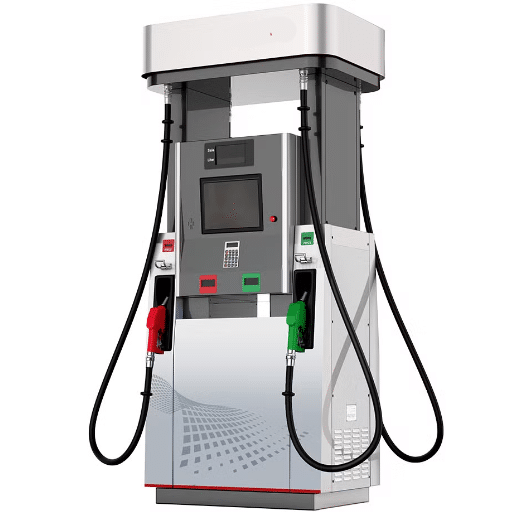

Modern fuel dispenser machines can be recognized as the heart of any modern petrol station, acting as the nucleus that links fuel storage systems with consumers. These machines are an essential guarantee for accurate measurement results, effective delivery, and a seamless experience for the customers. With the growing technological advancements, modern pumps have, however, pioneered sophistication, incorporating automation, security systems, as well as other independently operated payment systems. Warm-up Digital looks into its entailing technological complexity and innovation, as well as definitions of parts and use in fuel dispensers, to enhance the curiosity of interested persons. The guide deliberately designates explicit knowledge to petrol station operators and technicians, giving them a meticulous breakdown of basic operational principles. This guide is not just for anyone keen to explore how fuel dispensers operate. Instead, it is meant to become their personal aid in solving problems while furthering the discussion on cost-effective, secure fueling.

Overview of Fuel Dispensers

Machines are very critical in nature to allow for a steady fuel supply to an on-the-road & quiet operating gasoline outlet. These machines come with the major components like Fueling Unit, Meter, Hose, and Nozzle, all working collectively to provide excellent fuel dispensation to the vehicles. Specific technologies of the modern world have just heavily improved the level of precision to save fuel and maintain the safety of the general fuel dispensing operation. Many of these types of manufactured dispensing machines are composed of a user-friendly interface to enable you to operate them well with ease. These machines are as important in making the process fuel hazard, and, at the same time, for both customers and operators.

Definition and Functionality of Fuel Dispenser Machines

Fuel dispensers are machines designed to allow a safe and accurate transfer of liquid fuels such as gasoline and diesel from storage tanks into vehicle tanks or portable containers. It utilizes a combination of components, which include a powerful motorized pump, meters to measure volume accurately, fuel dispensing hoses, and nozzles equipped with automatic shut-off systems to avoid spillage. The state-of-the-art fuel dispenser integrates an electronic system that allows transaction management, inventory monitoring, and calibration to qualify for preset industry standards. Modern fuel dispensers come equipped with digital interfaces, card payment modules, and wireless connectivity for an enriched customer experience and streamlined operations. Consequently, the functions of fuel dispensers are crucial in providing efficient and environmentally friendly refueling procedures in wide-ranging contexts, including gas stations, commercial fleets, and industrial equipment refueling.

Types of Fuel Dispensers: Petrol and Diesel

Fuel dispensers for petrol and diesel are mostly distinguished based on how they operate and their purpose. The majority of the modern machines use suction, with some exceptions. In an instance of a suction mechanism, there is a pump located within the dispenser to control the movement of the fuel directly from the tank, which makes it the best choice for smaller setups or limited pump installations at a filling station. Submersible systems are seen, on one hand, to use a pump installed at the cistern to pressurize the fuel with respect to movement, hence optimizing high rates of flow, ensuring smoother operation even in high-density settings.

In a similar context, the dispensers are equipped with specialized nozzles, metering systems, and safety properties pertinent to petrol and diesel fuel characteristics. Gasoline requires advanced dispensers that use a special vapor recovery system to minimize emissions and maintain environmental compliance due to its low volatility. Diesel needs gasoline that is supplied in strong pumping mechanisms and hoses of larger diameters to handle a higher flow of traffic.

When it comes to choosing the type of fuel dispenser to be used, it always depends upon quite a few factors, which include the type of fuel, expected throughput, site layout, and the need for compliance with the prevailing local regulations. Both petrol and diesel dispensers are intrinsic to the effective distribution of fuel in different industries, ensuring safe, accurate, and environmentally friendly refueling operations.

Importance of Fuel Dispensing Efficiency

The objective is to have fuel dispensing carried out efficiently, improving efficiency and, in return, minimizing waste, enabling the customer to always be satisfied. High-throughput dispensers improve the throughput during the peak delivery hours in busy gas stations, well-placed in fleet operations, whilst reducing refuelling time. With precise metering and good calibration systems in new dispensers, the right delivery is guaranteed. This is so important for the management of operational costs and for more stringent compliance with regulations. Such efficiency ensures greatly reduced spillages of fuels and fumes, contributing hence to the environmental sustainability actions and its observance of safety standards. Automation, hence, appears as an example of technologies for introducing vapor recovery systems and data integration software that produce assistance through these processes, as operators can monitor fuel usage, discrepancies, and therefore, the existing integrity or capacity.

Components of a Petrol Pump

Fuel Dispenser

The fuel dispenser is a critical component that delivers gas to vehicles. It has all of the hoses, nozzles, and meters to control and gauge the flow rate with precision.

Underground Storage Tanks (USTs)

Placed below the ground, USTs are designed to safely store substantial volumes of fuel. Its leak-proof construction is key to preventing damage to the environment.

Pipes and Motors

Pipes transport fuel from the underground storage tanks to the car, and these are normally accompanied by motors to power the pipes for effective operation.

Fuel Management System

This data logging and transaction record-keeping system is used for monitoring fuel inventory and sales transactions, while ensuring that there is no unauthorized use of the stored fuel.

Metering And Calibration System

By this monitoring device, it is ensured and held to standards that the fuel delivered during each transaction is that which is actually sold.

Vapor Recovery Systems

Emission-free at the Refueling Cycle are claimed by Vapor Recovery Systems.

Safety Features: What safeguards also feature? In case of leaks, falls, or conflagrations, isolate the emergency valves, define the facilities for fire extinguishing, or activate the alarms.

These are the elements that we marry together for the attainment of fast, properly managed, and safer refilling activities.

Key Parts of a Fuel Pump Machine

| Component | Function | Key Features |

|---|---|---|

| Hose | Connects tank to dispensing nozzle for fuel transfer | Reinforced rubber compound, high-pressure resistance, flexible and durable |

| Display System | Provides real-time dispensing information | Shows fuel amount, cost, price per unit, touchscreen interfaces |

| Control Unit | Acts as the machine’s brain, synchronizing operations | Regulates fuel flow, interfaces with payment systems, supervises safety |

The Hose System

The hose acts as a long strip from the tank to the dispensing nozzle, which helps the fuel to travel right from the tank through the pump into the dispenser nozzle.

The hoses are made up of a rubber compound and are reinforced to withstand high pressures developed by the propelled fuel.

The hoses are serving dual purposes: they give flexibility to the fuel transfer machine while giving the product a degree of durability. These hoses are designed in such a way that they can, on one hand, withstand the high pressure and, on the other hand, resist rapid wear and tear caused due to repeated usage.

Display System

The electronic display shall provide real-time information to the user about the fuel dispensing information, the amount of fuel, the cost, and the price per unit. Advanced systems also have touchscreen interfaces to enhance interactivity.

Control Unit

In machine processing, the control unit often acts as the machine’s brain, controlling its operations and ensuring that all the components are synchronized. It is responsible for regulating fuel flow, interfacing with payment systems, and supervising safety mechanisms.

Through these processes, an optimal working environment is provided, maintaining the good working of fuel pump machines and regulating the correct measurements, environmental compliance, and safety of the user.

Understanding Nozzle Types and Their Uses

Vapor Recovery Nozzles

Vapor recovery nozzles can recover partially vaporized fuels from the surrounding gas stream and are common where there is a mandatory vapor recovery system (such as fleet fueling locations). Vapor recovery nozzles typically house a nonreturn valve, which is a basic passive control measure for preventing fuel seepage if the vapor recovery hose fails to connect or is removed too early. In terms of intervals of time, vapor recovery nozzles are beneficial during cold months once snowballs in the connectors have been removed.

Working on vapor recovery during the dispensing process is a nice witness to follow and to ensure that general emission standards are adhered to, while stored fuel vapors are not released. These nozzles provide many advantages in emission protection for those locations where stipulated emission standards are rather stringent.

Manual Nozzles

By contrast automatic nozzles, automatic nozzles are to be operated manually by refueling unit personnel. Composed of a simple configuration, manual nozzles are generally utilized in applications that require precision and control, such as the refueling of agricultural equipment.

Diesel-Specific Nozzles

These nozzles are specialized to work only with diesel fuel, the widened diameter on the nozzle tip preventing careless misfuelling in a gasoline tank. They are sometimes equipped for diesel vehicles with enhanced flow rates.

Each nozzle has been developed to cater to the need for safety, efficiency, and performance, and to the concerns and reasons for the application to be compatible while moving according to all rules and regulations. Knowing the uncommon usages of nozzles is important for selecting the right equipment for your fuel-dispensing system.

Technology Behind Modern Fuel Dispensers

Modern fuel dispensers comprise advanced technology-based systems created to provide more accurate measurements, more billing data, cost allocation, and environmental standards compliance. One of the basics of these dispensers is the metering systems, which are somewhat controlled by positive displacement meters, and also by mass flow meters or by electronic systems that ensure accurate fuel measurements. Control is in a microprocessor, while managing flow rate adjustment, registering transactions, and tracking cards with proofing reliability.

The digital ecosystem interface is becoming ubiquitous in fuel dispensers, which has facilitated users to personalize the system by providing touch screen or keypad input and enabling network connection. The interfaces integrate with the point-of-sale and fleet management systems, and software systems transfer data seamlessly so that the operation is centralized. At the same time, the technology comes with vapor recovery systems used to capture and reduce harmful emissions during refueling-align with environmental regulations.

Another example is that of secure payment systems that are now part of the systems of fuel dispensaries. In-built services now include card readers, contactless payment, and mobile payments. Proprietary encryption to protect the data of user is provided.

While more advanced technologies enter the field, the gasoline filling framework is being automated with the advanced IoT tools. Remote diagnostics, performance monitoring of components, and predictive maintenance alerts all reduce downtime and operational disruption, ensuring continuous functionality. In sum, these advancements underscore the role of cutting-edge technology in driving efficiency and sustainability in modern fuel dispensing systems.

IoT

Remote Diagnostics & Monitoring

AI

Predictive Maintenance

24/7

Continuous Functionality

Operational Aspects of Fuel Dispensing

Fuel dispensing operations are based on three key functional components, namely: metering, pumping, and control systems. The metering unit, which also involves the application of stringent technical standards of precision, ensures precise measurement of dispensed fuel. The pump is involved in providing the proper fuel circulation in continuous mode, no matter what the level of the tank is. Control mechanisms control an array of activities encompassing the recording of transactions and monitoring for safety, harnessing automation technology in many cases. Under a regulation-based framework, each of these facets works in unison to present increased fuel potency, safety, and accuracy.

How Fuel is Dispensed at Petrol Stations

The mechanical, hydraulic, electronic, and other systems used to dispense fuel at gas stations make sure that the dispensation is performed efficiently and safely. It starts by inserting the nozzle into the tank of the car and then activating the pump. The dispenser uses suction and submersible pump systems to extract fuel from the underground tanks. The flow meter is usually fitted with a turbine or positive displacement mechanism to measure the actual quantity of fuel being delivered and thus maintain the regulatory standards of accuracy.

Control systems, which are linked with the electronic management, regulate the flow of fuel and close it off automatically once the tank has filled up. Such systems operate with a small hole in the nozzle, which is connected to a valve for automatic closing. As the fuel level rises, it obstructs the passage of air into that hole, which in turn causes a change in pressure to throw the closing mechanism into action to prevent spills. Furthermore, besides payment systems for advanced dispensers, there is also vapor-recovery technology to alleviate environmental concerns, monitoring equipment to execute operational safety, and industry-required standards compliance. Finally, this will be a technology meshing fuel in an efficient, safe, and accurate manner.

Safety Measures in Fuel Dispensing Operations

Safety in fuel dispensing operations is crucial to ensure the safety of personnel, property, and the environment. To minimize risk exposure to all concerned, one must adhere to various stringent rules and protocols aimed at upholding safety and imposing several levels against carelessness. No leaking can occur as long as dispensers are regularly serviced, preventing any kind of fuel downfalls, meanwhile reducing emissions. A critical point of consideration is put on the use of vapor recovery systems in these kinds of operations. However, because otherwise damages could trigger ignition hazards, pumping operations are made safer by using static discharge as much as groundings and bonding requirements.

Personnel need to be trained with response protocols for emergencies, including spill response, firefighting, or exposure to hazardous vapors. Fire extinguishers and spill-containment kit areas must be nearby. Moreover, no smoking signs need to be displayed at these fueling areas. Some safety features take care of themselves through automation, like emergency shutoff valves and overfill prevention systems that are able to shut off fuel flow in case of any kind of system anomaly or malfunction.

Organizations like OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) set forth various standards concerning safety. It would be better if these standards were strictly adhered to. Regular inspections and audits may be up to the task of ensuring equipment and operations are maintaining legal and industry benchmarks in striving towards safety and sustainability.

Regular Maintenance of Fuel Dispenser Machines

Proper maintenance of fuel dispenser machines is crucial to ensure accurate fuel delivery, environmental safety, and operational reliability. Key maintenance tasks include regular inspections of nozzles, hoses, and seals for wear or leaks, as these components are prone to degradation due to heavy use and exposure to fuel. Calibration checks and adjustments should be conducted periodically to maintain dispensing accuracy, as inaccurate meters can lead to compliance violations and financial losses. Filters within the system must be replaced routinely to prevent fuel contamination, which could harm vehicle engines or damage the dispenser itself.

Another protocol has a method of checking on electrical connections, be it grounding or emergency power-off (EPO) principles. An equally preventive measure entails ensuring periodic software upgrades on dispenser management systems importance of which cannot be overstated because they contain what are essentially new operational facilitation tools and protective concerns. Adhering to these maintenance guidelines can ensure that the equipment runs smoothly for years ahead, reducing the risk of major downtime.

Market Insights and Pricing

With the rise in fuel demand, innovation, and growth in various fuel stations around the globe, the fuel dispenser arena is raging-the type of dispenser (whether suction or submersible) with which advanced features (such as contactless payment systems) are integrated, and their adherence to various proposed safety regulations influencing price structures. Per dispenser unit, prices usually range from USD 10,000 to 50,000. Other factors that significantly determine pricing are the company’s reputation for dispensers, how well the service warranty is glowing, and their customizability. The most important thing now is to invest totally in renowned brands, which is, of course, increased reliability and excellent performance, plus long-term cost-saving.

Current Trends in Fuel Dispenser Prices

Technological innovation, market demand, and changes in regulations are the few factors that continue to shape fuel dispenser pricing. In the latest scenario, the trend is more and more towards greener and energy-efficient models due to the environmentally conscious and government regulation push. New dispensers now come standard with contactless payment systems and a more digitalized interface that has inflated their upfront costs. Executives from a major industry source say the low entry price of basic fuel dispensers typically starts at around $10,000, but the units that are crammed with a number of advanced features and customizations can push the cost way beyond what you would normally expect. The market finds itself in a state of price volatility due to this recent spike in global logistics, coupled with fluctuating raw material costs, most for essential components like steel and electronics. So, if you are considering buying a fuel dispenser, always do a detailed cost-benefit analysis and calculate how much savings you could earn in the long run by buying luxury fuel dispensers.

Factors Influencing the Cost of Petrol Dispenser Machines

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Production and Shipment Costs | Advanced technology integration, bulk material procurement | Higher precision standards increase manufacturing costs |

| Portfolio Features | Digital meters, remote fueling, mobile billing systems | Advanced features optimize efficiency but increase expenses |

| Material and Component Quality | Metal combinations, rust resistance, electronic components | High-quality materials improve lifespan and durability |

| Safety and Regulatory Compliance | ATEX and UL certification requirements | Stringent testing and compliance increases production costs |

| Supply Chain Costs | Raw material price fluctuations, transportation costs | Economic factors cause price variations in global markets |

| Customisation and Branding | Personalized branding, custom dimensions, unique specifications | Individual production commands premium pricing |

These understandings enable more-informed decisions by allowing buyers to weigh the first cost against the long-term savings, for their operational efficiency and compliance benefits.

Leading Suppliers and Brands in the Fuel Dispensing Market

The fuel dispensation market is a sales area of established brands, all of which come up with innovative renovation and quality machines. They have a certain popular name in the market for cutting-edge technology, quality service, and advanced machines compliant with defined regulatory standards. They need no special mention for being the classic set of pump sets. The three names qualified for mention include:

Gilbarco Veeder-Root

A global market leader for fuel dispensant technology, Gilbarco Veeder-Root offers groundbreaking innovations in fuel dispenser panels and integrated forecourt solutions. Durability, ease of user access, and an advanced payment system are some technical characteristics that have become their trademarks. This brand also focuses on digital transformations with the creation of IoT systems to facilitate a forthright business and the acquisition of more data.

Wayne Fueling Systems

Wayne Fueling Systems has a reputation for producing effective engineering and dispensing solutions that marry precision, energy efficiency, and toughness. Additionally, a wide range of equipment is made available to accommodate the requirements of retail and commercial dispensers, while at the same time ensuring safety and environmental regulations.

Tokheim

This is probably one of Tokheim’s cornerstones: modules like dispensers and software solutions and, above all, the heavy-duty arrays depending on market requirements. Structuring any creative payments with security – that security is rather interesting as it must assure the client, rather, provide it to him, cloud-based monitoring for real-time management and service optimization.

Industry Leadership: These companies provide market leadership through continuous endeavor in R&D, making sure from start to finish that fuel dispensing equipment answers with the cited rules and technological status quo. People who are looking for quality and reliability are better off consulting these names for their wide variety of solutions.

Future of Fuel Dispensing Technology

Focus with regard to fuel dispensing technology intends the enhancement of efficiency, sustainability, and convenience for the consumer. Developments, such as compatibility with alternative fuels like biofuels, hydrogen, and electric charging for vehicles, were made to comply with the global shift that advocates for cleaner energies. Extremely smart fuel dispensing systems are now possible that can interact with the Internet of Things while being highly energized by artificial intelligence, thereby offering real-time data analysis, predictive maintenance, and improved customer experiences. Presently, following strict environmental laws will lead to huge innovations in vapor recovery systems, making leak detection and other methods crucial in reducing the environmental footprint. All these advances aim at satisfying the wishes of consumers and industry stakeholders eager to benefit from a growing energy landscape.

Innovations in Fuel Dispenser Machines

Fuel-dispenser technology has experienced rapid growth and change owing entirely to technological intervention, increased efficiency necessities, and increasing environmental legislation. Advanced fuel dispensers now come with digital interface technologies and a faster, more precise transaction system. The accolade goes to the contactless payment systems, which will comprise any form of RFID or mobile wallet applications, reducing waiting time and enhancing the overall customer experience.

IoT and AI, thus, foster predictive maintenance to come into play; with a real-time monitoring facility on fuel dispensers, there is a chance of targeting early deterioration by now decreasing downtime and operational costs. The days of high-accuracy fuel dispensing have finally come, towards less spillage and proper measurement, thus catering to cost optimization as well as legislative conformity. New mechanisms of vapor recovery are in place to channel the wasted fuel vapor from dispensing down to new pollution.

Automated monitoring systems will further provide for streamlined inventory management, ensuring timely refills and avoiding running out of stock. All of these features together are set to bring in operational efficiency, better safety standards, and reduced environmental impact, thus transforming the fuel dispenser machine into fulfilling the requirements of a sustainable and customer-centric energy market.

Impact of Electric Vehicles on Fuel Dispensing Systems

The rise of electromobiles (EVs) is altering the space of conventional energy systems. In my view, the acquisition of liquid fuels is dropping gradually with the rise in the adoption of EVs. Hence, fuel stations need to redefine their strategies and services, intertwined between electric chargers and normal fuel dispensers, to keep up with evolving energy policies. Furthermore, managing space efficiently and accommodating fast-charging technologies is important for customer satisfaction with evolving, different demands. This epoch is promising toward developing modern and fresher features in EV systems and energy systems.

Environmental Considerations in Fuel Dispensing Equipment

Environmental consideration within fuel product equipment is crucial in its design and operation. Modern systems must minimize emissions, leakage, and spillages through advanced containment and vapor recovery technologies. Incorporating Stage 1 and Stage 2 vapor recovery systems significantly reduces VOC emissions during the transfer and dispensing of fuel processes. Concomitantly, the utilization of double-walled tanks and piping systems will assure secondary containment, reducing the risk of soil and groundwater contamination.

When it comes to energy efficiency, it is necessary to know that newer models of fuel pumps and dispensers usually contain lower energy motors and parts so as to reduce the overall amount of carbon. We cannot forget that, due to the processes of wear and tear, only a proper schedule of maintenance, inspections, and tests can avoid insidious environmental toxicities such as unfathomable spills. Now, with the inception of stringent environmental regulations spread far and wide across the world, fuel distribution means committing to using green materials and ensuring that equipment conforms to standards such as those stipulated by the EPA to moderate the environmental degradation associated with fuel distribution.

Conclusion: The Evolution of Fuel Dispensing Technology

Modern fuel dispenser machines represent the pinnacle of engineering excellence, combining precision measurement, advanced automation, and robust safety features to deliver seamless refueling experiences. As the heart of any petrol station, these sophisticated systems have evolved far beyond simple pumping mechanisms to become intelligent, connected devices that optimize operations, ensure compliance, and enhance customer satisfaction.

The integration of cutting-edge technologies such as IoT connectivity, AI-powered predictive maintenance, contactless payment systems, and advanced vapor recovery mechanisms demonstrates the industry’s commitment to efficiency, sustainability, and safety. From the intricate components like positive displacement meters and microprocessor-controlled systems to the comprehensive safety protocols involving OSHA and EPA compliance, every aspect of modern fuel dispensers is engineered for optimal performance.

As we move toward a future that embraces alternative fuels, electric vehicles, and increasingly stringent environmental regulations, fuel dispensing technology continues to adapt and innovate. The transition toward greener, more efficient systems is not just a response to regulatory pressure but a fundamental shift in how the industry approaches energy distribution. Whether through enhanced vapor recovery systems, double-walled containment structures, or smart monitoring capabilities, the focus remains on minimizing environmental impact while maximizing operational efficiency.

For petrol station operators, technicians, and industry stakeholders, understanding the complexity and sophistication of modern fuel dispensers is essential for making informed investment decisions. With prices ranging from $10,000 to $50,000 depending on features and capabilities, choosing the right equipment from reputable brands like Gilbarco Veeder-Root, Wayne Fueling Systems, and Tokheim ensures long-term reliability and performance. Regular maintenance, adherence to safety protocols, and staying current with technological advancements are key to maintaining competitive operations in an evolving market.

The future of fuel dispensing lies in the seamless integration of traditional fuel systems with emerging energy solutions, creating hybrid stations that can accommodate both conventional vehicles and electric vehicles. As this transformation unfolds, the role of advanced fuel dispensing technology in shaping a sustainable, efficient, and customer-centric energy infrastructure cannot be overstated. The journey from simple mechanical pumps to today’s intelligent dispensing systems is a testament to human innovation, and the best is yet to come.

Professional Guidance: This comprehensive technical guide provides detailed information about fuel dispenser machines for educational and professional purposes. Always consult with certified technicians and ensure strict compliance with local and international regulations, including OSHA, EPA, ATEX, and UL standards when installing, operating, or maintaining fuel dispensing equipment. Regular training, inspections, and adherence to safety protocols are essential for optimal and safe operations.

Reference Sources

1. Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

2. Automatic Vehicle Fueling System using PLC Controlled Robotic Arm

Frequently Asked Questions (FAQs)

What is the purpose of the fuel dispenser machine in the petrol pump?

A fuel dispenser machine used in the petrol pump is to dispense fuel into automobiles’ tanks, thus guiding petrol and diesel toward their motionless discharge. It is installed inside service stations and is equipped with a nozzle that allows the customers to fill up their tanks in ways that are known to ensure that the accurate quantity of fuel dispensed is metered.

How do the fuel dispensers and pumps work, for example?

Fuel dispensers are essentially the pumps themselves. The fuel dispenser and pumps are usually engaged through a water-fueled pumping system, which consists of pumps with valves, drawing the fuel from an underground storage tank and sending it right to the nozzle. This machine is set to compute the volume of fuel being dispensed as soon as the nozzle is switched at its opening. An indicator would then open in digital form, revealing what amount of fuel being dispensed in this current purchase.

What are the different types of fuel dispenser options that can be availed?

The fuel dispensers come in several types, and the above are gasoline, diesel, and LPG dispensers. Each dispenser model is made for the specific kind of fuel type it dispenses, and it may or may not contain features like nozzles that can prevent spillage and enhanced flow rates for more efficient dispensation, respectively.

What is the price range of fuel dispensers?

The manufacturing and pricing of fuel dispensers can vary, ranging from basic to the most developed type available in the market. Generally, an automatic gas pump machine can cost from a few thousand to about ten thousand USD, depending on the producer and the specific features. The features mentioned in their machines are the ones presented in the models of Gilbarco Veeder-Root.

Why Gilbarco Veeder-Roots’ range of fuel dispenser machines is for you?

Gilbarco Veeder-Root has an excellent reputation for delivering the foremost accuracy and reliability within the industry. Their constructions for dispensers indicate that they are long-lasting, facilitating the consumable aspect of fuel dispensing and thereby making them the obvious choice among fuel dispenser suppliers.

What features should I look for in a fuel dispenser?

Make sure your fuel dispenser has an automatic shut-off nozzle, real-time fuel monitoring, compatibility with POS systems, along an uninterrupted supply of fuel flow to improve the level of service during busy hours.