Gas stations are important facilities to fuel vehicles. But with the flammable materials and heavy machinery being on site, unique hazards are created for interfacing with a possible hazard or accident. Knowledge of safety features and emergency procedures at these facilities can help in preventing accidents or in an efficient response when such incidents occur. This article explains the gas station safety system that comprises emergency shut-off controls and fire suppression facilities and provides stepwise procedures for dealing with emergencies. The information in this article will allow every driver, whether fleet or private, to perform his or her due diligence while traversing a gas station.

Understanding Emergency Stops at Gas Stations

Emergency stops found at gas stations are safety provisions intended to bring the fuel flow to an immediate halt if a hazardous situation should arise. These systems are actuated through emergency shut-off switches, which are normally set up in easily accessible spots and clearly marked, preferably just beside the pumps or near the cashier station. Some accidents may result in fuel spillages, create fire hazards, or cause defective equipment. Emergency stops are intended to prevent situations from aggravating. By stopping the fuel flow, these stops will help alleviate the hazard and ultimately protect people and properties. Hence, it would be best if you found out about the drug-switch locations and how to operate them first to remain safe during an emergency.

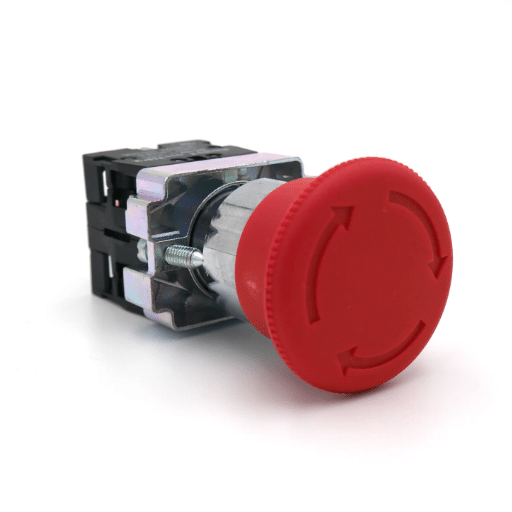

What is an Emergency Stop?

Emergency stop, or E-stop for short, refers to a safety mechanism that triggers an immediate stop of machinery or equipment to prevent accidents and mitigate hazards. Unlike standard stop buttons, emergency stops are made robust and highly conspicuous and placed within easy reach for the utmost effectiveness in the direst situations. They are placed in manual operation mode, activated by pressing the red mushroom-shaped button, usually with a yellow background, used as a standard in the industry. Emergency stops exist to protect workers, equipment, and the environment, and their use is certified by standards and regulations, making them a must in manufacturing and distributing areas, fuel stations, and others. The safety regulations and standards, including OSHA, ISO 13850, and ANSI/ISA, enforce the implementation of E-stops in any operation, representing how much operational safety is associated with them.

| E-Stop Characteristic | Description | Purpose |

|---|---|---|

| Design | Red mushroom-shaped button with yellow background | High visibility and easy recognition |

| Placement | Within easy reach in accessible locations | Quick activation during emergencies |

| Function | Immediate machinery/equipment shutdown | Prevent accidents and mitigate hazards |

| Standards | OSHA, ISO 13850, ANSI/ISA | Ensure compliance and operational safety |

Importance of Emergency Shut-Off Switches

Emergency shut-off switches form an essential component of operational safety systems; they are intended to halt machinery or terminate processes immediately upon a malfunction, hazard, or any other safety-critical incident. These switch types harbor the prevention of injuries, the limiting of damage to the machinery, and prevent the worsening or escalation of events such as the onset of fire, chemical leaks, and electrical troubles.

Emergency shut-off systems shall, as required by American and international standards such as OSHA and ISO 13850, be easily accessible, well-indicated, and capable of withstanding conditions to operate under extremes. So essentially, a shutdown can be initiated by any person in a matter of seconds without the need for any technical intervention or additional steps, which is generally crucial in industries with hazardous materials, heavy equipment, or high-risk operations, such as manufacturing, petrochemicals, and transportation.

Proper placement, testing, and compliance with regulations all determine the efficiency and reliability of the emergency shutdown switches. Furthermore, worker training and periodic inspections need to be in place to verify that these systems are in operation and meet the required standards to serve their purpose as a central mechanism of workplace safety and environmental protection.

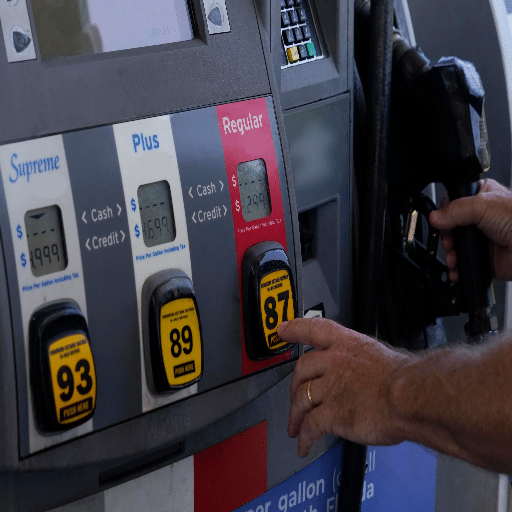

Common Safety Features of Gas Pumps

There are several safety features at gas pumps to protect customers, workers, and the environment. One important safety feature is the automatic shut-off, which automatically stops the flow of fuel when the tank is full in order to avoid overflow and spills. There also exist vapor recovery systems, which capture vapors from the fuel during dispensing to lessen emissions into the environment. In case the hoses are accidentally disconnected, breakaway couplings ensure safety by preventing any spills or fire hazards from occurring.

Emergency buttons are also at all gas stations to stop the fuel pumps immediately if there is an emergency. Another popular choice is to combine fire suppression systems so they rapidly address fire hazards. Today’s pumps also have anti-siphoning features and tamper resistance to lessen the risk of theft and fuel contamination. Adhering to strict regulatory standards, the operational safety and environmental care of fueling stations are safeguarded by such safety measures.

Automatic Shut-Off

Automatically stops fuel flow when the tank is full to prevent overflow and spills.

Vapor Recovery Systems

Captures fuel vapors during dispensing to reduce environmental emissions.

Breakaway Couplings

Prevents spills and fire hazards if hoses are accidentally disconnected.

Emergency Buttons

Immediately stops fuel pumps in emergency situations.

Fire Suppression Systems

Rapidly addresses and controls fire hazards at the station.

Anti-Siphoning Features

Reduces risk of theft and fuel contamination.

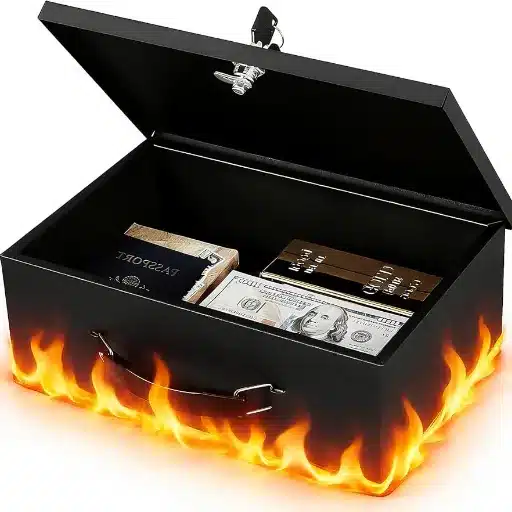

Introduction to Gas Station Safety

Safety concerns and hazards must be handled by gas station safety for the well-being of individuals and the environment. It primarily focuses on the mitigation of risks that include risks related to fuel handling, fire hazards, equipment failures, etc. Safety provisions generally consist of emergency shut-off buttons that immediately shut off the fuel flow in case of emergency; fire suppression systems that suppress fires should those fires start; regular maintenance of pumps and storage tanks in order to avoid leakage. Implementing the above measures, along with adherence to proper safety standards, will greatly diminish the risk of accidents and assist in the operation of gas stations.

Importance of Emergency Stops

Essentially, emergency-stop systems ensure the safety of personnel, equipment, and the environment by immediately stopping operations during hazardous situations. Usually, emergency stops are installed closer to hazardous areas, such as fuel dispensers, to allow immediate access during emergencies, e.g., fuel leaks, fires, or malfunctions. Emergency stops act to cut the power supply or shut off the fuel flow, thus ensuring that a situation does not develop into a bigger accident.

According to industry best practices, these means should be placed at locations that are clearly visible and accessible, should be regularly tested for functionality, and should be maintained according to the manufacturer’s instructions. The implementation of emergency stops also satisfies the regulatory requirements concerning the safety codes enforced by bodies such as OSHA and NFPA. If they are used and maintained correctly, this will greatly improve safety measures, mainly by effectively controlling the available hazards and reducing operational risks.

Overview of Gas Station Operations

Running a gas station involves the interplay of fundamental systems, regulatory compliance, and service standards, considerations for safety and functionality. Fuel storage and fuel dispensing systems form a crucial point in this process. These are subjected to stringent norms with limits to the potential for leaks and spills, or environmental contamination. Underground fuel storage tanks are preferably double-walled with leak detection provided to address any potential hazards. In a like manner, fuel dispensers and nozzles are periodically subjected to inspections and maintenance to maintain accuracy and keep them from malfunctioning.

The operational protocols also stress safety measures in the form of fire suppression systems, emergency stops, and proper ventilation to reduce the vulnerabilities potentially created by flammable materials. Training programs instruct employees on handling spills, equipment operation, and incident reporting, all toward keeping high safety standards. In addition, laboratory operations have been bound to come into compliance with other important federal and state regulations, thereby including those of the Environmental Protection Agency (EPA) and those of the Occupational Safety and Health Administration (OSHA).

Distributors work to ensure that the customer experience is efficient and convenient by installing up-to-date payment systems, keeping the facilities clean, and providing a wide range of accessible services that may include food and retail outlets. Automation and technology innovations have ensured a smooth customer experience while also enhancing the overall operational efficiency: examples include pay-at-the-pump concepts and smartphone apps. These layers combine to treat gas stations as safe places, operating efficiently and according to industry standards.

Common Safety Features

Numerous safety features are put in place in gas stations to safeguard both customers and employees while preventing hazards in the process of handling fuel. In fact, one of the key safety measures is something called a “fire suppression system,” which is automatic fire extinguishers located near fuel dispensers and designed to extinguish a fire should it start. Emergency shut-off switches are equally vital for stopping the flow of fuel immediately during emergencies. Double-walled underground storage tanks with leak detection systems and spill containment measures help prevent fuel spills and environmental contamination. Finally, adequate ventilation prevents the accumulation of flammable vapors.

The security measures in place for gas stations make the area safe by discouraging thieves and allowing for visibility at all times. Safety signs produced to display instructions on the prohibition of smoking and reminders for customers to switch off their engines while refueling serve in their risk reduction. Similarly, the gas station must be subjected to stringent government regulations-on-going inspections, and fire code compliance, including to ensure that they operate on at least equal standards of safety. Taken together, these features help to create a secure atmosphere for all concerned.

| Safety Feature | Function | Benefit |

|---|---|---|

| Fire Suppression Systems | Automatic fire extinguishers near dispensers | Rapid fire control and extinguishing |

| Emergency Shut-Off Switches | Immediately stop fuel flow | Prevent escalation of hazardous situations |

| Double-Walled Storage Tanks | Leak detection and containment | Prevent environmental contamination |

| Ventilation Systems | Remove flammable vapors | Reduce fire and explosion risks |

| Safety Signage | Display instructions and warnings | Educate customers on safe practices |

| Security Measures | Surveillance and lighting | Deter theft and ensure visibility |

Emergency Shut-Off Switches

Emergency shut-off switch installations are the critical safety features to immediately stop fuel flow payment emergencies like spills, leaks, or fire. These switches are usually installed in prominent and accessible places to enable quick activation by the staff or customers when necessary. The other side of the safety issues involved with handling is to stop the incidents of hazardous fuel dispensing systems. The regular inspection and maintenance of shut-off switches are necessary for them to perform and comply with safety codes.

What is an Emergency Shut-Off Switch?

The emergency shut-off switch is the most important type of safety device; it is designed to bring the operations of the fuel dispensing equipment to a halt in the event of some form of hazardous or emergency, such as fuel leakages, spills, or fires. Once the device is pressed, it rips all the power from the fuel pumps so that no fuel is further dispensed, hence lessening the opportunity for further escalation to take place. These switches ought to stand the test of safety regulations and are placed in good places with clear markings, so one can easily seize the chance to use them. Good working of emergency shut-off switches after a trauma holds the sit-down risk mitigation potential, provided that regular testing as well as maintenance is carried out along with legal compliance to safety standards.

How to Locate the Emergency Shut-Off Switch

The location of the emergency shut-off switch is obtained by first establishing its place design-wise, as per safety standards. Generally, the installation is evident, sitting on either the exterior wall or near the entrance/exit of the fuel dispenser, the whole idea being such that you do not miss it while walking towards the dispenser. A bright red or yellow switch is in there. It will be in a color-coded box with an unambiguous label, something along the lines of “EMERGENCY FUEL SHUT-OFF.” If unsure, consult the signage or diagrammatic instructions posted at the station giving directions around. Thus, the design and location attest to the fact that the duty of an accessible switch is taken into account while it also ensures its safety from facing any associated hazards during an emergency. For exact details on the layout, you may also consider looking it up in the station’s safety documentation or asking the personnel on-site to help.

Quick Guide to Locating Emergency Shut-Off Switches:

- Check exterior walls near fuel dispensers

- Look for bright red or yellow color-coded boxes

- Search near the entrance/exit areas of dispensers

- Read clearly marked labels like “EMERGENCY FUEL SHUT-OFF”

- Consult posted signage or diagrammatic instructions

- Ask station personnel for assistance if unsure

- Review the station’s safety documentation for layout details

When to Use the Emergency Shut-Off Switch

The emergency shut-off switch must be operated in any danger to safety or the environment given by a scenario. Common examples include a leak of fuel, equipment malfunction, or a visible fire hazard at the fueling station. Are you seeing uncontrolled dispensing or a possible spill? Start the switch to stop the release so that the spilled fuel is not at risk of catching fire or polluting the environment. A vehicle catching fire near a fuel area is another case where the emergency shut-off will prevent additional supply of flammable material. Using the switch whenever fuel-related hazards escalate beyond manageable levels and calling emergency services if need be is an expected proactive measure. Always make safety a priority and act quickly to contain the threat.

| Emergency Scenario | Action Required | Reason |

|---|---|---|

| Fuel Leak | Activate the emergency shut-off immediately | Prevent fire risk and environmental pollution |

| Equipment Malfunction | Stop fuel flow and alert staff | Prevent uncontrolled dispensing |

| Visible Fire Hazard | Use the shut-off switch and evacuate the area | Stop fuel supply to the potential ignition source |

| Uncontrolled Spill | Activate the switch and contain the spill | Prevent spill expansion and fire risk |

| Vehicle Fire Near Fuel Area | Emergency shut-off and call 911 | Prevent additional flammable material supply |

Dealing with Fuel Spills

Fuel spills should be quickly handled when time is of the essence in protecting the environment and human life from any hazardous disposition. Stopping the source of a spill may include shutting off the fuel pump, stopping the flow by using blockers that can be dropped in the side of the ditch or the leak, where feasible. After that, absorb the spill using absorbent materials, such as spill pads, sand, or even specialized containment kits for fuel. Never use water to wash fuel spills, as doing so may cause the spill to spread and increase the affected area. Once containment is completed, proceed to clean the site nicely and dispose of the contaminated materials in accordance with local regulations. Dosage: Heavy spills must be reported to local authorities to ensure adherence to environmental law. Make sure the setup is properly ventilated and far from any ignition source so that the fire hazard can be minimized.

Recognizing a Fuel Spill

Prompt recognition and response to a fuel spill are necessary to ensure swift abatement of the situation. Some of the visual signs would be pooling or sheen on surfaces, and discoloration of soil or water takes place with iridescence patterns typical of hydrocarbons. Having a smell is also common, as most fuel spills deposit their characteristic scent of gasoline, diesel, or other petroleum products. Spill detection by monitoring systems or alarms with their sensors to detect either hydrocarbons or volatile organic compounds can also occur in industrial environments. If not recognized promptly, a spill can cause damage to the environment; early recognition brings about safety measures taken to reduce risks to humans as well as the surrounding ecosystems.

Signs of a Fuel Spill:

- Visual pooling or sheen on surfaces

- Discoloration of soil or water

- Iridescence patterns are typical of hydrocarbons

- Characteristic scent of gasoline, diesel, or petroleum products

- Monitoring system or alarm activation

- Sensor detection of hydrocarbons or volatile organic compounds

Immediate Actions to Take

In an instance of a fuel spill, it is crucial to act promptly and systematically in the interest of risk mitigation and environmental conservation. The initial step would be to contain the spill so as not to allow for further spread. The area technically affected may be isolated with spill containment tools, such as booms, absorbent materials, or barriers. Following this, search for and remove any possible sources of ignition to prevent combustion or explosion since the spilled fuel is highly flammable. Safety must be guaranteed, which may include evacuating all personnel within the vicinity.

Following containment, clean up the substance by using absorbent pads or spill kits meant for fuel spills. In the case of big spills, environmental response professionals should be contacted as they are competent in the hazardous material cleanup in accordance with local regulations. Finally, report the spill to the appropriate authorities as required by law, providing them with details on the occurrence to promote proper incident documentation and further remediation. These immediate actions serve to promote safety and regulatory compliance, while means of reducing the environmental impact.

- Contain the Spill

Isolate the affected area using spill containment tools such as booms, absorbent materials, or barriers to prevent further spread. - Remove Ignition Sources

Search for and eliminate any possible sources of ignition to prevent combustion or explosion of the highly flammable fuel. - Evacuate Personnel

Ensure safety by evacuating all personnel within the vicinity of the spill area. - Clean Up the Spill

Use absorbent pads or specialized spill kits designed for fuel spills to clean up the substance. - Contact Professionals for Large Spills

For significant spills, contact environmental response professionals who are competent in hazardous material cleanup. - Report to Authorities

Report the spill to the appropriate authorities as required by law, providing detailed information about the occurrence.

Reporting a Spill

When reporting a spill, one must be sure to follow an orderly and thorough procedure that will satisfy legal and environmental requirements. This entails first contacting the local, state, or perhaps the national agency tasked with spill reporting in that area. In the U. S., this body would be the Environmental Protection Agency (EPA). Next comes giving more specific details about the nature, number, and quantity of substance spilled, exact location, and known cause of the spill if applicable; also important is any remedial action taken to minimize the impact of the spill event. Furthermore, given that the surrounding environment, especially in terms of proximity to a water body or a fragile ecosystem, has a bearing on the emergency measures that will be instituted, such information must also be provided.

Timely reporting is crucial. Response agencies must mobilize remediation action based on accurate information provided in time. You should be aware of the particular reporting requirements and thresholds as prescribed by law in your industry, as failure to file in a correct manner or in a timely fashion can lead to a fine. All communications must be recorded systematically for archival purposes as well as compliance requirements.

| Reporting Step | Details Required | Purpose |

|---|---|---|

| Contact Appropriate Agency | Local, state, or national agency (e.g., EPA in the U.S.) | Initiate official spill response process |

| Describe the Spill | Nature, quantity, and type of substance | Enable proper response planning |

| Provide Location | Exact location and proximity to sensitive areas | Determine emergency measures needed |

| Explain Cause | Known or suspected cause of spill | Prevent future incidents |

| Report Actions Taken | Remedial actions to minimize impact | Document response efforts |

| Document Communication | Record all communications systematically | Compliance and archival purposes |

Gas Pump Safety Procedures

Pre-Use Inspection of Equipment

First, inspect for any visible damage to the pump nozzle or hose and report any leakage or malfunction to the station staff. Do not use any equipment that has been compromised.

Remove Sources of Ignition

To avoid the ignition of fuel vapors, stop your car engine and do not engage any electronic gadgets, including your cell phone, while filling fuel. Static electricity might spark; always drag your hand on a metal surface that is away from the pump before handling the fuel.

Use Fuel with Care

Avoid overfilling the tank and leaving the pump unattended. Spilled fuel represents a fire hazard to both people and the environment. Station staff should be notified immediately in case of a spill so that they may clean it up.

Follow Signage and Instructions

Adhere to all warning signs and unique instructions posted beside the pump. When transporting fuel, use only containers approved for that purpose, and be sure to properly seal them.

In a nutshell, these basic instructions are set in place to ensure that all users, station staff, and the environment are kept safe while operating gas pumps.

How to Safely Use a Gas Pump

Observe the following important safety guidelines while working with fuel pumps:

Prevent Static Electricity Hazards

Always discharge static electricity by touching metal away from the nozzle before you fuel. Going back inside your car during refueling may generate static electricity that could ignite the flammable vapors.

Turn Off the Engine

Make sure the engine of your vehicle is shut off before you even begin to fill it. The engine being on can build up the danger of a fire or an explosion if fuel is spilled or vapors are ignited.

Avoid Flames or Smoking

It is very dangerous to smoke or light up a match near a gas station. The gasoline vapors ignite easily.

Do Not Overfill

Spills are possible when you overfill, and they are a big safety hazard for the environment as well. Always stop when the nozzle clicks off automatically.

Secure the Gas Cap

After refueling, make sure the gas cap is tightly secured, for evaporation of fuel might lead to damage to your car’s emission system.

Following these detailed and proven safety measures will greatly reduce hazards and foster a safe atmosphere for fueling for all.

| Safety Measure | Action | Risk Prevention |

|---|---|---|

| Static Electricity Control | Touch the metal surface before handling the nozzle; stay outside the vehicle | Prevents ignition of flammable vapors |

| Engine Shutdown | Turn off the engine before refueling | Reduces fire and explosion risk |

| No Smoking/Flames | Prohibit smoking and open flames in the fueling area | Prevents ignition of easily flammable vapors |

| Avoid Overfilling | Stop when the nozzle clicks off automatically | Prevents spills and environmental hazards |

| Secure Gas Cap | Tighten the gas cap after refueling | Prevents fuel evaporation and emission system damage |

| Equipment Inspection | Check for damage before use | Identifies malfunctions and prevents accidents |

Understanding E-Stop Functionality

The Emergency Stop (E-Stop) is an extremely important safety measure intended for the prompt stoppage of machinery during an emergency. In my experience, its principal function serves as a fail-safe protecting personnel, equipment, and sometimes the surrounding environment when an urgent hazard is created. E-Stops are thus installed with control systems to override the normal operating controls so that either power is disconnected or operation ceases immediately upon activation to further reduce risk. The location of E-Stop devices is carefully considered, and their design is rugged to ensure workplace safety and compliance in case of an accident.

Key Functions of E-Stop Systems:

- Prompt stoppage of machinery during emergencies

- Fail-safe protection for personnel and equipment

- Override of normal operating controls

- Immediate power disconnection or operation cessation

- Risk reduction through rapid response

- Strategically planned location for accessibility

- Rugged design for reliability in accidents

- Workplace safety and regulatory compliance assurance

Role of Electrical Safety in Gas Stations

Since combustible products are stored and dispensed in gas stations, electrical safety becomes paramount. Proper electrical installations, which extend to intrinsically safe wiring and installation of explosion-proof equipment so as to minimize any risk of ignition, must be maintained. The NEC, for example, provides specifications agreed upon to ensure that all electrical components are designed, installed, and maintained to prevent the production of sparks or overheating in hazardous locations. Next to that, grounding and bonding systems prevent any building up of stray static electricity that would normally be a potential source of ignition in such settings.

Routine visual inspections and maintenance must be carried out to detect and rectify faults in the electrical systems. Emergency shut-off systems provide the quickest response in case of any abnormality, such as leaks or shorts. Proper staff training on safety measures combined with advanced monitoring systems further serves to erect a safeguard against electrical hazards, ensuring a safe working environment for both the workers and the customers.

| Electrical Safety Component | Implementation | Safety Benefit |

|---|---|---|

| Intrinsically Safe Wiring | Special wiring designed to prevent ignition | Minimizes spark and fire risks |

| Explosion-Proof Equipment | Equipment rated for hazardous locations | Prevents ignition in combustible atmospheres |

| NEC Compliance | Follow National Electrical Code specifications | Prevents sparks and overheating |

| Grounding and Bonding | Systems to dissipate static electricity | Eliminates potential ignition sources |

| Routine Inspections | Regular visual checks and maintenance | Early detection and rectification of faults |

| Emergency Shut-Off Systems | Quick response mechanisms for abnormalities | Rapid containment of electrical hazards |

| Staff Training | Education on electrical safety measures | Proper response to electrical emergencies |

| Monitoring Systems | Advanced detection and alert systems | Continuous safety oversight |

Safety Best Practices Summary

Essential Safety Practices for Gas Station Users:

- Familiarize yourself with emergency shut-off switch locations before fueling

- Always turn off your vehicle engine during refueling

- Discharge static electricity by touching metal before handling the nozzle

- Never smoke or use open flames near fuel dispensers

- Avoid overfilling your tank—stop when the nozzle clicks

- Stay outside your vehicle during the entire refueling process

- Do not use cell phones or electronic devices while pumping fuel

- Inspect pump equipment for damage before use

- Report any spills or malfunctions to station staff immediately

- Know how to activate the emergency shut-off switch in case of emergency

- Follow all posted safety signs and instructions

- Use only approved containers for transporting fuel

- Secure your gas cap tightly after refueling

- Keep the area well-ventilated to prevent vapor accumulation

- In case of emergency, prioritize safety and call 911 if necessary

Emergency Response Quick Reference

| Emergency Type | Immediate Action | Next Steps | Who to Contact |

|---|---|---|---|

| Fuel Spill | Stop fuel flow; contain spill with absorbent materials | Remove ignition sources; ventilate the area; clean up properly | Station staff; local authorities for large spills |

| Fire | Activate emergency shut-off; evacuate the area immediately | Use a fire suppression system if trained; do not attempt to fight large fires | Call 911; alert station staff |

| Equipment Malfunction | Stop using the equipment; activate the shut-off if necessary | Secure area; prevent others from using faulty equipment | Station staff immediately |

| Fuel Leak | Activate the emergency shut-off switch | Evacuate area; eliminate ignition sources; contain leak | Station staff; emergency services |

| Vehicle Fire Near Pumps | Activate emergency shut-off; evacuate immediately | Move other vehicles if safe; establish a safe perimeter | Call 911 immediately |

| Personal Injury | Remove person from danger; assess condition | Provide first aid if trained; do not move seriously injured persons | Call 911; station staff |

Regulatory Compliance and Standards

Key Regulatory Bodies and Standards:

- OSHA (Occupational Safety and Health Administration): Workplace safety standards and requirements

- NFPA (National Fire Protection Association): Fire safety codes and standards

- EPA (Environmental Protection Agency): Environmental protection and spill reporting requirements

- NEC (National Electrical Code): Electrical installation and safety specifications

- ISO 13850: International emergency stop standards

- ANSI/ISA: American National Standards Institute safety requirements

Conclusion

Gas station safety is a critical responsibility shared by station operators, employees, and customers alike. Understanding the various safety features, emergency procedures, and proper fueling practices is essential for preventing accidents and ensuring a safe environment for everyone. Emergency shut-off switches, fire suppression systems, proper ventilation, and leak detection systems all work together to create multiple layers of protection against potential hazards.

The key to effective gas station safety lies in awareness, preparedness, and prompt action. Familiarizing yourself with the location and operation of emergency shut-off switches before you need them can make the difference between a minor incident and a major disaster. Following basic safety protocols—such as turning off your engine, avoiding static electricity, and refraining from smoking or using electronic devices—significantly reduces the risk of fire or explosion.

In the event of an emergency, whether it’s a fuel spill, equipment malfunction, or fire, immediate and appropriate response is crucial. Knowing when and how to activate emergency shut-off switches, properly containing and reporting spills, and evacuating the area when necessary can save lives and prevent environmental damage. Always prioritize safety over convenience, and never hesitate to seek assistance from station staff or emergency services when faced with a hazardous situation.

Regular maintenance, compliance with regulatory standards from organizations like OSHA, NFPA, and EPA, and ongoing training for station personnel ensure that safety systems remain functional and effective. As technology advances, gas stations continue to implement more sophisticated safety features, but the fundamental principles remain the same: vigilance, education, and respect for the inherent hazards of handling flammable materials.

By understanding and adhering to the safety procedures outlined in this guide, you contribute to a safer environment for yourself, other customers, station employees, and the surrounding community. Remember that gas station safety is not just about following rules—it’s about protecting lives, property, and the environment from the potentially devastating consequences of fuel-related accidents.

Stay Safe: Always remain alert, follow posted instructions, know where emergency equipment is located, and don’t hesitate to act decisively in an emergency. Your awareness and responsible behavior at gas stations help ensure that these essential facilities can continue to serve communities safely and efficiently.

Reference Sources

Risk Prioritization and Management in Gas Stations Using Fuzzy AHP and IPA Analysis

Analysis of a Gas Station Hybridization with a Solar Thermal Plant Using ETAP

A Survey on Smartphones Systems for Emergency Management (SPSEM)

Frequently Asked Questions (FAQs)

How will I move away from a spill at a gas station?

Once a spill occurs in a gas station, move away from it without delay. Never stand anywhere near fifty feet away from the area of the spill-for fear of inhaling vapors or the danger of being set on fire. Always inform the station attendant about the spill so that corrective measures can be taken to contain it.

What do I do if I see a bystander hanging out close to the pumps during an emergency?

One has to remove the bystander from the scene and calm him down. They must be kept at an arm’s distance from all imminent hazards such as spills or fires-and the gas station staff should be informed so that measures may be taken to ensure the safety of everyone.

Why is it important to stay upwind of a gas spill?

It is important to stay upwind from the gas spill to avoid inhaling any harmful fumes released during a leak. The wind is likely to carry these vapors past your position, which is why you must be upwind or minimize exposure to the vapors until the local fire department or gas station staff arrive to handle the matter.

How do I alert the gas station staff in case of an emergency?

In such a case of an emergency, it is advisable to notify the gas station personnel by reporting directly to them, provided it is safe to do so. You might also call them on the phone if needed. Convey sufficient information about what happened, such as the location of a spill or where they should enact an emergency stop, for appropriate action.

What is the role of the authority having jurisdiction at a gas station?

The authority having jurisdiction ensures all safety measures are carried out in the gas station. He oversees emergency actions, grants permission in regard to the installation of breakers and shutoffs at the gas stations as required by NEC regulations, and may even intervene along with the local fire department during an incident.

How could I prevent damage to property at a gas station?

One can aid in the prevention of injuries to persons and property at a gas station by observing one’s environment and reporting spills or malfunctions to the attendant right away. Another preventive measure is to inform the gas station staff or local authorities if you see anyone attempting to tamper with or reset the system.

What safety equipment is required to be present in convenience stores and gas stations?

Convenience stores and gas stations should have such safety equipment as fire extinguishers, spill kits, and emergency shutoff switches. When dealing with emergencies involving petroleum gas, these devices are indispensable in safeguarding customers and staff.