Gasoline and diesel pumps are installed in large numbers in all gas stations because they are the most used sources of energy for vehicles. But in that case, safety concerns would definitely be prioritized with the combustible liquids being stored in the station in large amounts. One of the most important safety features that the typical consumer may not see is the fuel shut-off switch (emergency shut-down mechanism). The system serves as an immediate stop for fuel dispensing during an emergency scenario, thus making fires, spills, and other accidents less dangerous. Gas station operators and employees, as well as customers, should all be aware of the mechanism’s operating principle, its timing, and its safety role. This article aims to offer a thorough examination of the fuel shut-off switch, explaining in detail its working, the regulations it falls under, and the things that should be done when using it. By the end of this article, you will definitely have an expert knowledge of this vital safety system.

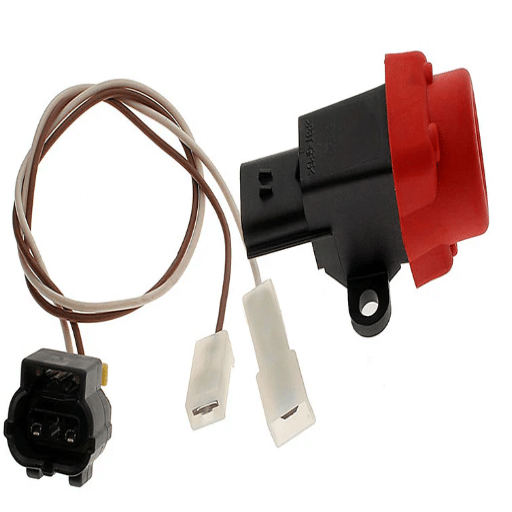

What is a Fuel Shut-Off Switch?

A fuel shut-off switch is a very important safety device that can prevent further flow of fuel from the dispensers in the event of an emergency like fires, fuel leaks, or other dangerous incidents. It is almost always placed in an easily reachable place close to the fuel pumps or within the building, and it acts as a rapid-response system to avoid the occasional accidents from getting worse. The disadvantage of having this switch is that one has to stop the fuel flow through the pumps, which in turn reduces the fire and environmental damage risks, thus securing human life and property.

Definition and Purpose

Emergency fuel shutoff switches are critical components in fuel dispensing systems, providing immediate control in emergencies and thus increasing safety. The installation and use of these switches are regulated by various industry standards, including those imposed by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA) in the USA. For instance, NFPA 30A states that emergency shutoff controls need to be located within a distance of 100 feet (30 meters) from dispensing machines, and they should be properly marked and accessible to the staff.

So, the placement of these switches is a key factor in the prevention of accidents. Safety case studies provide evidence that the prompt activation of devices can significantly diminish the fire-related incidents taking place at filling stations, which are responsible for about 2% of the fires in non-residential buildings in the U. S. every year. To this end, cutting-edge technologies, such as automated alerts and remote shutoff functions, are often part of today’s systems. The response time is considerably faster due to these technologies. Not only do these practices meet safety standards, but they also serve as strong protection against environmental pollution and the financial losses that may result from fuel spills or fire accidents.

How It Works

Currently, modern fuel station safety systems are based on a mixture of proactive monitoring, fail-safes, and automated processes. The fundamental components of the systems are the sensors, which measure the environmental conditions, such as temperature, pressure, and the amounts of volatile gases, constantly. For example, vapor recovery systems capture more than 95% of harmful fuel vapors and thus significantly cut off the emissions that enter the atmosphere and help maintain the quality of air that is breathable in and around the facility.

Moreover, the automated fire suppression systems resort to flame and heat detection technology that can recognize the potential hazards in a matter of seconds. The systems can use either dry chemical agents or foam to swiftly put out the fires while being careful not to cause much damage to the surrounding equipment.

Furthermore, the leak detection system is another critical component that takes advantage of sophisticated algorithms and precision instruments to detect leaks in underground storage tanks and piping with more than 99% accuracy. Contamination of soil and groundwater is prevented by this early leak identification, which is in line with the environmental compliance requirements.

Apart from that, the remote monitoring capabilities increase the reliability of the system significantly, making it possible for the operators to oversee and manage several stations from a centralized control center. Real-time alerts and the capability of performing remote shutoffs are features that come with timely action during emergencies, thus lessening the risks posed to property and public safety. The aforementioned features cumulatively form an integrated network of safety that leads to fewer incidents and effectively protects the critical infrastructure.

Importance of Safety Protocols

Safety protocols are the essential basis upon which the risk minimization and operational continuity in various industries are built. Comprehensive researches demonstrate that workplace accidents can be reduced by 70% with the proper safety measures implemented, leading to the benefits of personnel well-being and equipment durability. In fact, energy or manufacturing being the example of the major industries, the commitment to safety protocols is crucial not only for regulatory standards, like the guidelines of OSHA (Occupational Safety and Health Administration), but also for the prevention of expensive downtime and legal liabilities, thus safety measures kill three birds with one stone.

The modern safety technology advancement leads to a significant enhancement of the processes of hazard identification and reaction. Predictive analytics powered by machine learning algorithms can now spot potential failures before they happen, reducing unplanned incidents by up to 50% depending on the specific industry. What is more, the use of automated safety systems, such as pressure shutoff valves and fire suppression mechanisms, leads to a decrease in human error and guarantees quick action during emergencies.

The thorough training programs have to be implemented as well. The statistics reveal that 80% of the workplace accidents, which could be avoided with the right training, are due to insufficient training. The scenario-based training modules, which are enriched, interactive, and very immersive, have already been shown to raise the retention rates by 70% in comparison to the traditional methods, thus preparing the staff to act effectively in high-risk situations. When organizations connect systematic safety protocols with state-of-the-art technology and continuous education, a strong culture of safety that protects human resources and operational integrity will be created.

Types of Fuel Shut-Off Switches

Fuel shut-off switches are classified as safety devices to instantaneously cut down the fuel flow in the event of an emergency. There are mainly two types:

- Manual Shut-Off Switches: Such switches need to be physically turned on by the operator. They are mainly installed on machines and vehicles, which offer an undemanding way of stopping fuel flow when it is needed.

- Automatic Shut-Off Switches: These devices work without the user having to do anything, usually reacting to certain situations such as a rise in temperature, a change in pressure, or a breakdown in the system. They improve safety by being quick in their reaction to possible dangers.

Both types of switches are essential for risk reduction related to fuel systems and also for safety during operations.

Push Button Switches

The push-button switches are extremely adaptable parts that can be used in many different ways. These are already used in industrial equipment, household electronics, and automotive systems. The switches are very easy to operate, where pressing the button either completes or interrupts the electrical circuit, making it easy and reliable to quickly control the device.

On the other hand, the manufacturer has gone the extra mile in incorporating new materials and design improvements in the production of modern push button switches to increase durability, precision, and safety. For example, one of the features of the industrial-grade push button switches is the IP rating (such as IP67), which is one of the best methods for controlling dust and water ingress. This sealing is very beneficial in places that are subject to a lot of rough conditions, like manufacturing plants or outdoor installations.

Moreover, according to the research, the lifetime of high-end push button switches might reach up to a few million cycles of operation or even more, depending on the specific model and usage. This feature also makes them economical for those applications that require very frequent use. Besides, these switches are available in different configurations, particularly momentary and latching types, thus providing the necessary flexible functionality that is to meet diverse system requirements. Besides that, some models have LED indicators for visual feedback that are very helpful to the operator, as they also minimize the risk of errors in complex setups.

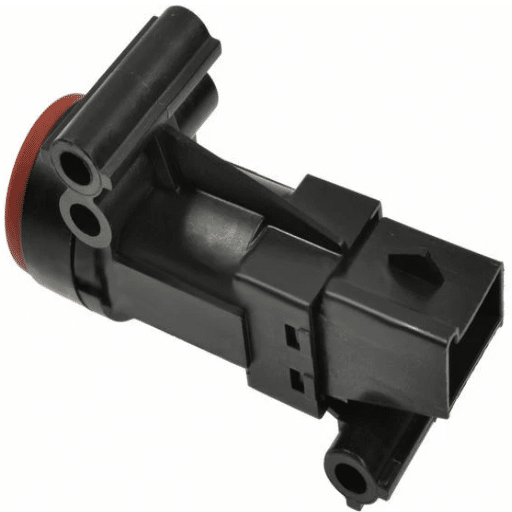

Automatic Shut Off Systems

Automatic shut-off systems are paramount to maintaining safety, energy efficiency, and the lifespan of the equipment in various industries. These systems utilize sophisticated sensors and programmable logic controllers (PLCs) to conduct real-time monitoring of the operational conditions and to carry out the shutdown processes when specified parameters are violated. In the case of industrial machines, for instance, automatic shut-off systems help to take the operations to a halt before the machines can get too hot, too loaded, or might break down, thus preventing done at the preset limits.

Research carried out recently suggests that up to 30% equipment downtime could be cut down with the introduction of automatic shut-off systems in the production process, which would mean an outright increase in productivity and a reduction in cost per unit. Moreover, in the case of electric kettles and space heaters, these systems in home applications, for instance, enhance user safety, thereby lessening the risk of accidents caused by overheating or the gradual running down of the appliance unattended. It is also worth noting that contemporary automatic shut-off systems may also employ IoT technology, where remote monitoring and control via smart devices is allowed. This aspect has contributed to a rise in the acceptance rate of smart home ecosystems and industrial automation, with the market growth projection being at a CAGR of 8.4% from the year 2023 to 2030, which is a strong indicator of the impact of technology in making shut-off systems indispensable in the areas where they operate.

Manual Switches at Gas Stations

The manual switches installed at gas stations are considered the main line of defense and are meant to bring the fuel flow to a stop at once during emergencies. Usually, the emergency shut-off switches are situated in places that are very easy to access, for example, next to the entrance of the station or near the fueling area, so that they can be quickly operated in case of a fire, spill, or any other hazard. Industry standards like those set by the National Fire Protection Association (NFPA) require that these switches be clearly marked, be routinely checked for functioning, and be inspected to ensure that they are in working order.

The latest technological developments have also brought about new and improved designs for switches that are more robust and resistant to tampering or deterioration due to environmental factors. The publication of such data by security and safety organizations demonstrates a compelling case of the reduction of catastrophic incidents to a great extent if gas stations use and keep manual shut-off systems properly. For instance, the systems that are properly maintained have been reported to decrease the number of fire incidents by 35% or more as a result of safety compliance studies. These switches cannot be considered as anything less than essential in the operation of gas stations, and they have to be kept in place as a measure of safety for the employees and customers, even in the worst situations.

Location and Accessibility of Shut-Off Switches

The placement and accessibility of shut-off switches are highly important for quick responses in emergencies. These switches need to be installed in clearly marked heights on locations that are easily visible and accessible, usually at the station’s main entrance or other similar places. Clear signs must be put up with the switches so that they will be recognized easily by employees and emergency responders alike. Furthermore, the federal and local safety regulations often dictate their position to be in line with the industry standards, thus emphasizing accessibility as a way to reduce response time and risks effectively.

Standard Locations at Gas Stations

Emergency shut-off switches are positioned in such a way that they can be accessed easily, and their presence improves the overall safety measures. Usually, the industry standards and data indicate that the switches are set up around 10-15 feet from the fuel dispensers so that in case of any emergencies, they would be quickly activated. To follow the safety rules similar to those issued by bodies like OSHA and NFPA, the switches are commonly placed at 42-48 inches above the floor level, which not only provides safety but also conforms to the accessibility standards that are easy to reach for people of different heights.

In the past few years, the analysis reveals that modern gas stations have taken up extra measures to enhance their visibility. The emergency shut-off switches come with bright colors like red or yellow, which easily contrast with the surroundings and are also given a reflective coating to make them visible even in darkness. Along with that, detailed instructional signs and pictograms are also used to further clarify the situation and, thus, the operational delays during critical incidents are minimized.

The industry data also points to the emergency switch location being in high-traffic areas like the entrance or exit of the fueling zone. That also means both the motorists and the attendants would easily and directly access the equipment without hindrance. To some extent, the gas stations now provide an auditory and visual alert near the switches that are activated whenever the switch is used, and this is yet another way of highlighting emergencies. These are some of the measures that reflect the ongoing evolution of safety practices that are there to safeguard customers, workers, and the infrastructure itself.

Visibility and Signage

The safety and operational efficiency at fueling stations rely heavily on proper visibility and well-designed signage. Emergency-related signs utilize high-contrast colors, like yellow or red, to guarantee their quick recognition under different lighting conditions. Research indicates that signs with bold letters and universally recognized symbols drastically enhance understanding, even under pressure.

Moreover, eye-level positioning and LED lighting at night further increase the visibility of the signs. It has been found that lighted signs can make things 50% more visible in situations with little light, thus providing access to important information around the clock. Directional arrows, hazard warnings, and fuel type labels should be placed in such a way that they do not confuse the users, but rather, facilitate their experience. Such measures will not only impact the operational flow positively but also reduce the risk of accidents due to miscommunication or unawareness.

Regulatory Compliance for Installation

One of the main factors to pay attention to when installing illuminated signage along with labeling systems is the necessity of compliance with regulatory standards. Visibility and durability are often the aspects that all signage must meet, and the materials used must be capable of withstanding environmental factors such as UV exposure, moisture, and heat and cold cycles. For instance, ISO 3864-1 standards have specified the do’s and don’ts for graphical symbols and safety colors so that everyone can understand them universally.

Moreover, the ADA (Americans with Disabilities Act) states that every sign must be easily read by someone with a disability. This applies to the use of non-reflective finishes, the presence of tactile characters, and the observance of proper character height and contrast ratios to guarantee reading. Besides, state and local regulations may define more requirements, for example, concerning fire safety, where signs must be made from fire-resistant materials and be visible in emergency lighting conditions.

Statistics support that following the proper installation methods is the best practice, as it minimizes the hazards. It is estimated, through research, that up to 20% of workplace accidents can be related to missing or unclear visual communication aids. Moreover, regulatory compliance is crucial in the avoidance of costly fines or closure. In the year 2023, OSHA established a fine of up to $15,625 per violation. The best way to minimize the impact of regulations is to incorporate them into the business culture, which subsequently allows for the protection of the organization’s workers and the company’s reputation and thus aids in creating a safer, more efficient operational environment.

Emergency Scenarios and Response

In the event of a crisis, a well-organized and prompt approach is necessary to reduce damage and protect lives. The first step is to evaluate the situation so that you can recognize the dangers and find out how widespread the emergency is. Next, set in motion the right emergency response plan, which may involve alerting first responders. Provide clear instructions to all staff by employing the means of communication that suit the situation best, for instance, give alarms, make announcements, or use visual signals to indicate what to do, such as which routes to take for evacuation or which area to remain in for shelter. It is very important for the staff to undergo regular training and participate in drills, as these will help them to be quick and efficient in their responses; thus, the risks and damages that may occur will be significantly lessened.

When to Use the Fuel Pump Shutdown

In situations that pose a definite danger to life, like fuel leaks, fire hazards, or system failures, the fuel pump shutdown should be switched on. During emergencies like fuel spills, the shutdown has to be done to eliminate the risk of fire or explosion. Moreover, it is important to follow the shutdown protocol when maintenance or inspection procedures are being conducted in order to prevent accidental fuel flow. Operators have to be very attentive to warning signs such as strange noises, overheating, or pressure drops, and should quickly act by starting the shutdown. Making sure that all the staff are adequately trained regarding the fuel pump shutdown procedures not only reduces the risks but also improves safety during high-risk moments.

Procedures for Activation

To operate a fuel pump in a safe and effective way, the operators are supposed to follow a sequential checklist. First of all, check the power supply and that all parts are in the right place. Look at the fuel pump and neighboring systems to see if there are any signs of damage, leaks, or obstructions. After the inspection is done, make sure that all the valves and connections are tightened securely according to the equipment specifications.

Then, switch on the primary power supply and slowly pressurize the pump system. While doing this, keep an eye on the pressure gauges to make sure the readings are within the equipment’s operating conditions. If there is a control panel, use it to start the fuel flow while keeping an ear out and a watch for any strange sounds, vibrations, or other problems. At last, check the delivery output metrics and perform a brief test of the system performance to confirm that the activation was successful. These measures are a guarantee of reliable and safe operations as well as a reduction in the possibility of equipment failure.

Training for Staff and Users

The introduction of effective training programs for both the personnel and users is one of the factors that will guarantee the maximum operation and maintenance of the machines. The training should present the equipment in a holistic view and shall contain its functions, safety measures, and troubleshooting methods. The syllabus will also contain understanding and applying the operating manuals, detecting the signs of failure early, and doing maintenance that runs smoothly. Enlightening practical training classes are very much advised so as to support the hands-on understanding, including real-life situations where the users can imitate the operational difficulties.

Moreover, workers should be made acquainted with the safety measures during accidents, like how to safely de-escalate the machine in case it goes wrong. Playing it safe through regular refresher courses will certainly strengthen knowledge, keep the tech equipment updated, and also make the users more confident. Organizations by adopt the same training practices and mix both the theoretical and practical ways can cut down the risks associated with operations, improve the performance, and also prolong the equipment’s life.

Maintenance and Testing of Fuel Shut-Off Switches

Correct care and periodic tests of fuel emergency shut-off switches are the lifelines of the system’s safety and dependability. The inspections should be carried out in accordance with the manufacturer’s guidelines, at the recommended intervals. Among the most important points in the procedure are visually looking at the switch and its connections for wear, corrosion, or damage, and checking if the mechanism moves smoothly and if there is no blockage.

Testing should comprise creating a situation that causes an emergency to ascertain that the switch activates properly, thus cutting fuel flow as intended. After testing, the system should be reset, and the checked that it is back to normal operation without any faults should be done. Always keep a record of the maintenance and testing activities so that it will be easy to comply with and track them. Following these practices, the cutoff switches will be functional and responsive in critical situations.

Regular Inspections

It is important to do routine inspections of the emergency fuel shutoff switches to keep them in top working order and to meet the safety regulations. Inspections should involve a detailed visual inspection to see if the switches and their parts are damaged, rusty, or worn out. Make sure that the switches are clean and clear of anything blocking them, and that the outer case is still intact so that there won’t be any impact from the environment. Furthermore, operational tests should be carried out at regular intervals to make sure that the switches can be actuated properly under emergency conditions and that they can return to normal without any delay or malfunction. The recording of each inspection is of great importance for keeping records and compliance audits, and it follows the best practices as proposed by regulatory standards and manufacturers’ guidelines.

Common Issues and Solutions

One of the most frequent problems that I face is a decrease in the sensitivity of the switches, which might be due to dust accumulating or internal parts wearing out. In order to solve this problem, I make sure that the cleaning is done regularly, and also carry out detailed inspections to find any worn-out parts that need to be replaced. Another common issue that I deal with is inconsistency in activation because of improper calibration. When this happens, I meticulously recalibrate the device as per the manufacturer’s specifications to ensure that it works at its best. If broken parts remain, I refer to the technical documentation that comes with the product and eventually reach out to the manufacturer for more help or support if needed.

Documentation and Reporting

Proper documentation and reporting are essential for stabilizing operational efficiency and meeting the requirements of the industry. While documenting procedures, I give the highest priority to accuracy and completeness, and I make sure that each step is clearly and concisely described. Maintenance activities, such as calibrations and repairs, are documented in comprehensive logs that capture the date, the people involved, the issues that were uncovered, the actions that were taken, and the outcomes. This practice not only allows for traceability but also helps to detect repeat issues over time.

Reporting is done using templates that are standardized to make sure that the reports are consistent and meet the requirements of either the regulators or the organization. The test results, the status of compliance, and the deviations from what was expected are among the key items included in the reports. In many cases, modern digital tools are utilized to automate the processes of data collection and analysis to achieve accuracy, whereas, for the stakeholders, the summaries provided highlight the important insights. The thorough and systematic documentation, along with the structured reporting, guarantees that the processes remain transparent, effective, and compliant with both the operational and safety standards.

Reference Sources

Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Analysis of a Gas Station Hybridization with a Solar Thermal Plant by Using ETAP

Variable Neighborhood Search Algorithm for the Green Vehicle Routing Problem

Frequently Asked Questions (FAQs)

What is a fuel shut-off switch at a gas station?

A gas station fuel shut-off switch is a significant safety mechanism that can halt the fuel flow in an emergency. It is usually positioned in a place that can be accessed easily to ensure the safety of the patrons and the staff. This switch, by severing the supply of fuel to the dispensers and pumps, can effectively avert dangerous situations.

How does the emergency stop switch work in a fuel station?

The emergency stop switch, or e-stop as it is sometimes called, is intended to immediately cease all gas station operations in the event of an emergency. Once the switch is pressed, a relay is activated, and it cuts the power to the fuel pumps and other electrical devices, which means no fuel is dispensed. This procedure is vital in accident prevention and the safety of the facility and its surroundings.

Where can I find the emergency shutoff switch at a gas station?

Most of the time, the emergency shutoff switch is found on the fuel island just beside the gas pumps. It is usually clearly labeled and in a spot that is not only visible but also advisable for the employees and firefighters to access quickly if there is a fire. The site could be different for different stations, but it is made to be quickly detected and reachable.

What role does the contactor play in the fuel shutdown process?

A contactor is a part of the electrical system that can be compared to a switch, which regulates the power supply to the fuel pumps. When the fuel shut-off switch is pressed, the contactor is opened, and power is cut off from the pumps; consequently, fuel dispensing is halted. This is a significant component for the gas station to be safe and meet the NEC code requirements.

What are shunt trip breakers, and how do they relate to gas stations?

Shunt trip breakers are protective devices that are capable of discontinuing the electrical supply to a circuit without delay in case of a fire or other hazards. In gas stations, these breakers are frequently used together with the emergency stop switch to confirm that the fuel pumps are turned off in a safe and quick manner. They improve the overall safety of the station by putting an extra layer of protection against adverse conditions.

What is the function of the fuel pump shut-down system?

The fuel pump shut-down system is meant to stop the flow of fuel if a breakdown or emergency occurs. The system can be triggered by different sources, like the emergency stop switch or a fault detection system. It is a key player in stopping the gas station area from being a spill and accident zone, thus ensuring the safety of the gas station environment.

Can a neutral wire affect the operation of fuel shut-off switches?

A neutral wire has the potential to influence the working of fuel shut-off switches. If the electrical ground connection becomes faulty or is not done correctly, it may cause a situation where the switch does not work at all or works inappropriately due to electrical issues. This poses severe safety problems, and thus it is crucial that all wiring, including the neutral wire, is done following safety codes and standards.

Are fuel shut-off switches required by code at gas stations?

Fuel shut-off switches are indeed required by different safety codes, like the NEC. These regulations compel the installation of emergency shutoff switches in order to better ensure the safety of gas stations and their users. The adherence to these codes is very important since it guarantees the safe and smooth operation of gas stations and, at the same time, reduces the hazards involved in fuel dispensing.

What should I do if the fuel shut-off switch is not working?

In case the fuel shut-off switch does not work as it should, the issue must be reported to the station management at once. Management should have an established procedure for dealing with such faults, which might involve bringing the operations to a halt and getting a licensed technician to look into and mend the electrical devices. It is really important for the station to have the right working condition of the shut-off switch as a measure for keeping its safety standards.