-friendly fuel dispensers are made up of creative technologies and the use of sustainable practices, and thus, their purpose is to stamp out the environmental impact completely. The current systems have added features such as vapor recovery systems, which hold and reuse hydrocarbons that would otherwise be released into the air during refueling, and thus, the emissions are cut a great deal. Moreover, new dispensers are using the resources and parts that are longer-lasting and less harmful to the environment, for example, the use of corrosion-resistant metals and Biodegradable fats.

One more significant characteristic is the installation of sophisticated control systems for the detection of leaks and their prevention, which in turn guarantees adherence to strict environmental regulations. Smart dispensers give real-time data analytics that allow operators to enhance the process of fuel delivery while cutting down on waste and energy consumption. The switch to hydrogen refueling and electric vehicle charging capabilities in dispenser units reflects the industry’s movement toward providing support for low-carbon and zero-emission energy solutions. These systems that are integrated not only with alternative fuels but also with future technologies, and therefore, can satisfy ever-increasing consumer and regulatory demands.

Without a doubt, the eco-friendly fuel dispensers have only represented a monumental step forward in the worldwide endeavor of making the planet free of incinerating gas emissions, giving the air a fresher quality, and making the use of renewable energy easier. Their production is a clear statement of the driving force behind innovation and environmental responsibility in the industry of fuel supply.

Safety Features in Modern Fuel Dispensers

Key Safety Features

Modern-day fuel pumps are created with sophisticated safety measures that ensure reliability in their operations and also protect the users, equipment, and the environment. Among the main safety features integrated into the dispensers:

- Emergency Stop Buttons: Instantly shut down the machine when pressed, thus lowering the risk in case of an emergency.

- Leak Detection Systems: Stop fuel spillages, which in turn cuts down on the possibility of the environment being contaminated and incidents happening due to safety.

- Overfill Prevention: Incorporated to stop fuel spillages and ensure safety during operations.

- Pressure Monitoring and Automatic Shutoff: Play a great role in safety by properly managing the flow of fuel and spotting any irregularities instantly.

- Flame Arrestors and Explosion-Proof Parts: Bring fire or explosion hazards under control while dealing with flammable fuels.

- Anti-Siphoning Valves: Secure the fuel against theft and notify when unauthorized access is attempted.

In order to meet the high safety and compliance standards, the materials used in the construction of the pumps are generally of a corrosion-resistant type and compatible with numerous fuels, including biodiesel and even blends of ethanol. The safety features, in sum, make it possible for the dispensers to meet the industry regulations while protecting both human and environmental health.

Challenges in Fuel Dispensing Management

The management of fuel dispensing has to deal with various major challenges, such as keeping the equipment reliable, ensuring efficient operation, and meeting the strictest safety regulations. Among these, equipment failures like malfunctioning nozzles or inaccurate pumps are the biggest issues since they can cause disruption of operation and also result in loss of money. Another concern is the management of inventory, where inaccuracies in fuel levels can be caused by leakage, stealing, or wrong measuring. Besides that, the compliance with the changing environmental as well as safety regulations leads to the continuous upgrading of systems and technologies, which could be a resource-consuming activity. All the above-mentioned problems need strong supervision systems, constant maintenance, and investment in cutting-edge technology for facilitating accuracy and security improvement.

Common Issues Faced in Fuel Dispensing Systems

The upkeep of fuel dispensing systems entails several recurring issues that need to be handled in order not only to keep the system working efficiently but also to meet the compliance standards. Among these, the foremost issue is metering inaccuracies, which are often caused by wear and tear on mechanical parts or drift in calibration, thus leading to incorrect fuel measurement. Another major issue is nozzle failure that frequently occurs because of blockages or broken seals affecting the flow of fuel, and as a result, the company has to deal with the wastage of the resource. Also, vapor recovery system breakdowns complicate the situation as they prevent not only the company from meeting the environmental regulations but also result in the loss of fuel and thus increase air pollution. Resolving these problems requires the implementation of routine maintenance, replacement of worn-out equipment, and installation of modern monitoring systems for maintaining diagnostics in real-time and enhancing operational integrity.

Key Challenges

- Equipment failures and malfunctions

- Metering inaccuracies

- Nozzle failure and blockages

- Vapor recovery system breakdowns

- Inventory management issues

- Regulatory compliance requirements

Effective Solutions

- Establish detailed maintenance programs

- Replace old equipment with energy-efficient models

- Incorporate high-tech monitoring systems

- Implement real-time diagnostics

- Regular calibration and inspection

- Investment in modern monitoring technology

Solutions for Efficient Fuel Management

For efficient fuel management, I would mainly focus on establishing a detailed maintenance program that would make sure that every system is running at its best. It would be of great importance to replace old equipment with new, energy-efficient, and reliable ones to increase reliability and decrease fuel waste. Moreover, I would incorporate high-tech monitoring systems that would give instant diagnostics, thus allowing quick troubleshooting and fixing of problems. Compliance would be improved, waste production reduced, and total system efficiency optimized through these actions.

The Future of Fuel Dispenser Systems

Fuel dispenser systems are developing very fast to meet the needs of all three areas: efficiency, sustainability, and modern consumer experiences. The application of IoT (Internet of Things) technology is a vital part of this process, allowing the creation of more intelligent dispensers that can perform data analytics in real-time. Such systems keep track of not only the fuel levels and usage but also the maintenance needs. The upshot is that reduced downtime is significant. The demand for sustainable practices, in turn, has ushered in new developments in energy-saving devices and alternative fuels. The alternative includes EV (electric vehicle) charging stations and hydrogen fueling stations. The digital payment integration and user interface features targeting the customers are also significant in changing the scenario of user experience by making the process smoother and providing customized services. In the near future, the use of AI and blockchain technology is likely to bring even more improvements to the accuracy, security, and transparency of operations at fuel dispensers. The cumulative effect of these developments is to produce dispensing systems that are not only highly efficient and planet-friendly but also very much appealing to consumers.

Reference Sources

Worldwide Fuel Dispenser Industry to 2025

Automated Fuel Dispensers: What You Need to Know

Fuel Dispenser Market Analysis and Forecasts 2024-2029

Frequently Asked Questions (FAQs)

What are the key parts that make up the fuel dispenser systems?

The fuel dispenser systems are mainly made up of the fuel pump, meter, nozzle, and control system as their most important parts. The fuel pump removes the fuel from the storage tank, the meter records the amount of fuel given out, and the nozzle gets the fuel to the vehicle in a safe manner. On the other hand, the control system is responsible for the whole operation of the dispenser, which ensures the right transactions are done.

What are the main differences between diesel and gasoline dispensing systems?

The diesel dispensing systems have been specially devised to cater to the diesel fuel’s unique characteristics, which are quite different from those of gasoline. For one, diesel is thicker and has separate pump mechanisms to extract the fuel from tanks. In addition, flow rates are provided along with nozzles that are distinct for diesel dispensers and can manage high-volume dispensing, thus making it a more efficient fueling experience for commercial fleets.

Why does proper fuel storage matter in dispenser systems?

Proper fuel storage is the key to quality fuel maintenance and efficient fuel dispenser systems. Poor storage results in fuel contamination, which in turn damages the equipment and affects the percentage of fuel sales. Aboveground storage tanks are usually the ones that are chosen due to their accessibility and being able to be monitored, thus the chances of encountering problems that are related to leaks and spills are reduced.

What are the factors that affect the pricing of fuel dispenser systems?

The price of fuel dispenser systems might be affected by different factors such as the type of fuel that is dispensed, the technology used, and the entire capacity of the system. Dispensers that can dispense high volumes might be more expensive due to their advanced features and increased throughput, while simple models might be more affordable for small operations.

How do fleet operators gain from efficient fuel dispenser systems?

Fleet operators can enormously benefit from efficient fuel dispenser systems as they can reduce the time spent on refueling and keep a better track of fuel usage. This can be a reason for huge savings of money as fleets would be able to consume proper fuel and keep their downtime to a minimum. Moreover, modern dispenser systems can sync with software for fleet management, thus having seamless operations.

What are the safety features that must be there in fuel dispenser systems?

Some of the must-have safety features in fuel dispenser systems include automatic shut-off valves, emergency stop buttons, and spill containment systems. These are put in place to avoid the incidents of fuel spills and leakages, thus providing a safe atmosphere for both operators and customers. In addition to that, proper signage and training for users add to the safety of dispensing operations.

Are the fuel dispenser systems capable of being tailored to certain products?

Definitely, fuel dispenser systems can be tailored to meet the needs of specific products, be it different grades of fuel, additives, or alternative fuels. Among the customization options are installing specialized nozzles, changing flow rates, and introducing specific payment systems, which make them very versatile regarding various fueling needs and business models.

Is there maintenance needed for fuel dispenser systems?

Maintenance of fuel dispenser systems is a must regularly so that their performance is not only optimal but also their life span is increased. Included in this are the routine inspections, cleaning of filters and nozzles, and calibration of meters. Among others, the condition of pumps and hoses should be checked, and if any repairs are needed, they should be done instantly to prevent service interruptions.