The act of gassing up your car might look uncomplicated; nevertheless, the majority of drivers still have doubts, like how the speed of the pump could impact fuel volume and overall efficiency. One of the questions that arises is the one that has been around for a long time, that gas pumping at a slower pace might actually be the case for the customer receiving more fuel for the dollar paid. However, is there any reality associated with this claim, or is it just another myth woven around driving? In this article, we have made an exhaustive study into the science and mechanics of fuel dispensing systems to reveal the truth. Considering parameters such as fuel vaporization, temperature, and pump calibration, our goal is to give a comprehensive answer to this fascinating question. By the time we finish, the readers will have a lucid conviction as to whether changing the speed of the pumping could really impact the amount paid at the pump, or whether it needs to clarify things once and for all.

The Science Behind Fuel Pumping

The speed at which fuel is dispensed at the gas station does not have a major effect on the total amount of fuel you get. Today’s fuel dispensers have modern calibration systems that keep the accuracy standard regardless of the flow rate. The systems, in turn, let you see the volume of fuel on the pump very close to the actual amount that is going to your tank. A further point is that the worry about the loss of fuel through vaporization due to high speeds is very slight because the fuel nozzles are fitted with vapor recovery systems that help reduce this effect. Hence, it does not matter if you pump slowly or quickly; external factors such as engine performance and driving habits continue to be the primary influences on fuel efficiency, and not the pumping speed at the station.

Understanding Gas and Vapor Interaction

Gasoline is a liquid that has a high rate of evaporation, so it turns into vapor easily under atmospheric conditions of temperature and pressure. This property is one of the reasons for selecting it as a fuel in internal combustion engines. Nevertheless, modern fueling systems have taken care of the problem of fuel loss during refueling because of evaporation. The gas nozzles at service stations come fitted with devices for the recovery of vapors. These devices capture the vapors that would otherwise escape and either recycle them back into the fuel system or store them for later processing. By employing this technology, the quantity of gasoline that disappears as vapor during the pumping process is cut down to a considerable extent.

Besides, the temperature is another factor that greatly contributes to the process of vaporization. Gasoline, for instance, is subjected to expansion during warmer weather, which results in the creation of higher vapor pressure. However, the amount of fuel delivered during refueling is only slightly affected. The gas pumps are calibrated with a range of different environmental conditions to make sure that the volume dispensed remains consistent, and hence accuracy is maintained.

Moreover, another factor that is not likely to affect gas and vapor interaction is the speed at which the fuel is pumped. The design of the system ensures that vapor loss is at a minimum regardless of the pumping speed. Furthermore, any outside factors that impact gas efficiency are more related to vehicle maintenance, driving habits, and weather conditions rather than the fueling process. Therefore, modern systems eliminate most possible concerns about gasoline evaporation, and so the fuel delivery is made efficient.

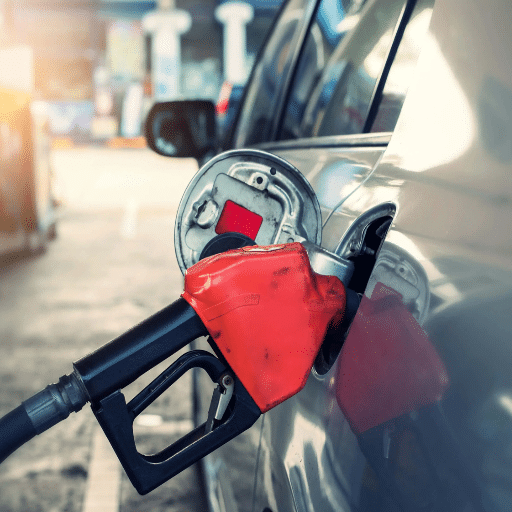

The Role of the Fuel Nozzle

The fuel nozzle is an important part of the fuel delivery system, which is responsible for the accurate and efficient transfer of fuel from the pump to the vehicle. Some of the advanced mechanisms that are present in modern fuel nozzles include prevention of overflows, reduction of vapor emissions, and providing safety during refueling. An example of this is the automatic shut-off valves, which sense the pressure change when the fuel tank is full, stopping the flow and hence preventing spillage. Also, the vapor recovery systems that come along with the nozzle, and hold and return gasoline vapors, are significantly reducing the emissions from the environment.

Fuel nozzles have been made with the aim of getting the best between flow rate and accuracy, along with the provision of different fuel types and vehicle designs. They are made so as to be able to withstand high pressures, and at the same time, leak-proof and long-lasting. Apart from that, nozzles also contain user-friendly features aimed at making the user more comfortable, such as swiveling connections and the use of lightweight materials. The operational aspect of the fuel nozzle is of great importance since it is the main factor that determines fast and efficient refueling, which in turn means the environment is spared and users are further facilitated.

Pumping Gas: The Basics

Filling up your vehicle’s gas tank might look simple, but it can be done in a safer and more effective way if certain guidelines are followed. Firstly, always park your car as close to the pump as possible and make sure that the tank of your car is accessible. Turn off your car’s engine before starting this process – this is a very important safety precaution because it will help to avoid the accidental ignition of the fuel vapors in the air. You should also refrain from using your smartphone during the time of refueling, as they, along with other electronic devices, can produce static electricity, which is a fire hazard.

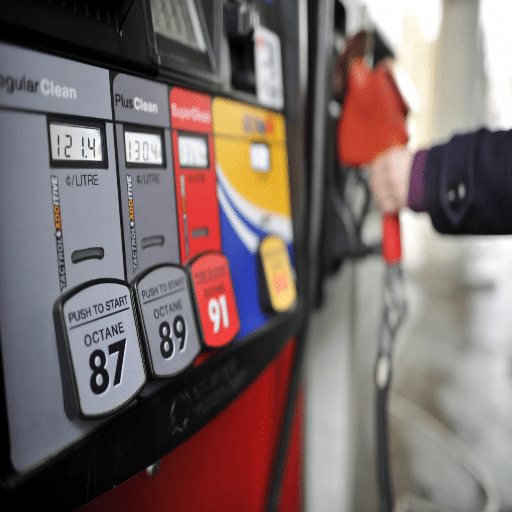

After that, choose the right type of gasoline according to the information in your car’s manual to bring out the best performance of your engine. Insert the nozzle into the fuel tank opening tightly and switch on the pump while making sure that there is no spillage of fuel. The majority of modern nozzles come with automatic shut-off technology, which halts the flow of fuel when the tank is full; let this technology function to prevent overfilling. When you finish refueling, gently take out the nozzle and put the gas cap back on securely to keep the gas from evaporating, as these emissions pollute the environment.

Frequent inspection for fuel leaks and using good-quality fuel can significantly improve and prolong the life of the vehicle. Careful adherence to safety protocols and following these steps would ensure that the whole process of refueling is safe and smooth.

Does Pumping Gas Slowly Help?

Pumping gas at a slower rate is one method you can use to make your vehicle more fuel efficient and, at the same time, reduce the emissions of gasoline vapor. When gas is pumped at a high speed, not only are more vapors released, but also these vapors can activate the pump shut-off mechanism, leading to the wastage of fuel. Besides, the slow pumping method prevents spills and makes sure that the tank gets filled more uniformly, thus helping in getting the best performance from the vehicle. Though it may take a little bit of time, this approach is the most efficient and greenest.

The Argument for Slow Pumping

Pumping gas at a slower rate caused a slowdown in the speed at which fuel vapors are released, and this is very important for the reduction of evaporative emissions that could be a danger to the environment. Gasoline vapors are a major factor in air pollution and smog, and a slow supply helps to better comply with the emission control measures. Moreover, when the fuel flow is fast, there is a greater likelihood of the automatic shutoff of the pump being activated before the tank is filled, resulting in underfilling and wastage. Slow pumping permits the gasoline to be settled correctly in the tank, thereby eliminating the air pockets that may cause inaccurate filling. This method also curtails the spilling of fuel, which is good for both the environment as well as the gas station because it means that all the gas can be sold. It is the gas station’s saving and environmental consciousness at the same time.

Potential Benefits of Slower Gas Pumping

| Benefit | Description | Impact |

|---|---|---|

| 1Enhanced Measurement Accuracy | The risk of vapor lock is considerably reduced with slower pumping, and therefore, the gasoline is dispensed accurately. This, in turn, reduces air pockets formation leading to the actual volume of fuel being reflected properly and hence preventing overcharges due to wrong readings. | Better fuel quantity accuracy |

| 2Minimization of Environmental Impact | Less fuel spillage and vapor emissions are the direct results of slow pumping, which contributes to the lesser release of volatile organic compounds (VOCs) in the atmosphere. This overall method of operation leads to better air quality, and at the same time, it is in agreement with the practices that are friendly to the environment. | Reduced emissions and pollution |

| 3Improved Vehicle Efficiency | No underfilling risk is guaranteed with properly filled tanks, and optimal fuel use is ensured, along with preventing engine performance inconsistency caused by uneven fuel levels. | Consistent engine performance |

| 4Extended Equipment and Pump Lifespan | Fuel pumps and dispensing equipment are less stressed, and hence the slow rate of operation results in less wear and tear. The gas station’s equipment life is thus not only prolonged, but also the efficiency of the entire machinery is enhanced. | Longer equipment durability |

Slower gas pumping methods can bring about the benefits of accuracy, eco-friendliness, and economic efficiency for both the customers and the gas station owners in the long run.

Consumer Experiences and Anecdotes

Consumers frequently report mixed experiences regarding the use of slow gas-pumping methods. For instance, many people claim that the slow gas-pumping method keeps the gas from spilling and gives the most accurate reading of the amount of fuel dispensed, thus instilling them with the confidence that they are receiving the full value of their purchase. Moreover, there are some drivers who have told stories that the slow gas-pumping has reduced vapor loss, and thus the storage and use of gasoline has been slightly more efficient.

On the contrary, there are some who are annoyed by the extra time required, especially during busy schedules or in cold weather. Travelers and fleet drivers often put the pump time as their top priority, so the convenience of working with efficiency for them is less practical than the speed factor.

The collective input from influential figures, such as fuel efficiency blogs and consumer forums, strongly points out the dualistic use of this practice—grabbing the accurate fuel and machine longevity, and at the same time being recognized as inconvenienced by the slow setting of users.

Effects of Pumping Speed on Fuel Efficiency

By delivering fuel at a slow pace, it is possible to obtain better fuel efficiency because of the minimized vapor loss and also the more precise fuel delivery. When fuel is delivered at a high rate, there is a greater chance that air and vapor will be mixed with the liquid fuel, which may cause slight inaccuracies in the amount of fuel drawn. Furthermore, slow delivery minimizes the chances of interfering with the auto shut-off systems, which can lead to a situation where the tank is not full. Even though the gain in efficiency might not be significant for each user, it is still a good practice that helps ensure the maximum amount of fuel is given for the price paid.

Slow vs. Fast: What’s the Difference?

The speed at which you pump fuel can have an impact on both the accuracy and the efficiency of the refueling process. When fuel is pumped slowly, it reduces the turbulence in the tank to a minimum, thereby lowering the probability of vaporization and assuring a more accurate measurement of the fuel. This results in a lower probability of vapor loss, which refers to the process that occurs when the fuel undergoes evaporation and gets collected by the pump’s vapor recovery system instead of going into the tank. On the other hand, if the fueling is done faster, there will be more turbulence and mixing of air around, which might lead to inaccuracies as well as to the premature shutting off of the process because of the formation of foam in the tank. Also, slow pumping is less likely to trigger the vapor recovery systems and contributes to a more consistent flow of fuel, thus enabling you to get the most out of your money in terms of fuel quantity.

How Pumping Slower Affects Tank Fill Levels

While pumping gasoline leisurely, the lesser flow rate decreases the turbulence and foam formation in the tank. Thus, the fuel gets well-distributed, leading to your tank being filled with more precision and fewer stops due to the foam activating the pump’s shut-off mechanism. Also, by pumping slowly, it lessens the chance of the fuel vapors going into the pump’s vapor recovery system, which makes sure that more liquid fuel reaches your tank. All of these factors together lead to a refueling process that is not only more efficient but also less costly while at the same time delivering the maximum actual volume of fuel.

Vapor Loss and Its Impact on Fuel Quantity

Vapor loss is a phenomenon that happens when fuel evaporates, and to make it worse, it is high temperature, quick dispensing, or defective equipment that vaporizes the fuel. Vapor recovery systems are nowadays fitted to modern fuel pumps to hold on to these vapors, but there is still some fuel that gets lost. It has a huge impact when it is hot because the volatile matter of the fuel increases with heat. The process of very fast refueling also causes the tank to be very tumultuous, which ensures that more vapors go to recovery systems than are actually kept in liquid fuel form.

So, it is better to refuel during the cooler times of the day, for example, early morning or late evening, when the temperature is lower, in order to reduce vapor loss and at the same time to deliver the actual fuel volume being delivered. Moreover, using a slow and steady refueling method operates below the tank’s turbulence and gives the fuel enough time to settle down, thereby reducing evaporation significantly. Consumers who take these precautions can not only improve their fuel efficiency but also do so with lower environmental impact and more cost-effectiveness.

Practical Tips for Pumping Gas Efficiently

- Refuel During Cooler Times: It’s better to pump gas in the early morning or late evening when the temperature is lower. The cooler temperatures will minimize the evaporation of the fuel, and you can be sure of getting the most accurate volume.

- Avoid Overfilling: When the pump clicks off, the refueling is done. Trying to fill up more can lead to spillovers, wastage, and even damage to the vehicle’s vapor recovery system.

- Tighten the Gas Cap Properly: After refueling, make sure that the gas cap is securely in place because it will prevent evaporation of the fuel and keep the system working efficiently.

- Drive Smoothly to Conserve Fuel: This is not directly related to pumping, but consistent speeds and no sudden acceleration can stretch the mileage of the gas you have already bought.

- Check Tire Pressure: Properly inflated tires draw less fuel and provide the driver with overall efficiency in driving.

It is enough just to follow these simple practices to get the most out of the fuel and to help cut down the wastage that is not necessary.

Optimal Pumping Speed for Maximum Fuel

In order to achieve the best fuel economy during the gas pumping process, it is suggested to pump gas at a moderate or low speed instead of the fastest one. Although gasoline flows from the pump as a liquid, sometimes, when it is pumped quickly, vapor will form, and that vapor will not fully go into your tank, causing a loss of gas. The majority of the gas station pumps in operation today have vapor recovery systems that can capture some of the vapors, but using slower speeds allows for almost eliminating vapor loss, which means less wastage and more fuel delivered to you for your money. Moreover, spills and overflows can be reduced dramatically by slow pumping, thus ensuring the whole process is eco-friendly and also more efficient.

Techniques for Reducing Vapor Loss

For an efficient vapor loss reduction during refueling, you might as well adopt these technical methods:

- Refueling in the Morning or Evening: With time-fuel density being a factor, the cooler temperature, usually in the early morning or late evening, will result in less fuel evaporation, hence better efficiency and lower vapor emissions.

- Overfilling the Tank Should Be Avoided: Refuel until the automatic pump clicks off. Fuel spills from an overfilled tank will only result in more vaporization because of the heat in the filler neck or spill points.

- Correct Pumping Speed Usage: Fueling at a slower rate can be less turbulent and create less vapor in the tank through the slower vaporization process. This slow vaporization process would then be absorbed by the vapor recovery systems effectively, thus complementing them.

- A Gas Cap That Works Properly Must Be Installed: Inspect and change gas caps that are worn or damaged on a regular basis. A broken cap might allow fuel vapors to escape, causing inefficiency and poisoning the environment.

Following these steps will help you achieve a considerable reduction in fuel loss due to vaporization, therefore benefiting the environment and improving fuel economy.

Understanding Your Fuel Tank’s Capacity

The fuel tank capacity is the maximum amount of fuel that can be put into the tank when it is full. The vehicle owner’s manual or the manufacturer’s specifications label will usually display this information. Passenger vehicles generally have a standard fuel tank of 12 to 20 gallons, but this can vary greatly depending on the car type, such as compact cars, SUVs, or trucks.

Knowing your exact fuel tank capacity is very important for trip planning, fuel efficiency understanding, and overfilling prevention, which can damage the vapor recovery system. Still, the usable capacity might vary a little bit more than the listed capacity because of factors such as reserve fuel levels and filling limitations. Today’s vehicles are equipped with overflow protection and expansion space, making them capable of safely handling temperature fluctuations without affecting performance. For the most accurate information, always refer to the documentation that is specific to your vehicle model.

Best Practices for Pumping Gas

- Switch Off the Engine: Always start with the engine off when gas is being pumped to be on the safe side and to reduce the risk of fire.

- Less Than Full: It is a no-no to say “top off” the tank. The extra fuel may ruin the vapor recovery system and cause leakage of fuel.

- Correct Fuel Type Use: Check your car’s manual for the correct fuel grade if you want your vehicle to have the best performance and be at most efficient.

- Run Off Static Electricity: Before getting the pump, eliminate the static by touching a metal surface away from the nozzle.

- Put the Nozzle in the Right Way: Insert the nozzle very securely into the fuel tank opening so that there will be no spills or incomplete fills.

- Never Leave the Pump Unattended: Stay where the pump is when fueling in case of any problems, and don’t walk away until the transaction is complete.

- The Tank Should be Covered Properly: Make sure the gas cap is tightly closed after fueling so that evaporation is prevented and system pressure is maintained.

Safety, vehicle performance, and environmental impact can all be reduced to a minimum by just following these practices during refueling. Additionally, consult your vehicle’s manual for the specifics that are tailored to your car model.

Techniques to Maximize Fuel Efficiency

Maintain Proper Tire Pressure

Tires that are not inflated to the right level create more resistance and, as a result, the car consumes more fuel. Tire pressure should be checked regularly and the tires inflated to the levels recommended in your vehicle’s manual. Tires that are properly maintained not only save on fuel but also contribute to safety and longer tire life.

Drive Smoothly and Avoid Aggressive Behavior

Fuel efficiency can drop significantly due to quick starts, hard stops, and high speeds. To maximize your vehicle’s performance and fuel usage, practice smooth driving: that is, more gradual acceleration and deceleration, moderate and consistent speeds. Use of cruise control on highways can also be advantageous in keeping speeds within the efficient range.

Reduce Excess Weight and Aerodynamic Drag

The weight of a vehicle loaded with unnecessary items reduces its mileage. The same is true of roof racks and cargo carriers that are not being used, which increase the vehicle’s wind resistance. In general, vehicles that are lighter and more aerodynamic use less fuel during and after operation.

Operate Within Ideal Speed Ranges

At 50 miles per hour and above, the rate of fuel economy decrease is very fast. To get the most out of your engine, keep it at the speed range that is recommended for your vehicle; otherwise, speeding will lead to a higher consumption of energy.

Schedule Regular Maintenance

Not to mention, a vehicle having perfect health is the one with the best fuel consumption. To that end, change air filters regularly, make sure the engine is tuned correctly, and keep the oil changed according to the manufacturer’s specifications in order to reduce wastage of fuel and keep the system running at peak performance.

When to Suck Gas Slowly and When to Suck Gas Quickly

Considering the fuel transfer and the equipment involved, I would take the context of the gas sucking decision slowly or quickly into account. If accuracy is necessary to avoid spills or for an exact measurement, I would suck gas slowly in order to keep control. Conversely, in case time is the main factor and the system can take higher flow rates without danger, sucking gas quickly will be my option. In the end, it all boils down to a trade-off between accuracy and speed according to the particular circumstance.

Tips for Reducing Fuel Wastage

Monitor and Maintain Equipment Regularly

Make sure that all fuel-handling equipment is well-serviced, leak-free, and functioning correctly. Wearing and tearing of equipment can be recognized and fixed before they become a cause of fuel loss. Quickly replace broken seals, hoses, or nozzles to keep the system running efficiently.

Optimize Fuel Transfer Techniques

During the fuel transfer, use the flow rates that are suitable to achieve the right mix of efficiency and accuracy. Do not fill tanks to overflow, since leakage can result in wastage and harm to the surrounding area. It is a good practice to control filling levels by flow control systems or to use an automated shut-off mechanism.

Adopt Efficient Operational Practices

Fuel handling by the personnel is done according to the best practices trained, e.g., limiting idle time and turning off the equipment when not in use. It is also possible to reduce fuel consumption by planning the routes or schedules for refueling.

Utilize Accurate Measurement Tools

Track fuel usage with calibrated meters or monitoring systems. You will get exact measurements and also be able to locate discrepancies that may be signs of wastage or theft.

Leverage Technology

Newer technology, like fuel management systems, delivers prompt information about fuel usage and storage. Such appliances make it easier to choose the right option and limit losses by spotting the weak points in the system.

Conclusion

The question of whether pumping gas slowly gives you more fuel has been thoroughly examined from multiple angles. While modern fuel dispensing systems are calibrated to deliver accurate volumes regardless of pumping speed, there are legitimate benefits to slower pumping that extend beyond mere fuel quantity. Slower pumping reduces vapor loss, minimizes turbulence and foam formation, prevents premature shut-offs, and contributes to environmental protection by reducing volatile organic compound emissions.

However, the actual difference in fuel quantity received may be minimal for most consumers due to advanced vapor recovery systems and precise calibration of modern pumps. The true value of slower pumping lies in its cumulative benefits: better measurement accuracy, reduced environmental impact, improved vehicle efficiency, and extended equipment lifespan. Whether you choose to pump slowly or quickly ultimately depends on your priorities—environmental consciousness and accuracy versus time efficiency.

By following the best practices outlined in this article, including refueling during cooler times, avoiding overfilling, maintaining proper equipment, and understanding your vehicle’s fuel system, you can maximize fuel efficiency regardless of your pumping speed. The key takeaway is that while pumping speed may have some impact, other factors such as vehicle maintenance, driving habits, and refueling timing play equally important roles in overall fuel efficiency and economy.

Reference Sources

“Freeze Drying Process: A Review”

“Idling Performance under Valve Deactivation Strategy in Port Fuel Injection Engine”

“Asymmetric Impact of Crude Oil Cost on Diesel Price in Canada: Evidence from Nonlinear ARDL Model”

Frequently Asked Questions (FAQs)

Do You Get More Fuel If You Pump Gas Slower?

It might happen that a slower gas pumping allows an extra fuel amount to go into your tank. At a high rate, petrol can produce bubbles that will form a layer above the liquid, and that will displace less liquid gas into the tank in total. By letting the gas flow slowly, you can reduce the mixing of air in the fuel, and subsequently, more liquid fuel can be deposited in your tank.

How Does Pumping Speed Affect Fuel Efficiency?

The speed at which you pump your gas can influence how efficiently it fills your tank. A slower pumping speed may reduce the formation of bubbles, which could lead to a more effective transfer of fuel into your tank. The difference might be negligible, but it can still make a small impact on the total amount of gas you receive.

Can You Get More Gas by Pumping Slower?

Indeed, a slow gas flow may be more favorable as it lets the flow meter perform at its best. If the gas flow is too rapid, it can cause turbulent flow and bubbles, and in that case, the regulator might incorrectly determine the amount of fuel dispensed. Drawing at a slower rate may also serve to keep more liquid fuel in the tank and reduce losses through vaporization.

What Happens When You Pump Gas Fast?

Using a fast gas pump can produce bubbles in the fuel and lead them to occupy space in the tank that could have otherwise been filled with liquid fuel. You might believe that you are filling up faster, but in actuality, you are getting less gas due to the increased presence of vapor and the reduced effective capture of liquid fuel by the flow meter.

Does Slowing the Flow of Gas Increase Fuel Amount?

Slowing the flow when you pump your gas can potentially increase the amount of fuel you get. By minimizing turbulence and allowing the vapor return system to function properly, you can reduce the amount of air mixed with the gas, leading to a more efficient fill-up.

Is There a Measurable Difference in Fuel Amount with Pumping Speed?

While the difference may be negligible for most consumers, there can be measurable effects when pumping gas at different speeds. Slower pumping can lead to more fuel being dispensed into your tank rather than being lost to vaporization or bubbles, which can slightly increase your total fill-up amount.

What Should You Consider When Pumping Gas Fast?

Pumping gas fast can lead to various issues, including the potential for air bubbles forming in the fuel, which can affect the accuracy of the flow meter. Additionally, fast pumping can lead to less gas and more vapor, meaning that you may not be getting the full amount of fuel you think you are, leading to wasted time and money.

Can Pump Shutoffs Affect Fuel Dispensing?

Pump shutoffs are designed to prevent overfilling, but their effectiveness can be impacted by the speed of the fuel flow. If you pump gas too quickly, the shutoffs may not function as intended, leading to potential spillage or inaccurate measurements of how much fuel is actually dispensed into your tank.