From an environmental perspective, gasoline vapor recovery systems must be installed in all operating-hour gas stations. These systems collect and contain gasoline vapors, supposedly harmful to humans when released into the atmosphere. On the environmental side, this prevents gasoline vapors from polluting the air, and on the economic side, it helps operators comply with stringent environmental regulations. In this article, we will discuss the importance of gasoline vapor recovery systems, their operation, and the benefits they provide to gas station operators, as well as their contributions to sustainability and the broader community. If you are an environmentalist or an owner interested in meeting the industry requirements, this guide will enlighten you on how these systems contribute to sustainability and efficiency.

Learn about gas station vapor recovery systems.

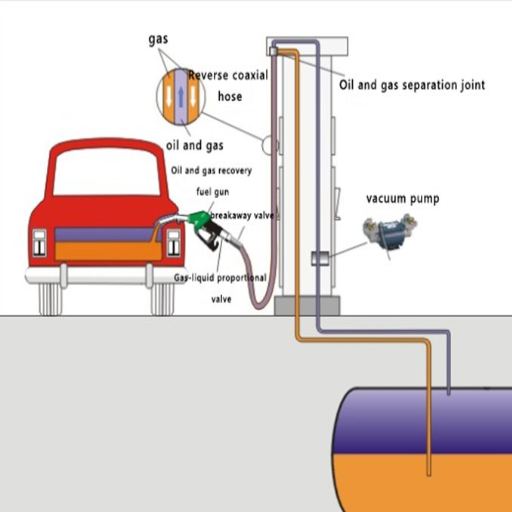

Gas station vapor recovery systems are designed to condense and collect gasoline vapors released during the fueling process. It is a method of keeping this threat-worthy vapor from floating in the air, thus preventing pollution and improving air quality. Vapor recovery usually involves two processes: First, Stage I captures vapors during a fuel delivery to an underground storage tank, and Stage II captures vapors at the pump, where the customer refuels their vehicle. With this, the release of VOCs into the environment is minimized, hence helping gas stations to comply with environmental regulations. In addition, the operators can reduce fuel loss and comply with environmental regulations through its installation.

What is a Gas Station Vapor Recovery System?

A vapor recovery system involves capturing vapors released during the fueling process, thereby preventing these harmful emissions from entering the atmosphere. It is usually a two-stage system. A Stage I system tries to recover vapors displaced from underground storage tanks by delivery trucks during fuel deliveries, thereby preventing the release of VOCs into the air. A Stage II system gets installed at the pump and captures vapors emitted as the customer fills his vehicle. It also traps these vapors through nozzles, and either returns them to the station’s storage tanks or treats them so they cannot be released into the environment.

Stage I vapor recovery systems are capable of a vapor recovery efficiency of up to 95% during fuel delivery, thus significantly reducing the risk of air pollution. Stage II systems have a greater impact in areas with high vehicular traffic, reducing VOC emissions that synergize with site environmental ozone concentrations and contribute to smog buildup. Over the years, improvements in vapor recovery technology have made these systems more efficient and reliable, with automatic monitoring systems ensuring continuous performance.

Vapor recovery systems’ integration is mandated in various parts of the world and is deemed essential for environmental sustainability. These systems reduce evaporative emissions, thereby ensuring better air quality and minimizing health hazards related to VOC exposure, which in turn strengthens global efforts to mitigate climate change. Gas stations equipped with vapor recovery technology demonstrate responsible environmental stewardship and compliance with stringent regulations.

How Gas Station Vapor Recovery Works

Gas station vapor recovery systems are engineered to capture and contain detrimental volatile organic compounds (VOCs) that are released into the atmosphere during underground gasoline refueling. The systems essentially counteract emissions with an effective two-stage recovery process.

Stage I Vapor Recovery pertains to the act of transferring gasoline from delivery trucks to underground storage tanks. With the entry of liquid fuel inside, vapor-laden air inside the tank gets displaced. Vapor recovery systems utilize a specialized type of piping and sealing mechanism, known as a vapor balance system, to redirect the displaced vapors back into the delivery truck, preventing them from escaping into the atmosphere. Studies prove that VOC emissions can be reduced by more than 95% in fuel delivery operations through Stage I systems.

Stage II Vapor Recovery begins at the nozzle when the vehicle needs to be refueled. The system cancels the escape of gasoline vapors when the liquid fuel enters the vehicle’s tank. The vacuum-assist or vapor balance nozzle either draws the vapors into the underground storage tanks at the station or keeps them contained for further emissions treatment. Stage II systems have the capacity, on average, to avert the release of 85% of VOCs into the air during vehicle refueling.

Modern technology has also helped incorporate monitoring and diagnostic systems to ensure optimal system performance. For example, in some locales, the vapor recovery system is equipped with sensors and automatic valves that adjust the flow in response to fuel flow rates and tank pressure. Such technological advances have helped meet stringent environmental standards, with several systems achieving an efficiency rate of up to 98 percent in volume recovery.

In addition to reducing air pollution, they conserve fuel that would have otherwise evaporated, thereby saving businesses money. The various carbon versions underscore the urgent need for vapor recovery systems to strike a balance between operational efficiency and environmental prudence.

Types of Vapor Recovery Systems for Gas Stations

The main types of vapor recovery systems for gas stations include Stage I, Stage II, Carbon Adsorption, and Membrane Separation systems.

|

Type |

Purpose |

Efficiency |

Key Feature |

Usage |

|---|---|---|---|---|

|

Stage I |

Capture vapors |

~95% |

Basic setup |

Fuel delivery |

|

Stage II |

Customer tank |

~98% |

Vehicle focus |

Refueling |

|

Carbon Adsorption |

Absorb vapors |

High |

Activated carbon |

Industrial use |

|

Membrane Sep |

Filter vapors |

High |

Advanced tech |

Specific setups |

The Importance of Gasoline Vapor Recovery

Gasoline vapor recovery is crucial for the environment and humanity. It prevents harmful vapors from being released into the atmosphere, thereby contributing to reduced air pollution and lower smog formation. The vapor recovery system, however, also helps conserve fuel by re-collecting vapors and reusing them; hence, from an efficiency standpoint, it is pretty advantageous. The implementation of well-designed and well-functioning vapor recovery systems enables industries and gas stations to comply with environmental regulations, protect public health, and adopt sustainable practices.

Reducing Emissions and Pollution

Emission reduction and pollution control are essential in mitigating climate change and improving air quality. Among the numerous sources of emissions, transportation is the largest. The United States accounts for about 29% of all greenhouse gas emissions. These emissions can be curbed through different measures, such as the use of EVs, improving fuel efficiency standards, and switching to renewable energy. For instance, EVs emit 50% fewer emissions (lifetime emissions) compared to conventional gasoline-powered vehicles, taking into account emissions from electricity generation as well.

Moreover, emissions from industries pollute the air on a vast scale. Carbon capture and storage (CCS) technologies that can reduce carbon dioxide emissions by up to 90% should be applied. The increased use of cleaner fuels, such as natural gas, and energy efficiency upgrades in small and medium-sized enterprises must also be encouraged to simultaneously reduce greenhouse gas emissions and other harmful pollutants, including sulfur dioxide and nitrogen oxides.

Confident choices can also help keep emissions low at the consumer level. Energy efficiency, the use of public transportation, and support for sustainable products can all help reduce individual carbon footprints. Collectively, these actions contribute to a more sustainable future, resulting in a significant reduction in the environment’s impact due to emissions and pollution.

Impact on Air Quality

Various industrial activities, transportation, and energy production release air pollutants. Recent findings indicate that approximately 7 million premature deaths occur annually worldwide due to air pollution, with fine particulate matter (PM2.5) and ground-level ozone being the most detrimental pollutants to human health. Air pollution levels in cities are usually higher due to population density and the emissions from all the vehicles, hence contributing to respiratory and cardiovascular illnesses.

Air pollution control efforts are yielding results. Cities that impose stricter enforcement of vehicle emissions controls, such as promoting electric vehicles and reducing fuel consumption from fossil origins, experience a dramatic decrease in nitrogen oxides and particulate matter. Other studies have shown that the creation of green spaces in urban areas helps improve local air quality. This green infrastructure acts as a filter for pollutants, providing cleaner air for the inhabitants.

The international emergence of renewable energies has had a positive effect on minimizing emissions of noxious substances, such as sulfur dioxide, which cause acid rain. More specific data shows that countries that have set their sights on solar and wind energy with great ambition have witnessed heavy decreases in health-related issues caused by air pollution. It is thus of utmost importance to continue mitigating the detrimental effects of air pollution at both local and international levels so that breathable air may be available for future generations.

Compliance with the Clean Air Act

The Clean Air Act has paved the way for numerous opportunities in air pollution control techniques, resulting in significant improvements in public health. The Clean Air Act has led to a 78% reduction in emissions of major pollutants, such as sulfur dioxide, nitrogen oxides, and particulate matter, since its passage in 1970, during a period of significant economic expansion and increased energy demand. Based on contemporary assessments, the EPA estimates that the clean air provided by this law has averted more than 230,000 premature deaths and a million cases of respiratory ailments annually.

The law served as a pathway toward innovation in cleaner technologies, encouraging industries to deploy the most advanced techniques for emissions control in factories, power plants, and motor vehicles. Recent research suggests that states with stricter air quality standards under the Clean Air Act have also observed improvements in respiratory health indicators and lower expenditures on care solutions for such diseases. Stronger monitoring and enforcement of air quality will now ensure compliance within sectors and lay the foundation for stronger air quality and health protections going forward.

Components of Gasoline Vapor Recovery Systems

A gasoline vapor recovery system comprises five components and various subcomponents that must work in concert to prevent gasoline vapors from entering and polluting the atmosphere. The components include:

Vapor Recovery Nozzle: A Specialized nozzle for the extraction of gasoline vapors while refueling.

Vapor Routing System: Pipes and hoses for transporting the vapors lifted off from the nozzle to the storage.

Carbon Canister: A filter that traps and stores gasoline vapors temporarily.

Vacuum Pump: To provide suction for the collection and transfer of vapors.

Storage Tank Vent: Safe release or containment of vapors from the storage tank, thereby ensuring the total efficiency of the system.

These components help reduce air pollution and promote environmental safety.

The Role of Nozzles in Vapor Recovery

Nozzles are at the heart of vapor recovery systems, facilitating the interface between fuel dispensers and the vehicle’s fuel tank. Advanced nozzles have been developed to prevent the escape of vapors during the refueling process. These nozzles utilize built-in seals and sensors to ensure secure connections and avoid fuel vapor leakage. These modern vapor recovery nozzles feature a double-hose system, where one hose carries the fuel, and the other collects the displaced vapors from the vehicle’s tank, transporting them back to the storage facility.

Studies reveal that these nozzles can recover up to 95% of fuel vapors, drastically reducing the emission of volatile organic compounds. This capability enables the resolution of air pollution issues on a broad scale, thereby contributing to improved urban air quality and the achievement of stringent environmental standards, as outlined by the EPA. With ongoing improvements, more advanced nozzles can now alert staff in real-time via sensors about any detected leak or malfunction, ensuring that all operations remain safe and optimized. These advancements further underscore the importance of nozzles in environmental protection during fuel dispensing.

Hydrocarbon Capture Mechanisms

Hydrocarbon capture mechanisms are a primary aspect of reducing emissions during the fuel transfer and storage phases. These systems primarily absorb vapor emissions that occur during fuel dispensing or in-store at the fuel tanks, preventing their dispersal into the atmosphere. Vapor recovery is perhaps one of the most popular technologies, operating mainly in two phases: Stage I and Stage II. The Stage I system captures vapors displaced from underground fuel storage tanks into the atmosphere during refueling and redirects them back into the delivery vehicle for recycling or disposal. Stage II systems instead capture vapors during vehicle refueling at the nozzle to minimize the release of volatile organic compounds (VOCs) into the environment.

According to recent research, advanced vapor recovery systems have been able to reduce hydrocarbon emissions by almost 95%. With activated carbon filters installed in vapor recovery units, the adsorption capacity is significantly enhanced, thereby improving overall efficiency. Additionally, other advanced systems break down hydrocarbons using thermal oxidizers or catalytic converters, thereby mitigating their adverse environmental impacts. The information suggests that these mechanisms not only ensure compliance with stipulated regulatory frameworks but also reduce the occurrence of urban smog formation, which is attributed to the reaction between VOCs and nitrogen oxides (NOx) in sunlight.

New constructs in hydrocarbon capture mechanisms, such as intelligent monitoring systems and automatic alerts, further enhance safety and reliability. These developments stand as candidates for any industry willing to align itself towards sustainability and diminish the adverse environmental impact caused by fuel emissions.

VOCs and Their Environmental Impact

Volatile Organic Compounds (VOCs) have been identified as a large group of environmental pollutants, their effects ranging from air-quality deterioration to adverse health consequences. Emitted by vehicles, industrial processes, paints, and household products, they serve as key precursors that form ground-level ozone and smog. Some VOCs can have indoor concentrations ten times higher than those outdoors, according to the Environmental Protection Agency (EPA), thereby exacerbating the threats to human health and the environment.

On the other hand, VOCs tend to impact the environment via global warming and ecosystem deformation. A report indicates that VOC emissions account for roughly 10 percent of the total anthropogenic non-methane organic compounds responsible for climate change. These compounds react with nitrogen oxides (NOx) in the presence of sunlight, leading to the formation of ozone, the most potent greenhouse gas. Furthermore, the accumulation of VOCs in soil and water bodies can impede plant growth and harm aquatic life.

Efforts to mitigate VOC-induced environmental degradation focus on developing more innovative industrial processes, implementing stricter regulations, and utilizing alternative materials with low or zero VOC content. The development of low-emission fuels and greener products is an example that has helped reduce VOC emissions. With these initiatives, both industries and the public can share the responsibility of working towards clean air and a healthy planet.

Implementation of Vapor Recovery Systems at Gas Stations

Vapor recovery systems are designed to trap harmful gasoline vapors produced during the refueling process. These vapors are collected and sent back to storage tanks rather than being discharged into the environment. This leads to a decrease in air pollution and minimizes the health hazards posed by the inhalation of volatile organic compounds (VOCs). Modern gasoline stations are equipped with Stage I recovery systems to treat vapors formed during fuel delivery and Stage II recovery systems to treat vapors that occur during vehicle refueling. By utilizing these systems, gas stations help clean the air while complying with environmental regulations.

Steps for Installing Recovery Systems

Site Assessment: The first task is to conduct a thorough assessment of the entire gas station infrastructure to determine if any vapor recovery systems can be implemented there. Checking for any existing piping, storage tanks, and ventilation systems will be part of that. The purpose of such an operation is to establish a design plan that meets environmental standards and ensures regulatory compliance.

Select the Right Vapor Recovery System: Choose between Stage I and Stage II systems based on local regulatory requirements and the station’s operational needs. Researching recovery methods and improvements, such as more effective vapor flow controls or automated monitoring, can prove to be worthwhile.

Install Vapor Recovery Piping: Install or upgrade the piping that connects the fuel dispenser hoses to the underground storage tanks. Use materials that are corrosion-resistant and capable of withstanding environmental impact for long-term performance.

Advanced Monitoring Systems Integration: Throughout this period, install real-time monitoring to detect leaks, oil in the vapor line, malfunctioning parts, or pressure irregularities. Thus, such systems will maximize the efficiency of the vapor recovery while minimizing environmental hazards through a timely reporting procedure for the faults.

Test and Certify: Conduct a comprehensive service check of the entire recovery system to ensure optimal performance and reliability. Certified technicians test for leaks and confirm recovery efficiency to ensure compliance with local emission standards. The result will be a report that aids in filing those standards.

Train Staff and Maintain Protocols: Train the operators on the correct use and maintenance of the recovery system with a thorough training schedule. Inspections and maintenance are scheduled to keep the system running at top efficiency, prevent disruptions, and avoid the higher costs of repair.

Monitor and Evaluate in Real Time: Vapor recovery monitoring will be achieved through the use of data analytics and real-time monitoring. Regular tracking of operational performance metrics will identify areas that require improvement and confirm the system’s ability to meet environmental targets.

When installing vapor recovery systems, businesses not only reinforce their commitment to reducing environmental impact but also align with evolving regulations and consumer expectations that favor sustainability.

Challenges in Refueling Operations

Refueling operations face numerous challenges, ranging from environmental to operational. One of the key issues is that during fuel transfers, volatile organic compounds (VOCs) are released into the atmosphere, causing pollution and posing a health hazard. Data from environmental studies reveal that during refueling, ground-level ozone formation in urban areas can occur up to a significant extent due to the release of VOCs. Thus, allowing businesses to invest more in vapor recovery systems and setting up these systems becomes a task in itself, with numerous operational and maintenance challenges.

Another major hindrance is that cohesiveness must be achieved despite stringent rules and regulations. Regulations for fuel emissions are escalating worldwide, putting pressure on businesses to adapt quickly to avoid penalties. This requires in many instances a hustle in system upgrades, consistent monitoring, and reporting in a very resource-draining way. Safety is also a paramount issue when dealing with flammable substances. For example, minor spills or equipment malfunctions may lead to costly accidents or downtime.

Resourcing bottlenecks hinder efficiency, with slow-flow fuel dispensers, underutilized machinery, or higher customer demand during peak hours working in tandem to cause delays and disgruntled customers. Exercise of combinations of technological upgrades, staff training, and sound contingency planning could tackle the impediments. Businesses should, therefore, consider short-term solutions and strategies to ensure long-term, sustainable, and efficient practices in refueling operations.

Best Practices for Effective Recovery

Invest in Modern Technology: Installing a state-of-the-art automated system, in other words, high-speed fuel dispensers coupled with real-time monitoring tools will significantly enhance operational efficiency. Data-driven tools enable the accurate tracking of fuel levels, predictive maintenance, and swift transaction processing, thereby reducing downtime and improving customer satisfaction.

Establish Maintenance Schedules: Regular maintenance is the most effective strategy against sudden equipment failure. It has been found that maintenance can prevent equipment downtime by up to 30%. Have regular inspections of the pumping infrastructure, hoses, and refueling equipment to ensure they are working optimally.

Train for Operational Excellence: Effective training teaches personnel to resolve technical issues, handle customer interactions efficiently, and adapt and perform under pressure. By coupling theoretical training with simulations that replicate realistic operational conditions during peak hours, staff preparedness will be enhanced, and service interruptions will be minimized.

Provide Advanced Analytics and Forecasting Tools: Analysis tools also enable demand forecasting to position refueling optimally when large crowds are involved. For example, using forecasting models to prepare for seasonal bursts or events ensures that enough human resources and inventory are available to serve customers.

Sustainability Practices: By equipping their businesses with energy-efficient equipment, business owners can reduce carbon emissions through innovations such as electric or hybrid fueling stations. According to the trend of recent years, stations practicing sustainability report greater customer loyalty and better brand recognition.

Establish Contingency Plans: Having a contingency plan in place is beneficial, as it is less likely that any untoward incident, such as a power outage or supplier disruption, will significantly impact the company’s operations for an extended period. For example, having arrangements for a backup generator and an alternative supplier ensures the company can continue operating during critical times should an issue arise.

Concentrating on the above aspects will help to develop greater resilience, along with improved customer service, and ensure operational carbon efficiency for refueling environments.

Future of Gasoline Vapor Recovery Technologies

Gasoline vapor recovery technology is the next big thing concerning capturing more vapors at fueling and storage. Technologies under development can also be integrated into electric and hybrid fueling infrastructure, thereby complementing a greener approach to energy utilization. These technologies consider every aspect of sustainability and seek more affordable solutions to reduce air pollution through a global strategy, aligning with current environmental standards.

Innovations in Vapor Recovery

Recent technological advancements in vapor recovery are focused on enhancing operational efficiency and minimizing environmental degradation. One of the more recent developments has been the introduction of Stage II vapor recovery systems, which utilize vacuum-assisted pumps to capture up to 95% of VOCs during fuel dispensing operations. Industry reports argue that the systems have achieved significant reductions in emissions at fuel stations, thereby improving air quality and contributing to compliance with increasingly stringent regulatory standards.

Another advancement introduced is the implementation of advanced sensor technology, which enables real-time monitoring and control of vapor recovery operations. Through the implementation of these sensors, facilities can detect leaks or inefficiencies, thereby limiting losses and ensuring the complete recovery of fuel vapors. Other innovations in carbon adsorption materials have enhanced the performance of recovery units in storage tanks and industrial settings, with a focus on improving vapor capture performance.

Hybrid vapor recovery systems are increasingly being integrated with electric vehicle infrastructure. These systems reduce emissions on both the fossil fuel and alternative energy fronts, fostering sustainability and preparing fueling stations to host energy solutions of the future. With the rising demand for greener practices worldwide, investments in such technologies are expected to grow at a rate of over 6% annually, according to market analysts.

Such improvements not only facilitate the enforcement of environmental laws but also enable businesses to reduce fuel losses, thereby increasing their operational efficiency.

Regulatory Trends and Changes

The recent past has witnessed a shift in the regulatory system in the energy sector, with climate change mitigation and carbon neutrality being of paramount concern. Governments worldwide have imposed stringent regulations to reduce greenhouse gas emissions. To cite examples, the European Union has come out with the “Fit for 55” package that aims at slashing emissions by at least 55% by 2030 as compared to 1990 levels, while the United States has implemented measures such as the Inflation Reduction Act to promote renewable energy and industrial-scale decarbonization, with a funding allocation of about $369 billion earmarked for climate and energy programs.

Industries are constantly evolving with tighter restrictions, including methane emission controls and reporting standards for sustainability. For example, in the oil and gas sector, methane regulations now focus on leak detection and repair, as well as the deployment of technologies capable of detecting leaks, with emission reductions of up to 75% expected in some jurisdictions. Emphasis is also being placed on carbon pricing mechanisms, such as the growing popularity of carbon trading in Asia-Pacific countries, essentially nudging companies toward greener practices.

Meanwhile, these are supplemented by international cooperation, including coal phase-out alliances and those facilitating the energy transition. Increasing traceability further forces firms to think one step ahead of standards in compliance, innovatively aligning all their solutions with regulatory changes to remain viable and sustainable.

Potential for Broader Applications

The possibility of a more widespread application lies in extending these regulatory schemes and sustainable practices to other industries and areas. I believe that it may be beneficial to develop a unified approach to addressing the world’s environmental concerns, with innovation generation at one end and economic and ecological resilience at the other. The bigger-scope sustainability drive stands to benefit if these measures are adopted and further developed.

Reference Sources

Advancing gasoline vapor recovery in oil depots: Integrating cooling and adsorption technologies

Frequently Asked Questions (FAQs)

What is a vapor recovery system, and how does it work?

A vapor recovery system is designed to capture vapors that are released during the gasoline dispensing process. When gasoline is transferred from the storage tank to the vehicle’s fuel tank, vapors can escape into the atmosphere. The system operates by utilizing a series of equipment, including nozzles and separators, to recover these vapors and return them to the storage tank, thereby reducing air pollution and complying with regulations such as the Clean Air Act.

Why are vapor recovery systems critical for gasoline stations?

Vapor recovery systems are crucial for gasoline stations as they help minimize hydrocarbon emissions that contribute to air pollution. By capturing volatile organic compounds (VOCs) during the refueling process, these systems not only protect the environment but also adhere to state implementation plans aimed at improving air quality.

What are the requirements for vapor recovery systems at gasoline dispensing facilities?

Owners and operators of gasoline dispensing facilities are required to be equipped with vapor recovery systems under various state and federal regulations. These systems must meet specific Phase I and Phase II requirements, which dictate the design and operational standards necessary to capture and recover vapors effectively during fuel dispensing and refueling.

How do vapor recovery systems reduce VOC emissions?

Vapor recovery systems reduce VOC emissions by capturing the vapors that would otherwise escape during the refueling process. The captured vapors are condensed and returned to the gasoline storage tank, preventing them from contributing to air pollution and potential health hazards associated with volatile organic compounds.

What are the economic benefits of implementing a vapor recovery program?

Implementing a vapor recovery program can be cost-effective for gasoline stations. By recovering vapors that contain hydrocarbons, stations can minimize product loss and improve fuel efficiency. Additionally, being compliant with emission regulations can help avoid fines and improve the station’s reputation among environmentally conscious consumers.

What is the role of the Clean Air Act in regulating vapor recovery systems?

The Clean Air Act plays a significant role in regulating vapor recovery systems by establishing standards for air quality and emissions control. It mandates that gasoline dispensing equipment be equipped with vapor recovery technology to help reduce harmful air pollutants and protect public health.

How do vapor recovery systems impact air quality?

Vapor recovery systems positively impact air quality by capturing harmful emissions released during the gasoline dispensing process. By reducing the release of VOCs and other hazardous air pollutants into the atmosphere, these systems contribute to cleaner air and help mitigate the harmful effects of air pollution on human health and the environment.

What specific technologies are used in vapor recovery systems?

Yes, vapor recovery systems utilize various technologies, including compressors and separators, to effectively capture and manage vapors. These technologies work together to create a vacuum pressure that draws vapors from the nozzle and returns them to the gasoline storage tank, ensuring efficient operation and compliance with environmental regulations.