Diesel fuel dispensers, an integral global fueling infrastructure, precisely and safely dispense fuel to vehicles, machinery, and equipment of all sorts. Yet, there is much more to the operation and design of these devices beyond their sheer objectives. The article intends to clear the mist over the complex workings, technologies, and standards governing fuel dispensers and pumps, especially with diesel applications. Whether you are a technical person in the industry, looking for technical insights, or a businessperson looking to invest in proper dispensing systems, this article is written for your understanding. We will cover all critical areas governing efficiency, safety, and compliance on the dispensing side, from the core basics of a diesel fuel dispenser to the latest in fuel-dispensing technology. Get set to view this crucial energy sub-sector from an engineering standpoint, mixed with practical applications.

Introduction to Diesel Fuel Dispensers

Diesel fuel dispensers are custom-built systems designed to transfer diesel fuel efficiently and safely from storage tanks to vehicles or equipment. They consist of an essential working station that needs to push the fuel, a meter to measure the volume of fuel dispensed, and a nozzle that controls the fuel flow. Most modern dispensers come with features that ensure safety, such as systems that shut off fuel flow in emergencies and digital interfaces that record dispensing accurately. The basic function of fuel dispensers is the accurate measurement of fuel so as not to let even a drop go to waste and to avoid any risk of an environmental mishap.

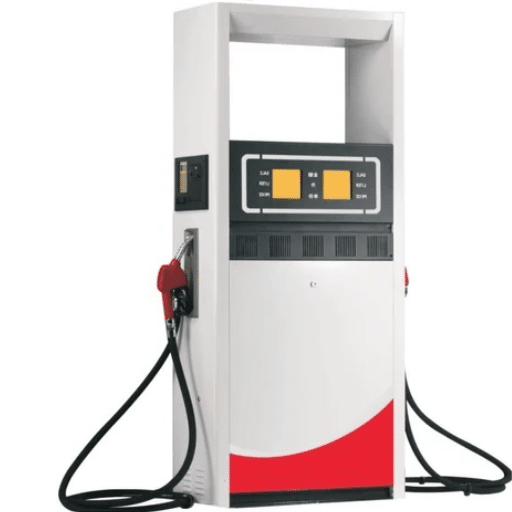

What is a Diesel Fuel Dispenser?

Typically, a diesel fuel dispenser must be engineered for the controlled discharge of diesel fuel from storage tanks to vehicles, machinery, or equipment. It works with the fuel being pumped, measured on the flow meter for volume accuracy, and regulated and channeled by the nozzle. Modern diesel dispensers typically incorporate various technologies that allow for precise monitoring via digital interfaces, preventing spillage through automatic shut-off, and keeping the fuel clean through the use of filters. They help to ensure that fuel delivery is efficient, accurate, and safe in the transportation, agricultural, and construction sectors while maintaining ecology and safety regulations.

Importance of Fuel Dispensers in Fuel Transfer

Due to their essential role, fuel dispensers are responsible for ensuring efficient and safe fuel transfer in multiple industries. They ensure precise delivery of fuels, thereby minimizing human mistakes and lowering the business costs to some degree. Their advanced metering system interplays with flow rate control mechanisms to ensure that these fuel dispensers are precise and reliable, which are indispensable features, especially in high-volume transactions like transportation and logistics. Sometimes, the modern-type dispensers are lined with vapor recovery and leak detection systems to meet the environmental and safety standards, to minimize fuel wastage and limit harmful emissions. Hence, these features place fuel dispensers among the vital tools in ensuring operational efficiency along with stringent regulatory compliance.

Overview of Different Types of Fuel Pumps

Fuel pumps are categorized by their specific mechanism or application, fulfilling the great variety of industrial and commercial needs. The primary types of fuel pumps include:

Mechanical Fuel Pumps

These pumps are mostly employed in older vehicles with carbureted engines. It operates by way of diaphragm action, mechanically driven through the camshaft of the engine. While cheap and easy, mechanical pumps are limited in their pressure output and are gradually being phased out in modern vehicles in favor of electric pumps.

Electric Fuel Pumps

Ejected in a fuel-injected engine, these pumps give a steady and high level of pressure so the engine can perform efficiently. Generally, these pumps are located within the fuel tank (in-tank pumps), therefore enhancing safety by limiting the chances of ignition of fuel. Recent designs incorporate pressure regulators and fuel filters for a much more efficient operation.

High-pressure fuel pumps

They form an integral part of direct injection systems by delivering fuel at a much higher pressure to meet demands set by current-day internal combustion engines. These very high-pressure pumps further the pulverization of the fuel to optimize combustion processes while simultaneously reducing emissions and improving mileage.

Rotary Vane & Gear Pumps

Rotary vane and gear pumps are frequently employed in industrial and commercial applications, giving precise handling for heavy volumes of fuel. They operate by rotating mechanisms that provide a steady flow, rendering them ideal for diesel, aviation fuels, and other heavy-duty applications.

Submersible Pumps

In a refueling system like that of a gas station, the pump becomes submerged in the fuel, thereby giving the benefits of efficiency, low vapor lock possibilities, and durability across the handling of various fuel types.

Basically, any type of fuel pump is essential for its operation; it addresses specific pressure, flow rate, and system requirements that are indeed crucial to operational and environmental efficiency. Selecting a fuel pump of the right kind depends on what it is to be used for, the design considerations of the vehicle or system with which it is to be used, and industry considerations.

Components of a Diesel Fuel Dispenser

A diesel fuel dispenser has several critical components, each having a specially assigned function, to ensure proper and efficient delivery of fuel:

- Pump Unit – To pump the diesel from the storage tank to the nozzle.

- Metering Unit – To register the volume of fuel dispensed.

- Filtration System – To remove any impurities from the fuel, to maintain its quality, and to protect the engines.

- Nozzle – Controls the flow of diesel fuel into the vehicle’s fuel tank and includes an automatic shut-off mechanism.

- Hoses – Designed to transfer diesel fuel from the dispenser to the nozzle, ensuring durability under high pressure.

- Control Panel – In which an operator can input, observe, and control dispensing operations.

All these parts come together in the functioning and the correct dispensing of the diesel, ensuring safety, accuracy, and reliability.

Key Parts of a Diesel Fuel Dispenser Unit

Diesel fuel dispenser units are precisely manufactured for an efficient and safe fuel management system. Concise answers to key questions are compiled below, following key insights from top online resources.

What guarantees fuel accuracy in dispensers?

Some of the meters employed are positive displacement meters or mass flow meters for measurement accuracy. They are regularly calibrated to uphold measurement accuracy.

How is safety ensured during dispensing?

The safety covers include an automatic shut-off in the nozzle, pressure-relief valves in the hose, and grounding to prevent the build-up of static electricity; all these components act together to reduce the risks of leaks, overflows, or ignition.

What materials constitute sturdy dispenser units?

Typically, dispenser parts are made of high-grade stainless steel and corrosion-resistant alloys, which make them last against the wear-and-tear of usage and exposure to environmental conditions.

How do control systems manage operations?

Such kind of digital control panels, interfacing with the sensors, regulate flow, display transaction data, and identify anomalies in the system. They frequently operate with integrated software systems for remote monitoring and diagnostics to provide further optimization.

These, together with the technical functions and very strong constructions, give an idea of the engineering meaning that goes into diesel fuel dispensers. It is Engineering that has to make these dispensers stand up to both the requirements of the user and the statutory compliance requirements.

Understanding the Nozzle and Gun Fuel Dispenser

The nozzle and gun assembly of a fuel dispenser play an essential role in the efficient and exact transfer of fuel. Present-day nozzles contain an automatic shut-off mechanism to prevent overfilling through pressure-sensitive valves. This safety feature ensures dispensing accuracy in conjunction with flow control so that fuel loss is reduced, along with environmental hazards.

Nozzles are generally manufactured using high-grade alloys or stainless steel so that they may resist corrosion caused by exposure to different types of fuels, such as gasoline, diesel, or ethanol blends. Modern ergonomic designs have been applied more recently to enhance user comfort and limit fatigue arising from prolonged use.

Fuel flow rates also depend on variations in application; a typical automobile nozzle usually dispenses fuel at approximately 10 GPM, while high-capacity industrial nozzles exceed 50 GPM. Moreover, systems have vapor recovery technology in place to meet the latest environmental regulations that capture fuel vapors during dispensing and re-channel them for emission reduction.

Key data monitoring takes place with the help of sensors integrated into the nozzle and dispenser unit. These sensors catch data in real time in different parameters: flow speed, pressure, fuel volume, etc. They then have to send this information to centralized control systems for further analysis. With the digitization wave, IoT-enabled components allow for their remote management and diagnostics, thus improving efficiency and diminishing downtime caused by nozzle-related issues. This is, in fine, the blending of mechanical and technological evolution, highlighting a key function of the nozzle and gun fuel dispenser in the modern-day fuel delivery systems.

Role of Filters in Diesel Fuel Dispensers

Filters constitute an integral part of diesel fuel dispensing networks, whose functionality guarantees the disposal of contaminants such as dirt, water, and rust particles from diesel fuel right before it is pumped into a vehicle tank. Inclusions of such anomalies could severely damage an engine with a decrease in its performance, resulting in expensive repairs and maintenance costs. Typically, fuel dispensers employ particulate high-efficiency filters or water-separating filters to address any such concerns that may come up. Modern filtration technology has further evolved, allowing multi-layered media to entrap more particulate matter over longer intervals, which amounts to the reduction of maintenance intervals. Moreover, through filtering, dispensers work better as they dispense only clean fuel, thereby protecting the internal components of a dispenser and the vehicles dependent on the fuel from damage. This particular functionality makes the filter indispensable in a diesel fuel distribution system to prolong the life of engines and ensure adherence to several regulatory standards for fuel quality.

How Diesel Fuel Dispensers Work

Diesel fuel dispensers draw the fuel from an underground or above-ground storage tank and deliver it to vehicles through a nozzle. In operation, the pump creates suction to draw diesel into the dispenser, where flow meters measure the volume of discharge to ensure it is supplied accurately. The flow of fuel is regulated using the nozzle fitted with an auto shut-off mechanism to prevent an overflow. Filters clean contaminants, ensuring the fuel remains clean and usable for the engine. These components must work smoothly to ensure dependable and efficient fueling.

Self-Priming Mechanism Explained

The self-priming mechanism in diesel dispensers removes the need for manual priming, thereby allowing for uninterrupted and efficient operation. This mechanism uses a mix of air separation technologies with specially designed chambers to draw the fuel into the pump automatically without losing internal pressure. Upon activation, the pump vacuum pulls fuel out of the tank, whilst any air trapped in the system is directed through a separate discharge valve.

Self-priming systems today are very efficient, and the majority of pumps can provide flow rates of anywhere from 15 to 130 gallons per minute (GPM), depending on their range of applications and design. The materials used in these installations include corrosion-resistant alloys and seals reinforced enough to resist prolonged exposure to fuels and adverse environmental conditions.

Some sources suggest that self-priming mechanisms might ensure a reduction of downtime, since the priming cycle can last anywhere from 30 seconds to initiate under favorable conditions. The ability to maintain constant fuel flow also reduces wear of pump components, hence increasing service life and decreasing costs of maintenance. With such advances in self-priming technology, modern fuel dispensing systems operate effectively and with minor operator intervention.

Steps to Dispense Diesel Fuel Efficiently

- Preparing the EquipmentMake certain the fuel dispensing system has been correctly installed and is fully operational. Check for any conspicuous damage to hoses, nozzles, and fittings; ensure everything is tight; and make sure the diesel tank has sufficient fuel.

- Priming the PumpIf the pump is not self-priming or requires priming, follow the priming procedure given in the user manual. Modern-day self-priming systems generally take only half a minute to become operational in optimal conditions.

- Checking for Safety MeasuresEnsure that safety measures, such as grounding to prevent static discharge, are in place and that fire extinguishers are readily at hand. The area should be clear of any potential ignition sources.

- Starting the SystemStart the fuel pump as directed by the manufacturer, setting the dispensing rate (if regulated) to guarantee a steady and smooth flow rate that should not exceed the mechanical capacity of one’s equipment.

- Monitoring of the Dispensing OperationProcesses should be continually monitored while dispensing fuel to check for any leaks or interruptions in the flow of fuel. Keep an eye on the nozzle and prevent overfilling of the tank.

- Close and Shut down the ProcessOnce the required fuel has been dispensed, the operator should release the nozzle trigger and ensure any residual fuel in the hose is emptied. Turn off the pump, clean any spilled fuel, and store all equipment appropriately to avoid damage or spilling.

- Post-Dispensing InspectionsInspection of the whole equipment for any leaks, signs of wear, and/or damage should follow the dispensing operation. Fuel consumption documentation is kept for inventory control purposes and to meet regulatory requirements whenever necessary.

These steps combine the best industry practices to ensure that efficiency, safety, and the diesel fuel dispensing process operate in compliance.

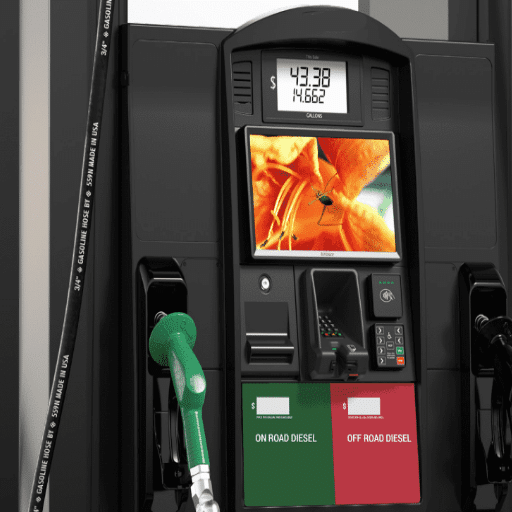

Automatic vs. Manual Fuel Dispensing

An automatic fuel dispensing system is designed to facilitate the processes and enhance operational efficiency through advanced technology. Components in these systems include flow meters, auto shut-off nozzles, and electronic controllers to ensure that fuel is dispensed with the least amount of human intervention. The better measurement accuracy, fewer chances of spills, and safety measures for shutting it down automatically during an anomaly are the principal advantages. Automatic systems fit best when serving a high volume of customers at the station or in a facility requiring an accurate track record of fuel consumed.

The manual way of dispensing fuel depends largely on the person using it and on simple mechanical tools to transfer fuel. While such systems are cost-effective and easily maintainable, they have a higher potential for human error, such as overfilling or spilling, and their efficiency dwindles as the volume increases. However, choosing manual systems can be viable for remote areas or those working with limited technical resources.

All in all, there are several operational factors affecting the decision between automatic and manual dispensing: volume, operating budget, technological infrastructure, and, in some cases, safety or compliance issues.

Choosing the Right Diesel Fuel Dispenser

Diesel fueling equipment selection must depend on its operational requirements. Automatic dispensers, being the fastest and most precise, are ideal for large and high-volume sites. Manual dispensers, on the other hand, offer cost efficiency for smaller operators and for use in remote areas where power and infrastructure are scarce. In all cases, ensure the dispenser is compatible with your fuel storage system, meets all safety criteria, and is guaranteed to last for many years.

Factors to Consider: Size and Price

In the evaluation of fuel dispensers, the size-to-price relation is one such factor that contributes to their usability, operational expediency, and final choice. Larger dispensers usually entail higher throughput and thus are suited for defining high-traffic areas or activities that call for fast refueling. For instance, commercial-scale dispensers are designed to exceed flow rates of even 60 GPM (gallons per minute), thus working very well with the time factor, but due to complex mechanisms and integration of advanced technologies, they usually tend to be on the higher price side.

Smaller dispensers, on the other hand, would be able to serve well for low-to-medium volume operations, such as with small fleets and in countryside areas, being much smaller in design and thus offering initial cost savings. So, a low-volume dispenser could work anywhere between 15 and 25 GPM and therefore benefits the user by being energy efficient and occupying less space.

Depending on the specifications of the materials, considerations of price and size are established. The selection between the stainless steel and corrosion-resistant components will lie in consideration of durability, but the overall price is a consideration, as they are tested to be reliable under harsh environments for long durations. Thus, the considerations between the dispensing capacity needed against the total cost of ownership must be established. Proper analysis of these factors, in concert with operational requirements, must be made to optimize performance while remaining fiscally responsible.

Comparing Mini and Full-Size Fuel Dispensers

Simply put, while mini and full-size fuel dispensers are different mainly because of their deployment, capacity, and operational mechanisms, mini fuel dispensers are smaller, with very limited-volume applications, making them suitable for minor operations on farms, service vehicles, or private stations. Their flow rate is kept smaller, usually between 30-70 liters per minute, which fits the customer needing very limited fuel requirements and restricting space for equipment. However, in spite of their smaller size, some advanced models of mini dispensers still come with all necessary features such as digital meters and simple communication systems.

Full-size fuel dispensers are designed mainly for heavy use, such as at commercial gas stations and industrial sites. With a typical flow of 75 liters per minute and higher, these dispensers meet the demands for uninterrupted large-scale vehicle fueling and support greater levels of automation and multi-product dispensing. Moreover, the dispensers are commonly equipped with additional technologies such as vapor recovery systems, payment terminals, start/stop buttons, fallback options, and remote monitoring, thus ensuring compliance and operational efficiency.

Each requires analyzing operational needs. While mini dispensers are cost-effective for less demanding applications, full-size dispensers play a crucial role in robust, versatile operations of high throughput.

Warranty Options for Diesel Fuel Dispensers

Invariably, in the consideration of warranty options for diesel fuel dispensers, manufacturers usually favor giving different coverages, i.e., to ensure that their equipment stands the test of time and performs reliably. These element warranties usually cover defective parts, labor cost, and installation of pumps, hoses, and nozzles.

Standard Warranty Coverage

The manufacturers are more or less giving a 1-2-year period of the standard warranty from the date of purchase or installation, in which they will usually replace or repair defective mechanical or electrical components under conditions of ordinary user operation. They really should exclude damages caused through improper installation, use, or lack of maintenance.

Extended Warranties

Extended warranty options are offered by many manufacturers for coverage beyond the usual warranty period, which is often 5 years. Usually, the plans would include ancillary services like on-site maintenance and inspections to provide preventive maintenance. The extended warranty would require an extra payment but could really provide peace of mind, especially when the equipment is being heavily utilized.

Component-Specific Warranties

Certain important components, such as the meter or the hydraulic system, may be covered by a warranty that might last longer than the main warranty. For instance, meters are warranted anywhere from 5-10 years, depending on the manufacturer. Do keep in mind that each warranty has its own limitations and exclusion clauses, so it is always better to read the fine print carefully.

The terms and conditions, protocols of service, and any additional costs for a warranty option must be considered as important factor. Awareness of these options guarantees your investment is well protected and, at the same time, ensures minimum downtime and unexpected operational costs.

Maintenance and Care for Diesel Fuel Dispensers

The maintenance of diesel fuel dispensers is an indispensable factor in keeping their operations efficient, accurate, and long-lasting. Some of the important maintenance procedures that need to be adhered to are:

- Routine Inspection: Examine the hose, lubricator, nozzle, fitting, and seals for any damage that may allow leakage of fuel. Fuel dispensing must always be safe and effective.

- Replacing Filters: It is an occasional job that must be undertaken periodically to ensure that fuel filters do not get clogged up, thereby letting unclean fuel pass through. The intervals ought to be set according to the manufacturer’s specifications.

- Calibration: Should be done regularly to ensure the accuracy of measurement and maintain compliance with applicable regulatory standards.

- Tank Monitoring: Check and clean the fuel storage tanks to avoid contamination that would affect dispenser operation.

- Environmental Protection: Prevent dispensers from exposure to adverse weather conditions and ensure they are properly grounded to avoid electrical hazards.

Observance of these maintenance schedules minimizes downtime and ensures precision in operation while reducing further repair costs. It is always advisable to consult the manufacturer’s manual to gain specific insights into recommended maintenance schedules and details.

Best Practices for Maintaining Your Fuel Pump

Fuel pumps must be maintained properly to ensure consistent efficiency and prevent expensive repairs. Here are some key best practices compiled from various trustworthy sources:

- Inspect and Clean Filters Regularly: Clogged or dirty filters obstruct fuel flow and put stress on the pump. Clean or replace filters on a routine basis with respect to the manufacturer’s specifications.

- Monitor Fuel Quality: Always use clean fuel with quality measures and occasional periodic testing for water content or debris, since these factors create premature wear or cause pump malfunction.

- Keep Voltage and Connections Proper: Fuel pumps need to be supplied with power consistently. Check whether electrical connections and wiring show signs of corrosion, wear, or inappropriate grounds. Bad connections result in fuel pump inefficiency and eventual damage.

- Avoid Running on Low Fuel; operating the pump under low fuel conditions will cause the pump to overheat, especially as the fuel indeed serves as coolant and lubricant to the pump. Always keep the fuel tank filled until it is at least one-quarter full.

- Familiarize Yourself with Pressure Tests: Use pressure gauges to check the output pressure of the fuel pump and confirm it complies with the specifications. Any erratic readings in the pressure may imply calibration needs or possibly replacement.

By adhering to these guidelines, you will increase the longevity of your fuel pump, improve its performance, and reduce any disruptions caused during its operation. Please always view any particular times and instructions in conjunction with the technical recommendations of your manufacturer.

Common Issues and Troubleshooting Tips

Common fuel pump problems I tend to experience are low fuel pressure, unusual noises, and sometimes complete failure of the pumping action. The usual way I diagnose a problem would be to check the fuel pressure with a good pressure gauge and use this to decide whether the pump is operating within the specified range or not. If the pressure is not steady, it is most probable that the fuel lines or filters need checking for infiltration. I listen even for strange noises because sometimes they could tell me about wear or mechanical damage, and also test the electrical connections to ensure they are getting the proper voltage. By working my way systematically through these steps, I can quickly find and fix the problem most of the time.

Importance of Regular Filter Replacement

If we think about it, filter replacement should be the very first step in one day of proper maintenance to ensure we have an effective system, to give it the damage-free opportunity that it deserves while doing its job, and to preserve it with operational efficiency over time. Cleaning or checking for filters would prevent these contaminants from circulating inside the system: debris, dirt, and particulate matter. Such clogging or wear on sensitive components due to these contaminants can prove troublesome for all parties. With time, such filters saturate and turn ineffective. Amongst other things, they create pressure drops or restricted flow in the system. Such obstructions cause stress to the system, higher energy consumption, and possible early aging of its key parts. Industry standards suggest that one must carry out periodic inspections and timely replacements as recommended by the manufacturers for extending equipment life and avoiding heavy expenditure on repairs. Proactively maintaining clean filters is the bedrock of any sound maintenance strategy.

Reference Sources

1. Fuel Automata: Smart Fuel Dispenser Using RFID Technology and IoT-Based Monitoring

2. National Comparison on Verification of Fuel Dispensers

3. Advanced Mathematical Model of Fuel Supply Operating Process

Frequently Asked Questions (FAQs)

What is the diesel fuel dispenser, and how does it function?

The diesel fuel dispenser is a type of pump designed to fill vehicles or storage tanks with diesel. Diesel fuel is drawn from the storage tank, and it is then passed through a nozzle into the desired container. These diesel filling stations may be fully automated to ensure precise measurement and no wastage.

What are the main components of a diesel fuel dispenser unit?

The main components of a diesel fuel dispenser unit usually include a fuel pump, nozzle, flow meter, and control system. The fuel pump draws diesel fuel from the storage tank, while the nozzle dispenses the fuel. The flow meter quantifies the amount of fuel dispensed, while the control system manages the operations of the entire unit.

How much does the diesel fuel dispenser package cost?

The price range of a diesel fuel dispenser package can vary widely depending on the size, features, and manufacturer. A basic one can cost a few thousand dollars, with automatic top-end units with upgraded security systems costing $20,000 or more.

How can I maintain my diesel fuel pump for the best performance?

Maintenance of a diesel fuel pump should include frequent checking and replacement of filters, examination of hoses and connections for leaks, and cleaning of the nozzle if needed, ensuring that it functions well. Following the maintenance intervals and service schedules as defined by the manufacturer is good practice to prevent operational problems.

What kind of safety features should a diesel fuel dispenser have?

Look for safety features such as an automatic shut-off valve, an anti-drip nozzle, and an emergency stop button when selecting a diesel fuel dispenser. Furthermore, given that the unit has specifications for leak detection and containment, these help avoid spills and ensure environmental protection.

Could a diesel fuel dispenser be used for other oils or fuels?

Diesel fuel dispensers are deliberately designed for diesel; however, some can be adapted for dispensing other oils or fuels. It is vital to check the manufacturer’s specifications to ensure the unit is compatible with the fuel you intend to use.