Diesel storage tanks are commonplace in business sectors such as agriculture, transport, and standby power supply. Storage must be kept in good working condition in order not to compromise the fuel, secure users, and the various and relevant policies that are in place. This paper aims to inform about the various kinds of diesel storage tanks, the main features, and the relevant legislation. Be it the expansion or the development of a certain part of the system, this makes little difference because even the development of the other areas is sufficient. The reader of this paper will have a clear understanding of what needs to be done. The ideas described below are crucial in the evaluation and resolution of a given problem with the design of a diesel storage tank.

Introduction to Diesel Storage Tanks

Importance of Diesel Storage in Various Industries

Diesel storage tanks are useful in many industries because they help run the operations of the business. For instance, there is diesel storage usage in agriculture, transportation, construction, manufacturing, and energy, as in the production of energy, where emphasis is put on the use of machinery, and the definition already gives examples of such machines, which include vehicles.

For instance, the use of diesel in agriculture is quite common; it is used for running machinery such as tractors, harvesters, irrigation, and other farm equipment. In harvesting, proper diesel storage is very critical to prevent obstructions in operations. Likewise, diesel engines are used to run earth-moving equipment such as excavators and cranes, and also the generators which are commonly used on construction sites. Availability of fuel facilitates the timely completion of work, especially when it is too much for the available storage facilities.

Given the nitty-gritty of power availability for mission-critical purposes, any clear-eyed observer would say, there is no reason to rule out a rise in global consumption of diesel generators to $30 billion by 2030. This calls for further efforts, particularly in industries where one cannot afford any form of downtime, but instead install adequate diesel storage facilities. On the same breadth, it can also be said that diesel storage should be done for the function of preventing leakages and ground pollution, especially with some public policies like the United States Environmental Protection Agency (EPA), which is known for such matters.

Also, owing to the significance of fuel storage, especially for transportation firms such as those in the freight and logistics industry, diesel tanks to refuel the lorries and the ships. It helps to maintain solutions by having diesel on hand to help optimize expenses and serve in case the price of diesel increases. And even within the buildings of these businesses, nowadays, they do have fuel caskets, which are complete with sensors that measure the use of fuel from a diesel storage tank.

To sum it all up, one might say a diesel storage tank is an indispensable apparatus in every field where diesel fuel should be available at any time and in any place. With all due respect, I beg to differ with this assertion because I believe that the expense of a proper storage infrastructure will go a long way in easing all the industrial operations and also help all the industries in being green.

Overview of Diesel Fuel Storage Options

Nowadays, you cannot think of an improved version of more efficient, safer, and environmentally compatible diesel storage tanks that someone would be interested to use as opposed to the advanced kind of such tanks. It has all kinds of features as well. The tanks are simultaneously made of either stainless steel or high-density polyethylene, in any case, since there is no corrosion on the time scale, and hence they can be used in rather difficult conditions. Moreover, a significant number of the containers produced today have double walls that make the escape of the fluid impossible, and this is very pertinent since it prevents environmental pollution.

One area of improvement is the smart monitoring systems already. According to the available statistics, 60% of administrations around the globe have a degree of fuel tanks equipped with real-time or present-day fuel level detection sensors integrated into these or other IoT systems. For instance, they enable estimation of fuel level and provision of a warning when running low, as well as when there is an unplanned leakage, thus conserving much fuel loss as well as time.

The diesel storage tank can be termed as variable in terms of size depending on the case; thus, holding as much as 275 gallons suitable for small organizations, while in the case of industrial expansion, it is more than ten thousand gallons. Current records reveal that tanks with a capacity ranging from 1000 gallons to 5000 gallons are preferred by the majority of the medium-scale industries. The reasons for this are adequate storage and occupational density.

A significant change, which can also be considered an improvement of some type, is the one that involves going green. In line with some of the new diesel storage tank provisions, they are mostly constructed based on strict footprints of the EPA – Environmental Protection Agency requirements, which include a secondary containment and tanks fabricated with an impermeable outer layer to keep the soil from getting contaminated by fuel. It simply means that there is less dirty work involved, and in any case, the bureaucratic issues are not too deep.

About these changes, all these goals of safe and efficient fuel storage can be ideally achieved while at the same time maintaining a sustainable level of cost and also environmental concerns. Purchasing a diesel storage tank, which will specifically be appropriate for the attainment of these objectives, has a tendency to increase the organization’s market share.

Current Trends in Diesel Storage Solutions

Several major trends are propelling the diesel storage tank industry’s growth over time. One, of course, is the steady increase in the purchase of double-wall tanks that have been engineered to prevent spillages and to promote safety among the users. Recent research indicates that double-walled tanks’ sales rate has increased by about 25% in the past half-decade, for instance, due to increasing bans and eco-related challenges.

Two features in relation to this would incorporate smart technology within the fuel systems. Such systems optimize operation through embedding the Internet of things where it consists of feedback mechanisms such as the levels and temperature of the contents in the tanks, thus facilitating ideal preventive maintenance of the tanks. Studies have indicated that the use of smart monitoring systems is expected to increase to 15% Cloudspiration Rate by the year 2027, signifying the advancement of the sector.

In the same vein, the environmental considerations determine the framework within which diesel storage tank designs are worked out. Similarly, propositions involving designing various tanks to fit different biofuels or even making tanks from environmentally safe materials seem to be more beneficial. A survey conducted by one of the top practitioners shows that nearly 40 per cent of storage facilities in use are constructed around sound present-day practice. This in itself is an indicator that this industry is also addressing environmental issues.

This need is at least supported by the fact that within these parameters, actions must be taken, and changes must be implemented to keep up with the changing technologies and market demands, thereby integrating modern diesel storage innovations. These changes if properly implemented, may make a firm more agile and law-compliant towards the environment and efficient in their operations.

Types of Diesel Storage Tanks

Single Wall vs. Double Wall Tanks

Tanks are normally made of a single layer of material, making them cheaper than other options available for a diesel storage tank. Single-wall cameras require some provision for containment since they lack their own secondary systems that will prevent the fuel from any spillage. In most cases, single-wall tanks work in scenes that do not have very stringent environmental laws or provide containment for the fuel that is spilled, if any.

On the other hand, the construction of secondary containment tanks incorporates the use of an exterior layer over the inner one. This lowers the possibility of environmental pollution or any spillage. This year’s industry notion is that there is a demand for safety, including environmental concerns. This report states that double-wall tanks are more frequent. The latest 2023 regulatory compliance survey by EPA reveals that all diesel storage tank systems that were recently installed had over 70% double walled tanks, thereby changing the image of the boundaries.

As for the two options of tanks, there can be countless possibilities, including polyethylene, fiberglass, and steel. The preference for either single or double-walled tanks is influenced by such factors as the environmental laws, the amount of diesel stored, and, lastly, whether there are such laws or maintenance costs involved.

Above-Ground vs. Underground Storage Tanks

When deciding to use surface tanks or underground tanks, the benefits and setbacks of any of the installations and applications must be defined. Typically, above-ground tanks are used for the reason that they are much easier to establish and maintain in view of the access issues. For these tanks, there is no need for deep covering, so the marking is quite low. In the USA, according to the Environmental Protection Agency, the installation of AST makes it easier to check for leaks; the chance of wearing out without detection is very low. This type of diesel storage tank shall be available in these and other materials; if needs in a certain area require it, double-wall tank systems and spillage containment can be provided.

Nevertheless, in situations where there is a need to limit the presence of large tanks in a given space, the installation of an underground tank is more beneficial. This is due to the fact that weather conditions have little or no impact on the tanks. However, the safety and environmental challenges that these tanks present are the burial of the tanks underground, which means the tanks do not require external corrosion protection. On the other hand, the initial cost is quite high since there is a need to obtain special licenses, carry out excavation and installation, and even have monitoring systems in place. According to a study in 2023, such an issue of leakage could be dealt with more effectively, and there will be no problem with corrosion of the diesel storage tank, thanks to the use of new-generation materials of fiberglass and plastics.

When assessing and determining the functionality of both ASTs and USTs, it is vital to take into account, to optimize one’s approach look at or even the very issues involving size, environment, and costs. The need to rationalize existing diesel storage tank inventory has been mainly dictated by the recent changes in the way that tanks are monitored, which are progressing towards more technical support, compliance with the relevant laws, or operational efficiency.

Mobile and Portable Diesel Fuel Tanks

Diesel and gasoline transport and storage are enhanced by mobile and fixed tanks with a diesel storage tank for several production scenarios. These types of tanks are used in different sectors of the economy, including forestry, agriculture, construction, and mining, where such tanks allow application and automobile operations to be conducted without devoting time for refuelling such machinery in the middle of fields. Most tanks are steel with a lining made of polyethylene or another non-corrosive material to enhance safety.

Spill control tanks with fitted pump units and programmed nozzles are also seen in today’s tanks. According to recent reports, the value of the market for mobile fueling stations is estimated to be about USD 960 000 000 and is foreseen to grow at a compound annual growth rate of 4.5% by 2028. One of the key reasons for this growth is the growing need for energy in off – grid areas and also improvements in tank automation technology.

Additionally, several manufacturers incorporate Telemetry in their designs; therefore, it is possible to incorporate a mobile app or access a cloud service to evaluate the remaining fuel. This aims to solve another problem that hunkers down as a supply chain, which is also a fuel shortage that leads to low performance. To utilize these types of tanks, participants are currently latching on to the fuel tanks constructed and manufactured to comply with approaches such as ADR – Agreement on the Carriage of Dangerous Goods by Road, as such transporting tanks and the like are UN-approved and tested otherwise.

Diesel storage tank is applied across various industries all over the world. Several diesel storage facilities exist in terms of tanks, but inasmuch as this is helpful, mobile and portable tanks technology looks promising in the sense that such equipment is safe and effective.

Key Features and Innovations in Diesel Storage

Capacity and Size Options for Diesel Tanks

There are various sizes of diesel storage tanks designed to suit different application purposes, both in industrial and commercial frameworks. To explain, the storage capacity of the tank could range from a small transportable tank storing 10 to 200 gallons of diesel to a very large ground tank holding more than 10,000 gallons. For instance, such tanks of petite dimensions find application within households or primitive shelters. On the contrary, tanks of greater dimensions are employed in agronomical, transportation, and industrial applications.

However, unlike drums and barrels, intermediate bulk containers are designed for the medium level of capacity between small and large containers, which can range from 200 to 1,000 gallons. Most of the studies point to the agricultural, logistics, and even industrial activities as the main consumers of 1,000-gallon linear tanks, engineered for ease of transportation and storage of fuel, without having to continuously refuel the tank. This was because Nyaguta improved the diesel storage tank, and steel was put in the rebar of the tanks so that no other framework, such as rebar or mesh, was needed.

Some further development has been incorporated into the design of tanks, for instance, vertical tanks, which reduce the usable space and the use of inner and outer tanks, as this assists in safe storage. To be more explicit, close to 70% of all well-established organizations have installed regimes of double-bodied tanks that prevent any form of leakage or spills that could occur alongside the compliance of environmental standards, and a trend is sweeping back to azines. In all these developments, one cannot fail to realize that the storage efficiency, the environment, and the basic operations have taken center stage.

The listed works seem to provide the evidence to suggest that In the same manner as in the case of biodiesel, diesel storage tank is also widely used for road transportation.

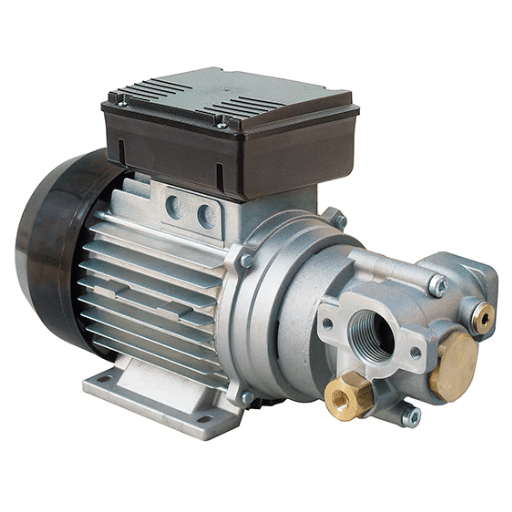

Advanced Fuel Pump Systems and Monitoring

Modern fuel pump systems have evolved in recent years with the aim of enhancing efficiency, precision, Ease of use or environmental standards. These systems are currently configured with the aid of smart sensors and the Internet of Things (IoT) technologies aimed at observing the amount of fuel and the overall performance of both the pump and the entire system in real-time. Many contemporary research studies also posit that more than sixty percent of new generation commercial fuel pumps these days have digital monitoring solutions in place that make tagging diesel storage tank units easier by about forty percent, because of reduced downtimes.

Moreover, the usage of such practices is very common as they are proven to be effective in detecting and preventing the loss of fuel by over 90%. Furthermore, with the assistance of cloud services, whether a public or a private cloud, facility managers are capable of managing their equipment, such as the diesel storage tank, from wherever they are, without any location constraints. All these line up with the attention fuel consumption and management activities are getting, and the impact fuel consumes and safety measures have on the robust utilization.

Durability and Material Choices: Steel and Beyond

Connecting with the fuel management systems, one of the issues is that it is extremely hard and expensive for high mass efficiency units and cheap to do. However, steel is also a frequent choice for construction things that require any degree of strength, since it has excellent mechanical properties and, when protected, is fairly corrosion-resistant and light enough to do jobs in rough conditions. According to pertinent industry information, corrosion-resistant steel tankage and pipe systems have a 30% higher service life advantage over non-cost-efficiently manufactured tanks of similar design and utilitarian purpose, over fitting (structural) tanks.

Recent endeavors have focused on the development of alternative solutions such as fiber-reinforced polymers and composites. This is due to the fact that these new solutions are not only lighter than steel but also more effective in terms of durability and corrosion. For instance, unlike in the case of steel tanks, reinforced plastic tanks and fiberglass have better chemical resistance, and many are safer against corrosion in some cases. Studies indicate that an FRP tank can be maintained for about forty years in an environment without extensive care, and this aids in bringing down operational expenses in some cases. The other aspect that offers improvement is the price of a reducer when there are goods or materials, such as a diesel storage tank that is made of steel.

Additionally, the physical components employed in most of these systems are significant to the structures that seek to promote sustainability. This has gone on to the present day in that most of these systems are composed of materials that are recyclable or manufactured in ways that are low impact on the environment. This is in anticipation of the whole world becoming ‘greener’ in terms of carrying out industrial activities, and a study in 2023 shows that the consumption of containers of sustainable fuels increased by 25% over the last year. The above examples demonstrate a growing trend of advancement in material science in the fuel industry.

The way each design of a diesel storage tank is constructed is one of the classical factors determining how heavy it gets. Diesel storage tanks are very heavy because of this, and incorporate a lot of parts into the construction of the framework. Some people often mention the external support that is provided for the tanks more than the introduced tanks.

Safety Standards and Regulations for Diesel Storage

Essential Safety Regulations for Fuel Storage Tanks

There are quite a few safety measures that apply to the utilization of fuel storage containers, especially for the diesel storage tank, leakages, several sources of fire, and environmental awareness issues. For instance, Environmental Protection Agency (EPA) rules stipulate that all underground storage tanks fabricated must be constructed using materials resistant to corrosion over time, such as Fibre-glass Reinforced Plastic or Cathodically Protected Steel, to escape prevailing exposure to damage and so forth. Tanks will also have а tank leak detection equipment and/or secondary containment features so that if a spill occurs, it is prevented and controlled as soon as possible.

In 2023, better results were obtained in the enforcement of the tank standards since more than 85% of facilities in the United States of America were found to adhere to the regulated storage requirements, as was the case in 78%. They make frequent calls for such measures as aboveground tank inspections, air systems cleaning, and emergency preparedness to foster the idea that in an occupational setting, safety is improved. This, therefore, entails coordination in both protective directions- the worker and the environment, due to the fuel storage that is consequently an aspect of sustainable development promotion as practiced in modern society.

Also, it should take into account recent stabilization with the new technologies enhancing the monitoring of the system elements, which in essence include – but not limited to – IoT sensors, thus the inclusion of a good number of advancements in the area of, say, diesel storage tank, which can notify of any changes in pressure, temperature, or fuel particular levels. Such measures serve to enhance safety procedures and allow for efficiency and effectiveness when it comes to safety standards shared by different people operating the facilities.

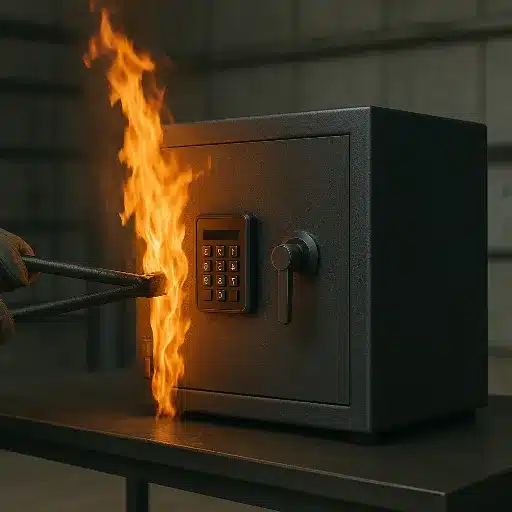

Fire Safety Measures and Best Practices

One of the most important factors in all facilities is fire safety measures for diesel storage tank as failure to do so has in many instances resulted in accidents. Another description of the oil and gas storage industry is entailed in a more recent academic work of fire suppression systems, whose relevance and updated importance are emphasized, forecasting that the industry will grow at a compound annual growth rate or CAGR of four point one from 2021 to 2026. For instance, hydrocarbon fires’ foam firefighting equipment has evolved much better than it was in the earlier decades.

Risk assessments and employee training programs that are realistic at the same time are the preferred methods of mitigating fire risks. Even in this scenario, the whole structure of fire avoidance has changed due to the usage of both the IoT and automation. For example, it is possible to have the integrative detectors or sensors installed in the system to alert individuals to the existence of any leak at any corner or a sudden hike in the temperature.

Besides the NFPA (National Fire Protection Association) requirements, many other standards do not exclude API (American Petroleum Institute) guidelines relating to safety in storing liquids. Fire protection techniques are generally developed taking into account the principle of protecting steel storage tanks. One might say, tanks are bonded and earthed, that we do various courses on tank inspections, and work on plan de catastrophe in case for storage fires. There is also a practice of this kind even in areas that have a simple, even a diesel storage tank.

Environmental Regulations and Compliance

The device, whose fuel storage function has made it very useful in energy supplies, is not without its demerits, and if ignored, can cause environmental issues. As of late, the commonest cause of pollution of groundwater and soil is due to the leakage or spilling of storage tanks. For illustration purposes, during the winter season, the Environmental Protection Agency (EPA), United States, reports that up to 500,000 underground fuel tanks are currently under surveillance to prevent leaks because oil, especially that containing petroleum hydrocarbon escapes from the tanks, and that hurts the environment and by extension, the entire ecosystem. A diesel storage tank may also be considered as an above-ground tank that saves diesel for a longer period of time, but there are many changes that occur, for instance, evaporation and even corrosion. Therefore, management or inspection of its content is carried out.

Few studies have empirically examined these strategies for grave concerns in risk categories where traditional approaches have been routinely applied to the development of reactive approaches. It uses advanced information technology – the likes of Automatic Tank Gauging (ATG) systems for diesel storage tank risks, leak detection software – ways of solving problems are found before they arise by the installations concerned, who adopt vertical water management policies. For example, as the National Oceanic and Atmospheric Administration confirms, about 14% of water pollution within the United States is caused by petroleum spills.

The model of waste governance in this context had to adapt from being passive to active due to changes in the legal framework, rather than the expansion of the limits of legislative regulations. One is a requirement for additional containment, for instance, lining the areas for regular diesel storage tanks with an extra wall so that any leaking tanks can be stopped. However, recent reports surprisingly reveal that the use of more efficient oils brought the averages of companies relying on such equipment to 30%.

Full optimization of a strategy that is enforced in a culture of compliant prevailing norms and in new technology implementation is extremely important in the perspective of how it is possible to combat the negative consequences of the storage of fuels, as well as the strategic quest to defend the ever-changing laws. There is a high level of importance placed on and prolonged engagement in the enhancement of processes, environmental management, safety in the market, fire safety, and even the protection of the surface of conventional diesel tanks.

Maintenance Tips for Diesel Storage Tanks

Regular Inspection and Maintenance Practices

Essential care must be taken to ensure that there is no damage to diesel storage tanks and that the facilities are inspected regularly. This reluctance can manifest in the thinking that it is a once-a-year restriction; there are some reports and recommendations that suggest that certain structures should be checked throughout the year to avoid any reasons for corrosion, any bubbling or leakage or excessive microbial activities, primarily due to these surfaces. Also, it has been observed that nearly 80% of diesel storage tanks fail due to either rust or improper maintenance practices.

Another widely accepted inclusive measure is that concerning water inspection due to potential excessive bacterial expansion inside the tank or water entry, and also, to some extent, lowering the quality of the fuel. This induces an advantage because as the use of superior monitoring devices and far placed monitoring helps once there is a change in fuel quality or the presence of any impurities. More than 25% of the time delay in performing tank maintenance can be cut, thereby maximizing educing how much time the tanks are held simply fluidly.

At the same time, it’s worth mentioning how the cleaning and desludging of tanks should also be carried out on-time, more so depending on peculiar variations such as in usage and in climatic conditions. As per the recommendations of the experts, it is advised to conduct desludging of the tank at least once in two to three years, since practically, the capacity of the tank can be increased by about forty percent after thorough cleaning of the tanks contrary to leaving it as it is.

Finally, it is always good for records to include a proper schedule of all inspection, cleaning, and maintenance procedures. This ensures not only compliance with safety and environmental regulations but also the foreseeing of potential problems before they escalate and transform into costly repairs or environmental spillage. In aiding modern monitoring systems, as well as performing certain procedures, diesel storage tank operators could protect this tank from such losses, which are both economical and environmental threats.

Common Issues and How to Address Them

- Corrosion of Steel Storage Tanks

A major problem of concern while working with a diesel storage tank is the rusting of the tank itself. Statistics suggest that 20% of tank failures arise due to the rust that is mainly caused by steel tanks that are either in moisture or other aggressive environments. The suggested strategies are normal inspection of the tank for corrosion on a regular basis and the use of epoxy paint as a protective coating. The use of such technologies is facilitated with plating or additional lining of metal, which is installed on the walls of the tank to prevent cathodic deterioration, and it should be noted that it significantly reduces the cause of such deterioration - Penetration of Water Inside

A major hazard facing diesel is water contamination in the tanks caused by condensation or inadequate sealing. According to the Environmental Protection Agency (EPA) research, water contamination supports bacteria, which result in the formation of slime or mild degradation of the fuel. This is an imperative precaution since it considers the installation of a water-absorbing filter as well as periodic water drainage. - Algal/Fungi/Bacteria Proliferation

New research has demonstrated that there is an increase in the number of incidents involving contamination of underground diesel storage tank systems by microorganisms, especially in humid areas. These microorganisms can build up and form biofilm that may subsequently clog the filters and the fuel lines, thus affecting efficiency. Control of the growth of microorganisms includes fuel tank management and the use of biocides, among other practices. - Leakages of Tanks

Even a minor leak of a tank tends to cause environmental and other financial problems and hence should be resolved immediately. Studies have shown that the soil and water beneath more than half of the areas where such tanks were installed is polluted due to the prophylactic protection of such tanks. Using woodworking techniques like ultrasonic detectors, it is possible to prevent every instance of the leak and introduce leak systems, which are an improved form of conventional leak detection. - Sludge and Sediment Accumulation

In the end, the build-up of sludge and drainage in the diesel storage tank leads to wear of the equipment of the diesel combustion systems. Prevention from those take place through cleaning of the tanks and using good quality diesel additives. Some operators, in turn, use fuel cleaning systems, so-called fuel polishers.

All these problems can be resolved by the application of timely and up-to-date steps. These allow the extension of the length of the operation of the diesel storage tank, and the operation is carried out without any deviations from the established rules of the specialists.

Best Practices for Long Life of Storage Tanks

- Decreasing the Concentration of Hydrogen Peroxide

Perform inspection from time to time, check for any symptoms of corrosion, significant leaks, or even defective structures. Research has revealed that tanks’ lives can be extended by up to 25 percent when they undergo inspection and maintenance once or more. This maintenance process includes cleaning the inner part of the tank, assessing the condition of the structure, and replacing any parts that might have been worn out already. - Permitted Degree of Use of Safety Measures and Coating

Corrosion is found to be the highest contributor to tank failure. Use surface protection enhancements in a proper way by applying coatings consisting of environmentally friendly materials, such as the outside and the inside should be coated with either an epoxy or polyurethane. Sacrificial metal anodes in cathodic protection systems achieve the target of extending the tank’s life by 50%. Whenever these anodes remain in places, check them to enable these anodes that have been in service already to be dismounted or replaced with others. - Diesel Storage Tank with Safety Mechanism

Impure petrol fosters the growth of tiny degenerate organisms and thereby enhances sludge build-up, which consequently could destroy a diesel storage tank. The use of fuel filters, synthetic dehumidifiers, and fuel stabilizing additives should eliminate any form of ‘dirt’ in the system. According to the 2023 industrial survey, correct servicing results to reduction in cases of contamination of tanks by thirty five percent. - Facility of Advanced Controls

Dedicated automated systems need to be installed that will monitor temperature, pressure, and ullages in the tanks. Since smart-sensing technology has been applied, discrepancies are spotted way in advance before they occur, and corrective action is taken. Most of the tank operators have managed to achieve a thirty percent drop in unanticipated downtime with the assistance of IoT tank monitoring. - Meeting the Standards Required in the Industry

The use of external associates to make sure that tanks are kept properly is important to preserve the use of the equipment and security that it provides, since it allows meeting additional international requirements. The research evidence indicates that significantly lower rates of tank failure exist when laws such as the referred ones are adhered to. - Appropriate cleaning and conservation

Premium materials that are often to protect the surfaces must be cleaned routinely to ensure that accessible surfaces are cleaned of possible sediments and pollutant layers where applicable. The service should be outsourced to those firms that have cutting-edge dust suppression accessories for instance, automatons, which improve efficiency while limiting idle time. This will always be dependent on tank usage, but as a rule, it is mandatory that this is done within 3-5 years, i.e., it should not go beyond that period for thorough cleaning to happen.

When these best practices are merged with state of the art equipment and its compliance controls, then it is possible to improve the longevity and safety of the diesel storage tank, including other parts, to maximize the use of the tank at a minimal cost that can be incurred in repairs during the usage of the tank.

Reference Sources

-

Aboveground Petroleum Tank – Purdue Extension

This document highlights the benefits of on-site diesel storage, including timely access to fuels and considerations for bio-based fuels.

Read the document -

Corrosion Risks in USTs Storing Diesel Fuel

A detailed report on the risks of corrosion in underground storage tanks (USTs) and their impact on groundwater contamination.

Read the report

Frequently Asked Questions (FAQs)

What variations in diesel tank storage are available?

Several types of diesel storage tank facilities exist to satisfy particular use cases, which include ensuring compliance with certain conditions and standards. Underground storage tanks (USTs) and aboveground storage tanks (ASTs) are the two most common types. The USTs are slotted into the ground for space economy and shelter from the elements, while the ASTs are easily accessible for checking and servicing. Other forms, such as single-walled or double-walled tanks, are available; the latter permits better protection from leaks than the former. The choice of tank is informed by factors like the amount of fuel to be stored, the installation site, and any local laws that may apply.

What qualities are vital for effective diesel storage tanks?

With today’s technology, there is fast-paced development in many aspects of the features of diesel storage tanks. This includes the use of materials that resist corrosion, the equipping of tanks with spill guard sections and overfill protectors, and so forth. In most cases, tank venting is also built in to eliminate high or low pressure conditions safely. Additional options like these that are accessible to many tanks enable the operators to, for example, monitor the fuel quantity, the temperature inside the tank, and if there is any leak, which helps in optimising the tank, ensuring that it remains within the regulated levels.

What are the effects of regulations on diesel storage tank use?

Safe operation and environmental management of diesel storage tanks is at risk without the necessary regulatory framework. Although they differ with jurisdiction, the listed provisions shall contain procedures for leak analysis, measures to prevent spills, and steps on how to conduct audits. Operators are also required to meet the requirements of bodies such as the Environmental Protection Agency (EPA) in the USA, which requires that all tanks are tested regularly and their maintenance activities documented appropriately. It is important to know both local and national regulations so as to control risks on taxes and the operation of the storage facilities.

What is the recommended frequency for inspecting and cleaning a diesel storage tank?

The interval of inspection and cleaning of the diesel storage tank is not fixed. The standing rule is for the person working under the premises of a storage tank to inspect it at least once every year for any major concerns, such as leaks or corrosion, which can lead to injury or death. So cleaning is prescribed either after 3–5 years or a little sooner in the case of high usage or spilling of bad diesel. As a result of consistent upkeep, the life of the tank is prolonged, and costly repairs or breakdowns are prevented.

Which energy delivery procedures prolong the operation of a diesel storage tank?

The methods (revolutionary) technologies cannot be limited to regularly improving the maintenance of diesel storage tanks; they go a step further and increase the efficiency of such structures. The critical parameters, such as values of the fuel in the tank, fuel temperature, and any leaks, are monitored by the automated fuel tracking systems, and alerts are realized in real-time s to operators. With the in-tank robots, new methods that help to reduce the time the tanks are out of service and enhance the cleaning process have been provided. This allows, on one hand, increasing the operational efficiency by incorporating these technologies together with inspection and compliance systems devoid of routine, and in another dimension, extends the life of the tank.

What is the downside of the inappropriate maintenance of a diesel storage tank?

Inappropriate maintenance has far-reaching impacts, including unsafe environmental consequences, fuel contamination, and high repair costs. Leaking or spilling tanks that are not maintained serve a major danger to the environment around and can-attract huge penalties for enforcement. More so, failure to control corrosion or sludge, for example, can reduce engine fuel quality and effectiveness, hence fuel operated equipments suffer. All these are serious threats, and the temptations of fuel tank storage without preventive maintenance are too high.