The gasoline nozzle plays a crucial role in the fuel delivery system, providing a link between the fuel pump and the vehicle’s tank. On the face of its appearance, the nozzle may seem like a simple tool; in actuality, the modern-day gasoline dispensing nozzle comes augmented with a good deal of high technology in pursuit of refueling efficiency, safety, and precision. This study provides an account of the design, functioning, and substantial applications of gasoline nozzles in establishing the framework for manufacturers accommodating different fuel types as well as observing relevant state- and federally-required standards and upholding user-related esthetics. With many years of experience in the petroleum industry, the engineer will never cease to investigate. This work has looked at the role of the fuel-pump nozzle in the system and its integration into the modern fueling system.

Introduction to Gas Dispenser Nozzles

Regarding the fuel delivery system, the gas dispenser nozzle is a vital component and its main function is to transfer fluid safely and cleanly from the pump into the tank of the vehicle. It is equipped with mechanical components to increase the accuracy of the fluid flowing, leakage control, and vapor emission control. Modern gas dispensers are usually equipped with automatic nozzles that shut off flow when the tank is full, thereby preventing overflow. The nozzles’ sturdy design allows them to withstand the rigors of frequent filling and long-term exposure to different fuel types, thus meeting safety and regulatory requirements. Those are the properties that make gas dispenser nozzles the very soul of the fuel dispensing system’s reliability and safety.

What is a Gas Dispenser Nozzle?

The gasoline nozzle is the crux of a petrol dispenser, meant for the correct transfer of fuel from the storage tank to the tank of the vehicle safely. It comprises a spout, a handle, and a trigger mechanism, which are further inbuilt with essential technological enhancements such as the automatic shut-off system to prevent and avoid overfilling and discharge. Most modern nozzles have a vapor recovery system to mitigate emissions and environmental hazards. Nozzles are made of strong materials that are meticulously sized to handle repeated use, surviving all potentially corrosive actions of various fuels. This sturdy treatment helps the fuel nozzle last longer and function with stability. Installation of such a fuel nozzle is a mandate for safety, also, as standards of quality and safety regulations to which it has been put need to be strictly followed in each instance in this chain of fuel supply.

Importance of Fuel Pump Nozzles

The fuel pump nozzle is a crucial apparatus in the energy, industrial, and transportation sectors since it functions as a means of providing safe, efficient fuel transfer from a storage tank into any motor vehicle or machine. These efficient, mass-produced fuel pump types have an excellent shutoff mechanism and minimize the dangers of overfilling and fuel spillage. The fuel pump nozzle fuels the vapor recovery system, designed to reduce hydrocarbon emissions and improve environmental compliance and air quality. Built from high-strength and rust-proof materials, they ensure heavy usage and hard conditions with excellent reliability. By undertaking these nozzles under strict guidelines to adhere to statutory standards as promulgated by the EPA and other authorities, these fuel pump nozzles promote safety to the user and enhance efficiency as sustainable operation within the fuel distribution market. Thus, its role is fundamental in compounding a fuel-efficient economy and maintaining high environmental standards in a growingly concerned industry.

Types of Nozzles Used in Gas Pumps

Gasoline pump nozzles differ on a similar design, utility, or application basis. This ensures that the nozzle can be directly compatible not only with various fuel types but with different systems as well. Various kinds of nozzles are discussed below:

Automatic-stop type of nozzles

They have notches for a sensor. When gasoline starts to back up from the tank’s fullness condition, the valve stops everything on its own accord. Accordingly, chances for spillage are considerably minimized; hence, a great standardization feature at the stores for user safety.

Vapor-return nozzles

To limit environmental pollution, vapor-return nozzles intercept fuel vapor upon refueling and direct vapors back to the storage system. This is a good method of recovering hydrocarbons and ultimately harmonizing the environment with so many set regulations pertaining to that.

Wide-nozzle, or heavy-duty

Popular uses of heavy-duty vehicles, mainly truck driver refueling, require various industrial services, and the nozzles designed to accommodate heavy-duty vehicles fill the bill for this need, achieving a higher consumption rate to reduce refueling time as well as to assist in small spare time outlets for truck drivers.

These nozzle industries have been meticulously organized around industry requirements and today adhere to statutory confines to become effective and manage environmental issues.

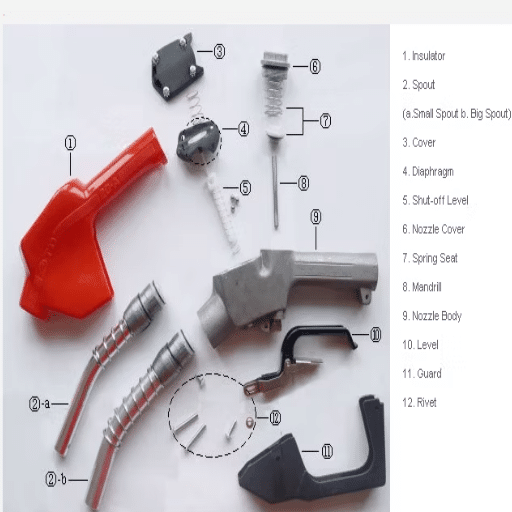

Components of a Fuel Pump Nozzle

Nozzle body: The primary cast section that houses all internal components and provides a framework for the flow and distribution of fuel.

Spout: The elongated tube through which fuel is delivered to the fuel tank of the vehicle to fit tightly and prevent spillage.

Valve mechanism controls the flow of fuel through the nozzle and allows filling to be more precise-start and shut off with each fill.

Safety Shut-Off System: It is there as an automatic system that stops the flow of fuel when the tank is full, and the danger of overflow prevents otherwise uncontrollable sources of lit flammables from causing an explosion.

Trigger Lever: The user-operated handle activates fuel flow and provides control during the refueling process.

Seals and Gaskets: They function to maintain a secure connection seal between the nozzle and the fueling system to prevent any leakages.

Swivel Connector: Swivels promote free movement and thereby minimize kinking and twisting of hoses in offering improved ergonomics.

Each one of these parts is crucial to the efficiency, safety, and dependability of the fuel pump nozzle.

Understanding the Hose and Spout

These components are very common to a fuel dispensing system, with a purpose designed to facilitate the safe, efficient transfer of fuel. Quality is the soul of the hose made up of heavy-duty materials, for example, reinforced rubber or thermoplastic, capable of resisting high pressures and various fuel types; therefore, minimizing chemical degradation. Flexibility and sturdiness do promote long-term service, keeping an open mind to the variety of fueling situations.

Now, the metallic spout is all about precision during fuel dispensing. The physical dimensions pertaining to the feed system have been heavily regulated so that a certain diameter of the nozzle is made standard, so that it is safer against misfueling situations. Typically, modern nozzles only come with a vapor recovery system for the purpose of catching bad emissions during refueling to be ever so friendly to the environment. Working as an elaborate system, the hose, accompanied by the spout, guarantees efficient flow by complying with safety and environmental regulations.

Functionality of the Handle and Automatic Shut-off

The fuel nozzles handle caters for a trigger mechanism to manage the flow of fuel. When the trigger is squeezed, it thus opens a valve to allow fuel to pass through the spout. An important safety mechanism is the automatic shut-off. This system is built to prevent refueling overflows. It works with the help of a small sensing hole located towards the terminal end of the spout. Here, any change in pressure is detected. A vacuum is created as soon as the fuel level within the tank impedes the airflow to the sensing hole. This vacuum then triggers mechanical action within the valve of the nozzle, such that the fuel lean will cease instantaneously. In summary, a combination of manual control and automatic shutoff creates an entire system to ensure accuracy and decrease waste, and it also increases customer safety while adhering to the strictest operational standards.

Role of the Swivel in Fuel Transfer

An important feature in the efficient handling, durability, and ease of use in a fuel transfer system is the swivel. This, how it works in a way as to let the fuel nozzle rotate freely without causing any harm to the hose, is especially significant in the service area energetic enough to fuel a rond-point station. By eliminating stress on the hoses, the swivel stops kinking and thus minimizes wear and therefore extends the life of the equipment. Rotation enables greater visibility for the user as well as higher flexibility in usage; consequently, less fatigue and more accuracy. The most frequently used manufacturing materials for this component are among the strongest ones available, such as stainless steel or aluminum, in order to resist exposure to acids and pressure changes while providing durable and safe performance.

Types of Fuel and Their Nozzle Requirements

| Fuel Type | Nozzle Requirements | Key Features |

|---|---|---|

| Gasoline | High-speed dispensing nozzles | Devices aimed at safeguarding against overflow conditions |

| Diesel | Larger bore diameter nozzles | Handles higher flow-volume and viscosity requirements |

| Ethanol-Blended Fuels | Corrosion-resistant components | Designed to counteract ethanol’s corrosive properties |

| Compressed Natural Gas (CNG) | High-pressure-rated nozzles | Pressure regulators and anti-leak systems included |

| Kerosene | Nozzles with fine filters | Used for heating processes and small engine applications |

Gasoline

Nothing is more important in the gasoline dispensing business than speed in dispensing quantity. To achieve this, high-speed nozzles are used, often complete with devices aimed at safeguarding against overflow conditions.

Diesel

Diesel nozzles typically have larger bore diameters when compared to gasoline nozzles owing to the different fuel-inlet specifications of diesel vehicles; due to this, it becomes more difficult to misfuel. They are constructed to withstand the higher flow-volume requirements that can occur due to the diesel fuel’s larger viscosity.

Ethanol-Blended Fuels

Special nozzles are required for ethanol-blended fuels that contain corrosion-resistant components to counteract ethanol’s slightly corrosive side and give durability.

Compressed Natural Gas (CNG)

CNG should be connected to vehicle tanks using nozzles with high-pressure-rated and securely fit to them. Pressure regulators and anti-leak systems are also put in place over the safety nozzles.

Kerosene

To withstand impurities, kerosene nozzles are often attached to the tip of fine filters, so they can be utilized for heating processes and applications of small engines.

These nozzles are all crafted to comply with unique fuel flow requirements to guarantee safety, efficiency, and uphold industry regulations.

Gasoline vs. Diesel Nozzles

Gasoline Nozzles

- Smaller diameter design

- Compatible with narrow fuel fill necks

- Prevents misfueling

- Includes vapor recovery systems

- Designed for lower-pressure systems

- Reduces emissions effectively

Diesel Nozzles

- Larger diameter construction

- Fits wider diesel nozzle necks

- Prevents cross-contamination

- Built for higher viscosity fuel

- Handles higher-pressure systems

- Designed for durability

The structure and functioning of gasoline and diesel nozzles are fundamentally divergent because of the different characteristics of the fuels they serve. In respecting the specific nature of gasoline requirements, gasoline nozzles are normally smaller in diameter to be compatible with the relatively narrow necks of gasoline fuel fills in gasoline cars, which minimizes the chance of misfueling. Oppositely, diesels tend to have a larger diameter as this has to coincide with the wider nozzle neck for the diesel vehicles, thus providing an added step to prevent any form of cross-contamination.

Because of their typically higher pressures, diesel fuel systems ensure diesel nozzles are designed to cope with that high pressure, which distinguishes them from gasoline systems. Moreover, gasoline nozzles frequently have vapor recovery systems in place to reduce emissions, while diesel nozzles are built bearing in mind how tough diesel fuel can be in view of its higher viscosity.

Both nozzles are engineered to ensure optimal safety and efficiency, but differences within their respective construction styles and specific purposes make them compatible with the gasoline systems. Conforming to the use of the correct nozzle is not only a regulatory requirement, but it is also necessary for the proper functioning of your engine and for avoiding expensive repairs.

Specialty Nozzles for Biodiesel and B20

Special nozzles produced for biodiesel and B20 blends indeed bear the mark of engineering to withstand the fuels’ peculiar properties, like high viscosity and susceptibility to moisture surges. Many of these nozzles consist of some stainless steel marking as a contribution towards solid resistance against corrosion courtesy of biodiesel’s specific chemical constitution. Moreover, seals and O-rings also have compatibility with biodiesel chemical composition, preventing decomposition over the course of time.

Manufacturers make certain nozzles maintain accuracy in flow rates and spray patterns to ensure the cleanest combustion and minimal gas emissions with biofuels. The designs must comply with dispensing standards and regulations for safe and most efficient utilization. Choosing the correct nozzle for biodiesel or B20 systems is essential for long maintenance-free periods as well as acceptable performance of the engine and dispensation systems.

Unleaded vs. Standard Fuel Nozzles

The difference between unleaded and standard fuel nozzles lies in the design and purpose, in the main. Unleaded nozzles typically have a narrower-diameter nozzle that will fit into the narrow filler necks of vehicles designed for unleaded fuel, thereby ensuring compatibility and preventing misfuelling. These nozzles also usually have a vapor recovery system to reduce emissions and comply with environmental standards.

Conventional fuel nozzles, suited for diesel or leaded petrol (where applicable), have larger spouts that do not fit into the filler necks of cars needing unleaded fuel, which acts as a safety against both cross-contamination and guarantees the vehicle gets the proper fuel. These nozzles are designed to cater to specific flow rates and operating pressures. On the other hand, the brass spouts of the unleaded nozzles are designed to meet the requirements of modern fuel standards and emissions, while the other will be for heavy-duty applications, such as diesel fueling systems. Proper selection and use of nozzles will reduce maintenance requirements and enhance equipment efficiency.

Safety Features in Gas Pump Nozzles

Gas pump nozzles have specific built-in features for safety to prevent accidents and allow the fueling process to operate properly. A very vital function is the now mandatory cut-off feature, which stops the flow of fuel when the gas tank is almost filled in order to prevent spillage and overflow. Moreover, they may also have vapor-control systems that effectively reduce air pollution by capturing fuel vapors during the dispensing process. Breakaway couplings are designed to disconnect the nozzle in the event it encounters excessive force, effectively protecting the unit from damage or even the spill of gasoline. These features collectively promote the safety of users and the environment and confirm the reliability of gas refueling.

Auto-Shutoff Mechanisms

The auto-shutdown device is a vane in the filler pipe that operates purely by vacuum-inlet pressure. A vacuum is required to travel together with the fuel as it is sucked into the tank. In the case of the usual car-filling station-filling mouth, a little air will flow freely under the vacuum while getting sucked into the gasoline tank, holding it compressed, and then the tube is gurgling (fuel). This vacuum is characteristic of the increased pressure inside the gasoline tank. This phenomenon triggers the nozzle’s internal diaphragm, which will close, so fuel will not be able to flow (an invention to be recognized always by security as a safeguard to keep fuel from overflowing the tank against all incidents, should the seal be good). In varying ambient temperature conditions or on hot and high-fill-rate days, some weather-related interference may bring about awaiting some judgments, but then, the devices are durable and do well in whatever working environment because of their simplistic construction and fit performance in fueling environments of all kinds, despite the engine fuel being high- or low-grade.

Pressure Control and Its Importance

Pressure control is an essential aspect of many diverse industries, such as the automobile, chemical processing, and aviation, to guarantee safety, efficiency, and reliability in fluid systems. A proper pressure management ensures that the equipment is always in control, thus averting the dangers of over-pressurization that could lead to equipment breakdowns, leaking, or being unsafe. As a result of this, our pressure control apparatus mollifies energy waste through its steady throughput at constant degrees and minimizes losses that would otherwise take place due to undue pressure transients.

Inventing pressure control system technologies would give a way to a regime that stands by a combination of components that include regulators, relief valves, and controllers that constantly readjust pressure dynamics in response to signals received by the systems. Regulators keep pressure values within certain constraints, relief valves behave as guardians against the emission of excess pressure, while controllers are highly responsive through feedback. These not only act on behalf of the infrastructure but also improve operational efficiency and the life of equipment.

Controlling pressure with precision has an irrefutably pivotal impact in terms of conserving the ecosystem; control eliminates – or at the very least minimizes – risks attributable to gas leakage or gas emissions from pressurized systems. In a move away from the conventional ways of doing things, industries are fast-moving to automation, using advances in IoT technology. Automation has a plethora of benefits with respect to the accuracy and predictability of issues that can later snowball into critical adverse effects; therefore, the essence of employing cutting-edge technology in modern-day pressure management practices.

Safety Standards for Retail Stations

Retail stations work to meet safety standards required for stable operations and to safeguard employees and customers alike. These regulations primarily concern the proper handling, storing, and dispensing of flammable fuels with guidelines from organizations such as OSHA and NFPA. Some firefighting measures comprise keeping clear spaces leading to the dispensing areas, ensuring access to a fire extinguisher, and regularly inspecting tanks and pipelines for leaks and contamination.

Electrical safety is equally imperative, warranting the need for proper grounding and the use of explosion-proof equipment in hazardous areas to mitigate fire hazards. Standard staff training is mandated lest workers be inept at handling emergencies in the face of incidents such as fuel spills and fires. Furthermore, environmental conservation should be considered. Regulations require vapor recovery systems, secondary containment for tanks, and rigorous checks for emissions to assure no harm is done to either community health or the environment around our facilities.

The safety compliance with which resultant audits are conducted regularly by the local and federal agencies underscores the imperative for continued vigilant operation in safety and environmental conservation.

Choosing the Right Nozzle for Your Needs

When selecting the right nozzle, think of three most important considerations: fluid type, flow rate, and application requirements. To begin with, ensure that the material of the nozzle is compatible with the fluid to be handled, because certain chemicals or fluids require materials that are resistant to corrosion, such as stainless steel or plastic. Secondly, one must have a flow rate to bear in mind when deciding the proper orifice size, as the flow rate significantly affects performance and efficiency. Lastly, the application-based requirement should be considered, covering spray pattern (e.g., full cone, flat fan, or mist), pressure, and the particular circumstances of use. Go by the manufacturer’s specification and, in case of uncertainty, pitch questions to a knowledgeable industry contact to guarantee the appliance’s capabilities.

Evaluating Flow Rates and Dispensing Efficiency

Flow rates, flow rate distributions, and dispensing efficiencies are so important for any distribution system that ensures it is working at an efficiency level that promises good performance. Flow rate has application in speed control of liquids, like volume per time, usually in Gallons per minute (GPM) or liters per minute (LPM); i.e., you should be able to identify the regional standards by considering the viscosity of the liquid. High-viscosity liquids may require larger nozzle sizes or higher-pressure setups.

The dispensing efficiency describes the rate of utilization of the distribution, with minimal wastage. Aspects to highlight here include proper alignment of the nozzle for droplet production, outlet pressure calibration, nozzle geometry, control within droplet size tolerances, and consistency of the spray pattern or uniform spray. It is imperative that your system meets industry-set standards concerning efficiency. Due diligence: a regular examination of the system to find worn or clogged components that might be drag-creating hotspots within the system; thus, consistent performance and efficiency will be upheld.

Finally, it is essential to match flow rates to the needs of an application, whether to irrigate fields or for industrial cooling or chemical applications. Ensure the use of flow meters and pressure gauges to observe system parameters in real-time and also modify them if needed. Referring to the operating manuals and advice from the manufacturers can throw the necessary light on the climatic handling system to be achieved accurately and efficiently.

Manual vs. Automatic Fuel Nozzles

When choosing between manual and automatic fuel nozzles, the specific operational aspects and efficiency requirements of the application come into play. The manual fuel nozzle requires continuous user control while using it, which makes the manual nozzle very simple, especially in the low-cost scenario. These could be very appropriate in applications where precision in fill levels is not a matter of concern or where there is a constant person watching over the same.

On the contrary, automatic fuel nozzles are thus built to ensure that fuel flow disallows any further fuel growth in the tank, as the measure would be visible through the fast-acting nozzles with automatic shut-off. This would automatically prevent tank overfilling during increased safety measures and almost zero spillage into the environment. Automatic EvenFlow Nozzles are efficacious for efficient and safe fuel refueling activities in scenarios with a high rate of fuel dispensing, as they help in protecting public safety and the environment greatly.”

Ultimately, the decision of selecting the right nozzle should consider the environment in which it will be operated, ease of control, and adherence to safety regulations and codes. This is also highly determinative of the overall noise level. Thus, it is highly recommended for one to look both at application peculiarities and design features to find an acceptable solution for fuel dispensation itself, performance, and return on investment.

Applications of Different Types of Nozzles

When determining the applications of different types of nozzles, I consider the operational requirements and the specific environment in which they will be required. Manual nozzles are suitable for low-flow-rate applications where direct user control is necessary, as in private fleets or in agricultural settings. On the other hand, automatic nozzles are the best for high rates of flow, such as commercial fueling stations, where other entrenched properties, such as efficiency and automatic shut-offs, are critical to avoid spillage and guarantee safety. By matching the type of nozzle to the performance requirements, I assure both that the utility property will remain intact and that the nozzles comply with the safety standards.

Reference Sources

Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Frequently Asked Questions (FAQs)

What is a gas dispenser nozzle, and how does it work?

A gas dispenser nozzle is a type of instrument located at the end of the pump hose, enabling the dispensing of fuel into a vehicle. It is usually equipped with a handle that, when pressed, allows fuel into the vehicle tank through the spout. Modern nozzles can be purchased with auto shut-off systems that will stop the fuel flow once the tank is full, thus giving you safe and efficient fueling.

What are the advantages of utilizing a manual fuel nozzle?

Manual fuel nozzles allow the user to operate the fuel flow rate accordingly, by quite literal means, due to manual operation. This is vital when doing precise fuel dispensing as per requirements, like fuelling equipment with the specific fuel quantity needed. Another advantage is the fact that it will be more reliable in comparison and won’t rely on electronic parts.

How does the function of the OPW fuel hose swivel improve performance?

The fuel hose swivel from OPW has been prepared in such a manner that flexibility and maneuverability in taking the fuel hose are made easy. The swivel prevents stains developed in the hose in the most mechanically perfect manner because it spins freely, allowing the hose to twist upon itself, and hence there are fewer bends in the fuel line, ensuring constant flow, especially at high-traffic retail sites where quick and easy fueling is needed.

What fuels pass through gas pump nozzles?

Gasoline, diesel, biodiesel, and ethanol blends like E85 fall under the capacity of what’s dispensed in gas pump nozzles. Some fuels would need specialized nozzles for dispensing, particularly those that deploy additives or call for certain modes of pressure to fill from.

Do modern fuel dispensers have safety features?

In a drip-free nozzle system, the fuel nozzle’s design plays a crucial role in fuel flow. An octagon nozzle, for example, offers a vapor-valve system that seals the nozzle shut even as the gasoline goes into the tank. This helps reduce emissions and improve overall cleanliness. Sonnet nozzles are another good example. The spout on this nozzle is curved, enabling the user to quickly drain the nozzle with the featured fuel receptacle built to take all fuel in the spout. This nozzle design decreases pollution through evaporation. Nothing comes into contact with the subject coming out of a fuel hose.

How can you choose the correct fuel nozzle when it comes to the pump efficiency?

The design of fuel nozzles, including the curve and lip shape, greatly impacts fuel delivery flow rate and efficiency. The well-designed nozzles allow for smooth and steady flow, which in turn reduces splashback and optimizes fueling. Nozzle design can govern the pressure needed for effective fuel delivery.

Which companies manufacture dependable gas pump nozzles?

OPW is among the most famous companies producing reliable gas pump nozzles, at the top in fuel-dispensing equipment. Their products are well-designed and well-equipped with a safety burner among other features, allowing their use for client confidence in performance during the whole process of fuel transfer.

- Gas Station Equipment List: Essential Fuel Station and Petroleum Equipment

- How Much Profit Do Gas Stations Make: Understanding Gas Station Profit Margins

- Understanding Fuel Dispenser Parts: Main Parts of the Fuel Dispenser

- Understanding the Profit Margin on Gasoline: Insights into Gas Station Profitability