For fleet operators, being efficient in fuel consumption is one of the most difficult tasks today. Due to volatile fuel prices, tougher environmental laws, and an ever-increasing imperative to cut logistical costs, old fuel-tracking methods are just not viable anymore. This is the cradle of Automated Fuel Management Systems. Such systems complement technology-based approaches to monitor, restrict, and measure fuel consumption in an instant, thus providing the most efficient solution for accountability. This article enumerates the evolving fleet operations via automated fuel management systems, their benefits, features, and, indeed, the real impact they can have on the success of operations. If you are a fleet manager looking to optimize costs or an industry professional considering newer solutions, this deep-dive guide will arm you with the know-how to make savvy decisions.

Understanding Automated Fuel Management

Before we dig further into the concept of fuel management automation, we should perhaps understand what the term means. In essence, fuel management remains a technology-driven system for monitoring, controlling, and optimizing fuel consumption through a fleet of vehicles. Such systems employ fuel sensors, GPS tracking, and real-time data analytics to appropriately analyze consumption patterns, guarantee fuel theft does not occur, and minimize waste. They eliminate manual systems that inhibit operational efficiencies, thus giving fleet managers reliable data with which to make informed decisions, all of which, in turn, saves costs and improves overall efficiency.

What is an Automated Fuel Management System?

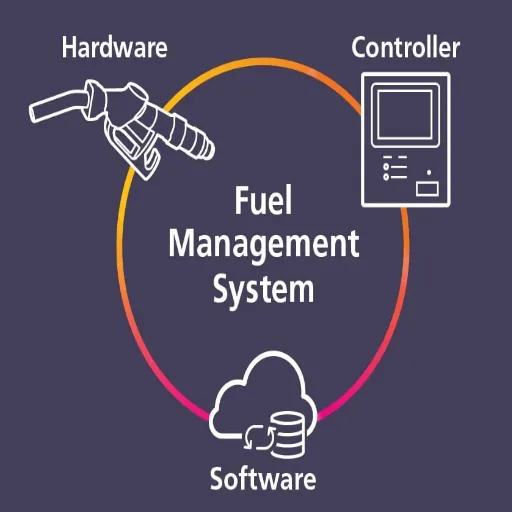

An Automated Fuel Management System (AFMS) is a high-tech system designed to monitor, control, and reduce fuel consumption. Various industries are served, focusing most on fleet management and large-scale operations. The system integrates hardware consisting of fuel dispensers, sensors, and telematics devices with state-of-the-art software that provides real-time information gathered from fuel consumption, tanks, and vehicle performance studies. A very important part of the solution entails the use of GPS in tracking vehicle routes to detect inefficiencies or deviations from planned routes and thereby assist the better route planning that uses less fuel.

The recent advances in technology further highlight AFMS’s ability to provide tangible benefits. Studies show that fuel-consuming companies with a fuel management system can draw up 10-15% fuel savings and hence substantial costs over time. Further, theft of discrepancies between fuel and usage is an important issue affecting 18-22% of fleet operations worldwide; alerting irregular fuel transactions through automated means is a way to deal with that. Automated fuel control has a big advantage in that it eliminates inaccurate fuel records and errors created inadvertently by humans, thereby making sure that the data supplied is as accurate as possible.

AFMS enhances operating performance and assists in compliance with environmental regulations by using analytics, cloud-based platforms, and mobile connectivity to minimize carbon emissions triggered by high fuel usage. This makes it a crucial tool in contemporary fleets and fuel management operations that want to maximize the efficiency of their resources and remain sustainable.

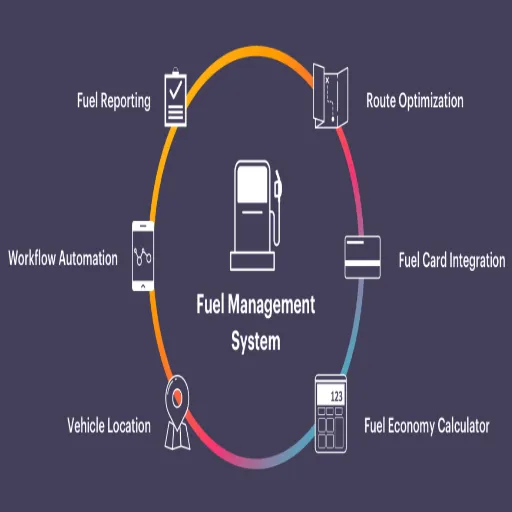

Key Components of Fuel Management Software

Fuel Management Software (FMS) comprises several critical components designed to improve operations and reduce costs, and promote sustainable practices. Modern-day FMS includes the following key elements.

Fuel Tracking and Monitoring

This core feature gathers real-time data concerned with fuel consumption, tank levels, and refueling events. With the advanced tracking via IoT sensors, fleet authorities can better perform fuel consumption analysis, leak detection, and theft prevention. Insights thus generated help fleet managers make data-driven improvements to efficiency while reducing wastage.

Telematics Integration

FMS integrates with vehicle telematics systems to give a holistic picture of vehicle performance, fuel efficiency, and driver behavior. Using GPS data mixed with fuel analytics, the managers will be able to plan better routes, reduce idling time, and schedule timely maintenance while reducing overall costs.

Reporting and Analytics Tools

Powerful data analytics and customizable reporting functionalities help fleet managers assess KPIs, trends, and projections. These tools can assist in ensuring compliance with legislation while budgeting and identifying opportunities for improvement.

Automated Refueling System

Automation makes fuel dispensation simple, supports authority protocols to ensure secure transactions, and reduces human error. Integrated systems mostly function through RFID or PIN technology to maintain better control and accuracy of records during refueling events.

Simple and Friendly Dashboards

Intuitive dashboards provide real-time metrics and let users observe any operations under it from a centralized interface. This component provides operational transparency while reducing administrative effort by gathering crucial information in a single platform.

These interconnected components empower organizations to optimize fleet efficiency vis-à-vis sustainability initiatives, making FMS one of the most indispensable assets in today’s transportation and logistics industries.

Benefits of Automation in Fuel Management

The automation in fuel management must be said to confer a host of benefits and streamline the operations of an organization while cutting down costs. It monitors fuel consumption accurately, so the chances of malpractices and theft are taken away. The automated systems keep track of fuel levels, consumption rates, and refueling activities all by themselves to give real-time data that can be used to increase visibility and control over fleet performance. Such a system decreases the chances of human error while saving more labor hours.

Cost OptimizationMap fuel consumption and find loopholes to reduce wastage

Automated AlertsScheduling maintenance or odd fuel activities to maintain vehicle efficiency

Environmental ComplianceTrack emissions and apply green practices for modern fuel management

Operational ExcellenceImprove operations, profitability, and environmental compliance

Fleet Fuel Management Solutions

Fleet fuel management solutions equip you with the necessary instruments for effective scaffolding monitoring, control, and optimization of fuel usage. Some major attributes:

- Real-Time Fuel Monitoring: Detects fuel levels, fuel consumption, and fuel refilling events to prevent any unauthorized use of fuel.

- Automated Reports: Pulls out detailed data insights for pointing out usage trends and inefficiencies.

- Route Optimization: Uses GPS technology to plan the most fuel-efficient routes for the dollar fuel operating costs.

- Maintenance Integration: Aligns maintenance with schedules that keep vehicles in operational states to prevent fuel wastage.

- Emission Tracking: Facilitates environmental standards by tracking and managing emissions.

With these features, a company reduces its cost for fuel while increasing the operational performance of the fleet and working towards its sustainability goals.

Importance of Fuel Management for Fleets

Fuel is a commodity that, if properly managed, can make or break fleet operations. With fuel prices rising, it really takes a large portion of the fleet budget; hence, fuel consumption must be optimized. Fuel management systems put fuel management in proper perspective by tracking fuel consumption in real-time, detecting any anomalies such as theft or inefficient use of fuel, and generating useful insights, all aimed at bringing down costs.

Proper fuel management further leads to the accomplishment of sustainability goals by tracking carbon emissions and making sure environmental laws are honored. In this way, businesses can stay tied to global green initiatives whilst improving their reputation. Advanced technologies like telematics and AI can support fleets in assessing driving behavior, and route and maintenance scheduling for more proactive approaches to reduce fuel consumption and enhance vehicle performance. Fuel management is thus a necessity in modern fleet operations, providing economic and environmental benefits.

How Automated Systems Improve Fleet Fuel Economy

An automated system ensures that a fleet is fuel-efficient through accurate monitoring and good data-driven decisions, and real-time implementation of necessary measures. Advanced telematics systems keep track of parameters like fuel consumption, engine parameters, and driver behavior, enabling fleet managers to detect exemplary behaviors. Predictive analytics, with the help of AI algorithms, optimize routes by considering traffic patterns, weather conditions, and distance while keeping idling at a minimum, thereby saving fuel. Moreover, automation can help to schedule vehicle maintenance before the trucks become fuel-inefficient, thereby promoting the highest performance of vehicles. These systems also track aggressive driving behaviors with adaptive cruise control and automatic braking, which is known to consume more fuel. By integrating automation into fleet operations, any company can decrease cost-impacts on the environment and adopt an efficient and green logistics regime.

Real-Time Monitoring and Reporting Features

Real-time monitoring and reporting systems provide a complete view into fleet operations using GPS tracking, IoT sensors, and advanced data analysis tools. The systems gather continuous streams of data comprising vehicle location, fuel level, engine health, and driver behavior, and present that information using a series of intuitive dashboards. Some of these dashboards come with the power of advanced manipulators and linking methods to draw out patterns and anomalies while offering predictive insights in real time so that a fleet manager can immediately resolve any issues relating to inefficient routing, excessive idling, or maintenance requirements.

Real-time reporting also supports compliance by maintaining records of important operational parameters concerning regulations. Immediate alerts and reports can flag issues before they cause downtime or cost anything to fix. When merged with predictive analytics, the real-time monitoring system permits fleet operators to react quickly to problems while also spotting the potential risks and ameliorating them. As a result, operational efficiencies are increased, safety is improved, and fuel and maintenance expenditures go down considerably.

Cost Savings and Efficiency

Advanced fleet management solutions present opportunities for direct and measurable cost reduction and productivity gains. In that matter, fuel consumption can be minimized by route planning and driver behavior analysis using real-time data sets. There can be fewer unexpected vehicle breakdowns perceived through predictive maintenance, resulting in lower repair and replacement costs since vehicles last longer. Also, scheduling and report generation automation aid in cutting down on administrative costs, leaving human resources to concentrate on value-added activities. Together, these efficiencies ensure substantial long-term cost savings and reliable and consistent operations.

Reducing Fuel Costs with Smart Fuel Management

Smart fuel management systems utilize high technologies like telematics, GPS tracking, and real-time fuel monitoring to regulate fuel usage in fleets. Knowing the exact fuel consumption helps these systems pinpoint wastages due to excessive idling, erratic driving behaviors, or non-adherence to routes so that corrective actions can be taken to eliminate such wastage. It also appears that by enforcing route optimization on an area basis, vehicles strictly adhere to the most fuel-efficient paths, thereby showing a huge reduction in the primary value of fuel consumed. More intelligent vehicle fuel management systems allow for fuel card integration and reporting to offer insightful analytics to facilitate further cost management and cost reduction. Organizations employing such systems stand to offer better management of their operations, better control over fuel costs, and reduced environmental degradation as a step toward sustainability.

Time Savings Through Automation

Automation significantly reduces the time for repetitive and manual jobs, thereby driving operating efficiencies in all areas. Systems that automate certain operations can include scheduling, dispatching, and route optimization, with no requirement for manual intervention that is resource-heavy. Automation thus allows a very fast decision-making process. This also allows changes to the settings depending upon real-time conditions, such as traffic constraints or weather problems. Besides that, an automatic workflow helps businesses process huge amounts of data with consistency and precision, making sure that there are fewer errors, thus better turnaround times. With such possibilities, organizations can automate laborious and basic activities so that the staff can concentrate more on activities of higher value; this improves their productivity and makes project completions faster with measurable savings in time.

Long-Term Financial Benefits of Fuel Management Software

Fuel management software provides ample opportunities for organizations to reduce operational costs and optimize resource allocation. When fuel consumption is tracked in real time, businesses can scrutinize inefficiencies, cut down waste, and prepare more realistic fuel budgets. Studies noted that perhaps fuel management systems can save up to 20% of the costs in fleet operations by reducing fuel theft and illegal consumption, which remain critical concerns for fleet operators.

Moreover, predictive analytics in fuel management solutions keep maintenance schedules proactive rather than reactive, minimizing breakdowns due to fuel system failures, which means fewer interruptions for service and longer life for the associated vehicle and equipment. This, in turn, makes repairs cheaper in the long run, vehicle downtime less, and, therefore, very cost-efficient.

The other area of financial gain is from reduced environmental impact. Through improved fuel tracking and reporting, organizations can reduce carbon emissions to regulatory levels, thus avoiding expensive non-compliance penalties. Moreover, companies deploying fuel strategies for sustainability often gain tax rebates and grants aimed at encouraging environmental stewardship, which immediately translates into additional dollars saved.

Fuel management software marries analytics, real-time monitoring, and customizable reporting, allowing organizations to optimize their operations, monitor the relevant KPIs, and remain profitable in the long term. At the heart of these systems are sound financial planning and return on investment, which, in turn, secure the ability of businesses to compete in a resource-conscious marketplace.

Diesel Fuel Management Practices

Effective diesel fuel management entails cost-cutting methods, waste minimization, and quality assurance. Some of the major practices include the following:

- Regular Monitoring: Routine checks on fuel levels, usages, and storage conditions are made to limit inefficient practices and discourage losses.

- Preventive Maintenance: Maintain the fuel tanks, pumps, and filters so as to avoid contamination and ensure maximum performance.

- Use of Fuel Management Systems: Implement digital tools for tracking consumption, preventing thefts, and rendering reports with higher accuracy.

- Proper Storage: Diesel must be stored in clean tanks that are sealed properly, away from extreme temperature conditions and moisture.

- Employee Training: Train employees on fuel conservation methods and the importance of observing the protocols.

The above improvements ensure lower operational costs, thereby higher efficiency.

Managing Diesel Fuel Tanks Effectively

Having efficient management in diesel fuel tanks ensures the quality of the fuel, guarantees that no contamination occurs, and retains the operational efficiency. The following are summarized practices gathered from the best industrial retrievals:

Periodic Tank Maintenance

Routine inspections and cleanings must be carried out to check for water deposits, microbial growth, and the buildup of sludge. Tank filtering can also be employed to lessen the ingress of debris and contaminants.

Water Control

Water-absorbing filter technologies must be employed while their potential issues, such as microbial corrosion, are controlled with adequate additives. Check for condensation within the tank with every inspection.

Housing and Layout of the Tanks

Store tanks in elevated and well-shaded areas to minimize temperature fluctuations that catalyze condensation. Proper anchoring of the tanks will help in preventing structural damage.

Monitoring Systems

Automated fuel monitoring systems are to be installed to ensure that fuel levels are checked on and off, leaks are detected, and environmental approval is given on time.

Preventing Contamination

The filler caps of the tanks must be securely sealed, with all equipment used for handling fuel kept clean, and access to the tanks restricted to trained personnel to avoid any chance of contamination.

The practices of properly caring for diesel fuel tanks prevent fuel losses and culminate in regulatory compliance.

Refueling Strategies for Fleet Vehicles

Efficient fleet refueling strategies are essential in reducing downtime, operational costs, and thereby producing desirable and constant operational results. Here are a few great strategies to maximize fleet refueling:

Centralized Fuel Stations

Keeping certain fuel stations as centralized refueling locations can offer direct bulk purchases of fuel and therefore maximize the cost savings; hence, fleet management will also be able to implement better fuel-use audits under such a system. The central documentation system keeps drivers from making random stops at commercial fuel stations. Hence, central stations cater to time efficiency.

Mobile Fuel Station Services

Taking mobile fuel services on-site has replaced the need for vehicles to be driven away from their operational zones; thus, keeping them active during the most important hour of work. In such scenarios, mobile fuel services reduce such non-value-adding times and provide a live-monitoring facility for fuel levels.

Fuel Card and Network Relationships

These fleet-specific fuel cards are connected to large fuel-selling networks and provide cashless transactions, ease of expense tracking, and discounted fuel price access. This fuel card is backed by software that provides a paper trail to associate fuel consumption with individual vehicles.

Planned Refueling Times

Such refueling times can be based on fuel consumption behavior and approximate mileage, hence maintaining the objective of providing vehicles with adequate fuel while eliminating the uncertainty of running on empty on the operational site.

Telematics and Fuel Management System Integration

The telematics system works with fuel management systems and provides an update on fuel consumption, vehicle location, and usage patterns, which can be utilized in planning fuel schedules, identifying results of fuel inefficiency, and identifying fuel-efficient routes for overall cost reduction.

Combining these fuel-refilling strategies would certainly enhance the operational abilities of fleet managers in managing the fuel efficiencies, reducing costs, and ensuring consistent operations.

Ensuring Compliance and Safety in Diesel Fuel Management

Compliance and Safety Requirements

The systems that ensure compliance and safety in diesel fuel management are critical to the enforcement of the law and to operational efficiency. For compliance, the fleet operators must meet the environmental standards laid down by authorities such as the EPA, which include requirements for proper storage, transportation, and spill prevention. Fueling equipment and tanks should be regularly examined to detect any leaks or possible environmental hazards. Safety measures must, therefore, be placed for the prevention of any risk that a fuel spill or vapor buildup may pose; these can include proper ventilation of the storage area and secondary containment systems.

By creating staff training programs on diesel fuel handling and responding to emergencies, the company can reduce the risks of human error and ensure correct preparedness should any incidents occur. Furthermore, automated fuel monitoring systems can assist with compliance by keeping accurate records of fuel consumption, inventories, and emissions, which can then be used for auditing and reporting. Having such procedures in place can thus help a company maintain legal and environmental standards while succeeding in providing a safer and more efficient environment.

Future Trends in Fuel Management

Automation, sustainability, and data integration are the adjustments shaping fuel management for the coming years. Predictive analytics applications, powered by AI, help dust-up clean fuel usage pattern prediction for optimizing inventory and minimizing waste. The transition to alternative fuels, such as biodiesel and hydrogen increasingly becoming the mainstay as organizations strive to keep their carbon footprints down while conforming to strict environmental regulations. Fuel-impregnated sensor systems, online and remote systems, are achieving greater real-time visibility into fuel operations for ease of work and compliance. Together, these new ideas are shifting the landscape toward intelligent, green, and resilient fuel management solutions.

AI-Powered Analytics

Predictive insights for fuel optimization

Alternative Fuels

Biodiesel and hydrogen adoption

IoT Integration

Real-time sensor monitoring

Sustainability Focus

Environmental compliance solutions

Integration of Telematics in Fuel Management Systems

Historically, telematics was introduced into fuel management systems to usher in more-than-advanced data insights. Telematics functions in setting real-time observation parameters for vehicle performance, fuel consumption, and drivers’ behavior. But by combining GPS for tracking basis with the analysis for fuel usage, companies can have routes optimized, avoid unnecessary idling, and unnecessary fuel usage. In addition, the present telematics systems can improve predictive maintenance by detecting those inefficiencies where excessive fuel is being consumed or leaked, which enables one to fix such issues before they become heavy repairs or service interruptions.

Another angle through which modern telematics tries to support fuel management lies in the sustainability side and beyond, whereby sophisticated tools can be used to measure and lessen greenhouse gas emissions, improve compliance with environmental regulations, and better allocate resources. The capabilities, such as real-time alerts and reporting, provided by telematics make sure that fleet operations are transparent and fleet managers are able to make operational decisions based on this approach to fuel management. Such a fuel management approach leads to the highest operational efficiency and pushes environmental responsibility of corporations forward.

Advancements in Tank Management Technologies

Being an account of the subject matter, advances in tank management technologies changed the monitoring, controlling, and optimization of storage systems. IoT sensors, real-time data analysis, and automated alert systems are capable of keeping track of inventory, temperature stability, or any leakage. Such systems offer rational insights through which facilities can be maintained beforehand, boosting the operational reliability and meeting the stringent environmental standards that are stringent. This integration of high technologies facilitates better management of resources and increased efficiency.

The Role of Data Analytics in Fuel Management Solutions

Data analytics, thus, completes the fuel management cycle by extracting patterns from the KDD process, orthogonal human-to-human data, and driving decision-making. Advanced algorithms negotiate precise fuel level monitoring and consumption forecasting, and route optimization, all to limit wastage and reduce operational costs. Thus, data analytics ensures predictive maintenance from the point of discovering inefficiencies or potential equipment failure, which could interrupt operations. When data from IoT sensors combine with telematic systems, they yield a wide range of insights supporting regulatory compliance, sustainability of the environment, and better supply chain synchronization. From the existing data, the company can optimize fuel consumption, cut emissions, and save a considerable amount of money in the short and long term.

Reference Sources

1. Automatic Vehicle Fueling System using PLC Controlled Robotic Arm

2. Sustainability of Supply Chain Performance Through Inventory and Collaboration Management

Frequently Asked Questions (FAQs)

What is an automated fuel management system?

An automated fuel management system is an information technology solution created to monitor and control fuel dispensing, keeping track of inventory levels, and managing fuel purchases. When these processes are automated, the organization could save a lot of money and enhance fuel security.

How does a fleet fuel management system help improve fuel efficiency?

The fleet fuel management system gives reports on how fuel is consumed so that fleet managers may be able to identify inefficiencies and change practices to work with improved fuel economy, such as tracking fuel usage habits and fuel consumption targets for drivers.

What are the benefits of using fuel tracking systems?

The system allows tracking fuel levels and consumption in real-time while also keeping track of expenses related to fuel and the dispensed fuel. It helps the company to extend and automate its data collection concerning fuel issues and speed up reporting and analysis with saved time and fuel wastage.

How do automated fuel management systems save time?

Automated fuel management systems accomplish things that previously required manual effort: dispensing, inventory tracking, and charting-more manual tracking and reporting, and huge losses of time during which staff could be trained in other pressing matters while keeping their fuel records accurately.

What capabilities should I look for in a fuel management software?

Thus, a good fuel management software has real-time tank-level monitoring, access control to fuel dispensing, reporting and analysis capabilities, and integration with your hardware and software for smooth operation.

How are fuel management systems improving fuel security?

Fuel management systems increase the level of fuel security by restricting access to fuel tanks and monitoring fuel dispensing. With comprehensive access controls and real-time monitoring of fuel dispensing activities, organizations can curtail instances of fuel theft while ensuring fuel is correctly utilized.

Can I manage multiple fuel types in a fleet fuel management system?

Most of the fleet fuel management systems, indeed, allow for the management of various fuel types, even as they broker efficient management of the different fuel types, such as diesel or gasoline. This type of flexibility ensures that the organization keeps a correct closing inventory and optimizes its purchases of fuel.

What is the role of the mobile app in fuel management solutions?

Mobile Apps can enhance fuel management solutions by allowing fleet managers to access fuel data anywhere, anytime, while monitoring and controlling fuel dispensing and inventory remotely. Such capabilities aid in better decision-making and quicker response to fuel-related issues.

How do fuel management systems help in reporting and analysis?

Fuel management systems assist with reporting and analysis by combining data gathering and producing comprehensive fuel reports. The insight hence acquired assists organizations to know about their fuel expenses; they track fuel cost to the fleet; they identify how to improve their fuel management.