Fuel dispensers are essential components of the worldwide fuel supply management system. However, their significance and main characteristics are still frequently neglected. The following article is going to explore the operation of fuel dispensers, the technology that makes their operation possible, the main parts, and the most famous examples around the world. It will also discuss the principles of fuel dispenser operation and mention how these principles are changing gradually, with the energy transition being diverse and multifaceted. So, whoever you might be — a fuel industry scholar, a gas station manager, or an inquisitive person regarding this tech product — the article is going to give you the ability to gain knowledge of the product’s workings as well as its practical applications. Get ready to accompany us on a deep technological journey!

Type of Fuel Dispenser

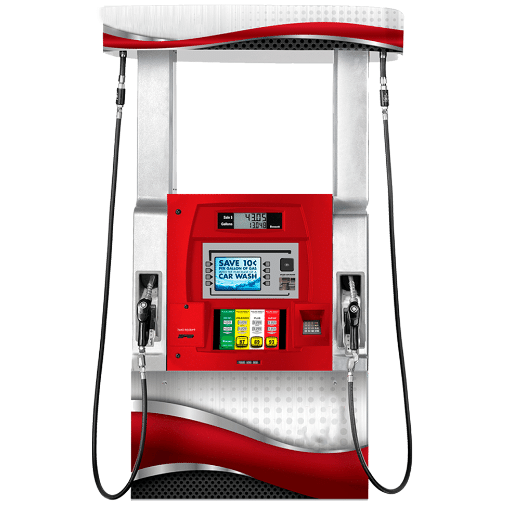

According to their technical and operational design, gas pumps can primarily be categorized into two major types:

- Mechanical pumps: They are based on a gear system along with a mechanical meter for measuring the dispensing of fuel. Although they are regarded as older technology, some gas stations still opt for them, particularly the ones that are not too advanced technologically or are in rural areas.

- Electronic fuel dispensers: They have digital systems for accurate and practical metering, and also have features like screens that show real-time data and sophisticated payment systems. Because of their efficiency and versatility, they are an advantage to the modern gas stations.

Both are able to comply with safety regulations and are intended to be the source of a safe and reliable fuel supply.

Gasoline Dispenser

Modern gasoline dispensers are now able to function with remarkable accuracy and high efficiency, all thanks to striking technological advancements. The control systems used in these devices are computerized and as a result, the metering is precise as per the stringent international standards, for example, those of the International Organization of Legal Metrology (OIML).

Moreover, using the latest technologies like volume sensors and automated control valves not only detects leaks or flow anomalies during the supply process but also maximizes production efficiency. Some devices are even capable of integrating into digital infrastructures, which allow for real-time remote monitoring and predictive maintenance optimization.

When it comes to longevity, today’s fuel dispensers are made from high-strength materials like stainless steel and reinforced polymers, which can endure even the harshest environmental conditions. Besides, a number of modern fuel dispensers are now equipped with advanced safety systems such as automatic shut-off when full and compliance with zero vapor emission requirements, hence, lessening their adverse impact on the environment.

Moreover, statistics show that in the last five years, more than 75% of urban gas stations have made the shift to electronic fuel dispensers, which is a clear indication of the energy sector’s gradual transition towards total digitalization.

Portable Fuel Dispenser

Portable fuel dispensers are an excellent and multi-functional fuel delivery option, particularly when mobile applications or no fixed infrastructure are present. These devices have been completely transformed in technology and functionality and have met the various needs of industries like agriculture, construction, and transportation.

From a technical point of view, the most sophisticated units come with electric pumps of large capacity and can have flow rates of over 50 liters per minute, which will lead to a very significant decrease in the time taken to complete the task. In addition to that, the majority of the systems are built using very resistant materials, which do not corrode easily, like high-density polyethylene (HDPE) or stainless steel, and can even endure the extremities of the weather, thereby being reliable for long periods even in the toughest of conditions.

The offshore distribution market has become a huge area during the past few years, largely due to the increase in demand for oil and gas in the hinterlands and in remote areas. Recent statistics reveal a compound annual growth rate of almost 6.8% for the last five years, with the major drivers being the developing markets in Asia and Latin America. This trend is closely associated with the growing need for supply chain solutions that are more adaptable and greener.

Consequently, the modern designs emphasize safety control features. Safety is also further ensured in some designs by automatic shut-off devices, pressure relief valves, etc., which, apart from conforming to the international safety standards, have also made the environment surrounding the fuel storage safer by preventing accidental spillage. The use of fuel is therefore not just an issue of practicality but a major part of responsible and eco-friendly operations as well.

Gas Station Dispenser

The gas stations have experienced a major transformation, one that is now leading to the implementation of various changes aimed at perfecting the aspects of accuracy, speed, and safety. Of the numerous technologies that have come to the forefront, the electronic metering systems are probably the most significant as they are the ones that provide the most accurate, instant readings, and the remote control systems thus allow having one central location where everything about the station is monitored. Moreover, the use of stainless steel and other materials contributes to high durability, while the fast-acting valves plus the leakage-proof control systems work together to cut down the environmental impact and meet all international standards that are applicable. These advancements are what make it possible for the center to not only be able to give excellent support to the customers at the end but also to be a partner in the sustainment and proper handling of the energy resources.

Key Components of Gasoline Distributors

Fuel Pumps

These pumps are responsible for moving fuel from the storage tanks to the dispensers, which in turn allows for a smooth and effective supply of fuel to be always available.

Hoses and Nozzles

Hose and nozzle are the components that link the dispenser to the automobile, and they allow the operator to have more control over the whole fueling process.

Flow Meters

They determine the fuel amount given out without depending on exact measures, thus the consumers’ trust is earned and the highest degree of accuracy is assured.

Filters

They filter out any dirt and particles that might negatively impact the purity and thus quality of the fuel offered.

Displays and Control Panels

They show information like price per unit and the amount of fuel dispensed, and at the same time, they allow interaction with the user.

Safety Valves

They manage the flow in case of emergencies, thus avoiding spillage and at the same time keeping adherence to the safety standards.

Gasoline Pump

A fuel pump is an essential part of a system that both fuels the car and consists of very technical and high-quality parts.

- Motor and internal pump: These two systems work by sucking up gas from an underground tank and supplying it to the nozzle at a steady pressure, thereby guaranteeing constant and equal delivery.

- Flowmeter: To accurately measure the amount of fuel given, the meters are highly sophisticated, and they use positive displacement or turbine meters; this data is vitally necessary for perfect cost calculations.

- Filtration system: Before the freight enters the car engine, it goes through a filtration system that removes engine-harming particles, water, and sediment from the incoming air.

- Control panel: The electronic interfaces present data in real-time, such as the total cost or the volume of fuel in liters. They also enable the input of the configuration, like fuel type or precise quantity.

- They come with pressure sensors that automatically cut off the fuel flow during refueling to avoid any spills.

- Regulatory compliance: To ensure that the pump meets the required standards, quality, and safety, it must go through a set of international and local regulations, for instance, API and NOM standards.

Gasoline dispensing machines are characterized by their specialization, and they are the result of precision mechanics combined with a cutting-edge technology system that delivers safe and reliable fuel.

Measurement System

Gas station metering systems are built to assure the precision, dependability, and occasionally, the regulation of each operation. Depending on the location, these systems make use of either volumetric or mass flow meters, which are certified to international standards such as API, OIML, or NOM for the regions that require it. While volumetric meters quantify the actual amount of fuel dispensed, mass flow meters determine the mass under different temperature or pressure scenarios, thus giving more accurate results.

On the other hand, metering systems make use of high-tech devices, including electronic sensors and control software that allow, for instance, real-time data logging, automated diagnostics, and the creation of detailed audit trails. All these aspects not only assist in enhancing the management of the operations but also continue to empower the users through dispensers showing readable and truthful readings.

Fuel Dispenser Accessories

Fuel dispenser accessories play a crucial role in the smooth and efficient operation of the system, as well as in the assurance of safety and compliance with the relevant regulations. The most frequent accessories are:

- Supply Tips: These nozzles are responsible for controlling the fuel flow and have an automatic shut-off system that prevents spills. There are different models of fuel nozzles available depending on the fuel type (for example, gasoline, diesel, or natural gas).

- Suction and Discharge Hoses: Hoses should be made of materials that can withstand extreme conditions because they are vital for the secure transmission of fuel. Some of the hoses even have an anti-twist feature to minimize wear.

- Fuel Filtration: This filter catches impurities that come with the fuel and are going to the vehicle. Thus, it protects both the engine and the dispenser.

- Flow Meters: New-age meters have electronic features built into them to provide accurate fuel measurement and transaction recording.

- Electronic Displays: They let the customers know the amount, price, and other vital information. The latest displays are digital and come with an interactive feature.

Properly selecting and placing these parts not only helps have a right functioning dispenser but also allows compliance with the fuel industry’s safety and reliability standards.

Maintenance and Care of Fuel Dispensers

To maintain the proper functioning of the water dispenser and prolong its life, regular maintenance is a must. Some of the important maintenance practices are:

- Visual Inspection: The hose, the nozzle, or the valve should be inspected for any signs of damage. Moreover, look out for leaks in the hose and make sure there are no loose connections.

- Clean Components: Dust and sediment on the nozzle, filter, and electronic screen should be cleared regularly so that there is no clogging and measurement accuracy is maintained.

- Accuracy Testing: The dispenser should be calibrated often to ensure that the volume measurement of what is delivered is correct and in accordance with the regulatory standards.

- Check the Electronic System: The screen and the controls should be checked and made sure they are working, including the electronic payment system (if any).

Proper routine preventive maintenance, in addition to preventing disruptions in operations, will also minimize the risk of expensive repairs in the long run.

The Importance of Regular Maintenance

Regular maintenance is a primary factor in keeping equipment, particularly in industrial or commercial settings, operating efficiently and safely. It allows for the detection and rectification of potential problems at an early stage, thus preventing them from becoming expensive and hazardous failures. Furthermore, it improves the life of the device or system and satisfies the requirements of regulatory and quality standards. The standard practices suggest that a proper maintenance schedule must have routine inspections, calibrations at regular intervals, and software updates when necessary. A maintenance schedule that is always followed not only restores performance but also aids in reducing future downtime and operating costs to a lesser extent.

Pump Maintenance Procedures

For the pump to function correctly and efficiently, it must be properly maintained. A proper pump maintenance procedure according to the best practices compiled from various sources includes:

- Polishing and cleaning: Visual inspections should be done regularly to find possible leaks, corrosion, and areas of the pump that are losing material. The pump casing, gaskets, and seals should be cleaned of any dirt, dust, debris, or buildup.

- Parts Lubrication: The level and quality of lubricants in bearings and other moving parts should be checked, and if necessary, replaced according to the manufacturer’s specifications so that wear does not occur prematurely.

- Seal and Gasket Inspection: Check the mechanical seals and gaskets to confirm that they do not leak and that they are not damaged. If any problem is found that might affect the pump’s performance, replace it immediately.

- Alignment and Vibration Review: Make sure the pump shaft is correctly aligned to eliminate destructive vibrations. It is advisable to use precision instruments to verify alignment and make adjustments if necessary.

- Impeller and Internal Parts Inspection: Look over the impeller for wear, cracks, or distortion. Clean or replace these parts when necessary, as they can change the hydraulic efficiency of the pump.

- Calibration and Operational Testing: Frequent calibration is the key to ensuring the pump stays at its best operating parameters. A functional test after each maintenance work is suggested to confirm performance.

With the consistent application of these practices, the operational risk is minimized, the energy efficiency is maximized, and the costs related to repairs, maintenance, and substantial downtime are drastically cut.

Problem Solution

Pump Not Operating

Possible causes: power cut-off or a connection problem.

Solution: turn on the main switch, check for any broken wires, and have a look at the control panel to see if you need to reset the whole thing.

Less Tension During Work

Possible causes: blocked or stuck pipes, leaking connections, or worn-out parts inside the pump.

Solution: inspect pipes and connections for blockages or leaks. Check pump parts: seals, internal valves, and replace if necessary.

Heating the Pump

Possible causes: Always running the pumps, not lubricating them enough, or not providing them with proper airflow.

Solution: Have the pump take a break in its operation; check that there is enough lubricating oil as per the technical manual; and make sure the pump is in a well-ventilated area.

Overuse of the Pump Leads to Excessive Vibration

Possible causes: incorrect alignment, broken bearings, or the presence of debris.

Solution: Align the rotating parts correctly, check the condition of the bearings and replace if they are faulty, and make sure that cleaning of the areas involved is done regularly.

Keeping track of the inspections and repairs in detail will be a great help in spotting the problems that keep appearing and also in making the operations more reliable.

Installing the Petrol Dispenser

- Prepare the work area: The area for installation should be neat and orderly, leveled properly, and devoid of any obstructions. Furthermore, the installation area should be in accordance with the safety regulations.

- Installing the unit: The dispenser should be positioned at the floor level in the area indicated. The unit should then be anchored to the ground using the right anchors.

- Connecting the plumbing: The pipes for incoming and outgoing water should be joined properly as per the manufacturer’s diagrams. The joints should be tested for leaks.

- Electrical Installation: The installation of the electrical cables should be done in accordance with the technical specifications and the current regulations for the power supply. Also, check if the power supply is stable.

- Final Verification: Before putting the dispenser into service, conduct a test of it to ensure that it is operating well. Make sure that all the safety systems are working correctly.

If these steps are closely followed, the dispenser will be installed without any hazards or difficulties.

Pre-Installation Requirements

In a nutshell, for any fueling station installations to be carried out, there are a couple of basic requirements that must be fulfilled beforehand to provide security and conformity:

- Permits and Local Regulations: Get the necessary permits from local tax authorities. Check that the chosen location adheres to building, safety, and environmental regulations.

- Suitable Site: Site suitability criteria include flat, unobstructed ground. Minimum distances from sources of ignition or buildings should be maintained as per the local regulations.

- Risk Analysis: A thorough risk assessment must be done to unambiguously map out the situation of hazards (leaks, explosions) and to think of ways to deal with them.

- Infrastructure Availability: Make sure the equipment can be connected to a reliable power source that is compatible. In addition, get the certification that the fuel storage system is up to code and can be connected.

- Training and Safety Equipment: Offer training to the workers who will be working on the installation and provide them with the necessary safety equipment, including insulating gloves, anti-static boots, and leak detectors.

Observance of these primary requirements is very important in preventing any unexpected events and in making the installation process not only efficient but also safe.

Installation Steps

Preliminary Inspection

All parts must be checked thoroughly before the equipment is installed, both visually and functionally. Inspect the entire installation site for the presence of humidity, which should not be too high, and for sufficient ventilation, because these factors might negatively impact either safety or the performance of the equipment. Moreover, all materials must be free from defects, corrosion, or damage, and the conditions at the site must be checked for humidity, which should not be excessive, and ventilation, which must be adequate because safety may be affected by the conditions or operational performance.

Component Installation

The major components must be assembled according to the manufacturer’s technical instructions down to the smallest detail. This would mean that using the right tool and the right technique, one would have to calibrate and then set the joints, connections, and seals with the help of specialized fastening materials, such as treated screws that have a high tolerance to pressure and temperature, for instance.

Connecting to the Supply System

By the time you are through with fuel and power supply lines installations and connections, make sure that you have complied with the relevant regulations, like IEC 60079 for possibly explosive atmospheres. The sealing of all conduits and control valves operating within their rated parameters is one of the things that you would have to ensure.

Functional Testing

An initial functional test should be performed, and it should start with a vacuum test to determine system pressure, valve operation, and flow rate (if applicable). Measure efficiency with a monitoring system (e.g., a calibrated sensor) and then compare the data with the benchmark that has been set for the equipment.

Post-Installation Safety Protocols

After the system has started working, regular automated leak detection should be done to find out if there are any leaks, if the temperature is not too high, or if there is no problem with the electrical system, etc. In addition, it is a good idea to keep thorough inspection and monitoring records as proof that these systems are being maintained according to all the applicable ISO standards.

The international regulations regarding maintenance must be strictly adhered to, and certified personnel must perform the maintenance. This will help to make sure that the system will continue to operate at its best and have a long life.

Safety Considerations

Consequently, system operation and maintenance safety in the highest state must be the prime factor in preventing any accidents and guaranteeing operational and equipment integrity, most definitely. When working on live systems, proper personal protective equipment (PPE) must be utilized, including insulating gloves, safety glasses, and insulated shoes, among them. Moreover, during maintenance lockout/tagout procedures must be strictly followed in order to eliminate all possibilities of inadvertently energizing equipment.

Risk assessments that are continuous must be carried out so as to pinpoint potential critical areas within the facility for proactive corrections. Personnel must be given basic training in the applicable standards (such as NFPA 70E and related IEC standards), and emergency management procedures must be updated routinely. Dry and flammable materials-free facilities must be the norm, plus no other factors that could increase the risk of accidents should be allowed in order to avoid any compromise on safety.

Testing of equipment must include insulation testing, resistance measurements, and ground verification to assure compliance with technical standards and prevent technical failures stemming from electrical discharges or short circuits. The strict implementation of these measures leads to a safe and efficient work environment.

Benefits of Using a Gas Dispenser at a Gas Station

- Efficiency: Gas dispensers are quick and precise in their operation, which leads to shorter customer queues and fair-priced fuel for everyone.

- Safety: The dispensers have various safety features, including shut-off systems that automatically stop the flow in case of a spill and thus prevent accidents.

- Accuracy: Each dispenser guarantees an exact amount of fuel that matches the customer’s payment through its accurate fuel metering system.

- Convenience: Gas dispensers are user-friendly, with simple operating methods and intuitive interfaces that make the procedure to get fuel effortless.

- Durability: Gas dispensers are built to last and endure the rigors of daily usage and adverse environmental conditions.

Customer Service Efficiency

The latest technology in fuel dispensers contributes immensely to efficient customer service at gas stations. These pieces of equipment allow customers to pass through the customer flow quickly and smoothly, thus reducing waiting times. Besides, automated payment systems make the process faster by eliminating queues for small payments and adding to customer satisfaction. Accurate fueling not only cuts down on time but also earns customers’ trust and loyalty. Moreover, the strength and user-friendliness of fuel dispensers guarantee that the service will still be available and reliable even in times of unplanned demand.

Reduce Measurement Errors

I am convinced that regular calibration of the measuring instruments and the application of modern technologies like high-precision sensors could lower the measurement errors. This would prevent the imprecision from reaching the point that accuracy is lost even in difficult conditions. Also, by daily control and occasional checks, the differences between the readings could be detected and rectified in no time, thus creating a working place that is both efficient and trustworthy.

Environmental Impacts and Regulations

In most instances, industrial production methods, as a rule, contaminate and consume natural resources, and therefore, they have a very negative effect on the environment. It is the goal of both global and local environmental regulations to limit industrial emissions and thus prevent the occurrence of global warming and the change of climate. Factories that are awarded the ISO 14001 standard for environmental management systems are the ones that, internally, perform environmentally sustainable and friendly production processes. It is possible to reduce energy and water consumption from an industrial point of view by installing carbon capture technologies and minimizing waste to meet the current environmental regulations, thus protecting ecosystems.

Reference Sources

2. Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Frequently Asked Questions (FAQs)

What is the meaning of dispensador de gasolina?

A dispensador de gasolina, or simply a gas pump, is a contraption that dispenses fuel into a vehicle at a gas station. It usually features a nozzle that allows the user to fill their tanks with gasoline or diesel fuel easily and safely.

How does a dispensador de combustible operate?

The funcionamiento de un dispensador de combustible has a pump that causes fuel to be drawn from an underground tank and bled into the nozzle. Once an authorized user turns the pump on, it sucks the fuel up and sends it down the hose into the tank of a motor vehicle.

What is the proceso de llenado with a gas pump?

The proceso de llenado through a dispensador de gasolina goes off with the user selecting the type of fuel, pulling out the nozzle, and inserting it into the filler neck of a vehicle. After that, the user presses the handle to start the flow of fuel until the desired amount of combustible is dispensed.

What kind of combustible can be dispensed from a gas station?

Gas stations can provide all or some of the following kinds of fuel: regular, premium gasoline, diesel fuel, and sometimes alternative fuel, such as E85 or biodiesel. Each fuel type has its own storage tanks, dispensing directly to a nozzle assigned to it.

How must a gasoline dispenser be cared for?

Mantenimiento del dispensador de gasolina (Maintenance of a gasoline dispenser) is vital for its longevity and reliability. Regular inspection should include checking hoses for leaks, making sure nozzles work properly, and checking the pump’s calibration to ensure it delivers the correct amount of fuel.

What should I know about the life span of fuel dispensers?

The life span of fuel dispensers varies greatly with usage, maintenance, and environmental factors. Nonetheless, with good upkeep, it can be expected for a gas pump to last somewhere between 10 and 15 years before it gets replaced.

What safeguards exist in gas stations for fuel dispensers?

Gas stations implement various safety measures to protect users and property. These measures include overfilling prevention systems in gas pumps with a shut-off mechanism, spark-proof components, and proper signage to instruct customers on safety procedures during refueling.