Each part from the nozzle to the fuel dispenser plays a significant role in ensuring a smooth transfer of fuel from the tanker to your vehicle. The article discusses the primary components of a gas pump, providing detailed explanations of their functionality and revealing the complex processes behind everyday interactions with modern machinery. If you are simply curious about all this or are willing to dive deeper into the wonders of technology, this guide ought to provide you with just that fascinating insight, an appreciation for the complexity behind all that we call making a “quick fuel stop” in life.

Introduction to Gas Pump Parts

A perfect system of this service entity in a gastank balances and provides fuel. The nozzle is the human element part that directs the flow of fuel into a vehicle’s tank. The hose connects the nozzle to the pump, allowing fuel to be poured at all times. The motor inside the pump powers the system, and the flow meter measures the amount of fuel dispensed. The dispenser’s control panel shows the fuel quantity, price, and other relevant information to the attendant. Each component is designed with accuracy, safety, and user convenience in mind during the dispensing process.

Importance of Understanding Gas Pump Components

Lacking an understanding of a gas pump and its components would pose a significant hazard to life, efficiency, and cost in the process of fuel transactions. Modernity has equipped these gas pumps with refined technology to dispense fuel and collect data for improved accuracy. For instance, being the most critical units for determining the quantity of fuel dispensed, flow meters have to be expertly calibrated to ensure accurate measurement. Industry sources indicate that any inaccuracy in fuel measurement results in economic loss for both consumers and fuel suppliers, which is why regular maintenance is necessary.

Furthermore, many gas pumps have advanced security features installed to counter fraudulent activities. Consumers are no longer at risk of card skimmers; therefore, installations of encrypted payment systems alongside tamper-resistant designs have been made. According to studies, these technologies have significantly reduced payment fraud that plagued fuel stations; thus, understanding the components becomes crucial for both operators and users.

Last but not least, knowing the components of a gas pump can help identify a fault or irregularity. For example, if the nozzle is non-responsive or has erratic display readings, it could be a sign of issues within the mechanism, such as with the flow meter or the control panel. By being aware of and diagnosing such signs, repairs can be attended to in a timely manner, thereby reducing downtime and improving the overall reliability of the station. In summary, being familiar with the workings of a gas pump ensures a safer experience and helps make fuel distribution more transparent and efficient.

Overview of Fuel Dispenser Parts

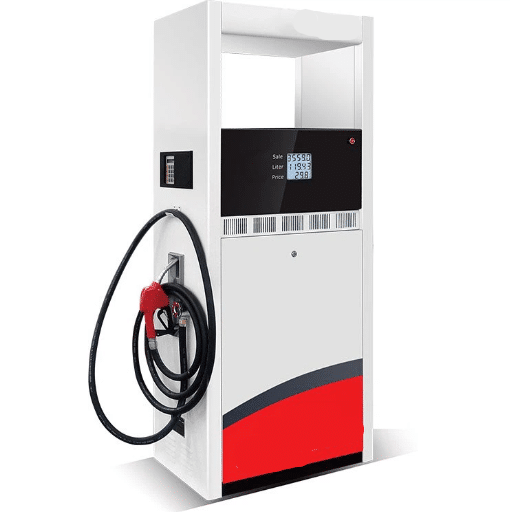

Fuel dispensers, also known as gas pumps, are intricate systems featuring highly specialized components designed to convey fuel efficiently and safely. Knowledge of these parts is essential for appreciating their operational requirements. However, a detailed description of the main elements will follow:

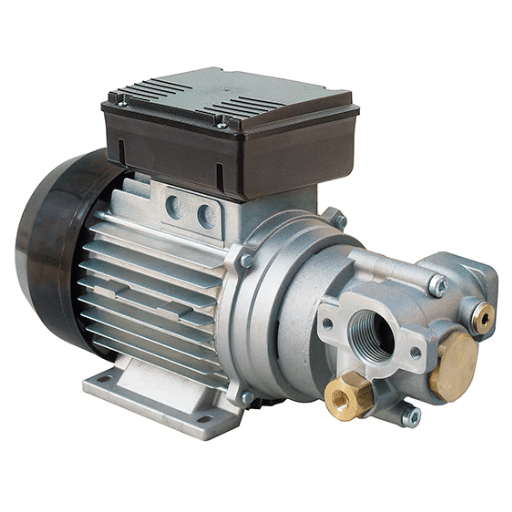

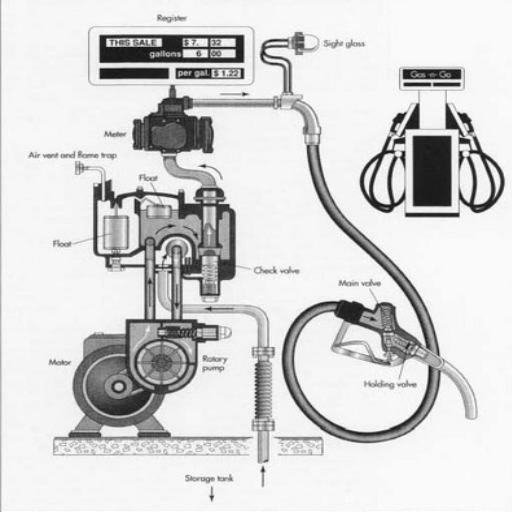

This hydraulics portion of the dispenser transfers fuel from the underground tank to the vehicle’s fuel tank. Major components include the motor, pump, and valves. Most modern-day dispensers utilize gear or vane pumps, with flow rates ranging from 40 to 60 liters/min for standard vehicles and higher capacities for commercial fueling stations.

A flow meter is a precision instrument that registers the volume of fuel dispensed. Advanced dispensers employ flow meters that utilize the positive-displacement or turbine principle to ensure high accuracy, respecting the “customer should get exactly what they pay for” clause of the law. According to the calibration standards used, flow meters may detect an error of up to 0.1%.

Filtering oils are those that maintain oil purity by removing contaminants or unwanted particulates. A good filter presents better engine performance and lessens wear on vehicle parts favorably. Several studies have demonstrated that regular maintenance and replacement of fuel filters enhance the efficient operation of the dispenser and reduce contamination hazards.

Nozzles are created for easy use and safety. An automatic shutoff mechanism averts overflows after the tank has attained its full capacity. Special nozzles exist for alternative fuels such as CNG, LPG, or hydrogen, as well as for ever-changing energy demands. The ergonomics of nozzles were improved to ease the fueling process for customers.

A hose is reinforced to the extent that it withstands constant use and exposure to the weather, while a breakaway is a safety device that unfastens the hose if excessive force is applied: during drive-offs, for example, which prevents the dispenser from getting damaged and, more importantly, fuel spills.

In most modern fuel dispensing systems, computerized control systems have been introduced to achieve the acceptable accuracy of data. They regulate the amount of fuel dispensed, monitor the transaction in real-time, and display relevant information to customers. Touchscreen interfaces, tamper-resistant keypads, and RFID readers have been installed on premium dispensers to provide seamless payment and personalization options.

To comply with environmental regulations, vapor recovery systems are installed to capture fuel vapors emitted during refueling. Such systems help reduce hydrocarbon emissions in support of air quality preservation and regulatory compliance.

Understanding these components and their roles helps operators or other technicians ensure the operational reliability of fuel dispensers. Innovations in materials and techniques are continuing to enhance the efficacy, sustainability, and user-friendliness of fuel distribution worldwide.

Types of Gas Pumps Available

Installation of gas pumps was done keeping in consideration the different types:

- Self-Serve Pumps – The most common type, where the customer is required to operate the pump independently. They have direct instructions and card payment systems with safety features, making the process convenient and efficient.

- Full-Service Pumps – And then there are the traditional gas stations with pumps manned by attendants who refuel your vehicle. They may also wash the windshield or check the tire pressure, offering convenience for those in a hurry or who simply prefer to be attended to.

- High-Flow Diesel Pumps – By their nature, these pumps are designed to deliver fuel at a rate higher than usual to large vehicles, such as trucks and buses. They significantly reduce the time required for refueling, which is particularly valuable to commercial vehicle operators.

- Fleet Fueling Pumps – These pumps are designed and built for business or government entities that maintain fleets of vehicles. They typically pack the troops with all sorts of advanced features such as tracking systems, secure access control facilities, and reporting mechanisms, all designed to facilitate operations.

- Alternative Fuel Pumps – These pumps are becoming increasingly common nowadays as sustainability is considered more important. These include pumps for compressed natural gas (CNG), liquefied petroleum gas (LPG), and electric vehicle chargers. In this manner, they serve environmentally conscious users and further the cause of clean energy.

By learning about the different types of gas pumps available, businesses and end-users will have an easier time choosing gas pumps best suited for their needs. A smooth and efficient fueling process would then be desired.

Key Components of a Gas Pump

- Nozzle – Nozzles are the things dispensed into a vehicle tank. It typically features an automatic shut-off mechanism to prevent overfilling.

- Hose – This is a flexible hose connecting the pump with the nozzle, allowing smooth flow of gasoline.

- Display Screen – The display would show all necessary information, such as price, fuel dispensed, and total charges of the transaction.

- Keypad or Card Reader – To process payments, such devices ensure that customers pay securely with cards or other methods.

- Fuel Dispenser Unit – This mechanism weighs and transfers fuel from the pump to the vehicle.

- Pump Housing – It encloses the gaseous pump’s inner working and shares branding or signage for easy identification.

While these components fuel efficiently and safely, they also help in creating a user-friendly experience for the customer.

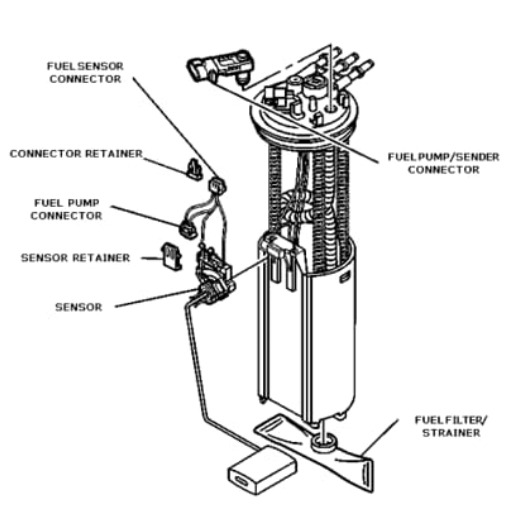

Fuel Pump: The Heart of the System

The very existence of a fuel pump sustains the very existence of an efficiently working gas station, and cars. It sucks fuel out of the underground storage tank and discharges it into the vehicle’s fuel tank at a predetermined rate. Modern pumps utilize the latest technology, including electronic sensors, to control the quantity of fuel dispensed and ensure adherence to specific safety standards.

The features one can find in such a product include a durable build that sustains temperature variations, the ability to handle different types of fuel, and compatibility with digital systems for real-time monitoring. Furthermore, such devices must incorporate safety measures to prevent any spilling or leakage during their operation. This ensures the accuracy, safety, and promptness of fuel being transferred, while also maintaining their goodwill among consumers and, in effect, easing operations at the station.

Gas Pump Nozzle: Design and Functionality

Gas pump nozzles are engineered with a focus on aspects such as performance, safety, and user convenience. The nozzle and its supporting structure are rugged and ergonomic, enabling easy handling and smooth fuel delivery into the vehicle. This arrangement features an automatic shut-off mechanism that prevents fuel spills once the tank is full. This is accomplished by a vacuum sensor that detects a change in pressure in the flow.

Most nozzles are also made from materials that resist corrosion and wear, ensuring they withstand the rigors of various fuels and environmental conditions. The design of the nozzle also requires it to be compatible with a vapor recovery system, which reduces the environmental hazards posed by emissions released during refueling. Through sound engineering and rigorous safety standards, gas pump nozzles enhance the user experience while also ensuring environmental protection.

Meter: Measuring Fuel Dispensed

Fuel meters on gas pumps utilize advanced technologies to ensure the precise measurement of fuel dispensed. These fuel meters commonly use positive displacement or turbine mechanisms that measure fuel flow and volume passing through the pump. A positive displacement meter traps fill volumes of fuel, whereas the turbine measures volume by speed of flow across it. Both types are calibrated to maintain accuracy, generally to within 0.5%.

The present-day fuel meters are all governed by very stringent industry standards to promote uniformity and reliability, and are often subjected to rigorous testing. Weighing and Measures Authorities located in various countries. The digitalized system with fuel meters provides a concurrent display of volume and price, enhancing both transparency and goodwill. In combining mechanical accuracy with cutting-edge technology, the fuel-metering system achieves the ultimate in precision and efficiency.

Additional Parts of the Fuel Dispenser

- Hoses and Nozzles – This is the outlet through which fuel flows from the dispenser to the vehicle’s tank. The nozzle has an auto-shutting system to prevent overfilling.

- Display Panel – Displays real-time information, including the amount of fuel dispensed, price, and other transaction details.

- Pump Unit – Pumps fuel from the storage tank inside the dispenser, allowing it to be discharged through the nozzle.

- Filters – Remove impurities from the fuel, and clean fuel is then delivered to the vehicle.

- Keypad or Payment System – Allows payment directly from the pump to the customer, providing convenience and efficiency.

- Vapor Recovery System – Captures the vapors of fuel during the refilling process to reduce environmental emissions and for safety.

Different parts that need to work together to maintain proper function, accuracy, and safety are involved during the fuel dispensing process.

Hose: Types and Materials

The hose is an essential part of a fuel dispensing system, as it is supposed to supply fuel from the pump to the vehicle safely. Hoses can be classified depending on their material and intended use. The most common types are rubber, composite, and polyurethane hoses. Rubber hoses are stiff yet quite flexible and wear-resistant; that’s why they are generally used for standard fuel dispensing. Composite hoses, constructed with multiple layers of materials such as fabric and metal, are highly corrosion-resistant and ideal for handling more corrosive types of fuel. Polyurethane hoses offer a lighter alternative with oil abrasion resistance, making them suitable for environments that require greater flexibility.

Materials used in fuel hoses must meet strict industry standards to withstand forces such as high pressure, severe temperature extremes, and the effects of fuel or chemical vapors. Moreover, many hoses are reinforced with steel or textile braiding for added strength and durability. Another critical factor in choosing a hose is the nature of the fuel used, including gasoline, diesel, or biofuels.

Fittings and Connections: Ensuring Efficiency

Fittings and connections are required to make fuel hose systems efficient and safe. Suitable fittings provide an excellent seal and are resistant to pressure and environmental conditions during fuel transfer operations. They are generally made of brass, stainless steel, or aluminum because of their durability and compatibility with various fuel types. A fitting should be chosen based on whether it is barbed, crimp, or compression, depending on the hose and application criteria. There is also a consideration regarding the compatibility of the fitting with the fuel being used and its pressure ratings, ensuring that a failure can be avoided and the system performs optimally. It should be inspected and maintained regularly to ensure longevity and reduce the risk of malfunctions in the system’s operation.

Filters: Maintaining Fuel Quality

Fuel filters play a crucial role in maintaining fuel quality by filtering out impurities such as dirt, rust, and debris before they enter an engine or fuel system. Such particles, when left, can cause clogging, loss of efficiency, and even equally costly damage. Various types of fuel filters are available, including inline filters, cartridge filters, and spin-on filters, which are used according to application requirements and filtration levels.

When choosing a fuel filter, consider fuel type, system flow rates, and particle size requirements. These filters can be replaced regularly to ensure maximum performance and prevent clogging, as recommended by the manufacturer. Good filters improve engine life, reduce emissions, and lower fuel consumption. Your system will remain clean and efficient with thorough inspection and maintenance.

Specific Models and Their Unique Parts

The A1000 is equipped with a fuel filtration system that offers high efficiency for heavy-duty applications. The unit’s distinguishing features include its multi-stage filtration media and corrosion-resistant housing, which ensure durability in harsh operating conditions. Maintenance is conducted by filter replacement every 10,000 miles.

The B2000 is designed to achieve the best fuel economy and reduce emissions. Its main feature is an advanced water separator that protects the engine by removing water from the fuel system. This model requires filter replacement every 15,000 miles to maintain optimal operation.

Small and compact, the C3000 is ideal for smaller engines, offering higher particle filtration performance. Its unique modular filter design allows the filter to be replaced in seconds. Filters have to be changed every 12,000 miles, depending on operating conditions.

Gilbarco Models: Key Features and Parts

Gilbarco is recognized for its reliable and durable fuel dispensing systems, offering models that meet various operational requirements. These models by Gilbarco feature advanced filtration systems, ergonomic designs, and technologies designed to achieve the highest efficiency. Most of these models are equipped with a high-flow fuel delivery system —a mechanism that makes refueling faster, allowing stations to reduce downtime-related losses. Additionally, the system offers ease of operation and maintenance through a user-friendly interface.

Checking out Gilbarco fuel dispensers, all standard parts would include the pump meters, nozzles, filters, and hoses. These parts are designed to be easily replaced with minimal disturbance during servicing. Customization also plays a significant role in Gilbarco’s ideology, allowing operators to select configurations best suited to their specific needs. Typically, maintenance should be performed, with recommendations implying filter replacement and performance tests corresponding to the model specifications for optimal product life and performance.

Bennett and Tokheim 39: Comparisons and Components

| Feature | Bennett 39 | Tokheim 39 |

|---|---|---|

| Visual Appeal | Higher and leaner design | Curved panels and box-style structure |

| Build Quality | Sturdy construction | Rugged build with attention to detail |

| Display Window | Slightly larger for better visibility | Standard size |

| Design Style | Collector’s favorite | Timeless elegance |

One giant trio of vintage gas station designs is constructed by sturdy build and an excellent, simple façade. Comparing the two, one is often told that the Bennett 39 tends to be higher and leaner in visual appeal. In contrast, the Tokheim 39 is appreciated for its rugged build and a great attention to manufacturing detailing.

Both models contain specific major components—the meters, registers, hoses, and nozzles—that work together to deliver fuel, emphasizing their effectiveness and reliability throughout years of service. Bennett pumps usually have a slightly larger window to showcase gallons and prices, providing added visibility, which is why they are the collector’s favorite. The Tokheim 39 type, on the other hand, is noted for its curved panels and box-style structure, which lends it a timeless elegance.

Customization stands out for both models, as each pump can be restored with various color schemes, emblems, and lighting arrangements that historically matched the company colors. Maintenance for these two is, in essence, the same, requiring the careful lubrication of meters, the inspection of seals, and frequent washing down of the nozzle and hose to preserve function and charm. Both Bennett and Tokheim 39 pumps stand as proud testimonies of the exquisite craftsmanship of a bygone era and remain a favorite choice for restoration all over the world.

Wayne Models: Innovations in Design

Wayne fuel dispensers are generally known for having cutting-edge technology and a sleek design. In the early twentieth century, Wayne had revolutionary thoughts on fuel dispensing, prioritizing efficiency and accuracy. One standout innovation was the use of the Calculator Pump, which calculated and simultaneously displayed the price and volume of fuel for the benefit and convenience of the customer, marking the first of its kind.

Currently, Wayne models include advanced features such as state monitoring via the cloud, allowing station owners to view performance data, fuel levels, and maintenance schedules in real-time. Being energy-efficient is another economically important attribute that ensures better alignment with international sustainability objectives of saving energy. Wayne pumps derive their strength from durable materials and require streamlined components to withstand harsh weather systems while performing optimally. Industry sources disclose that modern Wayne designs bring down dispenser downtime by as much as 30%, confirming their stance on operational reliability. These innovations explain Wayne’s fuel-dispensing leaders’ position, which is constantly shifting in response to consumer requirements and modern technological needs.

Maintenance and Service of Gas Pump Parts

Important: Proper maintenance of the gas pump parts is key to a longer lifespan and consistent performance. One should check the components, such as hoses, nozzles, and filters, for their wear or any damage and replace them if the situation demands it to avoid fuel leaks.

Cleaning dispensers and setting up calibration correctly will ensure accurate fuel measurement. Following the manufacturer’s instructions for routine servicing, such as lubrication and system checks, will likely save the cost of significant repairs and long hours of downtime. Certified technicians should always be retained for any serious maintenance or system diagnostics to ensure safety and compliance with industrial standards.

Regular Checks and Replacement Parts

Regular inspections and subsequent replacement of parts, if necessary, are crucial for the safety and efficiency of fuel dispensing systems. According to industry reports, a continuous inspection of equipment such as hoses, nozzles, filters, and the like can reduce the chances of such equipment failure by nearly 30%. For instance, the filter should ideally be replaced every 6-12 months to prevent contaminants from clogging the system and impairing fuel quality. Frequent checks for seals and gaskets can reveal the early onset of wear, which can be unpleasant since damaged seals may cause leaks that lead to both environmental issues and financial losses.

The use of high-quality spare parts is necessary for an extended equipment lifespan. Research studies demonstrate that premium-grade components increase performance by 15% to 20% compared to inferior components, while also meeting regulatory standards. During installations, inspections should be carried out quarterly to confirm that all components are within the manufacturer’s specifications, thereby preventing unplanned downtime. Through preventive maintenance, companies can optimize operational reliability and reduce long-term maintenance costs.

Common Issues with Gas Pump Components

Certainly, wear and tear, clogged filters, malfunctioning nozzles, and dispensers are some of the common problems that occur in gas pumps. From my own experience, most of these problems can be addressed through routine maintenance and part replacement. Inaccuracies in fuel dispensing are another common problem that can be addressed through proper calibration and inspection.

Service Kits: What to Include and How to Use

In a nutshell, a good service kit for gas pumps should cater to the more common maintenance and repair issues by providing spare nozzles, filters, seals, gaskets, O-rings, and calibration tools usually used within the scope of the operation. Additionally, including an operational user manual or a servicing guide for specific pump models is quite advantageous since it will make servicing quicker.

A service kit is employed to repair or maintain the pump. First, identify the issues with the pump, such as leakage, clogging, and calibration errors. When disassembling parts of the pump, follow the procedure outlined by the manufacturer strictly. Part replacement then follows using the spare parts provided in the kit, after which all installations ought to be securely reassembled. After completing the repairs, test the pump’s performance to ensure it complies with accuracy standards and remains free from any new problems. Well-laid preventive maintenance plans, along with regular inspection and maintenance schedules for the gas pumps, which include a full-service kit, will increase the lifespan of gas pump components and ensure they serve reliably.

Summary

Understanding the intricate components of gas pumps reveals the sophisticated engineering behind what appears to be a simple fuel dispensing process. From the precision flow meters that ensure accurate measurement to the robust nozzles designed for safety and convenience, each component plays a vital role in the overall system’s functionality.

The evolution from basic mechanical pumps to today’s computerized dispensers with advanced features like vapor recovery systems, electronic controls, and fraud prevention measures demonstrates the industry’s commitment to safety, efficiency, and environmental responsibility.

Whether you’re a station operator seeking to optimize performance, a technician responsible for maintenance, or simply someone curious about the technology we interact with daily, this comprehensive understanding of gas pump components provides valuable insights into the complexity and reliability of modern fuel dispensing systems.

Regular maintenance, proper component selection, and understanding of each part’s function are essential for ensuring safe, efficient, and reliable fuel dispensing operations that serve both business needs and customer satisfaction.

Reference Sources

1. Fuel System Operations and Components

2. Gasoline Distribution and Regulation

3. Airlift Pump Performance with Annular Venturi Injector (AVI)

Frequently Asked Questions (FAQs)

What are the main parts of a gas pump?

The main parts of a gas pump include the nozzle, hose, meter, and the pump proper. Each piece plays a vital role in dispensing fuel and guaranteeing that a safe and efficient amount is delivered to the vehicle’s fuel tank.

How does a gas pump nozzle work?

A gas pump nozzle controls the flow of fuel from the pump to the vehicle. There is a handle on the nozzle: when the handle is squeezed with the fingers, a valve opens, allowing fuel to flow through the hose. Another safety feature will shut off the flow when the tank is full.

What materials are used in the various gas pump parts?

Gas pump parts are most commonly made from cast aluminum, brass ends, and polished aluminum. These materials are selected for their exceptional corrosion and wear resistance, providing years of service in diverse environmental conditions.

What is the function of the fuel filter in a gas pump?

The gasoline-filtering process is used to remove impurities and contaminants from gasoline before it reaches the vehicle’s ignition system. Highly essential to engine performance and damaging internal components.

What type of gas pump is there?

There exist many types of gas pumps, including submersible pumps, oil pumps, and models such as Gilbarco 96 and Tokheim 39. All are designed for different applications, and one may find other options in terms of their components and configurations.

What is meant by ad glass in a gas pump?

Ad glass, also known as advertising glass, is the glass plate used to display fuel prices and promotional information on a gas pump. This aspect not only relays basic information to customers but also serves to advertise the gas station’s goods.

How do I install a universal gas pump kit?

Typically, this involves installing the universal gas pump by following the manufacturer’s instructions. This involves joining the various parts together, such as hoses, fittings, and the pump, ensuring that all connections are secure and no leaks are present. Furthermore, the electrical connections must be performed with great care to ensure safe operation.

What safety features does a modern gas pump have?

Modern gas pumps incorporate several safety features, including explosion-proof electrical components, automatic shut-off valves, and robust construction materials such as chrome-plated ends and rubber seals. These features help mitigate the risk of spills and other accidents during fuel dispensing.

How do I keep fuel dispenser parts in working condition?

Checking parts of the fuel dispenser for any leakage, removing any clogs of the filters, and verifying that the hoses and nozzles are not worn are some upkeep procedures. An adept pump and its constituent parts will work efficiently at the ground and offer the safety of consumers at the fuel station.