The siphoning of gas is an operation that necessitates the use of appropriate tools, precision, and safety to be done effectively. It does not matter in case you are beset by an emergency, maintaining the vehicle, or simply transferring fuel, because learning to siphon gas the right way is a must. But, although it may look very simple, the transferring of one tank’s fuel to another brings along a few risks and potential hazards if not done in the right way. This guide is a map that will take you from the beginning to the end of the process with easy-to-understand instructions and necessary safety considerations. You will be able to do the fuel transfer tasks in a responsible manner and at the same time, making the risks to yourself and the environment as low as possible when you finish reading this article.

Understanding the Siphon Method

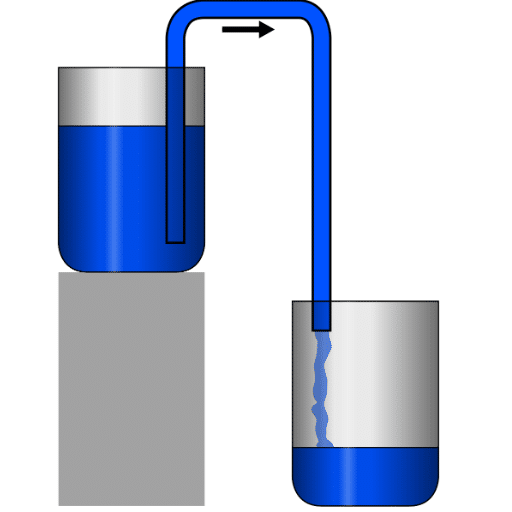

The siphon technique, which is based on the laws of nature, is a very straightforward and powerful method of moving fuel from one container or tank to another. Generally, a hose or pipe is used, which has one end in the source tank and the other in the receiving tank. At the source end, the liquid is sucked in by a pump or manually, and it flows through the hose due to gravity. The transfer continues to be maintained by gravity as long as the receiving tank is lower than the source tank. It is very important to have a perfect connection at all points and also to make sure that no air bubbles are in the hose for a hassle-free operation. The use of safety gloves and working in ventilated areas are some of the proper precautions that are necessary for the safe handling of the materials involved.

What is a Siphon?

A siphon could be defined as a tool or action that aids in the shifting of liquids from one vessel to another, mostly using the combination of gravity and atmospheric pressure. The mechanism includes a tube or pipe filled with the liquid, wherein one end is submerged in the higher source container while the other end is placed in the lower receiving container. The liquid is either taken through the siphon due to suction or by filling the tube before starting the process. When the liquid starts the flow, the power of gravity will be the only force to help in the movement of the liquid as long as the receiving container is kept lower than the source and the air does not get into the tube to stop the flow. Siphons are used in a range of situations, such as fuel transfer, fish tanks, and irrigation systems, where they are liked for their capability to move liquids in a manner that is both easy and efficient without the requirement of mechanical pumps.

How Does Siphoning Work?

Siphoning is a process that uses the forces of gravity and atmospheric pressure as its major principles. The whole procedure starts by moving a liquid from a higher level to a lower level through a tube. The movement of the liquid within the tube is facilitated either by suction or pre-filling, and at the same time, the atmospheric pressure is pushing the liquid in the source container toward the tube’s opening. Gravity takes over the flow at this point, and the liquid is moved continuously until it reaches the lower container. However, if there are any interruptions of air in the tube, they would cause the pressure differential needed for flow to be disrupted, and hence the whole process would stop. Such a simple but powerful mechanism is applied in various ways, such as in the case of transferring fuel or emptying water systems.

Benefits of Using a Siphon for Fuel Transfers

The use of a siphon for fuel transfers has some clear benefits, which confirm their practicality and efficiency. The first one is that it is a cheaper solution compared to electric pumps, as most siphons depend on gravity and pressure differentials, thus avoiding the need for an external power source. This makes the process not only economical but also portable and convenient for remote or off-grid places. Another advantage of siphoning is that it guarantees total fuel transfer control and accuracy, thereby minimizing the chances of spillage and wastage, which is very critical in the case of flammable or hazardous fuels. Moreover, siphons can be easily operated, and their maintenance is less tedious because of the very easy mechanical design, hence less downtime and no high technical skill required. Lastly, their flexibility makes them suitable for different types of liquid fuels and also for different container shapes, thereby making them an excellent tool in many industries and applications.

Essential Tools for Siphoning Gas

To perform the task of siphoning gas safely and properly, it is necessary to have the following tools:

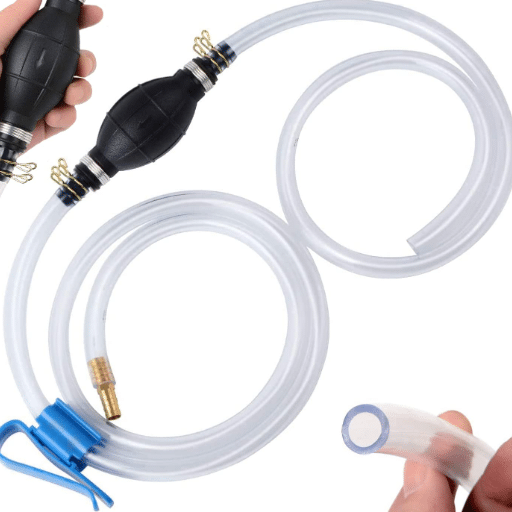

- Siphon Pump – A manual or electric pump mainly for the movement of fuel with the least spillage and the most precise control.

- Fuel-Grade Hose – A tough plastic hose that is not reactive and thus does not leak and resists corrosion even with constant exposure to fuel.

- Gas-Approved Storage Container – A storage space that is certified for fuel, therefore, safe, and in compliance with regulations.

- Protective Gear – Gloves and safety glasses as protection against fuel contact that is not intended.

- Funnel (Optional) – For help if needed in directing the flow of the fuel.

The mentioned tools, working together, increase the safety, efficiency, and accuracy of the process of siphoning, thus meeting the standards set by the industry and the practice.

Types of Siphon Pumps

Several kinds of siphon pumps exist based on their methods of operation and the use they are intended for. The following are the principal categories:

| Type | Description | Best Use |

|---|---|---|

| Manual Hand Pumps | Siphon pumps of this kind require manual effort to generate suction, usually through a hand-operated lever or bulb. They are inexpensive, straightforward to use, and can be used in small-scale tasks of transferring fuel or liquid. | Occasional-use tools for small-scale transfers |

| Electric Siphon Pumps | These pumps are powered by electricity and give a substantial degree of convenience and efficiency in the transfer of liquids. They are equipped for fast operation and are suitable for a very large volume of fuel, water, or chemicals. Automatic shutoff systems are common in electric siphon pumps. | Industrial and commercial applications with large volumes |

| Gravity-Based Siphon Pumps | The working of these pumps is based on the force of gravity. A hose is used to move liquid from a higher position to a lower one. They need priming to get started and are an easy, low-cost way to accomplish liquid transfer. | Simple transfers with adequate height difference |

Understanding the properties, advantages, and disadvantages of different types, users can decide upon a siphon pump that perfectly fits their needs and working environment.

Choosing the Right Hose for Siphoning

The choice of the right siphoning hose is very important for the fluid transfer to be both safe and efficient. The most important factors to check are material, diameter, and length:

- Material: The hose material must be compatible with the liquid being siphoned in order to avoid any degradation or contamination. The most common materials used include PVC for general-purpose, rubber for durability, and silicone for chemical resistance.

- Diameter: The speed of fluid transfer is higher with a smaller diameter hose as the resistance to flow is reduced, while the smaller diameter is good for precision or when limited space is a factor. For best performance, match the diameter to the input specification of your siphon pump.

- Length: The length of the hose should be such that it can reach the high point or the distance between the source and the destination area. Long hoses may lead to reduced flow because of friction, while short hoses may not be suitable for your application.

Considering these factors, users can be sure that the selected hose meets the required technical specifications and, at the same time, operational needs are satisfied.

Portable Fuel Transfer Pump Kits

Portable fuel transfer pump kits are multipurpose items made for the safe and smart way of moving fuels from one container or tank to another. Your perfect kit selection should be guided by the following main aspects:

- Flow Rate: The pump kit with a flow rate equal to or higher than that of the volume you are going to transfer should be your choice. Portable applications usually have flow rates from about 10 to 30 gallons per minute (GPM), ensuring not only fast but also reliable operation.

- Compatibility: Check if the pump, hoses, and seals’ materials are compatible with the fuel type (e.g., gasoline, diesel, or kerosene) you are going to transfer. Compatibility is a key factor that secures the lifespan and avoids chemical destruction.

- Power Source: There are different power sources for portable pumps, such as battery-operated, manual, or electric (12V or 110V). Pick one that goes with your working conditions and the power source available.

- Portability and Design: It is better to go for a light-weight and ergonomically designed kit that will make it easy for you to transport and operate. There are many kits that come with built-in handles, small storage cases, and quick-connect fittings for more convenience.

- Safety Features: Systems equipped with automatic shut-off valves or anti-static components and thus reducing the risk of fire and explosion while handling flammable liquids, should be your choice.

Technical and operational factors in the kit, thus making it safe, efficient, and reliable for fuel transfer without loss of performance or safety. These are expert insights and excellent solutions from the market that have been combined to make it easier for you to make an informed choice.

Step-by-Step Guide to Siphoning Gas

- Collect What You Need

The things you need are a siphon pump or hose, a gas collection container, and protective equipment like gloves and goggles. - Observe Safety Rules

Choose a place with good air circulation, far from any flames or sources of sparks. Check that the container used is safe and meets the requirements for the storage of flammable liquids. - Arrange the Setup

Put the container lower than the gas tank so that gravity will help you in the process. Take one end of the siphon hose and place it in the fuel tank while putting the other end in the container. - Initiate the Siphoning Process

In case you are using a manual siphon pump, read the manufacturer’s instructions and apply them to start the pumping. For a plain siphon hose, employ the suitable technique (like priming) to get the fuel flowing. - Keep An Eye On The Transfer

Take note of the gas coming out very carefully so that the container does not overflow. Do not let the transfer go longer than the amount of fuel you want. - Putting the Equipment in a Safe Place

Disconnect the hose or pump from the fuel tank and the container. Quickly close the container to avoid spillage and evaporation. - Burn and Dispose of the Residues the Right Way

Clean up any spillage and make sure that no fuel is left in the equipment. Keep the siphon tools and container in the correct place to be used in the future.

By using these methods, gas siphoning can be performed safely and with less chance of accidents.

Preparing the Gas Tank

Following these steps is paramount to properly preparing your gas tank for maintenance or fuel transfer operations.

- Stable Surface for the Vehicle

Make sure to park the vehicle in a place that is stable and flat, plus apply the parking brake so there won’t be any movement during the process. - Reduce the Fuel Level if Necessary

If the tank is filled up above, siphon out the excess gas with a proper siphoning device as discussed in the steps above. Always check the container for fuel extraction to ensure it meets legal and safety standards. - Disconnect the Battery (if required)

In case of fuel tank maintenance, it may be necessary to disconnect the vehicle’s battery to avoid unintentional sparks that cause fire hazards. This precaution is very critical when it comes to the replacement or repair of fuel tank parts. - Depressurize the Fuel System

Before taking any further steps, relieve the fuel system pressure. This is mostly done by finding the fuel pump relay in the vehicle’s fuse box and then starting the engine until it shuts down. Check the vehicle manual to get specific instructions for your car. - Clean the Area Around the Fuel Cap

During maintenance, dirt or debris left around the fuel cap or inlet might get mixed up with the fuel system and contaminate it. So, wipe the area clean to keep the system intact.

All the preparatory work done provides your gas tank and fuel system with safe and smooth maintenance or repair operations. Always consult your vehicle’s service manual for specific procedures related to your make and model.

Setting Up the Siphon Hose

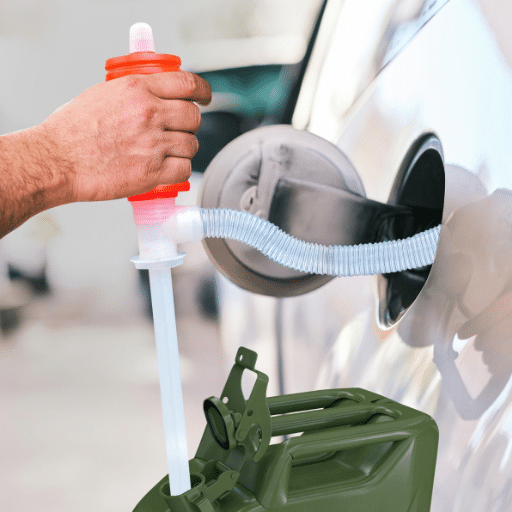

Pick the Right Siphon Hose

Get a siphon hose that is perfect for gasoline or whatever fluid you are dealing with. The material of the hose should be able to tolerate chemicals, and also, safety measures for fuel handling should be met.

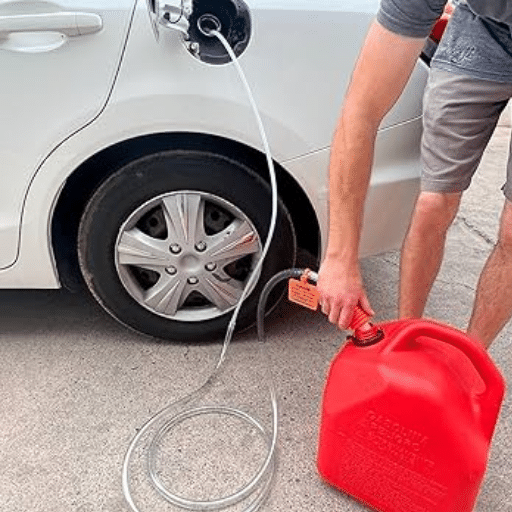

Determine the Position of the Containers for the Source and the Destination

The source container (for instance, a gas tank) should be put at a height that is greater than that of the destination container, so that gravity aids the siphoning process. Also, make the containers stable to avoid any accidents.

Siphon Hose Insertion

Take care and upload one end of the siphon hose into the source container, where it should be completely submerged in the liquid. The other end of the hose should also be inserted into the destination container, and you should make sure that it is firmly placed so there is no movement or leakage.

Start and Observe the Flow

In case a manual siphon pump is being used, start pumping to generate the required suction. For self-priming siphon hoses, gently shake the hose to get the fluid moving. Watch the flow all the time so that the destination container is not overfilled or air drawn in.

Lock the System and Finish

When the siphoning process is done, pull out the source end of the hose from the liquid to stop the siphon and to cut off the flow. Just as it is mentioned in the local regulations and manufacturer guidelines, safely store or dispose of the siphon hose and containers.

Following these comprehensive points, you can safely and efficiently use a siphon hose to transfer liquids with the least risk of contamination or spilling. For best results, always refer to the specific instructions that come with your siphon equipment.

Executing the Siphoning Process

The siphoning process is to be conducted smoothly only if the following steps, which combine the best methods from the top resources, are strictly observed:

- Preparation: It is necessary to confirm that the siphon hose that you are taking is the right one for the liquid to be transferred. Check for any cleanliness and damage. Place the source and receiving containers on steady and flat surfaces, making sure that the receiving container is at a lower level so that flow by gravity is possible. Always use personal protective equipment (PPE) correctly, such as gloves or goggles, when handling hazardous fluids.

- Priming the Siphon Hose: Take one end of the hose and put it in the source fluid. Follow the device-specific instructions for manual or pump siphons to get the flow started, often by pushing a bulb or pump mechanism. For traditional hoses, use pressure or a vacuum pump to create suction, but be very careful and do not get in direct contact.

- Monitoring the Flow: Once the flow is established, it should be continuous. Secure the positioning of the hose to make sure it does not get dislodged, and continuously check the process to prevent overflowing or air entering the system, which can break the siphoning process.

- Ending the Process: Once the required transfer volume is reached, lift the source end of the hose above the fluid levels and take it out of the source container to stop the flow. Immediately re-seal all containers and clean the siphon hose.

If these meticulous steps are followed, you will have safety, efficiency, and adherence to the recommended siphon methods. Always check the manufacturer’s recommendations and local laws for specific requirements.

Safety Precautions When Siphoning Fuel

- Use Approved Equipment: It is very important always to use a fuel-grade siphon hose or pump that is specially made for working with flammable liquids. Doing so reduces the risk of leaks and accidents considerably.

- Work in Well-Ventilated Areas: Make use of outdoor areas or places with good ventilation when siphoning fuel to make sure that no harmful fumes are produced and to eliminate the risk of inhaling them.

- Avoid Open Flames: Before you start handling fuel, make sure that there is no source of ignition in the vicinity, such as cigarettes or sparks.

- Wear Protective Gear: The use of gloves and safety goggles will protect your skin and eyes from any splashes that might occur.

- Prevent Spills: Take good care of the containers you are handling so that there are no fuel spills, which could lead to environmental pollution or fire hazards.

- Follow Local Regulations: Always check and comply with the laws and guidelines related to fuel handling and transfer that are applicable in your area.

In the end, if you practice the above precautions, you will be able to cut down the risks associated with siphoning fuel to a very large extent.

Understanding the Risks of Gasoline

Gasoline, being a very combustible and volatile substance, its handling is therefore very risky to handle. Among the many dangers, producing explosive vapors is the most significant risk, which can be ignited by even a tiny spark. Sooner or later, skin contact with gasoline will lead to irritation or chemical burns, and inhaling fumes will cause dizziness, headaches, or respiratory irritation. Also, if gasoline is not stored or disposed of properly, it can lead to pollution of the environment, particularly soil and water, which are the most affected ecosystems. The awareness of these risks emphasizes the need for proper safety measures and compliance with local regulations to eliminate possible hazards.

Using Proper Protective Gear

For the handling of gasoline, it is very important to wear the right protective equipment in order to minimize health and safety risks. One of the main things that the use of chemical-resistant gloves, such as nitrile or neoprene, can do is to eliminate the chances of skin contact or irritation, or even burns. Goggles or face shields are a must in order to keep the eyes safe from splashes and also to avoid accidental exposure to harmful gases. In addition, respirators with organic vapour cartridges should be used by those working in areas that are not well ventilated to ensure that they do not inhale toxic fumes. Choosing protective wear that is chemical permeation resistant will also help to prevent skin contact with gasoline. Thus, by relying on good personal protective equipment and following safety rules, one can still reduce the risk of accidents significantly.

What to Do in Case of Spills

In case of a gasoline spill, it is very important to act quickly in order to reduce hazards. The first step is to make sure that the area is well-ventilated. This can be done by opening windows or using fans to blow away the smoke. Turn off all potential sources of ignition, including open fires, sparks, or any equipment that uses electricity, as gasoline fumes are extremely flammable. Moreover, use absorbent materials like sand, vermiculite, or commercial pads to encircle and contain the spill and make sure that it doesn’t spread further or get into the drains or water bodies. After that, use absorbent materials to clean the surrounding area and put the used materials into a container marked as hazardous waste for proper disposal. Always comply with the local laws regarding the handling of hazardous waste. In case the spill is large or it contaminates the surroundings, make sure to notify the environmental authority responsible for the area without delay to receive further directions and to undertake remediation actions. Quickness in action, correct containment, and following of safety measures are the key points in effective spill control.

Common Mistakes to Avoid While Siphoning Gas

Using Unsafe Equipment

The use of wrong tools, for instance, unapproved hoses or containers, may result in leaks, spills, or accidents. Nevertheless, always use the equipment that is exclusively meant for gas siphoning.

Lack of Proper Ventilation

Siphoning in sealed-off areas makes it easier for one to inhale the toxic fumes, which is a serious health issue. So conduct the operation outdoors or in areas with good ventilation.

Ignoring Safety Gear

Not wearing safety gloves and goggles can put you in direct contact with harmful chemicals and accidents.

Overfilling Containers

Spillage caused by overfilling can create fire hazards and contaminate the environment. Hence, it is important to leave enough space in the container for gas expansion.

Not Grounding Containers

If one neglects proper grounding, static electricity may be created, which can ignite gasoline fumes. Therefore, always keep the containers properly grounded while siphoning.

Improper Disposal of Residues

The throwing away of gas residues or polluted materials in the wrong manner can harm the ecosystem and break the law. Thus, it is recommended to utilize designated hazardous waste facilities for disposal.

Using the Wrong Equipment

Gasoline can be very hazardous if handled with the use of inappropriate or incompatible equipment. Non-approved material fuel storage containers, such as certain plastics and metals, may corrode, degrade, or leak volatile fumes, which can then lead to the accumulation of ignitable fumes and their subsequent ignition. Furthermore, the use of pumps, hoses, or siphons not approved for gasoline and other combustible liquids may cause static to build up, leaks, or sparks, which would be very risky. It is very important that all the tools and storage containers are guaranteed by industry standards such as UL (Underwriters Laboratories) or DOT (Department of Transportation) certifications to prove that they are suitable for use with gasoline. Always check the manufacturer’s guidelines and safety documentation for equipment selection in order to minimize risks most effectively.

Neglecting Safety Protocols

Inattention to safety protocols might result in dire consequences, such as the breakdown of equipment, fire risks, or injury to someone. As for me, I make it a point to comply with all safety requirements by rigorously following the directives of the manufacturer and by employing tools and containers that are certified for proper use. This preventative method not only lowers the hazards but also helps to keep the workplace safe.

Overcomplicating the Process

Usually, a procedure is overcomplicated due to superfluous steps or very intricate methods, which, in turn, can decrease efficiency and cause misunderstanding. The best way to prevent this is to simplify the workflows by pinpointing and getting rid of the duplicative actions, but still sticking to the norms and protocols that are most needed. Joining forces with the experts from the best sources clearly emphasizes the importance of simplicity—easy documentation, direct communication, and properly set goals are the main things that make the process more effective. Concentrating on the primary duties and making use of the usual tools or methods increases productivity, and the risk of making mistakes is reduced, so the best results are obtained without the complexity of unnecessary steps.

Reference Sources

University of Hawaii: Siphons, Revisited

Explores the scientific principles behind siphoning, which can provide technical context for your article.

University of Utah Health: Dos and Don’ts in Case of Gasoline Poisoning

This source discusses the dangers of gasoline exposure, including risks associated with siphoning.

Blue Ridge Poison Center (University of Virginia): Gasoline Siphoning Warning

Provides a detailed warning about the health risks and dangers of siphoning gasoline.

Frequently Asked Questions (FAQs)

Fuel pump and gas siphoning: Is it legal to siphon petrol?

In most cases, siphoning petrol from another car or a gas station without consent is illegal and is seen as stealing. Even in cases where you are just shifting fuel from one container to another or transferring it between vehicles, local legislation and gas station procedures may restrict how you can get gas or at what time. Regulations must always be verified, approved equipment used, and in case of uncertainty, contact roadside assistance or the property owner rather than trying unauthorized siphoning.

Gas siphon pump and safety: how dangerous is siphoning liquid fuel?

The siphoning of liquid fuel poses a variety of risks: inhaling gas fumes, fire-causing spark or flame, skin touching, and drinking fuel if the tube is not positioned correctly. It’s strictly forbidden to use your mouth for obtaining gas or recruiting it in via the tube; resist creating gas in your mouth and requiring sucking of the fuel. Always protect hands, work outdoors with good ventilation, ensure there are no ignition sources around, and prefer a pump or electric fuel transfer device to reduce the chance of contact and exposure to fumes.

Fuel line and anti-siphon devices: why won’t gas flow from the tank?

A lot of contemporary cars have anti-siphon devices or valves in the line that allow only one way for the gas to flow, i.e., out of the tank, which is why they do not cause a siphon. If inserting a hose does not cause gas to flow, a filter or an anti-siphon may be obstructing it from reaching the bottom or creating flow. In such cases, trying to circumvent these devices can cause vehicle damage and is also illegal in most cases; consult a mechanic or roadside service for the secure transfer of fuel.

Suction and need to siphon gas: what are safer alternatives to learning how to siphon?

If your car runs out of gas or you need to move fuel, the use of a gas siphon pump designed specifically for fuel transfer, an approved portable pump, or calling a service that can deliver gas are all safer alternatives. These methods completely bypass the danger of doing something like putting one end of the tube in your mouth, blowing into the tube, or creating dangerous air pressure and vacuum methods. Just making sure gravity is on your side is not enough; for that to happen, the proper setup and safety precautions must be in place.

Nozzle and pump gas: Can a gas station help fill a container to be siphoned later?

Due to safety and liability reasons, gas stations generally do not allow customers to fill containers that are not approved or assist with siphoning. If you need to store fuel, use a proper gas container and inquire about the procedures permitted by the station attendant. Many stations do not allow the filling of portable containers with gas or require staff assistance to avoid spills and fumes.

Hand pump and length of hose: what should I look for in a container to siphon or transfer fuel?

When moving fuel safely and legally between an approved container and a vehicle, opt for clear tubing or a pump specifically for gasoline, ensure that the hose length is adequate to reach into the bottom of the source container, and use a gas container that complies with the petrol rating. A dedicated gas siphon pump or electric fuel transfer pump fitted with proper seals and filters lessens the chance of spills, keeps the operator away from fuel fumes, and prevents contaminants from entering the fuel line or filter.

Empty gas and storing fuel: how much gas can I safely store and for how long?

The maximum amount of gas that can be stored safely is different depending on local fire codes and the ratings for containers; never store more than you can handle in a residence. Always use a container designed for gas, store it in a cool place that is well-ventilated and away from any potential ignition sources, and label the container. Fuel gets rotten over time, so practice the storage-fuel rotation and add a stabilizer if you plan to keep petrol longer than a few months.

Electric fuel and pressure in the tank: can I use a pump instead of gravity?

Yes — an electric fuel transfer pump or a hand pump for gasoline is much safer than just relying on gravity or manual suction. These pumps avoid creating unsafe air pressure in the tank, decrease the necessity to insert a hose into the tank filler neck, and eliminate risky actions like sucking the fuel. Employ only equipment certified for use with petrol and adhere to the manufacturer’s guidelines to avert spills and static buildup.

Gas pump and stopping siphoning: when should you stop and call a professional?

If you smell strong gas fumes, see spills, have trouble taking out the siphon pump, or the vehicle has anti-siphon devices hindering the flow, stop the transfer right away. If you run out of gas in the middle of the road, cannot safely reach the filler with a proper hose, or are unsure about the condition of the fuel filter or fuel line, call roadside assistance