Although siphoning gas from a car might be a methodical task in the case of emergencies, vehicle maintenance, or fuel changing, it requires proper tools, techniques, and precautions to ensure safety and efficiency. The way of siphoning gas might look simple, but it is not really so. This guide will walk you through the process of siphoning gas with minimum risks involved, and, thus, will be very helpful in your attempts to safely and efficiently. At the end of the article, you will know everything about the siphoning equipment, the techniques available, and the necessary safety precautions. This guide is published not only for unforeseen difficulties but also for occasions when you need to move fuel from one place to another.

Understanding the Siphon Process

The siphon process is a technique that utilizes gravity and atmospheric pressure as its main forces in liquid transfer from one container to another. It all starts with a tube or hose that is put into the source container, which is filled with gas, and then the open end of the hose is placed below the level of the liquid in the second (destination) container. The flow can be started by either sucking the liquid up the hose manually or using a pump. When the liquid is in motion, gravity will still pull it down until either the source container is emptied or the flow is stopped.

What is a Siphon?

A siphon is an apparatus that allows the movement of liquid from one vessel to another by means of gravity and atmospheric pressure. The liquid goes through a tube or hose which has one end immersed in the source of the liquid and the other end lowered in the container where the liquid is being transferred. The method relies on the creation of a flow that does not stop, which is accomplished by first filling the tube with liquid, thus getting rid of air and creating suction. After the siphon is set in operation, liquid flows owing to the difference in potential energy of gravity, while atmospheric pressure is the force that keeps the flow going. Siphons are frequently referred to in various practical applications, such as emptying tanks, moving oil from one place to another, or watering farms.

How Does a Siphon Work?

A siphon is governed by gravity and air pressure, which means it is able to transfer liquid between two places, provided that the liquid outlet is at a lower height than the inlet. The very first step is to create a vacuum inside the siphon pipe, which is usually done by manually pouring liquid into it or removing air with an external force. Once the siphon is working, the force of gravity drives the liquid down through the outlet while the air pressure on the top side of the liquid column provides a balancing force and allows the flow to continue. The liquid will keep flowing until the heights in the containers become the same or the flow is stopped by air entering the tube. This physical law makes the siphon indispensable in the maintenance of aquariums, in the transfer of fuel, or in case of emergency draining of water, for instance.

Common Uses of Siphoning

Siphoning is a tool that can do many things and is extensively used in different industries and applications. One of the main purposes of siphoning is aquarium maintenance, where a siphon is used to suck out the substrate and, at the same time, to extract water. Another typical use is in fuel transfer, which enables the fast and safe transition of gasoline or other liquids from one container to another without having to use mechanical pumps. Moreover, in emergencies, siphoning can be of help in draining water from inundated places or unclogging pipes. These practical scenarios demonstrate the siphon’s capability and necessity in both routine and highly skilled operations.

Preparing for Gas Siphoning

Gather the Necessary Tools

For siphoning, you will need either a siphon pump or a flexible tube that is made of a material that is good for gasoline. Check that the tube is clean and has no breaks or blockages.

Wear Protective Gear

Put on gloves and goggles to protect yourself from skin and eye contact with gasoline; it can irritate or cause serious damage.

Choose a Safe Location

Siphoning should take place in a place that has good ventilation, far from open flames, sparks, or heat sources to reduce the danger of fire or explosion.

Secure the Containers

Make sure both the source and receiving containers are solidly placed and arranged in a way that they will not spill. The receiving container should be lower than the fuel source to allow a nice flow.

Inspect Before Starting

Look at all the equipment for damage or leaks, and check that the length of tubing is suitable for the job.

By observing these stages, you can perform gas siphoning safely while following the best practices.

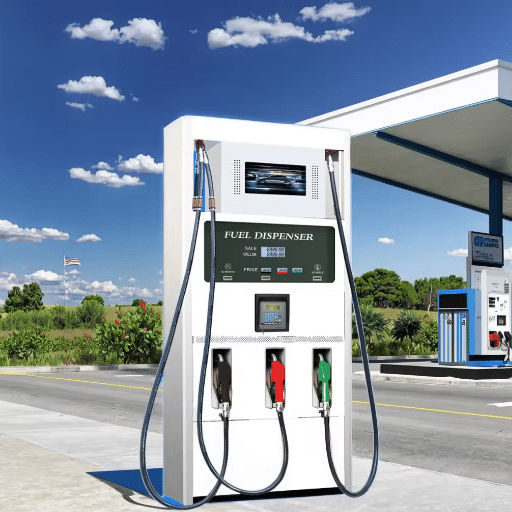

Essential Tools and Equipment

The following tools and equipment are crucial to carry out the process of gas siphoning effectively and safely:

- Siphon Pump or Hand Pump – A siphon pump or hand pump, either manual or automatic, is extremely important in transferring the fuel in a safe and clean way as well as minimizing the risk of spills or fumes.

- Durable Tubing – Clear, chemical-resistant tubing made of PVC or rubber is recommended to monitor the fuel flow and, at the same time, avoid damage to the tubing due to gasoline exposure.

- Fuel Containers – Gasoline should be collected and transported in approved fuel storage containers with proper and leak-proof lids.

- Personal Protective Equipment (PPE) – Safety gloves, goggles, and a mask will give users protection from skin exposure, inhaling fumes, or accidental spills.

- Absorbent Pads or Spill Kits – Keep the absorbent materials or spill response kits handy so that you can quickly manage any accidental fuel leaks or spills.

- Funnel (Optional) – By using a funnel, the exact amount of fuel can be transferred, which in turn minimizes spills during container pouring.

Properly used, these tools increase safety and efficiency in the gas siphoning operations, while also reducing the environmental and personal risks.

Choosing the Right Hose

It is extremely important to choose a proper hose for siphoning fuel as it will affect efficiency, safety, and durability. One should look out for hoses that are resistant to fuel made of materials such as reinforced rubber or high-grade PVC that can endure the harsh conditions and still remain intact. The thickness and the length of the hose should be in accordance with the siphoning process— usually, a thickness of 3/8 to ½ inch is good for most cases, with a length enough to easily reach between the place you are taking from and the place you are going to without twisting. Also, check for the hose to be flexible so it can maneuver easily, while at the same time, the hose being strong enough not to collapse under suction pressure. Hoses with anti-static features can be considered to reduce the chance of sparks occurring, particularly in areas where there is a high risk of fire. Ultimately, the selection of quality and compatibility with the fuel type and transfer system is the most important for safe and effective siphoning.

Safety Precautions to Consider

When siphoning substances, always follow the recommended safety precautions to reduce risks and facilitate smooth operations:

- Proper ventilation: Siphoning should be done in areas that are well ventilated in order to prevent the buildup of hazardous gases that could lead to respiratory problems or fire hazards.

- Use suitable personal protective equipment (PPE): Always put on gloves, goggles, and, if necessary, a respirator to protect from chemical exposure, splashes, or fumes.

- Do away with ignition sources: Fire hazard is minimized by keeping siphoning equipment as well as flammable liquids at a distance from open flames, sparks, and heat.

- Ensure the equipment is intact: Before using siphoning hoses and tools, check them for leaks, cracks, or any signs of wear. Using defective equipment can result in severe spills or accidents.

- Do not suck by mouth: A mouth is not a proper way to make suction, as it involves a great chance of health hazards, and the possibility of accidental swallowing or exposure to poisonous chemicals is increased.

- Properly contain and dispose of spills: Keep your spill containment materials always ready in case of accidental leaks, and make sure you follow local regulations for proper disposal of your materials.

- Know the materials compatibility: Ensure that the siphoning equipment materials can withstand the fuel or chemical being transferred to avoid breakdown or reactions.

Usage of safety precautions can prevent accidents and environmental problems while simultaneously making siphoning activities safer and more reliable.

Step-by-Step Guide to Siphon Gas from a Car

- Gather Necessary Equipment: A clean siphon or hose designed for fuel transfer and a container for gasoline storage that is recognized as suitable should be the first things you acquire.

- Locate the Fuel Tank: Open the vehicle’s fuel cap and have access to the fuel tank. Cars must be parked in a safe manner on level ground with the engine off.

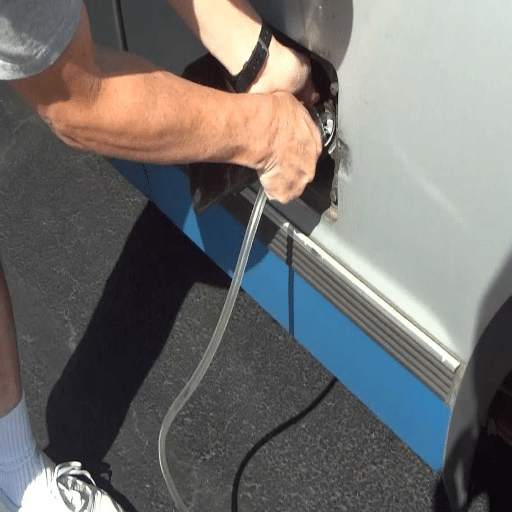

- Insert the Hose: Take one end of the siphon hose and put it into the fuel tank, but do it very carefully so that it reaches the fuel.

- Position the Container: The fuel container is to be placed at a lower level than the fuel tank so that gravity helps the siphoning process.

- Initiate the Siphon: If you have a pump mechanism, then use it to relatively fast transfer the fuel. If it is a manual siphon hose, then very slowly and carefully create suction to start the flow.

- Monitor the Transfer: The transfer must be monitored, and make sure that there is a constant flow of fuel into the container without spilling or overfilling.

- Stop the Flow: Once the required amount of fuel is moved, take the hose out of the container first, then the tank, so that there are no drips or spills.

- Seal and Store: Make the container with the fuel airtight and put the vehicle’s fuel cap back on.

- Clean Up: The tools and any surfaces that have been in contact with gasoline should be wiped, and your hands should be washed thoroughly.

Important Note: Siphoning fuel is subject to local laws and environmental regulations, so be sure to follow them. This method should only be used for legitimate purposes and not in unauthorized or unlawful situations.

Step 1: Gather Your Supplies

Before starting the process, make certain that you have gathered all the necessary tools and equipment. A siphon pump or a hose that is appropriate for transferring fuel, a clean and sealable fuel container for the gasoline, and, if needed, a funnel for precise handling of gasoline will be required. You might also need to use gloves and safety glasses, depending on your situation, to protect yourself while working with dangerous substances. Check your siphon pump for proper operation and ensure your fuel container meets the safety standards for storing gasoline.

Step 2: Position the Hose Correctly

Take your time to get the end of the hose or siphon pump that is to be used for gasoline extraction into the source accurately, and make sure that it comes to the bottom so that you can draw off the largest quantity of fuel. The other end should be placed in the container for fuel so that no spillage or overflow occurs. In case of siphon pump usage, make sure that the pump mechanism is working properly before starting the transfer. Moreover, it is important to clear the hose of any kinks or blockages so that a good flow is maintained. Correct positioning not only reduces risks but also enables a clean and controlled transfer, which is the main point of the operation—safety and accuracy.

Step 3: Initiate the Siphon

To initiate the siphoning, first check that all the couplings are tight and the siphon is set in the right way. If you have a manual siphon pump, just keep squeezing or priming the bulb until you get suction and the liquid starts flowing through the hose. In the case of gravity-fed systems, make it a point that the source container is higher than the receiving container, thus letting gravity do the transfer easily. Always keep an eye on the flow to ensure it is constant and no air bubbles are present to interfere with the siphoning. If you are using an electric pump, turn it on and stay by it to check that it is working correctly. Taking the occasional check during the process period lowers the risk of leaks or spillages, thus making both efficiency and safety a priority.

Alternative Methods for Fuel Transfer

Manual Pumping

The hand pump system is a manually operated pump for transferring fuel. It’s nothing complicated, easily movable, and particularly if the electricity is cut off in the area, you will never have to be without the pump. Just confirm that the pump can work with the fuel to prevent damage to the pump or filament contamination.

Gravity Feed System

The gravity feed system works by putting the source tank higher than the receiving tank. This method uses gravity as the only force for the transfer, and therefore, no extra equipment is needed. It’s easy to set up, but monitoring carefully is a must in order to prevent spilling.

Electric Pumps

Electric pumps are super efficient and great for transferring huge amounts of fuel. They are automated, and their flow rates are steady, which means less work for humans. Such systems are for industrial or high-demand applications, but of course, the electric power supply is a must.

Squeeze Bulb Transfer

The channel of the squeezing bulb allows you to move small amounts of fuel by hand. The technique can be used effectively for very limited quantities, like fueling a small engine, but it is not recommended for larger cleaning jobs, as it would be less efficient.

All methods, anyway, should be selected according to the fuel volume, the resources available, and the specific operational requirements. Always put safety precautions and compatibility checks first, no matter which method is applied.

Using a Siphon Pump

A siphon pump is a great device for transferring liquids, even fuel, with good performance and safe usage. The method goes like this: the liquid flow is controlled from the higher position to the lower one using a flexible hose or tube that is flexible, and with gravity helping the flow once it is started. To work with a siphon pump:

- Container Placement: Make sure the container with the liquid is higher than the one receiving it so that the flow can be by gravity.

- Pump Priming: Based on the siphon pump type, either manually compress the built-in bulb or fill the tubing beforehand with the liquid to get the movement started.

- Transfer Supervision: Keep a steady connection and supervise the transfer to stop any overflow or air entry that can disturb the flow.

- End the Process Safely: Pinch or shut the tube to cut off the liquid, and at the same time, be careful so that no fuel is spilled in the process of moving it.

This method is perfect for intermediate-sized liquid transfers, especially when there are no electrical or heavy mechanical methods. It is very important to check if the siphon pump is compatible with the liquid you are transferring and to always follow the safety rules strictly in order to reduce the likelihood of problems like spills, contamination, or exposure to toxic fumes.

Utilizing a Manual Siphon Pump

A manual siphon pump works by generating a vacuum or pressure difference that makes it possible to transfer liquids from one container to another. In order to get the most out of a manual siphon pump, first of all, make sure that the pump’s materials will not be adversely affected by the liquid that is being transferred – this is especially crucial for corrosive or hazardous substances. Next, place the pump’s intake tube into the source container and the output tube into the target container, positioning the source container higher than the target container for the best flow.

The pump mechanism should be activated, usually by squeezing a bulb or using a hand lever, to start the flow of liquid. If you keep the pump going constantly, you will get a continuous flow; however, once siphoning has started, gravity will do the rest with barely any input on your part. Always check the flow rate and make adjustments if needed. When done, gently take out the tubes and put lids on both containers to avoid leaks. Cleaning and regularly checking seals are some of the maintenance activities that, if carried out, would prolong the life of the pump and also make it more reliable.

In addition, it is good practice to use the pump in a well-ventilated area when dealing with volatile liquids and to wear gloves and goggles while handling hazardous materials. A combination of good technique, the right tools, and safety precautions will make liquid transfer processes run efficiently with very little to no risk involved.

Battery-Powered Pumps for Convenience

Battery-operated pumps have been changing the liquid transfer processes by providing portable and effective solutions to different industries. They run on rechargeable or non-rechargeable batteries, thus doing away with human operation or electric plugs. These pumps are perfect for transferring liquids like water, fuel, chemicals, or oil, and they are made for comfort and practicality.

The major benefits of battery-operated pumps are their lightness and compactness, which make them highly mobile and easy to store. Most models come with a very simple operating system that sometimes has a single push button for operation, thus making them suitable for both experts and the inexperienced. Also, the high-end models come with safety features such as an automatic shut-off that prevents overflows or leaks during operation, which is quite safe.

The battery-powered pumps are very versatile and can be used in a wide array of applications, like changing car fluids, carrying out field work, taking care of fish tanks, and transferring fuel to machines. The use of top-notch materials in their making guarantees the longevity of the pumps, while their modern counterparts are energy efficient and thus, battery life is prolonged for longer periods of use. Thus, this pump category marks a big milestone in the creation of innovative and dependable liquid transfer tools that are efficient.

Safety Tips for Siphoning Gas

- Use Proper Equipment: Always rely on a siphon pump, which is specifically made for gas transfer, in order to prevent any accidental spills or inhalation of toxic gases. Never attempt to siphon liquids by mouth since it may lead to severe health complications.

- Work in a Well-Ventilated Area: If necessary, do the siphoning in open air or in a room that has good airflow to avoid the accumulation of bad air that might harm your health.

- Eliminate Ignition Sources: Turn off all the lights, and keep away from anything that can create sparks or heat. Gasoline vapors are very volatile and might catch fire in no time.

- Wear Protective Gear: Always wear gloves and safety goggles to reduce the risk of skin and eye irritation from gasoline, which could be very painful.

- Prevent Spills: Set up a sturdy container for receiving the gas you have siphoned off and ensure that you do not fill it up completely. As soon as a spill occurs, clean it up and put away the wipes or towels that were used for the cleanup appropriately.

- Follow Local Regulations: Be sure to check and comply with all the local statutes and directives related to the storage, movement, and discarding of gasoline. It is not only a matter of safety but also of legality.

The above-mentioned precautions will allow you to work with gasoline in a safe manner that will not endanger health and the environment.

Preventing Spills and Accidents

In order to prevent spills and accidents during gasoline handling, it is necessary to follow safety guidelines and best practices. Use only approved containers for fuel, which are clearly labeled and designed to prevent leakage or spillage. Containers should not be overfilled; they should have an appropriate air gap for fuel expansion. Gasoline should be stored cool and well-ventilated, far from the sun’s rays or any possible fire sources. Whenever fuel is transferred, make sure that the container and the tank receiving it are both grounded to avoid static discharge. Besides this, keep the working area tidy by cleaning up spills immediately with absorbent materials and disposing of them according to local hazardous waste management regulations. Storage containers and transferring tools must be inspected regularly as part of safety measures to further reduce the chances of accidents. These measures, when taken, will significantly decrease risks related to personal safety, property, and the environment.

What to Do in Case of a Spill

In the event of a spill, my first step would be to evaluate the situation right away in order to protect myself and others. I will create a barrier around the affected area to keep unauthorized people away and also determine what the spilled substance is. I will use absorbent materials to contain the spill and make sure it does not go to the drains or the waterways, wearing the proper personal protective equipment (PPE). I will then report the incident to the right authority, who will have been designated, and the waste will be disposed of according to the relevant local hazardous waste regulations. Lastly, I will record the incident and hold a debriefing to find ways of avoiding the situation in the future.

Proper Disposal of Used Fuel

The correct disposal of used fuel is a must that will eliminate environmental contamination and guarantee safety. First, used fuel should be kept in an approved, labeled container that is not leaking and is intact. Fuel should never be disposed of illegally by pouring it down the drain, sewer, or on the ground, since that can severely damage the ecosystems as well as contaminate the water supplies. Rather, locate hazardous waste disposal facilities or recycling centers nearby that are allowed to process used fuel. In addition, many auto repair shops or community collection programs take used fuel for proper treatment. It is important to adhere to all directives of federal and local environmental agencies to ensure that legal as well as environmental standards are respected, thereby reducing at the same time the risks to human health and the environment.

Reference Sources

Frequently Asked Questions (FAQs)

Fuel transfer pump vs hand pump: which is the most efficient gasoline transfer method?

A fuel transfer pump (manual or electric) or a portable transfer pump kit is usually more efficient for fluid transfer than merely using a siphon hose and mouth suction. To transfer fluids, electric pumps and battery-powered units provide a constant flow and are applicable to car, generator, or diesel tanks. Hand pump options are good as a straightforward, dependable backup and stop the risk of drinking gas; pick up a transfer method that is leak-resistant and has a nozzle or valve for controlled delivery into gas cans or a portable fuel container.

Fuel line and filler neck: how do I insert one end correctly?

Insert one end of a clear hose or siphon hose securely into the filler neck or directly into the fuel tank so it reaches the bottom of the tank to access enough gas. The other end should be inserted into a gas container with a secure nozzle or rest to avoid spills. If the filler neck is narrow, use a long hose or a siphon tube designed for the task; ensure the connection is tight and the hose stays below the tank to maintain flow.

Siphoning gas safely: what safety gear and precautions should I use?

Always wear gloves, eye protection, and keep a fire extinguisher nearby in case of fire. Work in a well-ventilated outdoor area away from flames or sparks, and do not smoke. Use a transfer pump kit or anti-siphon devices that reduce fumes and prevent spills, and keep a spill kit and absorbent materials on hand. Proper safety gear and safe operation significantly reduce risks during emergencies or routine fluid transfer.

Dealing with anti-siphon devices: Can I still get gas out of the tank?

Many modern vehicles have anti-siphon devices in the fuel tank or filler neck to prevent theft. These devices can block a simple siphon hose, but can sometimes be bypassed legally and safely by using a portable pump or an approved transfer pump kit designed for automotive use. For vehicles with integrated anti-siphon valves, consult the owner’s manual or a professional to avoid damage and to ensure safe, legal removal of fuel.

Diesel or petrol: are there differences when siphoning different liquids?

Yes. Diesel and petrol (gasoline) have different viscosities and odors; diesel is less volatile but still flammable. Use a clear hose and a pump rated for the specific liquid (some pumps are labeled for diesel or petrol). When transferring diesel into gas cans or a generator tank, ensure filters and nozzles are compatible and that the pump reaches the bottom of the tank to draw enough fuel. Clean the hose thoroughly between different fuels to prevent contamination.

Emergencies: how to transfer fuel to a generator or reach a remote fuel tank?

For emergencies, keep a portable fuel container and a transfer pump kit or a battery-powered pump on hand so you can perform an efficient gas transfer without delays. Use a long hose and nozzle to reach from the gas tank to the generator’s filler neck, secure the gas container on stable ground lower than the fuel tank, and operate the pump portable unit or hand pump for safe operation. Make sure the setup prevents leaks and that you have enough gas for the task.

Common mistakes: How do I avoid putting gas in my mouth or creating spills?

Never use mouth suction to start a siphon — this risks ingesting petrol or diesel and inhaling fumes. Use a manual or electric pump, transfer pump kit, or a siphon hose with a built-in valve. Avoid hoses that are not chemically compatible, do not overfill gas cans, and always use gas cans rated for fuel storage. Securely fasten hoses, watch the flow of gas, and stop pumping when gas begins to reach the receiving container to prevent overflow and contamination.