Gas pumps must be highly reliable and have great quality on the industrial fluid management level and at fuel stations. The great number of manufacturers in the market-they all have their own thing to offer in terms of features and technology-can make one go crazy making a choice. This guide intends to ease the selection process with an in-depth discussion on the top 10 leading gas pump manufacturers in the industry. From bleeding-edge innovations through to durability, we discuss how these companies are setting the groundwork for fuel dispensing technologies. By the conclusion of this article, the reader shall be conversant with the important players in the market and what sets them apart, to the extent that they will be able to make a well-informed decision with respect to their business or project needs.

Top 10 Leading Gas Pump Manufacturers

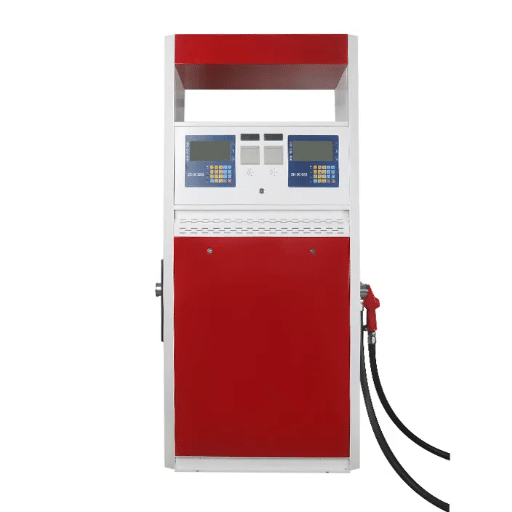

1. Shandong Shengrui Intelligent Equipment Co., Ltd.

Founded: 1998

Introduction:

Located in China, it is a top innovator in fueling equipment and systems. The company is prominent due to its advanced manufacturing capabilities and an emphasis on the integration of intelligent technologies.

Main Products:

- Smart gas dispensers

- Mobile fueling systems

- Automated payment terminals

Key Advantages:

- Advanced technology integration

- Highly durable and reliable products

- Customer support and training programs with a recognized reputation

Disadvantages:

- Direct sales of some products are limited in some areas; thus, distributors must be relied on to find the product

Official Website: Shandong Shengrui

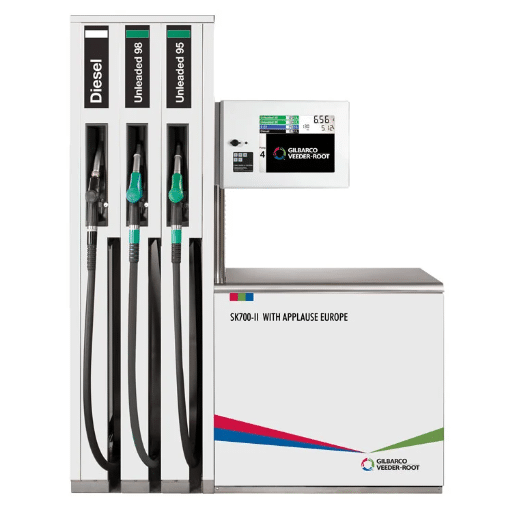

2. Gilbarco Veeder-Root

Founded: 1865

Introduction:

Gilbarco Veeder-Root is a well-known name in the fueling industry, based in Greensboro, North Carolina. It is known for designing and implementing a wide range of fueling and retail solutions.

Main Products:

- Gas dispensers

- Tank gauges

- Forecourt payment systems

Key Advantages:

- Excellent global presence and customer service network

- Focus on sustainability and advanced technology

Disadvantages:

- Costlier starting price than some competitors

Official Website: Gilbarco Veeder-Root

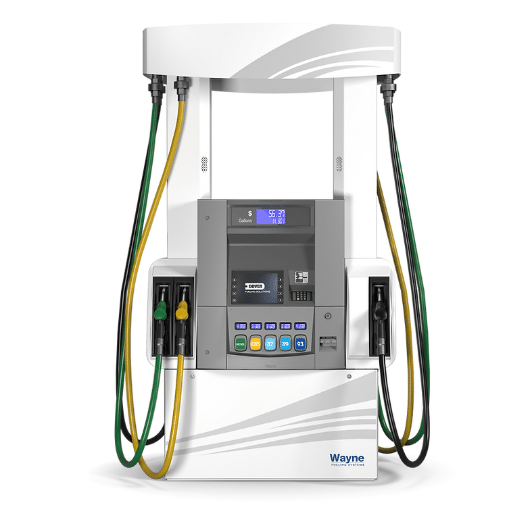

3. Wayne Fueling Systems

Founded: 1891

About:

Wayne Fueling Systems was located in Austin, Texas, with a deep-rooted history of innovation in fuel dispensers and forecourt technology. It is a subsidiary of Dover Corporation.

Main Products:

- Fuel Dispensers

- Payment Terminals

- Vapor Recovery Systems

Key Advantages:

- First movers in IoT technology integration

- Reliable and durable machines

Disadvantages:

- Smaller product portfolio when compared to its competitors

Official Website: Wayne Fueling Systems

4. Tatsuno Corporation

Founded: 1911

Introduction:

Tatsuno is a Japanese manufacturing firm with its main line of manufacturing consisting of fuel dispensers and related equipment. It enjoys the reputation of precision engineering and upholding quality standards on the world stage.

Main Products:

- Fuel dispensers

- Flow meters

- Payment terminals

Key Advantages:

- Engineering and design of the highest standard

- Long-lasting and durable products

Disadvantages:

- Limited availability for certain models outside Asia

Official Website: Tatsuno Corporation

5. Bennett Pump Company

Founded: 1919

Introduction:

From its base in Spring Lake, MI, USA, Bennett has carved a niche for itself in a wide array of fuel dispensing equipment for retail and commercial fueling markets.

Main Products:

- Fuel dispensers

- DEF (Diesel Exhaust Fluid) systems

- Retail and fleet fueling solutions

Key Advantages:

- Solutions tailored to different markets

- Focus on green energy initiatives

Disadvantages:

- Limited international footprint as compared to bigger competitors

Official Website: Bennett Pump

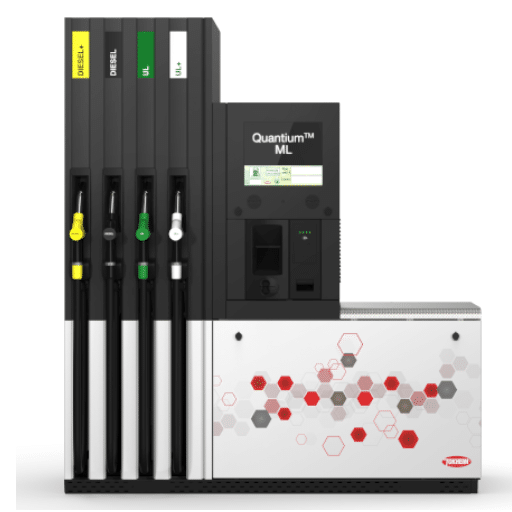

6. Tokheim

Founded: 1901

Introduction:

Reinforcing an important title in the market, Tokheim, French in origin, offers a full complement of fuel dispensers and forecourt integrated solutions.

Key Products:

- Fuel pumps

- Automatic payment systems

- Management software

Key Advantages:

- Full complement of integrated products

- Strong legacy and strong reliability

Disadvantages:

- Higher maintenance costs for some legacy systems

Official Website: Tokheim

7. ZHEJIANG LANFENG MACHINE CO., LTD

Year Founded: 1995

Introduction:

Headquartered in China, Lanfeng is engaged in the designing and manufacturing of fuel dispensers for the world markets with quality at an affordable price.

Main Products:

- Fuel dispensers

- Tank level gauges

- Self-service payment kiosks

Advantage Services:

- Competitive price

- Highly customizable designs

Disadvantages:

- Service support outside Asia is limited

Official Website: ZHEJIANG LANFENG

8. OPW (A Dover Company)

Date of Establishment: 1892

Introduction:

OPW, located in Ohio, USA, is a worldwide supplier of fueling components, equipment, and environmental systems.

Main Products:

- Fueling components

- Dispensers

- Containment systems

Key Advantages:

- Strives to become increasingly environmentally responsible

- The product mix covers a wide range

Disadvantages:

- Less focus on standalone dispensers than the others

Official Website: OPW

9. PIUSI S.p.A

Founded: 1953

Introduction:

PIUSI, being an Italian company, manufactures and engineers pumps and meters as well as systems for fueling. The services it provides are primarily agricultural, automotive, and industrial.

Main Products:

- Fuel and oil transfer pumps

- Flow meters

- Self-service systems

Key Advantages:

- High efficiency, precision engineering

- Solutions versatile enough for any purpose

Disadvantages:

- Limited to large retail fuel systems

Official Website: PIUSI

10. SCANIA Fuel Systems

Year of establishment: 1911

Introduction:

Starting in Sweden, SCANIA provides custom fuel system design and quality standards that will be accepted by international markets.

Main Products:

- Fuel dispensers

- Filtration systems

- Intelligent management solutions

Key Advantages:

- Versatile product range

- Strong global distribution networks

Disadvantages:

- Bigger pricing for customized systems

Official Website: SCANIA

Quick Comparison Table

| Rank | Company Name | Founded | Country | Key Strength |

|---|---|---|---|---|

| 1 | Shandong Shengrui | 1998 | China | Smart technology integration |

| 2 | Gilbarco Veeder-Root | 1865 | USA | Global presence & sustainability |

| 3 | Wayne Fueling Systems | 1891 | USA | IoT technology integration |

| 4 | Tatsuno Corporation | 1911 | Japan | Precision engineering |

| 5 | Bennett Pump Company | 1919 | USA | Green energy initiatives |

| 6 | Tokheim | 1901 | France | Integrated solutions |

| 7 | ZHEJIANG LANFENG | 1995 | China | Competitive pricing |

| 8 | OPW | 1892 | USA | Environmental responsibility |

| 9 | PIUSI S.p.A | 1953 | Italy | Precision engineering |

| 10 | SCANIA Fuel Systems | 1911 | Sweden | Custom system design |

Frequently Asked Questions (FAQs)

What products are regarded as key in gas pump manufacturing?

A typical gas pump manufacturer offers a comprehensive product line ranging from gasoline-type pumps to diesel fuel dispensers, oil pumps, and fuel management systems. They cater to both retail technology for gas stations and industrial applications, thus fulfilling the diversity of their clientele. Some also supply aftermarket solutions and customize their offerings to enhance fuel efficiency and regulatory compliance.

How would a gas pump manufacturer maintain industry standards for conformity?

To maintain conformity with the industry standards, a gas pump manufacturer will have to observe those standards as set by societies such as ISO and UL. This includes testing and quality assurance of their pump products and equipment. Often, manufacturers will try to stay abreast of changes in regulations so that they can continue to assure due dependability and safety to their fuel dispensers and petroleum equipment.

What types of fuels do manufacturers of gas pumps usually deal in?

A variety of fuels are offered to customers by the gas pump manufacturers: commercial gasoline, diesel fuel, compressed natural gas (CNG), liquefied natural gas (LNG), or alternative fuels such as hydrogen. Being able to set up customized gas pump solutions according to the fuel types allows these manufacturers to meet the disparate needs of gas stations and industrial uses, thus assuring easy refuelling.

Why is leak detection in fuel pumps important?

Leak detection ensures environmental protection and safety in the fuel industry establishments. This detection system would stop even potential fuel spills that threaten contamination and fines. A dependable gas pump manufacturer incorporates cutting-edge, high-precision leakage detection systems within its fuel dispensers to deliver gas at all times without safety compromise.

How do oil and gas manufacturers upgrade their equipment?

The oil and gas producers present a good opportunity for upgrading equipment with new technologies, such as modular pump designs or advanced fuel management systems. Upgrades may include the integration of a user-friendly interface and contactless payment for improving the customer experience at the gas station. Continual improvement keeps these pumps lining up in competition with fast-evolving markets.

How does customization play a role in the pump industry?

Customization plays a great role in the pump industry, allowing manufacturers the opportunity to tailor their products to meet particular customer needs. Be it adapting fuel dispensers for electric vehicle charging or designing submersible pumps for customized industrial needs, customization essentially gives the equipment greater adaptability and functionality to satisfy diverse market needs.

What are some advantages that come from partnering with the leader in gas pump manufacturing?

Working with the leading gas pump manufacturer will give you numerous perks, such as a complete fuel product line, cutting-edge technology, and customer service beyond compare. These manufacturers usually have records of dependability and quality; businesses that rely on their products for smooth operations can just rest easy.

How do fuel management systems maximize efficiency at the gas station?

Fuel management systems maximize efficiency at gas stations by providing real-time fuel measurements, sales, and inventory management data. Such technology enables gas stations to optimize their operations, minimizing waste and ensuring appropriate fuel availability for the customers. Advanced systems can even integrate with various pump products to help enhance the overall performance of fuel dispensers.