Hard rock drilling is a special kind of operation that needs the creation and application of tough solutions, very much like high-tech machines able to operate under extreme conditions. The job augers do: they are durable and able to work efficiently in harsh environments. Rock augers are designed for heavy-duty drilling of hard rock, to cut dense, abrasive materials with precision and confidence. In this article, the main aspects of rock auger drill bits are considered, describing their importance to today’s drilling and increased productivity with lower downtime. The more one knows about these rock augers, will heighten their level of working efficiency and therefore the success of their project in construction, mining, and utilities.

Understanding Rock Augers

Rock augers are specialized drilling tools designed for penetrating hard, abrasive materials like rock, concrete, and compacted soil. Constructed with heavy-duty materials and reinforced cutting edges, they provide maximum durability and efficiency in harsh environmental conditions. These tools are used chiefly in foundation drilling, excavation, and installation of utilities, applied accordingly when the highest precision and reliability become mandatory. Their design minimizes wear and optimizes cutting action, making their use essential in modern-day drilling operations.

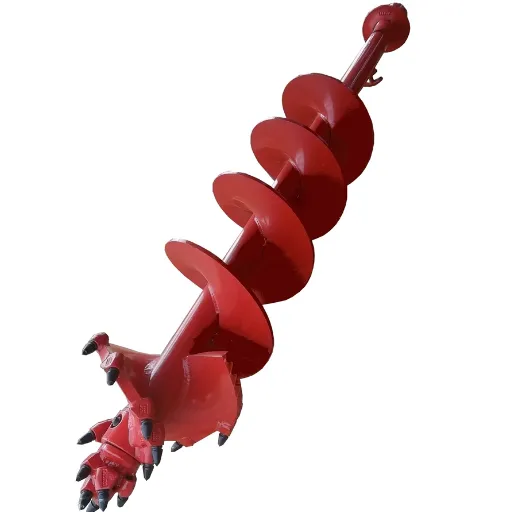

What is a Rock Auger?

The rock auger represents a type of specialized drilling tool used to penetrate hard materials like rocks, densely compacted soils, and any other kind of hard geological formation. The teeth are very strong, usually made of tungsten-carbide or similarly hardened metals, to resist the tremendous pressure and abrasion. The cutting edges on a rock auger are arranged such that they maximize material removal while minimizing wear, thereby prolonging tool life and increasing operational efficiency. The diameter of rock augers varies widely between 6 inches to more than 60 inches, depending on the drilling application requirements.

Because of their robustness, these augers are capable of producing high torque and cooperating with heavy rigs. They may, depending on the rig and geological environment, drill depths up to several hundred feet.

From the drilling rock auger applications perspective, consider foundation piling, installation of geothermal probes, mine exploration, and utility pole installation. Advanced configurations can have, among other things, hardened pilot bits and replaceable cutting teeth to accommodate the varying degrees of hardness in rock and its ultimate compressive strength beyond 15,000 psi in quite a few formations. Rock auger drilling can assure precision, reliability, and efficiency even in the most demanding conditions.

Components of Rock Augers

Rock augers consist of several critical components maximized for operative efficiency and durability in hostile drilling environments:

The Pilot Bit

The pilot bit is situated in the center of the auger and initiates the drilling operation by positioning the tool into the ground. As it is generally confronted with abrasive conditions and extreme pressure, it might be manufactured from hardened materials.

Cutting Teeth

Positioned at the edges of the auger, these teeth serve to break and cut into rock formations. Types of teeth can be carbide-tipped and rotating picks, selected based on the relative hardness of the rock and drilling application.

Flighting

The flight is a helical structure responsible for lifting debris and rock cuttings to the surface. In rock augers, flighting is usually heavy-duty and is coated with wear-resistant surfaces for greater efficiency and longevity.

Core Barrels (Optional)

Integrated into drill designs with certain applications in mind -splitting rock, core drilling, or dealing with harder formations for which standard cutting teeth are ineffective.

Hub and Drive Connection

This securely attaches to the drilling machine, transmitting torque and power efficiently for cutting operations. This connection is the basis for holding the cutter firmly during rotation.

Wear Pads and Hardfacing

Wear pads and hardfacing are applied to areas of the auger subjected to high spots where friction and stresses would wear down the auger over time if left alone. These reinforcements reduce wear and maintenance costs.

Each component can be configured to meet specific project requirements so that rock augers can handle applications in environments ranging from soft sedimentary layers to ultra-hard igneous formations. The development of an efficient maintenance and parts replacement schedule would go a long way to sustain performance.

Types of Auger Bits

Auger bits are numerous and varied, purposefully designed to optimize the performance of each drilling operation for given materials and varying conditions. The primary kinds are:

Standard or Earth Auger Bits

These bits are really good at drilling in soft to medium-density soils like clay, silt, and loose sand. They have extra-broad spiral flighting that helps eject loose material at a good rate, thus making general-purpose tasks like landscaping or post-installation easier.

Rock Auger Bits

The rock-type ones are placed inside harder substrates like shales, limestones, and other moderately hard rocks and thus are provided with carbide-tipped teeth or bullet-style cutting heads for enhanced penetration and wear qualities. The bits are often accompanied by wear plates and reinforced flighting to bear the high-impact drilling conditions.

Tree Auger Bits

Auger bits of this sort are used for things like planting trees or removing stumps. The dark auger has a tapered shape and a pointed cutting head to bore clean, narrow holes without wetting or disturbing the adjacent soil. This type offers smooth operation on the auger and reduces the load on the machine.

Combination Auger Bits

Combination auger bits are designed to work in conditions where there are alternating layers of soil, gravel, and soft rock. They have features of both standard and rock augers, including different tooth configurations and tough flights. Operators can drill through layers of soil, gravel, and soft rock with an auger bit of their choice without having to alternate tool life.

By choosing the right auger type for a particular job specified by the material, the operator can increase all advantages: better efficiency, less wear, and fast and precise drilling over a wide spectrum of geological conditions.

Torque and Performance

Drilling sites require considerably high torque, hence giving it back its prime significance in the optimization of efficiency in drilling operations. The higher torque gives the needed force against soil or rock to assure a minimum performance capacity under awkward working conditions. Performance is therefore maximized by the adequate selection of an auger torque capacity in relation to the specification of the machine and the material to drill. Reduced output, operational wear, and rubbing to the disorder level result from inappropriate torque levels. In any case, torque output should be continually observed to ensure that it matches the manufacturer’s specifications for best use.

Importance of Auger Torque

Anything rotary must be constrained along with the auger torque to attain maximum drilling efficiency and ensure the longevity of the equipment. Correct torque will provide enough rotational force to penetrate the materials, which may be soft soil or hard rock formations, maintaining consistent and effective performance. Lesser torque may stall, thereby inefficient operation and delay; more torque will wear down the equipment, cause structural damage, and may compromise safety.

Torque levels must be set while considering site conditions, such as the density and moisture content of the material. Following manufacturers’ settings and, as much as possible, maintaining regular checks and preventive maintenance on auger bits and other hydraulic components will ensure the best performance. Optimized torque increases productivity while decreasing operational costs and increasing the service life of drilling equipment. Proper torque management helps attain successful outcomes for an array of applications, varying from construction to agriculture.

Measuring Torque in Rock Drilling

Torque measurements in rock drilling employ special tools and monitoring equipment for accuracy and implementation in activities. The force moment is usually measured via torque transducers/sensors, which are adapted for integration with drilling equipment to provide real-time information. They convert mechanical force into electrical signals so the operators can keep track of the torque variation with great accuracy. Other factors affecting torque measurements are rotational speed, hydraulic pressure, and drill bit resistance, and need to be well-monitored during operations and consistency measurements.

Contemporary torque monitoring systems function on wireless and digital interfaces for seamless torque data collection and analysis. Calibration protocols are also supplied by manufacturers to ensure the reliable functioning of the torque measuring instruments. In rock drilling, correct torque measurement reduces equipment wear, avoids material damage, and optimizes penetration rates. Using these measurements, operators exercise better control over drilling performance in adverse geological situations.

Heavy Duty Rock Performance

In rock drilling, heavy-duty drilling with accuracy and durability for maximized performance in various geological environments is required. Modern drilling systems would use advanced materials and highly efficient torque-measuring instruments to become operationally consistent. According to some leading industry sources, correct torque application can reduce mechanical failure by 20%, thus increasing penetration rates in much harder rock formations. Manufacturers stress regular maintenance and calibration to enhance operations, stating that neglect causes equipment to become inefficient and will need a very costly repair. In addition, adaptive drilling technologies serve as another reliable way of improving performance by adapting to underground conditions in real time. These new-age technologies enhance operational output, making rock drilling projects more reliable and cost-efficient.

Auger Teeth and Their Functionality

Auger teeth are very important and necessary parts of drilling equipment; these teeth cut soil, rock, and other materials that come through excavation. The teeth are placed along the auger, and their sharp edges are very effective in breaking apart materials as the auger rotates. Their objective is to lessen the force needed to go through the ground and to ensure the smooth removal of materials so that they do not get blocked. To get quality products and to maintain durability and versatility in the rough working conditions, shock-resistant materials like carbide are mostly applied. Keeping the picking performance up and the project running efficiently can only be guaranteed whenever proper maintenance and timely replacement of worn-out running teeth are given equal attention.

Different Types of Auger Teeth

Auger teeth can be categorized with regard to shape, materials, and eventual function. Among common types, we count:

-

Standard Digging Teeth

They are all-purpose teeth and are good for use in average soil. The simple design usually entails moderate wear resistance and thus makes good applications for soils soft to medium-hard.

-

Carbide-Tipped Teeth

Being tipped with tungsten carbide, these teeth give the utmost wear resistance and cutting capability. The very abrasion-resistant and impact-resistant qualities of tungsten carbide make it most appropriate to cut through abrasive or compacted materials, such as rocky soils and clays.

-

Flat Teeth

Flat teeth do scraping and leveling jobs. The wide cutting surface is used to cut through hard grounds or layers of compact soil.

-

Pick Teeth

Pick-shaped teeth are designed for penetration into dense, hard soil or rock. They possess a pointed, conical design that allows precision cutting and enhances penetration, which is a necessity in difficult drilling conditions.

-

Chisel Teeth

The chiselled teeth combine the function of cutting and breaking, excelling at mixed soil and rock conditions. Their sharpened and beveled edges make for efficient fragmenting of hard materials.

Choosing the right type of teeth for an auger is critical in achieving the most efficient drilling, reduction of wear, and the good life of the machine.

Choosing the Right Auger Teeth for Hard Rock

Material composition, tooth design, and drilling equipment fitment have to be taken into consideration when selecting auger teeth for hard rock drilling. Since this type of tooth is made of tungsten carbide, which gives it its extreme hardness and wear resistance, it is highly recommended in all hard-working abrasive environments. In hard rock, bullet-style teeth guarantee penetrating and wear qualities; their original straight conical shape reduces stress concentration, so they are less likely to break.

However, consideration must be given to tooth spacing and rotation, so that there is uniform wear, preventing excessive loading of a particular tooth. Analyze wear and replace the worn teeth; such maintenance is the key to efficiency. The fit should be investigated as to whether it can be cast in the auger attachment because that fit conversion from torque to drilling force should be sturdy; the better the fit, the more productive it is in hard drilling applications.

Maintenance and Wear of Auger Teeth

Proper maintenance of the auger teeth entails guaranteeing maximum performance, longevity, and safety of the equipment. Foremost, one should clean the auger teeth after every use to avoid the accumulation of dirt, debris, or corrosive materials that may hasten wear. Frequent inspection of the teeth, especially looking out for signs of rounding of edges or cracks and fractures, should be done. Worn or damaged teeth should be promptly replaced, since any uneven stress distribution may cause damage to the adjacent components.

Another important maintenance in the upkeep of the auger teeth is lubrication to reduce friction and protect against wear and tear during operational movements. Sharpening is also another method used to remedy dull teeth, thus gaining more cutting ability, contrary to hard or rocky grounds. Lastly, one must observe the recommended torque value during installation to avoid loosening or compromising the auger teeth.

The use of high-quality and compatible replacement teeth, compatible with the materials and working conditions of the project, will greatly enhance all operational objectives, including durability and maintenance frequency. Finally, storing augers inside a dry, clean environment away from corrosive atmospheres will greatly enhance their potential service life. Consistently applying these measures reduces downtime, improves efficiency during operations, and prevents the double costs of repairs in highly stringent drilling applications.

Applications of Rock Augers

A rock auger comes into play where some sort of work is involved, drilling into hard, rocky terrains. The usual applications include foundation drilling for construction, installation of poles for utilities, and mineral exploration. They are specifically designed to cut through dense substrates for the precise and efficient excavated environment where a standard auger will not do. The qualities of having durability and strength make it indispensable in the infrastructure commissioning and resource extraction industries.

Using Augers with Skid Steers

When combined with skid steers, these augers represent a highly efficient and versatile system for digging operations in many industries. Skid steers are fitted with hydraulic auger attachments that allow the torque needed to break through tough soil and rock conditions. These attachments are usually easy to install, hooking up directly to the skid steer hydraulic system, allowing for quick installation and operational flexibility.

Augers for Excavators and Mini Loaders

Excavators and mini loaders fitted with augers are highly adaptable machines serving earthmoving and drilling activities and operating at very high operational efficiency in many applications. Augers for these machines are found in many sizes and configurations to accommodate both small landscaping jobs and big industrial projects.

Applications in Heavy Duty Drilling

An equipment for heavy-duty drilling, a feat for its durability and precision, must also function efficiently. Excavator augers play an important role in projects involving foundation drilling, utility installation, and geological sampling. Main Applications, Utility Installation, Geological Sampling, Foundation Drilling, and Other Industry-Wide Applications: Excavator augers can cut through any soil conditions, ranging from hard clays to shales to permafrost. The advanced models, as designed, offer huge torques, and they come with replaceable cutting edges for maximum versatility when drilling through very challenging substrates. Features such as hydraulic drives and shock absorbers reduce vibrations, thereby allowing for improvement in their control. Such high-end attachments allow the operator to do the job with much more accuracy while minimizing fatigue and the wear of the machinery.

Some important things to consider for the optimal use are choosing the correct auger bit type and size for the specific applications, say, a standard bit for soil or a rock auger for drilling through harder materials. Also, maintaining both skid steer and auger attachments is another important part of the task, including the checks on hydraulic connections and cutting edges of the auger, ensuring they remain sharp for best working. Imagine you have auger extensions sitting in storage; these extensions can help augment digging depth to tailor to the specifics of the project. Together, they carry out excavation tasks fast and accurately, which is extremely important for any fencing, tree planting, or foundation work.

| Machine Type | Torque Range | Hydraulic Pressure | Maximum Depth |

|---|---|---|---|

| Excavator Augers | 4,000 – 35,000 Nm | High-capacity systems | Up to 30 meters (98 feet) |

| Mini Loader Augers | Variable by size | 2,000 – 3,500 PSI | 4-36-inch diameter capability |

| Skid Steer Augers | Hydraulic driven | Direct hydraulic connection | Variable with extensions |

Advanced models are made out of heavy-duty materials such as hardened steel, guaranteeing their durability and a long service life, even under the harshest conditions. Depending upon the various specifications of the machine, augers for excavators can achieve torque maxima anywhere within 4,000 and 35,000 Nm (Newton-meters). The enormous torque value allows drilling with high efficiency through hard soil, clay, and gravel, and even certain types of rock. Furthermore, with the appropriate auger extension, depth can reach up to 30 meters (98 feet), making them perfect for piling or foundation work at such great depths.

Auger mini loaders provide enhanced maneuverability and are suitable for projects that require working within confined spaces or urban environments. These micro-sized yet hefty machines allow for augers measuring anything from a 4-inch diameter to 36 inches: an advantage that trumps any job requirement. Further, the hydraulic system powers the mini loader while exerting huge working pressure from 2,000 PSI to 3,500 PSI, and delivers direct power in adverse work conditions.

Choosing the right drive unit, and one that matches the hydraulic flow rate of the excavator or mini loader, is an important consideration when using augers. Today’s drive units come with advanced motors for high efficiency and good control at any speed. Carrying out maintenance-having the auger drive components inspected and lubricated on time-will ensure the best service with less downtime.

With robust engineering and state-of-the-art designs, the drilling augers for excavators and mini-loaders continue to speed up the utility pole installation, tree planting, and retaining wall construction tasks. Operators can increase productivity while ensuring higher accuracy and reliability in drilling operations by applying these machines with suitable attachments.

Auger Range and Options

The range of augers provided is meant to meet a myriad of applications light-duty landscaping tasks to heavy-duty construction and industrial operations. Augers are generally sorted by diameter and length, with the color and material allowing the operator to specify the right tool for the job at hand. By and large, the major types of augers are earth augers that generally drill soil, rock augers for reinforced and dense fractured material, and combine augers that offer some level of versatility against more than one substrate. Three more enhancements include extensions, wear parts, and special teeth configurations that allow operators to customize their equipment to fit the demands of their projects. Thus, with the right auger plus attachments, operators can maximize efficiency and reduce downtime.

S2 to S6 Auger Range Overview

The auger range from S2 to S6 is designed to provide top drawing power in a variety of drilling applications, both standard and heavy. The S2 auger will perform well for light-duty work and can drill in soft to medium-hardness grounds with relatively smaller equipment. On the other hand, the S4 are meant for medium machinery where they excel in engaging compacted soils and similar materials with greater precision.

With the S5 and S6 ranges designed for heavy-duty work, they possess reinforced hubs and intricate tooth configurations that perform well under high torque on hard grounds, rocks, and even fracturable substrates. Big machines coupled with these augers grant them all the durability and long-life operation required for working under harsh conditions. Customizable to include wear-resistant cutting edges, special pilot bits, and incisive tooth designs, they suit problematic grounds. The combined S2 to S6 auger range thus provides for the highest productivity capacity, lowest wear rate, and trouble-free integration onto various types of construction and drilling projects.

Hub Options for Different Machinery

When talking about hubs for different machinery, I tend to favor compatibility and efficiency. Depending on the machine and application, I consider hubs for different mounting systems–hexagon, square, or round–as they should be compatible with the rotational torque and operational demands intended for each application. Other considerations include the strength of the hub and the materials of construction to ensure high-stress durability. Choosing the right hub gives me that leverage to maximize the performance while ensuring smooth functioning between different machinery setups.

Choosing the Right Auger for Your Needs

Choosing the right auger depends on technical aspects relevant to its application. Firstly, consider the material with which you want to work: earth, clay, concrete, or ice; an auger is manufactured for each circumstance, with variations of blade configuration and material for its performance. In the case of earth drilling, select an auger with steel alloy blades and with a coating to protect against wear and corrosion.

Next comes the diameter and length of the auger, depending on the size of the holes required. The smaller ones (2-4 inches) satisfy minor gardening needs, while the larger diameters (6-18 inches) are for construction applications or industrial applications such as fence posts or foundation piling. Power must also be factored into the equation; a manual auger would do for light work, whereas gasoline or hydraulic augers offer more torque and drilling efficiency for the heavy and demanding jobs.

Last, look into compatibility with your machinery concerning the mounting system and torque requirements. Properly aligning the auger with the drive system works toward minimizing mechanical stress and imparting increased life to the operation. Consciously thinking about these considerations will help you select an auger that suits your functional needs for ensured performance over varied working environments.

Key Selection Criteria Summary

- Material Compatibility: Match auger type to drilling material (earth, rock, concrete)

- Size Requirements: Consider diameter (2-60+ inches) and depth needs

- Power Source: Manual for light work, hydraulic/gasoline for heavy-duty applications

- Machine Compatibility: Ensure proper hub fit and torque capacity

- Maintenance Needs: Factor in replacement parts availability and service requirements

- Environmental Conditions: Account for weather, soil moisture, and working space constraints

Reference Sources

Interpretation of the results of mechanical rock properties testing with respect to mining methods

NOY: a neutrino observatory network project based on stand-alone air shower detector arrays

Frequently Asked Questions (FAQs)

What are rock augers, and how do they operate?

Rock augers are very special drilling tools used for boring into hard and solid rock formations. With very strong rock auger teeth that can slice through very hard material and are mounted on all kinds of machinery, from a high-flow skid steer to an excavator, we must allow the rotating rock mechanism to cut some very steep spiral cuts so that the process can be done.

What is the difference between the S2, S4, and S5 auger ranges?

The lighter scenarios are handled with an S2 auger. Medium-duty works are done with S4 augers. The S5 augers are meant for heavy-duty sites suitable for high-flow skid steers and excavators. Each range differs as to auger wear resistance and the type of machines it accommodates.

How do auger torque and rock pilot contribute to drilling?

Designed to deliver greater rotational force and maintain stability during drilling, auger torque can indeed be considered a performance enhancer for rock augers. The rock pilot is a unique feature that guides the auger into the ground more accurately, ensuring precise drilling and efficient working, especially in harder ground conditions.

What are the advantages of using heavy-duty rock augers?

Because these heavy-duty rock augers are hard-facing steel materials, they provide the necessary toughness and remain tough when faced with tough job conditions. Making use of the most innovative rock auger teeth and tapering the cutting path, these augers serve excellent penetration to hard rocks and also prevent hard-rock wear.

Can I get spare parts for my rock auger?

Yes, spare parts for rock augers, including auger bits and teeth, may be found very easily, thus assuring maintenance of your equipment when necessary and changing out worn components to keep your drilling activities efficient and effective.

What types of machinery are compatible with rock augers?

Rock augers are compatible with almost any machine, from mini excavators ranging from 1t to 5t, 4.5 to 8t, to 17 to 45t excavators, backhoes from 8t to 22t, and mini loaders. They can also be fitted on high-flow skid steers and telehandlers, thereby being multifunctional in their drilling abilities.

What are the defining characteristics of the rock picks that rotate?

Rotating rock picks are the tools that enable the rock auger to drill with better efficiency. Their design allows a more penetrative cutting action that drills efficiently through solid rock. These picks are used alongside heavy-duty rock augers to enhance performance and reduce costs.

How do I maintain rock augers in their wear-resistant state?

To prevent the auger from wearing down, one should ensure proper maintenance. This can involve identifying the rock auger teeth for damage; replacing the worn-out parts, and ensuring proper lubrication for the auger. Another way is to use the wrong auger for the job or maintain correct spatial speed adjustment. These options will also help prolong the life of the equipment.

What does a shallower pitch of flights in rock augers give?

The shallow pitch flies experiment improved material removal, especially while drilling through solid rock. This gives better transport of soil and debris and reduces clogging, thereby providing better overall efficiency of drilling.