Ensuring that a vehicle’s tires are inflated to the correct pressure is crucial for both vehicle safety and efficiency. What many people do not realize is that at the core of this process, there is one piece of equipment which makes it all possible – the gas station air compressor. These are the ever-present helper devices all drivers have an obsession with, as they offer a fast and reliable way to inflate spare tires to the correct pressure. This paper aims to bring out the significance of gas station air compressors in terms of their working mechanism, salient characteristics, and their importance in the general upkeep of vehicles. It doesn’t matter if you have been driving for many years or have just gotten your license; knowing these devices could help you become a better driver in terms of taking care of your vehicle.

Understanding Air Compressors at Gas Stations

To increase safety and fuel economy by controlling and maintaining the required tire pressure, there are numerous gas station air compressors. Their designed features enable drivers to inflate their tires until a particular PSI/pounds per square inch is achieved, which enhances vehicle performance. They usually contain a pressure gauge, hose, and controls to set and/or check some desired tire pressure. In the case of its usage by drivers, they will simply put the nozzle onto the tire’s valve, adjust the required pressure, and switch the compressor on, which inflates the tire. Since sustained correct tire pressure enhances tire durability and enhances stability, air compressors can be handy during the normal maintenance of vehicles.

What is a Gas Station Air Compressor?

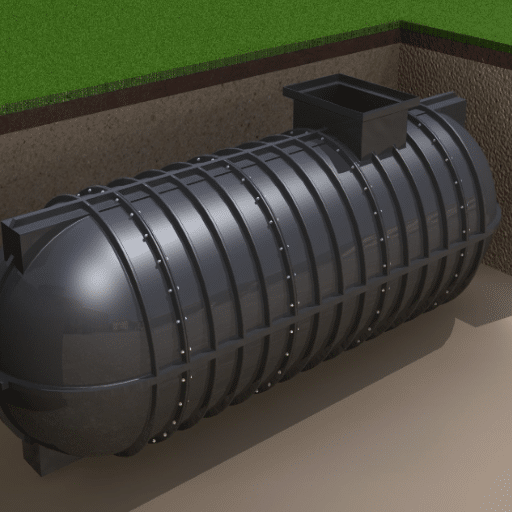

An air compressor at a gas station is used solely for the purpose of inflating a flat tire or any other object that needs pressing. These machines can work under two systems, which either ask the user for a token to operate or are free based on the policies of individual stations. The coin-operated air compressors in filling stations have features like strong hoses, a meter, and an adjuster to accommodate the required tire pressure set of a customer. These compressors air into the machine and compress the air to the required pressure and supply it through a long tube through which the end user receives. The majority of these machines are equipped to read and build up pressure to ensure maximum tire care is observed for the purpose of safety, energy conservation, and optimal performance.

Types of Air Machines Available

In general, gas station air compressors can be grouped into three major types that serve particular functions:

Electronic Air Packers

Think of a dotted line cutting through a white screen where a driver attempts to fill a car tire on the left with compressed air. That is the virtual environment digital air machines provide. They offer a digital control panel display that helps on determining the pressure in a tire for correct adjustment. Most of them have several programs that allow for setting the required pressure level in the tire in order to provide a self-stopping process of air supply. This is for vehicles that have contemporary inflation norms.

Hand-Pump Air Packers

Gas station air compressors and tires can present their users with a different approach to monitoring and inflating the tires. While there is nothing very modern about these machines, they are still in use because of the issues posed by the other, more modern designs. As the user makes a turn in the knob or lever, at the same time, a gauge observes the pressure to make sure it is the correct setting needed. In such systems, older gas stations and places where advanced facilities are scarce would have more users of such systems.

The Vacuum Blower and Air Blower Blower Vacuum Systems

These combination units enable the inflation of the tires and the cleaning of the interior of the vehicle using a single machine. These kinds of systems are very useful to clients who seek to do more than one maintenance job at a time and in the same place. It is for this reason that although their air compressor-like technologies may not be as accurate as the standalone digital compressors, they have taken root in such places that require a lot of services or stations that provide full services.

Gas station air compressors are not all the same. Different models come with different levels of functionality and efficiency as well as a price tag, and gas stations make a choice based on the assistance technology, at the same time, the number of customers to be served, and the efficiency of service in terms of maintenance. This allows users to have access to the most appropriate tools for looking after the tires on their vehicles.

How Do Air Compressors Work?

Air compressors operate by changing the power into kinetic energy towards gassing up the air, employing several strategies. The general procedure in use has a motor that compresses air into a container with the help of a piston or rotary section. When the capacity in the container is attained, the compressor goes off without releasing the air, which is useful for future purposes. Through the process activities, there is a release of compressed air from the container using a valve, and working tools and equipment are engaged using the air energy produced. Among the positive displacement types are the reciprocating piston compressors, and among the dynamic types are the centrifugal compressors, with each type aimed towards meeting industrial, commercial, or even leisure needs. Realistically, this is the kind of compressor that can be found in gas station air compressors and ambulances.

How to Use a Gas Station Air Compressor

- Find the Station that Hosts a Compressor

Begin by looking around for an air compressor station, which is normally installed around the gas station dispensers or in a specific position within the station area. Confirm that it is functional before any pre-operation activity. - Determine the Recommended Tire Pressure

This information can be found in the user manual of the car or on the sticker found on the inside of the driver’s side door. Do you know that it is given in pounds per square inch (PSI). Remember that safety as well as the ride are both compromised when the tires have more or less air than required. - Locate the Valve

Remove the valve’s cap without misplacing it. See to it that the valve lies clear of any external material to make a connection. - Use the Compressor

A token, a card, or any other form of initiating the compressor machine is called by the station. These compressors are available for a short period, check that you are working under pressure. - Fix The Nozzle Direction in The Valve

Fix the air hose nozzle to the tire valve in a secure manner. Avoid inflating the tire when you can hear hissing of the air because the tire is losing air. - Keep Track all the Gains

Monitor the PSI level on the gauge attached to the compressor, or a separate pressure gauge as required when pumping the tire pressure with air. Ensure that the inflow is reduced to prevent overinflation. - Completion and Check

After obtaining the required pressure level, do not pull the nozzle; place the valve cover well, and check for any defects within the tire. Do the same to all the tires if necessary. - Stop the compressor

Remember to turn off the compressor unit if it is necessary before you leave. This, however, applies to a few systems, as modern ones turn off automatically.

Pro Tip: Following the steps mentioned above will help you to properly inflate the tires, which look rather simple, yet so much increases the gas mileage, durability of the tires, as well as the safety elements of the car.

Step-by-Step Guide for Tire Inflation

Finding the Right Tire Pressure

Do not use the values written on the tire about the maximum PSI because this may not be what your car needs. Check the owner’s manual of your vehicle or the commonly found sticker on the inside part of the driver’s door for the correct air pressure of the tires.

Prepare Required Supplies

Make sure that you have a tire pressure gauge and an air pump. It is better to use digital pressure gauges for accuracy, but a scale type is more convenient. If you do not have any of these devices at home, you can utilize many sensors provided by gas station air compressors.

Look Out for COLD Tires while Checking

Take a measurement when the tires are cold, importantly, before driving or after any long parking periods. Driving incorporates heat and causes the tire air will increase, giving a wrong reading.

Place the Tire Gauge

Take off the cap on the tire valve and fix the pressure gauge on it. Take down the reading on the gauge. Compare the measured PSI with the recommended one to determine whether air should be added or released.

Appropriately Inflate or Deflate

In case the tires are discovered to be underinflated, one should inflate them with an air compressor. Securely attach the nozzle to the valve of the tire and conduct periodic checks with the gauge to avoid excessive inflation. In case of an overinflated tire, the central metal press-fit pin on the valve will be depressed so as to allow air out.

By obeying this particular prescribed instruction, it is possible for drivers to learn how to look after their tires properly, promoting better fuel efficiency, less tire depreciation, and, more importantly, higher road safety. These guidelines incorporate important aspects based on other top institutions.

Understanding PSI and Tire Pressure

Pounds per square inch or PSI is the basic unit used to determine the pressure present in a tread indicating the strength of the air in the tire. Proper inflation of the tire is important for ensuring effective performance, design, and fuel economy in a car. In this brief section, we shall provide quick answers to the most popular questions, such as:

How many PSI do you put in a car tire?

Generally, most passenger vehicles have a PSI of around 30-35 in the tires. It is, however, advisable to check the owner’s manual or the plaque on the driver-side door frame for precise recommended values.

Why is it important to have the correct air pressure in the tires?

In this period, it is preferable to hold correct tire pressures as the weight of the vehicle is spread evenly, increasing the tread surface wear and mileage, whereas fuel expense is also reduced. Incorrect inflation leads to more rolling resistance and reduced fuel economy, reducing control while increasing fuel consumption due to less inflation. Over-inflation of the tire can also create premature tread wear and increase rider discomfort.

How often am I supposed to check the pressure in the tyres?

If you are not aware, it is recommended to calibrate the pressures on your tires at least once every after some number of days and particularly, before embarking on any lengthy travel. This is because extreme temperatures tend to warp the tire’s measurement units due to their inability to maintain their static form during such period thus, thus the need for constant tire monitoring regardless of the weather conditions, especially with the changes in the climate.

Do changes in tire pressure adversely affect the stability of tires?

To answer that question, it was because pressure in tires directly correlates with the safety and control, that with less or more than the required quantity, the movement of the vehicle is compromised. That is why, for optimal quality as well as safety, it is always wise to ensure that the tires are filled with air up to the threshold as stipulated by the manufacturer.

This section adds valuable and up-to-date information from reputable automotive publications, reminding drivers that knowing and controlling tire pressures is part and parcel of ensuring the longevity of tires as well as improving driving skills.

Common Mistakes to Avoid

Over or Underinflation of the Tires

Probably the biggest tire-related dread measure is not keeping them and their pressure to the manufacturer’s expected limits. Overfilling them causes not enough adhesion to the ground and tends to wear the middle of the tire more, whereas, in comparison, too little air in the tire would also come with excess heat, waste gas, and make the tire abnormally worn out.

Skipping Routine Pressure Testing

A number of vehicle owners do not give enough attention to a very basic and important vehicle maintenance practice: checking tire inflation periodically. Temperature variations and pressure loss over a long duration tend to be continuous changes that cannot be easily detected, yet these can make one or both tires unsafe. One should carry out this exercise every month or before embarking on any long-distance journeys.

Leaning on the Visual Evaluation presents a Wholly Different Risk

Visual inspection in place of a good quality gauge is a bad idea because it will almost always lead to inaccurate readings. The bow forward position of such slightly above or below the range fills tires may not be consistent with bare-eyed detection, but does existing constraints.

Failing to Appreciate Load Changes on Tires

Most passengers on board will cause the liner frame to sag, and some gas station air compressors that have been fitted in the past have very low nitrogen pressure in their tanks.

Additional force due to plywood or concrete in the boot or more passengers has a profound influence on tires. Applications in which the tire pressure isn’t adjusted after the specifics swimmers up include cases that cause wear and should roll flat tires while driving.

Using Sidewall Pressure as Reference

Most drivers make the mistake of taking the maximum pressure indicated on the tire instead of the pressure indicated on the label posted in the car, specifically on the driver’s side, and this pressure promotes the tire’s performance endurance and is safe for driving.

Important: All of the common mistakes outlined above could be avoided by drivers enabling their tires to be in a good working condition, which enhances safety, the ability to drive longer distances with minimal effort, and several other factors.

The Importance of Tire Inflation

Tire checks and adjustments are one of the most important services when driving because they take care of fuel consumption and, more importantly, car and tire safety. In order to produce the best grip on the road and optimal handling as well as braking, the tire should be pumped with the amount of air that has been described by the vehicle’s manufacturer. At low tire pressure, the tires wear out non-uniformly due to the dirt layer, fuel consumption of the car goes up, and the possibility of bursting is high, whereas high tire pressure reduces traction, thus making the ride bumpy and uncomfortable. It is also advisable to make use of vehicle tire pressure principles, which means filling the tires with the correct pressure and checking using gas station air compressors where applicable.

Why Proper Tire Pressure Matters

Keeping the tires correctly inflated is imperative to prevent accidents, improve the handling of the car, and reduce fuel consumption. Tires that are filled properly will increase the contact between the tires and the road, hence enhancing the stability of the vehicle, steering response, and braking effectiveness. When tires are under-inflated, the rolling resistance is higher, which means the engine will be consuming more fuel because it works less common practice very good example of this is excessive friction that results in heat that destroys the tire. On the other hand, when the tires are over-inflated, there is less contact with the road, and this will result in less traction and grip, less comfort during the ride, and tire wear. Also, there is an impact on the load-carrying capacity; how the weight of your car is handled also depends on the tire pressure. Reducing extra costs while making sure the performance of the vehicle is at the normal high level can only happen through continuous surveys of the pressures using reliable air pressures or gauges and following the regulations of the vehicle as indicated in the owner’s manual or on the door placard.

Effects of Low Tire Pressure on Vehicle Performance

The way that low tire pressure changes vehicle performance is more serious than some would think. For instance, when the tires are not adequately inflated, the rolling resistance increases, and the engine must exert itself more. Hence, fuel consumption increases correspondingly. This is problematic because it increases fuel expenditure and is also not environmentally friendly. Low pressure is also a common cause of wear and tear around the outside of the tread of the tires, which reduces the life span of the tires and forces them to be replaced ahead of time. The loss of ten percent in pressure is enough to make handling difficult and handling particularly unstable, especially in the case of braking distances, curl curves, or even more so, wet and slimy surfaces. Apart from that, under inflation decreases the load-carrying capacity, which eventually deforms and stretches the carcass, resulting in its rupture or, in the most extreme cases, even a blowout. These dangers, however, can be minimized by adhering to a particular tire pressure-setting as specified by the manufacturers of the tires.

Convenience of Using Free Air Machines

Gas station air compressors are a common sight at many gas stations, convenience stores, and auto shops. They make it easier and cheaper to keep your tires inflated to the recommended levels. They do not compel vehicle owners to invest in any particular tools at home, since they enable precise inflation by a pressure gauge. Also, they appear along busy roads, meaning that it is possible to fix a tire during regular road use or while on a journey. This is because free air machines can improve the mileage of the car, if under- or overinflation becomes an accident in waiting, as well as a means of wearing out tires in less time than is expected.

Features of Modern Air Compressors

Quantified Pressure Distribution

Most air compressors nowadays are supplemented with digital displays that show exact readings of the pressure as a ratio of distribution, thereby helping avoid the trial and error within the inflation process.

Stop Inflation Once the Pressure Has Clamped Down On the Power Of The Wind

This special function helps the air compressor when the pressure inside the other limits, which overworks the pump.

Lights ‘n’ Carry Along

These are the latest additions to air compressors designed to relieve the users. They are machines that have simple portable systems that can enable the user to carry the machine easily at home.

Multiple Types of Nozzles

There are replacement nozzles- if you need to fill up a ball, such as a basketball or a soccer ball. This also comes with a ball, tires, a mattress, sports equipment, or more.

Silent Performance

The modernized technology made it possible to increase the sound efficiency rate to a level that would be appropriate for usage in homes or gas station air compressors.

The mid effect

Electro-mechanical motors with reduced strain and weight, thus power consumed would not exceed, and efficiency would be achieved.

PSI Settings and Adjustments

Pound Force per Square Inch (PSI) Equivalently Describes What Pressure Unit Is Derived From the Area of One Lb/In^2 Compression That One Lb That One Applied Pressure Unit Per Square Inch of Our Air Compresses in the Engineering Science field. These compressors not only allow one to inflate tires but also other objects as the need may arise. For example, passenger car tires will need to be inflated to between the range of 32 and 35 psi. On the other hand, on operation purposes, the large equipment of trucks will require compressions of something like 120 psi or more.

To modify a specific output PSI range effectively, it is anticipated that a regulator on the compressor, instead of the standby filter, will be used. Start with the guideline that is given by the manufacturer with respect to pounds per square inch. Over-inflation and under – inflation will also cause danger or lower the efficiency. Meanwhile, most compressors also have a pressure gauge so the user can check if the particular values are respected. For that reason, it is suggested to have the gauge checked regularly after a specified period of use for it and for the machine itself to function properly.

In most cases, the use of intelligent control with the assistance of water meters, available at the falling value of the temperature threshold, provides a more rapid motion throughout the working range of the equipment. Accordingly, an autonomous gas station air compressors 12V DC with a petrol generator ensuring possibility of blow off of inflation opens the entire mechanism for action. This allows hygienic cleaning of all parts of the compressor, even for non-axial applications such as sewing machines, due to the fact that additional support handles offer enhanced stabilization.

Bear in mind, however, that a majority of such compacts fail, and they can be repaired within a short period before mechanisms are expected to achieve operational efficiency, at most.

Durability and Maintenance of Air Machines

It is important that, in order for air machines to last, they have to be serviced regularly and only used within the specified operating conditions by the manufacturer. Routines such as checking for any types of damage to wearable parts, for example, seals, hoses, couplings, are a huge contribution in avoiding leakages and loss of inefficiencies. Timely greasing / lubricating the moving parts protects them from wear and also guarantees the sustained performance efficiency of these components.

Air filters also need to be cleaned every once in a while, as they can get clogged, causing the system to overwork, which eventually degrades its performance. To add to this, collected water in tanks or lines should be removed to avoid corrosion, as these components are prone to rusting. The use of thermal imaging and vibration measurement may also provide warning signals of breakdown before they become apparent.

Prioritize the use of sturdy materials, for example, those with enhanced corrosion resistance and wear reinforcement for rugged environments. Preventive measures and regular professional maintenance extend the service life and improve the reliability of pumps, reducing downtime and financial rehabilitation for damaged air conditioning systems or gas station air compressors.

Innovative Pump Designs for Efficiency

Industrial fluid machines, including pumps, have been evolving for decades now with many technological advancements, improvement of performance, and safer operations. A useful technique among these is the use of frequency drives (VFD), which control the speed of a motor for different levels of demand by the system and lowers power used. In magnetic drive pumps, no mechanical coupling elements are used, hence no chances of leakage when handling toxic substances. Other mergers include advanced impellers like back-swept or mixed flow types that have been tailored to reduce hydro losses and increase efficiency. Further, the use of CFD (Computational Fluid Dynamics) in designing has significantly reduced turbulence, thus improving the flow patterns inside the pumps. With the elemental materials, such as rocks, sand, or concrete, fuels, oils, adhesives, water, and other petroleum-based products, plastic materials, durable and high-tech resins, metal, and overlays (fabrics), and clays, new building materials and coatings, and the service life of machinery increases considerably. Using these disruptive innovations, cost-cutting measures, environmental benefits, and enhanced performance are all achievable for a given industry.

Maintenance and Repair of Air Compressors

A prime aspect related to the usage of air compressors is regular attention towards their maintenance. The most important aspects are maintaining air filters by cleaning or replacing them, examining and, if necessary, retightening internal connections, making sure there is no water in the tank; otherwise, all metallic tanks would undergo corrosion, even stainless steel ones. Moving parts have to be lubed up, bearing in mind specific timelines provided by the manufacturers, so that wear and tear due to movements is minimized. One should also ensure that check smooth levels of oil in oil rigs, as low levels of oil shorten the useful period of such compressor models.

As for faults such as a jerky or monotonous pressure build-up, overheating, or producing strange sounds, should be rectified immediately. Fix other defects that are easy to solve, for instance, check crack areas that could leak, turn off fans to clean out the filter, and if they are damaged, change relevant parts. Advanced servicing and repair works are best performed using the manufacturer’s repair instructions and only by qualified persons to avoid accidents and to maintain the efficiency of the system. Scheduled maintenance, together with the timely repair of malfunctions, increases the operational life of the machine and decreases the time taken to repair the machine in case it breaks down.

Regular Maintenance Tips for Air Machines

Examine and Purify Filters Consistently

The significance of air filters lies in their roles of ensuring free passage of air and dust entrapment. At a minimum, inspect them monthly, and if soiled, clean or replace them. This should be done in accordance with the manufacturer’s instructions. If the filter is dirty, it makes it more difficult for the machine to operate, decreases performance, and puts the machine at risk of damage.

Keep an Eye on System Pressure

Adhere to the recommended pressure level given in the equipment’s user manual. Both the high and the low pressure levels can create pressure on the components and result in a malfunction. For calibration of the system’s performance, use a calibrated pressure gauge routinely.

Moisture Build-Up Relief

Moisture may build up in the air compressor tanks or allied systems, hence encouraging corrosion or diminishing operational performance. Remove any collected moisture every day, particularly in cases of working in damp surroundings, to avoid damage to the inner parts of the system.

Check the Hoses and the Joint Areas

Hoses, seals, and joints are to be all inspected in case of any aging, perforation, or leaking. Defective hoses result in leakage, whether of air or power, thus affecting the system’s efficiency. Ensure that the components are fixed promptly to avoid the problem from getting worse.

Application of Lubrication on Mechanical Components

In order to decrease wear damage experienced by motors, bearings, and so on, regular greasing is essential. To ensure smooth operations, only the most suitable lubricants, as per the maker’s instructions, should be used regularly as scheduled.

Schedule System Maintenance As Often As Possible

Check if the equipment produces any strange sounds, shakes, or raises the temperature. The diagnosis of such symptoms on time will save you both money and time from expensive and long-lasting breakdowns. Make sure you have detailed files of machine maintenance for every service inspection.

Following these regular maintenance steps will help the air compressor work more effectively, and the devices will last longer without frequent failures.

Signs Your Air Compressor Needs Repair

Any sudden drop in air pressure accompanied by unusual grinding or hissing noises, the occurrence of overheating, or still weather conditions, means the air compressor needs repairing. The same applies if oil leaks continue or control systems are faulty, which also calls for repairs from professionals in order to maintain operation as intended.

Finding a Reliable Air Compressor Repair Shop

In trying to find the right air compressor repair facility, one’s own experience, qualifications, and customer feedback should be considered. They should use trained technicians who are qualified for all major types and models of air compressors. It should be the business’s good service and good reviews, which may be inclusive of quick services, no hidden charges, and a fast response that one wishes for. On top of this, see to it that they service all areas well, beginning all the way from checking to spare parts provision, and even warranting repairs as a measure of ensuring that repairs do not fall through. Moreover, it is advisable to seek opinions from fellow sector personnel or the preferred service agents from the manufacturers to identify and outsource a credible source.

Reference Sources

MDPI – Impact of Compressor Station Availability on the Techno-Economics of Natural Gas Pipeline Transportation. Read the article here

ScienceDirect – Compressor/Pump Stations in Natural Gas Transmission Pipelines. Read the article here

ASME Digital Collection – On Compressor Station Layout. Read the article here

Frequently Asked Questions (FAQs)

What alternatives do you have in the supply chain for gas station air compressors?

As for the gas station air compressors, there are different models of them, such as free-standing on a pedestal or enclosed inside a cabinet, wall-mounted air systems, or air and water centers with these units in them. Manufacturers supply designs optimized with sufficient levels of volume delivery rates from the air compressors, which are appropriate from the service station to the garage. It may be a coin-op system, and you may recognize equipment bearing branded images, and these packages may include gas station equipment with hose reels and stand-up inflators.

How is a coin-operated kit monetarily friendly for a service station?

It works by making a station air machine a pay-on-use service, and this, in turn, brings a steady income level due to regular usage. These appendages have provisions for a coin box or an electronic coin acceptor, a timer, and containers or pedestals, and appendages, in which you will need no staff to gain additional revenue. The existence of the visual pay air machine, as well as good signage, will usually help lure drivers to the car washes and gas stations situated in the heavy traffic areas.

Is a delivery and installation kit provided with Jeffers for gas stations?

Experienced contractors and architects will tell a customer that there can be some suppliers that have designed a complete delivery and installation kit, which consists of bolters, hoses, fittings, and a complete on-site setup. A complete delivery package includes placement consideration — usually in the middle of a traffic route- and technological calibration for effective inflation of tires. Additionally, some vendors offer troubleshooting assistance and continue service stations regularly.

What are the pros and cons of coin-operated dispenser systems?

Coin-operated supply systems are advantageous as they offer additional income, have minimal staffing requirements, and are easy to operate by customers, especially in pedestal-type exposed locations. However, they are disadvantageous as cartridges have to be emptied, risk of coins and the cabinet being vandalised, and mechanical fixations have to be done on occasion, unlike the modern cashless system of payment, where it can only be used if in good condition. Choosing good quality brands, in most cases, helps prevent downtime and extends the life of these coin-operated dispensers.

In what ways do station air machines influence the proper inflation of tyres?

Characteristics such as pressure gauging, volume flow or delivery, and air flow control are important for proper tyre inflation. Most high-end devoted inflators come with a digital read-out, precise cut-off at a given pressure, and some service station accessories to attain the correct tire PSI. Of course, in order to retain the accuracy, the machine should be periodically serviced as well as recalibrated.

When it comes to car washes and garages, will a coin-op or pay-air machine be more preferable?

For car washes, a more convenient air machine with a coin-op or pay system positioned near the center of the wash encourages additional expenditure by a customer and promotes ease of access for services. Garages, on the other hand, could easily operate non-coin machines to offer free or paid services operated by the staff. It all depends on the nature of the business – coin and pay machines generate tangible revenue in places with plenty of foot traffic, whereas garages with staff may focus more on the ease of operation.

What are the items needed for the maintenance of the air compressor, situated at the station?

A maintenance kit should have a set of filters, a petrol gauge, several clamps, tubes of lubricant, and a simple set of card or coin operating parts of the machine, otherwise known as ottoman vendor parts. Periodic maintenance tends to ensure that the machine supplies the required volume, which helps in minimizing the machine Downtime and protecting the image of the machine for the customers at the gas station. General check-ups minimize the risks of system breakdown.

How are the pedestal and the cabinet installed according to safety and viewing perspectives?

Pedestal devices are designed to be prominent and accessible for quick vehicle drive-ups, resulting in impulse sales uplift towards the center of the filling station. Cabinet devices, on the other hand, are more weatherproof and vandal-resistant and can also contain more sophisticated coin-op electronics or water and air-tight strongboxes. The choice between the two depends upon the anticipated foot traffic, the level of security required, and whether the unit will be required to deliver high volumes for fleet operations.

Is it possible to include gas station air compressors in a system that provides services such as car washing or fleet delivery?

Yes, it’s possible to include multi-station connections, larger compressors, and centralized payment or service systems in one universal kit that connects with car washing facilities, delivery service depots, or garages. Uniformity across locations, support for fleet maintenance with in-vehicle justice, even inflation, and enhancement by a brand or operators with multiple locations are all enabled by integration.