Fuel dispensers are the core component of modern refueling capabilities, and they are the main equipment that ensures the smooth and swift fuel transfer in various sectors. They are everywhere, from retail gasoline stations that satisfy the needs of the average driver to industrial usage that feeds gigantic machines; thus, these devices become a very important part of the energy distribution process. Herein, we have an extensive discourse on the whole process of fuel dispensers and pumps, examining how they work, the main parts that allow their efficiency, and the increasing technology that leads to the extinction of certain old ways of operating. If you happen to be a person working in the energy field, a business owner handling fuel systems, or just a curious one wanting to know more about this basic technology, then this guide will surely give you the necessary information about the backbone of our fueling systems.

Introduction to the Fuel Dispenser Machine

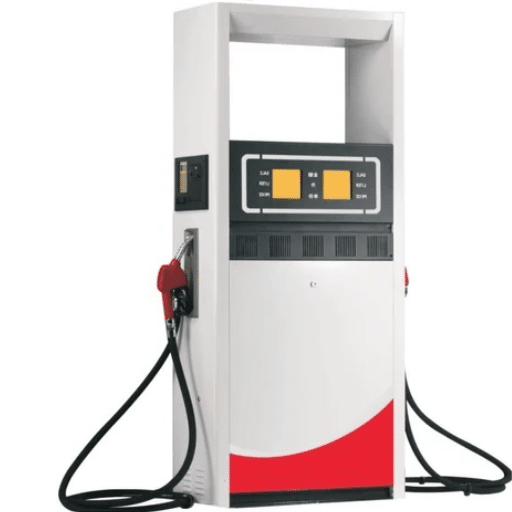

Fuel dispenser machines, more popularly known as gas pumps, are machines that have been invented for the purpose of the safe and effective transfer of fuel, such as gasoline or diesel, from the tanks into vehicles. They work by a system of underground fuel tanks, pumping mechanisms, metering components for accurate fuel measurement, and hoses with nozzles for direct delivery. The latest models have electronic displays that indicate the volume and cost of the dispensed fuel, thus ensuring transparency and consumer-friendliness. Also, safety features like automatic shutoff valves are incorporated into the machines to avoid overflows and spills during the transfer of fuel. Their design focuses on durability and precision, which is why they are a must for both commercial and personal applications of fuel.

Definition and Functionality of the Fuel Dispenser Machine

A fuel dispenser is a machine that transports liquid fuels like gasoline, diesel, or kerosene to either a car or a storage tank. It works in a way that the fuel is pulled from either an underground or above-ground reservoir, the amount of fuel is measured, and then it is sent through a pipe into the container. The current-day fuel dispensers hold two main functions: the measurement of fuel with precision and the delivery of fuel in a safe manner.

To make it possible for the machines to perform their functions, metering systems for accurate volume measurement, pumps for fuel transfer, and electronically controlled displays for user interaction are among the critical components. The flow meters and pressure control systems are often used for better performance and reliability are often used. Safety is the primary concern in the design of these machines, as they already have vapor recovery systems that are designed to reduce emissions, automatic shut-off systems that prevent spillage, and secure payment systems to not only make transactions faster but also to protect data. The state-of-the-art fuel dispensers come with a feature that enables them to detect leaks and monitor the levels of the inventory, thus making them a must-have in all places where both retail and industrial fueling operations are being carried out.

Types of Fuel Dispensers machine

Fuel dispenser machines can be divided according to their operational capabilities, the fuels they dispense, and the modern technology they use. Here are the major types:

Suction-Type Fuel Dispensers: These devices utilize a suction pump that is mounted at the fuel tank, and this pump is responsible for drawing the fuel from the tank to the nozzle. Their simple design and low cost make them preferred in small fueling stations. In addition, their performance is not constant and highly depends on the distance between the dispenser and the fuel storage tank.

Submersible Pump Fuel Dispensers: These dispensers consist of a submersible pump that supplies the fuel under pressure from the storage tank to the nozzle. This type of dispenser is best suited for large volume fuel stations as it will provide high flow rates over longer distances and will surely keep up with heavy fuel demands.

Single-Product and Multi-Product Dispensers: Single-product dispensers are designated to handle the dispensing of just one type of fuel, for instance, diesel or gasoline, whereas the multi-product dispensers are in charge of combining and consequently distributing the different types of fuel with often separate nozzles for unleaded, premium, and in some cases, E85 alternative fuels.

Electronic and Mechanical Dispensers: Mechanical fuel dispensers are those that use meters and dials of a rotating mechanical nature to show the quantity and price of fuel and are thus usually part of the older fueling systems. In contrast, electronic dispensers employ sophisticated digital interfaces with the addition of card payment terminals and automated fuel management systems as their features.

High-Flow and Ultra-High-Flow Dispensers: These dispensers are specially designed for industrial use and heavy-duty vehicles and provide very high flow rates, allowing for fast refueling of trucks, ships, or large equipment, thus reducing the time taken for the operations to be completed.

All types of fuel dispensers ensure optimal operation and efficiency by catering to the specific needs of the stations in terms of volume, fuel type, and requirements.

Importance of Fuel Dispenser Machines in Retail Fuel

Fuel dispenser machines are essential parts of the whole retail fueling station infrastructure, and they are responsible for delivering fuel to the customers accurately, quickly, and securely. The major dilemma that the devices pose is dealing with the accurate measurements and dispensing, which in turn eliminates the mistrust between the. retailers and the customers, besides complying with the regulatory requirements. The next-gen fuel dispensers feature a bunch of technologies like digital meters, programmable flow rates, and integrated payment systems, all working for better operational efficiency and customer convenience.

Moreover, they provide real-time monitoring of the fuel levels, thus reducing the chances of errors and helping the operators of the stations to manage the inventory better. The modern dispensers can also accommodate various types of fuels such as gasoline, diesel, biodiesel, and even alternative fuels such as LNG or hydrogen, which gives the retailers the flexibility to adapt to the changing needs of the customers. The machines are crucial in quality control, preventing contamination, and participating in the environmental and safety regulations, thus increasing the reliability and reputation of retail fueling operations.

Components of a Fuel Dispenser Machine

Hydraulics System: This system helps to move the fuel from the storage tank to the nozzle in an easy and controlled way.

Metering Unit: It measures the exact amount of fuel that is being dispensed, thus keeping everything accurate and in line.

Electronic Control System: It takes care of the dispenser and all its functionalities, such as transactions, display settings, and connection with other management systems.

Nozzle: This is the spot where fuel is given to the vehicle’s tank, and it has a shut-off mechanism that ensures safety and accuracy.

Hoses and Pipes: They are the safe passage for the fuel to travel between the dispenser’s internal components and the nozzle.

Display Panel: It is the source of vital information like price, volume dispensed, and type of fuel, thereby making it clear for consumers.

It’s the cooperation of these elements that makes it possible for retail gas stations to have fuel dispensing that is efficient, accurate, and safe.

Understanding the Fuel Pump

A fuel pump is an essential part of modern cars and the whole retail fueling system. Its main duty is to move the fuel from the storage tank to the engine or to the dispensing nozzle for consumer use. Modern-day fuel pumps can be classified as electric and mechanical, with electric pumps being mostly used in fuel-injected engines because of their precision and effectiveness.

Pumps push the fuel through the network of pipes or hoses to where it should go by creating pressure. The retailers rely on the integrated pumps, sensors, and valves in the dispensers to control the fuel flow, hence preventing overfilling or leaks. Such advanced systems have even included features like automatic shut-off devices and gas recovery for eco-friendly purposes.

The design and regular maintenance of the pump are the two main factors that influence the performance and safety of any fuel pump, as the pump that is well maintained is the one that performs optimally under the safety standards.

Role of the Nozzle in Fuel Dispensing

The nozzle is an essential part of the fuel dispensing process, playing the role of a controller for the transfer of fuel from the pump to the vehicle’s tank. Most modern fuel nozzles have the automatic shut-off feature, which uses a small venturi tube to recognize when the tank is full, thus preventing overflow and spillage. Moreover, these nozzles are built up in such a way that they allow the flow of fuel to be accurately controlled, which leads to less wastage and the right amounts being delivered to the customers.

Furthermore, nozzles frequently have vapor recovery systems that trap fuel vapors and reroute them to the storage tank, thus minimizing air pollution and complying with the strictest emission regulations. The nozzles are also ergonomically designed to provide comfort and safety to the operator while ensuring compatibility with different fueling systems. The nozzles should be inspected and maintained regularly to ensure their longevity, accuracy, and compliance with safety regulations.

Overview of the Meter and Flow Rate

The meter in a fueling system represents the key element that has the purpose of measuring the amount of fuel dispensed with the utmost precision. In general, the operations of positive displacement meters or turbine meters are taken up because of their high reliability and accuracy, even in varying flow conditions. The installation of modern meters comes with digital interfaces and sensors that guarantee real-time monitoring and data logging, thus enabling compliance with industry regulations and enhancing operational transparency.

Flow rate, which refers to the amount of fuel delivered in a given time, is affected by several factors, including pump capacity, design of the nozzle, and fuel viscosity. It is of utmost importance to keep the flow rate at the right level in order to avoid over-pressurization and, at the same time, to make the process more efficient and safe. To achieve this with the least possible mistakes and without causing environmental risks that result from spilling or overflowing, advanced systems utilize automatic flow regulators. Furthermore, regular calibration and quit adherence to the laid down standards in the industry are very important as these two factors determine the accuracy of the meter and the uniformity of the flow performance.

Different Types of Fuel

It is the source and application that classify fuel types. The list of treatment types typically includes:

Gasoline – A fuel made from petroleum that is mostly used in combustion engines for cars. The refining process is aimed at getting the highest of both energy and performance.

Diesel – Diesel is also produced from petroleum, but its higher energy density makes it suitable for heavy machinery, trucks, and industrial vehicles.

Natural Gas – A fossil fuel that burns cleaner than others and is therefore often used in homes for heating, cooking, and as a power source; also in some compressed or liquefied forms (CNG/LNG) for transportation.

Ethanol – A plant-derived biofuel that, through fermentation processes, is made from non-food crops and is usually mixed with gasoline to form a more eco-friendly fuel.

Biodiesel – A renewable resource for the production of diesel fuel from fat and oil, which is intended for reducing the emission of carbon dioxide and other greenhouse gases.

Kerosene – A fuel used for aircraft engines and heating, that is particularly appreciated for its clean-burning qualities.

Propane – It finds application as a fuel for heating and cooking, sometimes also serving as a power source for forklifts or other specialized equipment.

The choice of these fuels depends on factors such as their availability, price, and appropriateness for particular uses.

Petrol vs Diesel: Key Differences

Petrol and diesel are still the two main fuels of choice for internal combustion engines, and each fuel has its own unique properties and characteristics. The following aspects can be identified as the main differences between petrol and diesel:

Combustion: petrol engines are the ones that ignite the spark, and the best way to do it is with a spark plug that ignites the air-fuel mixture. On the other hand, diesel engines work by compressing the air and directly injecting the fuel; therefore, the heat generated by the compression goes up to the point of the fuel igniting.

Efficiency: Diesel engines are, in general, more fuel-efficient than petrol engines, the reason being that the former process has energy density and the latter process is efficient in using the fuel; thus, becoming more economical in long-distance and heavy-duty applications.

Power and Performance: petrol engines provide a smooth power increase and can reach higher RPMs, which is mostly liked by passenger cars that need consistent performance. diesel engines, however, supply torque which is higher than the power rating of the engine, and thus they can be called for the road, especially where heavy vehicles moonlight and tow cases.

Environmental Impact: the scenario is that diesel, or rather the former engine species, emits less CO2 per mile than their petrol counterparts, but in fact, the latter emits more in emitting pollutants like nitrogen oxides (NOx) and contributes to the air quality concerns as they are so tiny that they hang around for long periods of time in the atmosphere.

Cost: petrol is most of the time less expensive than diesel in terms of the initial vehicle costs and the prices of fuel in different areas. However, diesel cars often have cheaper operational costs because of good fuel economy.

Maintenance: Diesel engine maintenance is intricate and can be costly because of its sophistication, but on the other hand, petrol engines are relatively cheap and simple to repair.

These basic differences show how application requirements, environmental regulation, and economic factors are important in making the choice between petrol and diesel engines.

Gasoline Diesel Fuel Usage

Gasoline and diesel fuels are three quite different products. Their differences manifest in a lot of ways, such as the variety of their uses, the specific application where one of them is most efficient, and the overall suitability of the fuel type across the different sectors. Gasoline fuel is the first choice for passenger vehicles, motorcycles, and indeed any smaller vehicle where a spark-ignition engine is used. These engines produce less noise and their operation is smoother compared to other types of engines. In contrast, diesel is the first choice in the names of large transport like commercial vehicles and the equipment in manufacturing due to its high energy density, torque, which is sufficient for lateral movement of machines, and also because of its better fuel economy in long run working hours. Gasoline-energized vehicles are usually more active and are suitable for short distances and lighter loads, whereas diesel units have a stronger presence in long-haul applications and heavy-duty work. The choice between the two fuel types is determined by several factors, including engine structure, performance expected, and cost, among others, and at the same time is ruled by changing environmental regulations and the progress in engine technology.

Understanding Oil Fuel in Dispensers

Dispensers that are oil fuel are usually attributed to the systems and devices that are involved in the delivery of fuel at gas stations, factories, or depots. The main elements are storage tanks, fuel pumps, metering systems, and nozzles that are specifically built to handle fuel types such as gasoline, diesel, or biofuels. These dispensers are required to comply with the industry standards and government regulations concerning the environment to stop leakage, which would be an unsafe and inefficient situation.

The latest fuel dispensers have been installed with advanced flow-regulating mechanisms and meters that enable the delivery of very precise amounts of fuel, thereby greatly reducing wastage. Furthermore, being able to work with vapor recovery systems is an important feature that complies with environmental regulations for lower emissions. The construction of dispensers involves the use of materials that are suited to the type of fuel in order to prevent corrosion and degradation, and this also helps in ensuring long-term reliability. Besides, the development of digital interfaces has made real-time monitoring and user-friendly operations possible, thus allowing seamless integration with payment and inventory systems. All in all, the proper calibration and following of operational guidelines are the key factors to maintaining these systems and eventually getting the desired performance and regulatory compliance.

Price Factors for Fuel Dispenser Machines

The price of fuel dispensing machines is determined by several important factors:

Fuel Type: Dispensers for diverse fuels or for specialized ones, such as biofuels, are usually costly because of the need for special parts.

Technological Features: The overall cost is raised by advanced features like integrated payment systems, real-time monitoring, and digital displays.

Material Quality: The price of high-quality, durable materials that resist wear and corrosion is typically higher, but they enhance the lifespan of the product.

Compliance Requirements: Pricing could be impacted by dispensers that are made to fulfill certain regulatory standards or secure certifications.

Pump Capacity: Often, machines with the ability to dispense more quickly or handle larger volumes come at a higher price.

Installation and Maintenance: Expenses may include the cost of installation, depending on what is required, or future maintenance costs.

By knowing these factors, buyers can choose dispensers that fit their operational needs and at the same time their budget constraints.

Analyzing Dispenser Price Variations

Price differences among dispensers are a result of many factors coming into play and should always be acknowledged during the analysis stage. Quite often, the high-priced dispensers are those made of extra heavy-duty materials like stainless steel or corrosion-proof alloys that can be used for years in tough environments. Similarly, the prices of dispensers with advanced features such as motion-sensor operation, digital monitoring systems, or programmable settings are at the very high end of the market due to the inclusion of state-of-the-art technology.

The certification costs and meeting the related legal and industry requirements, including NSF (National Sanitation Foundation) or ADA (Americans with Disabilities Act), also lead to price increases. These certifications are important for the respective industries and, therefore, are very much in demand because they guarantee safety, hygiene, and accessibility. Furthermore, the pump capacity, either in terms of flow rates or volume per cycle, is a direct determinant of price; typically, dispensers that can support industrial or commercial applications with higher throughput are at the high end of the price spectrum. Finally, the expenses of installation, the customization of the dispenser to meet the specific requirements of the facility, and the contracts for ongoing maintenance can all add significantly to the overall cost, depending on how complex the setup is and the skill level of the provider.

By being aware of these factors, companies can make the right purchasing decisions, and their investments can be perfectly in tune with both the operational needs and the financial planning process.

Machine Fuel Dispenser Price Comparisons

Prices of various machines in fuel dispensers are influenced by factors ranging from dispenser type, capacity, and integrated technologies. According to information compiled from major websites, the prices of a simple single-hose fuel dispenser usually hover between $2,000 and $5,000. More advanced models with multi-hose systems, integrated payment systems, and digital monitoring systems, however, cost far more, generally going from $7,000 to $15,000.

Additionally, fuel dispensers designed for high-volume commercial or industrial use tend to be very expensive, generally running over $15,000, because they are required to be more durable, more precise, and highly automated compared to regular fuel dispensers. The installation cost must also be considered, as depending on the configurations needed for the system or the complexity of the installation, the installation cost may be added to the purchase cost by 10% to 25%. Maintenance of the employed equipment, such as hoses and meters, is an additional long-term cost and should be factored into the budget.

Upon identifying these patterns in pricing, buyers will determine those models that best meet their operational needs, considering upfront cost versus efficiency and scalability over time.

Factors Affecting Fuel Dispenser Pricing

Fuel dispenser prices result from a complex interaction between various technical, operational, and external factors in the market. Below are listed the key factors:

Technology and Features: Advanced features such as digital payment integration, automated reporting systems, and security systems tend to increase the price. Dispensers with IoT functionality and cloud-based monitoring also tend to cost more because of their state-of-the-art technology.

Materials and Build Quality: The materials used in construction, which include stainless steel parts, corrosion-resistant surface treatments, and high-quality hoses, all have their impact on durability and on cost considerations. Dispensers claiming durability will be costlier but are reliable over time in various environments.

Capacity and Flow Rate: High-capacity dispensers are priced higher compared to standard dispensers that flow fuel at a slower pace in smaller fuel stations.

Compliance and Certification: Costing also arises from the fact that regional compliance standards and certifications have to be complied with, such as those related to Weights and Measures. Compliance is ensured for the safety, accuracy, and legality of operations; however, certified equipment must be procured at a price.

Brand and Manufacturer Reputation: Contrary to the more renowned brands, known for their reliability and hence after-sales service, tend to be more costly, meaning more benefits, like better warranties and after-sales support systems, for the buyer.

Market Demand and Supply Chain Issues: Prices also evolve through the variation of raw material costs, logistics of the supply chain, and regional demand. Global variables affecting the manufacturing industry and the oil markets can cascade down pricing processes in dispensers.

When these factors are considered, decision-makers can choose whether to purchase in alignment with the performance requirements and budget allocations.

Operational Aspects of Fuel Dispensers

Key Components and Functionality: In essence, fuel dispensers are used for the transfer of fuel from storage tanks to vehicles in precise and safe amounts. The pump, flow meter, hose, nozzle, and display unit are some main critical components. The pump pushes the fuel through the system while the flow meter ensures accurate measurement. Also, the nozzle features an automatic shut-off to prevent overflows during dispensing. The display unit provides real-time information on the amount dispensed and the price.

Maintenance and Reliability: In order to keep dispensers in proper working order and in compliance with accepted standards, periodic maintenance is necessary. This includes performing calibration procedures on the flow meter and checking hoses for wear. Also, it includes inspecting the hoses and nozzles for proper operation of safety functions, among others. Service intervals recommended by manufacturers are to be observed as they reduce downtime and extend the life of the system.

Safety and Compliance: Overriding operational safety is ensured by modern dispensers employing vapor recovery systems to limit emissions and comply with local regulatory standards. Proper installation, grounding, and maintenance procedures would mitigate risks related to static electricity and fuel leakage, hence protecting users and the environment.

Safety Features: Shut-off Valves and Automatic Fuel Nozzles

Shut-off valves and automatic fuel nozzles play a safety role in the operation of the fuel dispenser. The shut-off valve inhibits uncontrolled flow of the fuel should a system failure occur or in the event of an emergency, thus stopping the supply to reduce threats. There are shutdown valves that work on pressure-sensitive mechanisms, which get activated under abnormal surge conditions that arise to cause harm to equipment or personnel.

Automatic fuel nozzles integrate safety features involving automatic shut-off systems driven by pressure variation. These nozzles register a fill level at the tank, and upon the tank attaining capacity, they will cease fuel flow. This helps in avoiding spillage and consequently minimizing environmental hazards for the operation. In accordance with the intent to protect users, the newest design incorporates anti-static and vapor recovery technologies to mitigate the safety risks occasioned by static discharges and emissions. These features thus became part of the most important fuel dispenser safety protocols, protecting compliance with the most stringent regulatory requirements while considering operational safety and environmental conservation.

Manual vs Automatic Fuel Dispensing

From my standpoint, the distinction between manual and automatic dispensing mainly lies in control and efficiency. Almost all manual loading and emptying of a tank requires constant supervision and operation by the user. This may allow precise control of fuel quantity but at the risk of human error and spillage. Meanwhile, automatic dispensing controls the flow of fuel by preset mechanisms or sensors, which greatly enhances the accuracy, limits wastage, and poses fewer safety hazards. Manual dispensing might be suitable for smaller or special uses, while automatic ones are more reliable and generally conform to prime safety and environmental legislation.

Maintenance of the Fuel Dispenser machine and Pumps

Fuel dispenser machines and pumps must be properly maintained to maintain operational efficiency, safety, and standards of industry standards. Some maintenance-related activities are the following:

Inspection and Cleaning: Inspect all of the dispenser’s parts on a routine basis; hoses, nozzles, and filters are often subject to wear and tear or may even suffer damage or blockage. Clean the equipment to prevent any buildup of particles or fuel residues that could impair the function of the equipment. Ensure to change the filters as recommended by the manufacturer to ensure the best filtration.

Calibration: Calibrate the dispenser from time to time to guarantee accurate fuel measurement, thus avoiding under- or over-dispensing and ensuring regulatory and customer adherence.

Testing and Monitoring: Pressure test and monitor the fuel line system for leaks. Early detection of fuel leaks prevents fuel losses and fuels environmental concerns.

Electrical System Checks: Inspect and maintain electrical components, including wiring and control panels, to avert failures and improve reliability. Electrical system faults might bring about operational stoppages or place safety hazards.

Lubrication and Maintenance of Moving Parts: Lubricate moving parts, such as pump shafts and bearings, to reduce wear and prolong equipment life. All mechanical components should move smoothly without any obstruction.

Compliance with Regulations and Record Keeping: Maintain detailed records of all maintenance conducted, inspections performed, and repairs made to meet safety regulations, legal statutes, and environmental standards. Documentation provides traceability and aids in the scheduling of future maintenance activities.

Above above-stated procedures ensure high performance, less downtime, and fewer chances of safety and environmental mishaps for fuel dispenser machines and pumps.

Reference Sources

Automatic Vehicle Fueling System using PLC Controlled Robotic Arm

Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Frequently Asked Questions (FAQs)

What is a fuel dispensing machine? How does it work?

A fuel dispensing machine, usually called a petrol pump machine or fuel dispensing apparatus, is a machine used for dispensing fuel into vehicles. It operates by first measuring fuel flow, then it supplies fuel in the right amount through a nozzle and into the fuel tank of a vehicle. It is made up of several mechanical and electronic components that provide smooth operation and an efficient fueling experience, such as a meter to measure the amount of fuel dispensed from the dispenser to the vehicle, with an automatic shut-off to prevent the fuel being put in the tank from going over an assigned level.

What kind of fuel dispenser does a petrol station have?

The petrol stations normally have various fuel dispensers for gasoline, diesel fuel, and LPG. The dispenser manufacturers like Gilbarco and Tatsuno have various models for the various fuel options, so that the stations can satisfy the clients’ demands; but of course, each dispenser would be different from one another depending on the fuel type that it deals with, as well as the flow rate of the fuel-it should have a positive impact on the fueling experience.

How can I provide good maintenance for my dispenser so that it may reliably perform on demand?

For any fuel dispenser to have reliable performance, regular servicing must be carried out on the mechanical systems, electronic parts, and safety equipment. The following maintenance operations would guarantee an optimum fueling experience: checking the fuel hose for any leaks, ensuring that the nozzle works properly, and checking emergency stop buttons and shut-off valves intermittently. Hence, having regular maintenance renders the proper functioning of each step during fueling.

What specifications should I look for in a diesel fuel dispenser?

Some of the features that can be considered when buying a diesel fuel dispenser include a high flow rate, an automatic fuel nozzle, and compatibility with portable fuel tanks. One can also go for dispensers with a digital fuel management system so that tracking of fuel dispensing can be obtained in real-time. Gilbarco Veeder-root makes diesel dispensers, thus ensuring good quality in the delivery of diesel fuel as well as complying with the relevant safety specifications.

What is an estimated price range for fuel dispensers and pumps?

Fuel dispensers and pumps may sell and buy at various prices depending on features and manufacturer. Generally, the machine fuel dispenser price ranges from a couple of thousand dollars to tens of thousands of dollars, mostly depending on the sophistication of the equipment and additional features such as a digital display or even remote monitoring capabilities. It’s always wise to compare prices from different dispenser manufacturers and settle for the best deal that suits your needs.

How can a petrol dispenser maintain fuel quality?

Maintaining fuel quality can be done through a petrol dispenser using filtration and ensuring proper underground storage conditions. Inspections are then called for on the fuel tank and dispensers, at least periodically, in order to avoid contamination. Not to mention, those dispensers must have meters that effectively measure fuel, so the stations give the right amount and quality of fuel to their customers.

Is a portable fuel dispenser suitable for my trucks?

Yes, a portable fuel dispenser can cater to various applications, including fueling trucks. A truck fuel dispenser typically has a flexible hose with a high flow rate so that it can quickly fill the truck with fuel. Brands like OPW offer portable fuel dispensers that conform to safety regulations and would perform satisfactorily in commercial use.

What are the benefits of digital fuel dispensing systems?

These systems boast improved fuel measuring accuracy; they also monitor fuel levels in real-time and record transactions automatically. They supplement the fuel dispensing operations with enhanced user experience by reducing human errors and thus making the subsidizing and program management of stations and petrol station dispensers less cumbersome.

What factors should I consider for my business when choosing a fuel dispenser?

In selecting suitable fuel dispensers for your business, the considerations should include the type of fuels offered, the flow rates that can be expected, and the general layout of the fueling station. Choose those dispensers compatible with your brand image and customer service ethos. Also, ensure that the dispenser’s mechanical and electronic features align with your particular requirements, as well as the local registration laws.