Being rather indispensable to the modern transportation system, gas stations pump fuel into millions of vehicles on a daily basis. Have you ever stopped to think about the various systems and technologies behind the seamless operation of a gas station? Several precise mechanical, electronic, and safety operations take place between the moment you insert the gas nozzle into your vehicle’s fuel tank and the moment it automatically shuts off. This article explores the background of gas stations, especially of gas pumps: their design, working principles, and the technology that keeps them working satisfactorily. Whether you’ve wondered how fuel is put in, measured, or controlled, this one really covers the interesting operations that make refueling easy and safe.

Introduction to Gas Stations

Gas stations play the role of establishments where vehicles are refueled with gasoline, diesel, or other power sources. They combine storage tanks with pumps and dispensers through which fuel is delivered to the customer, safely and efficiently. In modern times, facilities include automated systems for accurate measurement of fuel quality and for credit card payment, maximizing convenience and reliability for the consumer. However, the essential purpose of these facilities is to provide energy solutions for transport, with safety and environmental standards.

Overview of Gas Stations

Gas stations are sorry places now. In the fast-evolving world where technology changes almost every day, and we are witnessing shifting energy-consumption patterns, the very meaning of gas stations is transforming with the changing demands of the transportation sector. The blooming hybrid and electric vehicles (EVs) scene has compelled gas stations and street fuel pumps to co-develop charging infrastructure for EVs.

Moreover, the gas station experience is being rebuilt via digital transformation. Contactless payments and app ordering for fuel now stand alongside real-time price update features found in the majority of locations. Select gas stations are now using artificial intelligence to predict fuel demand and optimize inventory control.

Environmental considerations also play an essential part in the modernization of gas stations. These days, fuel storage systems minimize leak risks to the utmost extent, and many stations are implementing renewable energy solutions such as solar canopy systems with a view to reducing their carbon footprint.

These advancements clearly indicate how gas stations have been dynamically changing from being oriented merely toward convenience to becoming oriented toward sustainability and innovation to satisfy modern transportation needs.

Importance of Gas Stations in Daily Life

Stations are a daily solution and an essential base for serving as infrastructure for private, commercial, and industrial transportation fueling. According to data, the retail and service sectors provide places for operability. There can be found 145,697 gas stations in the U. S. alone, supporting an estimated number of 276 million registered vehicles in operation. Thus, gas stations become a means for allowing mobility at a widely varying scale, ensuring that economic and social activities take place with ease.

From the argument for filling, one must think of a modern gas station as a multi-service center. Most of them have convenience stores whose sales contribute to roughly 80% of the gross sales of the store, and are considered to be one of the largest sources of retail sales. These stores provide motorists with the essential needs, including food, drinks, and automotive supplies, while also offering services such as ATM access, oil change, and minor car maintenance- an ultimate different channel serving technician needs on the move.

In addition, in terms of employment and taxation, gas stations make profound contributions locally and nationally. Over 2.4 million people are estimated to have jobs in the gas station and convenience store industries in the United States, whereby billions of dollars are made in revenues every year. Moreover, alternative fueling options, such as EV charging stations, elevate their prestige toward supporting a sustainable energy future that surely bolsters their relevance in times to come.

Hence, gas stations remain pertinent as they cement transportation networks, sustain commerce, and serve the everyday needs of an ever-active and highly dynamic mobile society.

Basic Components of a Gas Station

Gas stations are complicated facilities designed to meet various customer requirements while ensuring a level of safety, efficiency, and adhering to the respective regulations. The following are components of a gas station and their functions:

1. Fuel Dispensers

Fuel dispensers stand in the middle of the customer interface and the fuel supply. These modern dispensers feature all sorts of contemporary technology, including digital display screens and payment terminals, and are capable of dispensing several grades of fuel, such as gasoline, diesel, or alternative fuels like E85 ethanol and CNG. More than 140,000 such stations are believed to exist in the U. S., a majority of which have installed dispensers that double as EV chargers and hydrogen fueling facilities.

2. Underground Storage Tanks (USTs)

There are many opportunities for fuel storage in underground storage tanks. These tanks are usually made from corrosion-resistant materials such as fiberglass or steel and can hold tens of thousands of gallons of fuel. UST systems are tightly regulated to prevent fuel leakage into the environment. For example, to meet environmental standards, modern USTs will have leak detection, double-wall systems, and automatic monitoring.

3. Convenience Store

Convenience stores at gas stations nowadays account for a significant chunk of these stations’ revenues. They offer a mix of ice cream, beverages, automotive supplies, and general consumer goods. Reports stated that convenience store sales account for nearly $250 billion a year within the gas station retail industry. An increasing number of stores are incorporating grab-and-go meals and healthier food options to appeal to evolving consumer trends.

4. Systems of Payment and Security

When it comes to gas-station operations, a POS and security play a very critical role. Presently, gas stations use EMV-compliant card readers, contactless payment options, together with mobile apps to facilitate fast payments. Additional security measures include fraud detection at payment terminals and video surveillance, together maintaining the financial and safety regulations.

5. EV Charging Stations

With the gradual transition toward EVs, gas stations are quickly evolving to host a Level 3 DC fast-charging station so as to keep up with the infrastructure needs laid down by the EV users and guarantee the continuity of gas stations during this energy transition. According to recent reports, there are now over 55,000 EV charging locations in the U. S., and an increasing number of these are now hosted by gas stations, thus helping them form a resilient energy ecosystem.

6. Air and Water Stations

Complementary facilities such as secondary air pump stations and water dispensing units are available to further enhance the customer’s convenience. These stations center on tire inflation and windshield cleaning-aiding in vehicle maintenance while improving customer satisfaction. Roughly 80% of all gas stations offer such services either free of charge or at a nominal fee.

7. Waste and Recycling Facilities

Being environmentally friendly has become a widely acknowledged concept; hence, many gas stations are also accommodating waste bins and recycling stations. The timely disposal of waste ensures the cleanliness of the facilities and is also aligned with consumer consciousness towards eco-friendly practices.

Each of these items plays a crucial role in the efficient delivery of services while observing safety norms and fulfilling the continually changing requirements of a mobile and eco-aware society.

Gas Pumps: The Heart of a Gas Station

Gas pumps are integral in dispensing fuel efficiently and safely to vehicles. They draw fuel from underground storage tanks through a system of pipes and dispense it at a regulated rate according to customer specifications. Modern pump installations are equipped with digital interfaces to support calculating fuel quantities accurately and processing transactions. The pump design includes safety features, such as automatic shutoff valves, to reduce the chance of overfilling and spills. They are designed to withstand all kinds of weather yet remain adequately operable for years to come.

How Gas Pumps Work

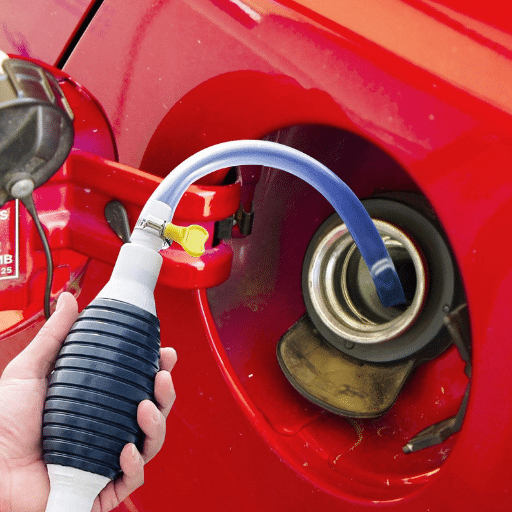

Conceptually, gasoline pumping consists of some mechanical systems mated to sophisticated controls to ensure that fuel is provided accurately and safely. When a customer lifts the nozzle and selects a fuel grade, this action turns on the pump and creates some suction to draw fuel from underground storage through its network of pipes. The flow is regulated by some form of submersible and suction pump, so the fuel gets delivered steadily right up to the nozzle.

The nozzle houses another check valve and flow restrictor so that the fuel cannot pass too fast or overflow. In modern pumps, a venturi tube senses changes in air pressure. The air pressure mechanism is the key to automatic shutoff; when the tank is full, the path for the air is blocked by rising fuel, forcing the nozzle to cease dispensing.

Using sensors and microprocessors to get precise measurements during fuel dispensing, the digital interface guarantees accurate billing for the exact amount dispensed. Other safety features include emergency shutoff switches, pressure sensors, and vapor recovery systems to minimize the risks and the environmental impact. Such technical enhancements have seen to it that gas pumps are kept efficient and safe as per industry standards.

Types of Gas Pumps

Modern gas pumps can be divided into various categories, with each being deployed for a special application or operational features. The major ones include:

| Type of Gas Pump | Description |

|---|---|

| Mechanical Gas Pumps | These traditional pumps with their manual gears and levers measure and dispense fuel. Though replaced in large measure by their more modern digital counterparts in most urban areas, some mechanical pumps still find space in far-flung territories or in less developed areas. Their simple working principle, less complexity in maintenance, and greater durability stand them in good stead. |

| Electronic Gas Pumps | These were fitted with a digital interface and could measure the volume of fuel accurately with the aid of sensors and microprocessors. They support payment by cards, programmable limits on the quantity dispensed, data logging for tracking efficiency in operation, and so forth. |

| Submersible Gas Pumps | Design-wise, submersible pumps locate the fuel pump inside the storage tank. This arrangement foregoes suction lines, reduces pressure drops along the fuel line, and generally allows better flow rates. These systems are the choice of fertilization stations for high demand, efficiency, and energy reduction. |

| Suction-Above-Ground Gasoline Pumps | These are pumps that use suction to draw fuel from underground storage tanks to the dispenser. On the other hand, they are simpler to operate compared to submersible systems. They are, however, better for lower-capacity fueling needs and are mostly found at smaller stations or even private installations. |

| High-Flow Diesel Pumps | Also, high-flow pumps are considered heavy-duty vehicle fuel-pumping machines, pumping large volumes of fuel at high rates. These pumps are thus found in commercial fueling stations for trucks, buses, and industrial plants, where faster fueling means less downtime and increased efficiency. |

Different pump designs are in accordance with various operational requirements to make them versatile for varying demands from users in the petroleum fuel business.

Key Features of Modern Gas Pumps

Modern-day gas pumps are engineered with user-oriented features promoting efficiency, safety, and convenience. Characteristics include:

- Flow Control Systems – These involve high-precision flow meters with automatic shut-off features that ensure accurate fueling and prevent fuel overflow, thus minimizing economic losses and environmental risk.

- Digital Integration and Connectivity – Touchscreens and NFC technologies help provide a rich user-interface experience to allow payments-by-card in contactless mode and track transactions in real-time, while many pumps also connect to back-end systems for heavy analytics purposes on behalf of the operator.

- Safety Mechanisms – These systems also incorporate safety features, including emergency stop mechanisms, leak detection, and vapor recovery units, which prevent fire hazards and environmental contamination.

- Structural Strength – Durability: Designed for longevity, these pumps feature weather-resistant materials and components that ensure consistent performance with lower maintenance costs and withstand the harsh environment.

- Customization and Compatibility – The pumps are designed such that they can dispense more than one fuel grade, including alternative fuels, such as CNG, LPG, and hydrogen, for the different demands of the industry and the environmental standards.

These features are actually the pinnacle of tech ingenuity combined with pragmatic design so that gas pumps properly and efficiently meet the changing demands of users and station operators.

Gasoline Storage Tanks

Gasoline storage tanks are designed to hold fuel safely yet with the least chance of jeopardizing environmental safety, while also ensuring compliance with the regulatory set standards. Made from steel or fiberglass to resist corrosion or leakage, these tanks are designed to either be installed underground or aboveground, depending on site requirements and availability of space. Accessories such as the leak detection system, overfill prevention devices, and adequate ventilation for vapor control are essential. Periodic maintenance and inspections keep them safe and enhance their service life. These storage systems are the killing ground behind the maintenance of continuous fuel supplies to gas stations and other facilities.

Types of Gasoline Storage Tanks

These tanks are classified into two groups on the basis of installation and structural design: underground storage tanks and aboveground storage tanks.

Underground Storage Tanks (USTs)

Having been built underground, they are ideal for sites having limited space. At stations run by petrol companies, these tanks are generally used for the storage of gasoline and other chemicals while minimizing risks relating to environmental pollution and fire. USTs are generally larger in size and may have features such as double-wall construction, use of corrosion-resistant materials, and heliarc welding to curb problems of leakages and provide long-term durability and environmental protection. Operating resiliently depends on preparing sites well, including conducting regular inspections for maintenance and adhering to regulatory standards.

Aboveground Storage Tanks (ASTs)

ASTs are above the surface, making them easily accessible for installation, repair, or inspection. Depending on the condition, these tanks can be installed in an industrial, agricultural, or commercial area where space is not an issue. They are made of sturdy materials such as steel or fiberglass and may be coated for corrosion resistance. Secondary containment systems like containment dikes are also used to avoid spills and leaks that may affect the environment. Installation of ASTs is cheaper; however, robust safety plans must be introduced, given their exposure to external and weather-related factors and physical damage.

Each tank type serves the purpose(s) of storage suited to given operational requirements and must underlie the law of the land imposed in the practical environment-given set, be it regarding the environment, safety, and fire control regulations, thus offering an efficient gasoline storage solution.

Function and Importance of Storage Tanks

Storage tanks have a pivotal role when it comes to the safe containment and handling of liquids, including fuel, chemicals, and water, within industrial, commercial, and residential domains. These tanks mainly act as reservoirs, avoiding the release or spillage of any along with contamination that can sometimes arise from negligence by humans or environmental issues. Modern storage tank designs thus emphasize the materials and engineering aspects that should make them last longer and resist corrosion or weathering. At the same time, they allow easy inventory management where the storage of goods at bulk levels is promoted, and the distribution processes become simpler. Proper compliance with such a standard would make these tanks even more important, such as with EPA and NFPA codes, which in fact address the safety and environmental protection issues.

Regulations Surrounding Gasoline Storage

Gasoline storage regulations are intended for safety, environmental contamination prevention, and mitigation of fire hazards. The major guidelines are given by bodies such as the Environmental Protection Agency, the National Fire Protection Association, and the Occupational Safety and Health Administration. The EPA primarily discourages the leakage of any kind through proper design, maintenance, and monitoring of underground storage tanks (USTs) so that groundwater is not polluted; this is under the Resource Conservation and Recovery Act (RCRA). The NFPA codes would give specifications about the construction, placement, and fire protection of gasoline storage tanks, be they above or below ground, as per NFPA 30 (Flammable and Combustible Liquids Code). The OSHA regulations assure safe handling and storage practices by employees regarding labeling, ventilation, and spill control systems. These regulations need to be complied with so that the risks are reduced and safety is assured at operations and the environment.

Flow Mechanisms in Gas Stations

The flow mechanisms are provided at the gas stations with considerations for safety so that fuel is dispensed with efficiency and accuracy. The fuel pumps are the major systems that are used to pump gasoline or diesel with suction or submersible pumps from the underground storage tanks. When activated, the fuel passes through meters that measure the exact quantity dispensed, and then, finally, the fuel is pushed to the nozzle. These nozzles are also automatic in that when the tank fills, the flow of fuel stops, thus preventing overflows. Flow rates are controlled to allow speedy refueling but with adequate precautions to ensure safety, while all components of the system are constructed to suit industrial standards on reliability and environmental protection. General upkeep and inspections are required to ensure good working conditions and that no leaks or malfunctions occur.

Understanding Flow Meters

Types and Functions of Flow Meters

Flow meters are instruments whose applications involve measuring velocities of liquids, gases, or steam through a given system, which in turn has applications in industries such as oil and gas, water treatment, and manufacturing. Differential pressure and velocity flow meters determine flow rate by differential pressure across an element; positive displacement meters take one discrete volume or unit of flow at a time; and mass flow meters calculate flow rate based on the mass of fluid that is flowing through a pipe or conduit. Each has its own advantages and disadvantages depending on the accuracy required and the nature of the fluid, and the working environment.

Failure and Calibration of Flow Meters

Proper calibration is imperative to guarantee the accuracy and reliability of flow meters. Therefore, it is a process for adjusting measurement capabilities against a standard. Deviations may occur in a flow meter due to wear, buildup, environmental influences, etc. The process not only assists in meeting the regulatory standards but also optimizes operational efficiency and minimizes the risk of errors with financial and safety consequences.

Key Factors in Choosing a Flow Meter

The type of fluid (liquid/gas), operating conditions (pressure, temperature), level of accuracy required, and compatibility with existing systems should be considered when selecting flow meters. Materials of construction used in flow meters should be selected for chemical compatibility and mechanical durability with a view toward the specific conditions to which they are exposed. In view of the above criteria, system operators can select the most effective flow meter for their specific applications so as to ensure that they perform well and last long.

The Role of Check Valves

Basically speaking, check valves get their name from a system where fluid flows in only one direction, allowing flow in that direction while opposing flow in the opposite direction. Thus, their primary objective is to guard pumps, compressors, and other equipment against destruction and damage due to reverse flow. Present-day check valves are designed as, amongst others: swing check valves, lift check valves, and ball check valves, each intended for specific applications according to flow rate, pressure, and system considerations.

The other important issue in the selection of a check valve will be performance criteria such as cracking pressure (the minimum upstream pressure required to open the valve) and pressure drop from upstream to downstream of the valve. For example, since the swing check valve provides a very low resistance to flow, it is usually applied in low-pressure systems, whereas lift check valves find applications in high-pressure systems because of their small design and the fact that they are quick to close in.

Research studies have demonstrated the proper working of check valves in maintaining process integrity. For instance, in water distribution systems, swing check valves are said to reduce pipeline surges and the water hammer effect, hence maintaining the integrity of the infrastructure. Moreover, modern materials such as stainless steels and high-performance plastics have found greater use in construction to enhance chemical resistance and operational life and assure valve reliability in high-pressure or corrosive surroundings.

Maintenance of check valves guarantees long-term durability and prevents inefficiencies in systems. Proper checking at regular intervals and maintenance activities performed per the manufacturer’s instructions minimize the possibility of valve failure or leakage. Given their importance in flow direction and protection of system equipment, check valves should be properly installed and maintained to enable optimal system performance across industries ranging from water management to petrochemical.

How Automatic Shut-Off Works

An automatic shut-off system, based on the detection of anomalies such as excessive pressure levels, leakages, or flow irregularities, uses these sensors and actuators and control mechanisms to shut off a valve in the shortest time possible, preventing the flow of liquid or gas. These systems have different activating strategies depending on their applicability; they may heed a pressure sensor, a flow meter, or some temperature-based mechanism that would guarantee the shut-off is done accurately and swiftly. Automatic shut-offs are used in industrial pipelines, home water systems, and gas distribution networks; this modern technology ensures safety and cleverly prevents waste of resources and damage to equipment.

Safety and Maintenance at Gas Stations

Safety and maintenance at gas stations are of utmost importance in order to prevent accidents, protect the environment, and keep all their equipment in working condition. A periodic inspection and maintenance of fuel pumps, storage tanks, and piping systems will reduce the chances of leaks or any other malfunctions of equipment. The valves used for emergency shut-off and fire suppression systems must be tested for functionality periodically. Training employees for handling all flammable materials and emergency response processes should be done. Compliance with safety requirements and regular maintenance will ensure gas stations maintain a safe environment for all customers and employees, thus preventing any hazard occurrence.

Safety Protocols for Gas Pumps

Spill Management

Keep a container ready for capturing spilled gasoline, and promptly clean spilled gasoline by soaking it with sand, sawdust, or absorbent materials. In the event that the spill is large, the area must be isolated; thus, the burned area should not be beyond 30 square meters to be covered with sand very quickly at the end of 10 minutes following the spillage. It is forbidden to mop gasoline spills with water.

No Smoking

To prevent ignition, the ignition of fuel vapors in the fuel dispensing area must be prevented at all costs.

Correct Use of Pumps

The driver should switch off his vehicle’s engine while refueling so that in the case of an accident, the ignition fails to take place. The nozzle should be inserted fully into the tank and secured so that no fuel can spill out during filling.

Static Precautions

Do not return to the vehicle during refilling, as this can cause static to build up. If a driver must touch the vehicle, he should touch a metal surface away from the fuel nozzle to safely discharge the static charge.

Emergency Shutdown Procedures

There should be emergency shutdown switches accessible to be employed during an equipment failure and potentially dangerous situations that immediately stop the fuel flow in any of the gas pumps. Such switches must be well labeled and known to all employees.

Equipment Inspection and Maintenance

Inspection of pumps, hoses, and nozzles should be done regularly to detect wear and tear or damage that may cause leakage. Preventive maintenance schedules must be strictly applied so that all equipment is maintained to operate safely and efficiently.

When the safety protocols are implemented, gas stations could protect themselves as per legal requirements and mitigate potential hazards from dispensing fuel onto customers and infrastructure.

Maintenance of Gasoline Storage Tanks

The maintenance of tanks storing petrol would be largely encompassed by regular inspection and cleaning to prevent contamination and ensure structural integrity. I would check for corrosion, water intrusion, and fuel leakage, which are all factors that can jeopardize tank safety and performance. Calibration of the tanks would hence be carried out on a scheduled basis, assuring the accuracy of fuel measurements. Additionally, I would also follow a stringent lifestyle in compliance with environmental and regulatory requirements, including proper documentation and testing.

Emergency Procedures at Gas Stations

Emergency procedures at gas stations are critical to saving people and property. It typically goes as:

| Emergency Type | Procedures |

|---|---|

| Fuel Spill Response | The area should be immediately isolated from ignition sources, such as sparks or open flames; spill containment equipment can be set up, for example, absorbent material; and disposal must follow relevant hazardous waste regulations. If spills exceed threshold limits, the local environmental agency must be called in. |

| Fire Safety | Evacuate the premises as soon as a fire has started. Emergency stops should be activated to cut off the fuel supply. Fire extinguishers should be employed, with dry chemical powders suitable for Class B fires, while simultaneously calling fire services. All personnel should be trained in using fire extinguishers and should be aware of the escape routes. |

| Gas Leak Detection and Action | On the detection of a smell of gas, the gas supply must be shut off. Ventilate the area if possible, but never use electric switches or ignite open flames. Contact emergency response services and follow their instructions. |

| Electrical Failures | For any power outage, emergency lighting must be operational, and dispensing of fuel should not be manually carried out. All pumps must be secured against unauthorized use until power is restored and operations can safely resume. |

| Customer and Employee Safety | Communicate clearly with signage and announcements during an emergency. The emergency action plan should always be current; safety drills should be recurrently conducted; first aid kits and emergency contact numbers should always be easily accessible. |

Following these procedures will minimize risk, ensure compliance with the regulations, and provide an effective response to any incident.

Reference Sources

- Key Findings: This research explores health conditions related to working in gas stations, with special emphasis on how exposure to gasoline and diesel fumes led to multisystem health symptoms among workers. It proceeds to pinpoint the contributing factors to these illnesses.

- Key Findings: This research simulates, based on CFD, the dispersion and incineration hazards at petrol stations. Following this, we studied safety measures and risk mitigation strategies.

“Analysis of a gas station hybridization with a solar thermal plant by using ETAP”

- Key Findings: This study is very much concerned with integrating solar thermal technology into a gas station to improve energy efficiency and reduce dependence on conventional forms of energy.

Frequently Asked Questions (FAQs)

How do gas stations work with pump gas?

The fuel is loaded into the vehicles through pumps. Customers may then choose from the various available grades of gasoline, differing in octane. Once the nozzle is put into the vehicle’s fuel tank, the pump is activated. The selected quantity of gas is dispensed through the dispenser from the storage tanks, allowing the gas to be filled in the customer’s vehicle.

What is the role of the flow control valve in a gas station?

The flow control valve regulates the speed of flow of the gas from the storage tank to the dispenser; hence, it speeds or slows down the dispense of gas so as to avoid leakage above the fluid owing to the air-tight seal. It works together with the pump motor to keep a hold of the flow of the gas.

How do several thousand gallons of gas get managed by gas stations?

Gas stations usually contain thousands of gallons of gasoline underground in gasoline storage tanks. Most of these tanks maintain vacuum pressure to avoid vaporization, keeping the gasoline in a usable state for longer periods. Periodic inspection of the fuel level and fuel quality is done by station owners to keep the gas fresh for the customers.

What does the automatic shut-off at gas stations do?

The gas station’s automatic shut-off prevents overflow; the moment the tank reaches capacity, the flow of gas is stopped. The mechanism uses a blend valve, which senses when the level of the gas is full within the vehicle’s tank. Approximately 10 to 15 seconds after it has reached the desired level, the shut-off is brought about, thereby freeing the customer from manual intervention.

How Does the Suction Pump Work at a Gas Station?

A suction-pump vacuum pulls gas from the storage tank and delivers it to the dispenser. The pump generates a vacuum while an impeller spins, drawing gas up into the dispenser. This system ensures continuous operation, thereby providing uninterrupted gas flow to the suction pump while keeping the wear and tear of the suction pump at a minimum.

What is the function of the check valve in gas stations?

The check valve in gas stations prevents the backflow of gas into the storage tank and fuel lines. The moment the pumps are switched off, the check valve makes sure that the gas which is still in the dispenser will not fall back into the tank and thereby keeps the measurements accurate and prevents fuel loss.

How are gas prices determined at gas stations?

Would you want to know how gas prices are fixed? The prices at gas stations are controlled by quite a few factors: the crude oil price, supply and demand situations, and the respective regional market setting. In extension, the station owners may consider gasoline’s octane rating and grades in deciding their prices. Changes in the factors that have just been explained could cause a different price for gasoline in the same area.

Can gas stations offer different grades of gasoline?

In fact, gas stations in many places do offer and market gasoline of different grades or octane levels. The higher the octane rating of the fuel, the better the recommendation for performance vehicles, as it can help them improve efficiency and sometimes reduce engine knocking. A gas station owner may opt to provide two grades of gasoline to suit the mixed demands of consumers.