Fuel dispensers and pumps have been facilitating smooth transportation and industry ever since their invention. Often taken for granted as mere utility tools, these devices are elaborate systems engineered with a precise focus on fuel delivery accuracy.

But how does one go about working with them, and what makes them so reliable in terms of meeting daily energy needs? This comprehensive guide explores the fundamentals of fuel dispensing systems and pumps, revealing their inner workings, components, and the technology that drives their performance.

Whether you’re a businessman, an engineer, or simply a curious soul wondering how fuel reaches your car, this article will provide valuable information on an often-ignored yet critical component of our everyday lives.

Overview of Fuel Dispensers

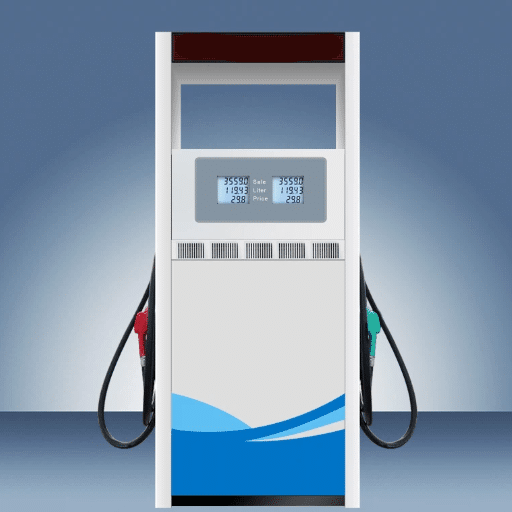

Fuel dispensers are specialized machines designed to transfer fuel from storage tanks to vehicles or containers. They act as pumps to draw the fuel, and a metering system carefully measures the amount before the fuel is released from the nozzle.

Fuel dispensing is all about the safe, precise, and effective delivery of fuel, which is essential from both the customer’s and the industry’s perspective. Modern fuel dispensers are equipped with sophisticated digital measuring displays, payment mechanisms, and safety features for enhanced ease of use and credibility.

What is a Fuel Dispenser Pump?

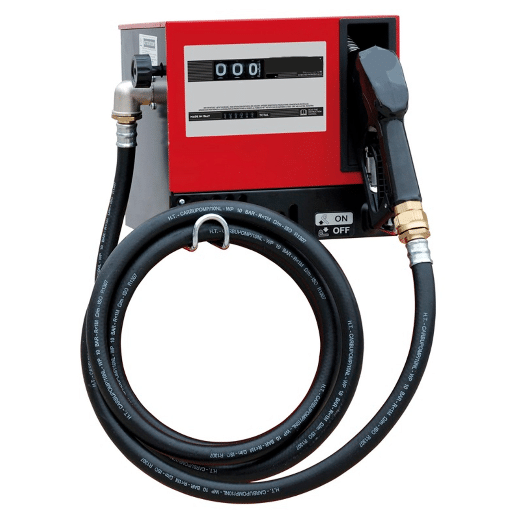

A fundamental element at fueling stations, the fuel dispenser pump is tasked with transferring fuel from tanks to vehicles or into portable containers. The apparatus is composed of several main parts, each contributing to the operation:

🔄 Submersible/Suction Pump

Accepts fuel from underground storage tanks, ensuring reliable fuel extraction with precision engineering.

📏 Metering Unit

Ensures exact fuel quantity delivery, calibrated to comply with regional standards and regulations for accuracy.

🚗 Hoses & Nozzles

Dispense fuel directly into vehicles with automatic safety shut-off features and spill prevention technology.

Modern Features Include:

- Digital displays with price per gallon, volume dispensed, and total cost information

- Integrated payment systems supporting debit, credit, and contactless payments

- Safety systems featuring emergency shut-off valves and spill prevention mechanisms

- Environmental compliance through advanced vapor recovery systems

- Sustainability solutions for alternative fuels including biodiesel, ethanol blends, and EV charging

Types of Fuel Dispensers

Fuel dispensers are broadly classified based on the type of fuel dispensed and the technology used. Here are the major types with detailed analysis:

⛽ Gasoline and Diesel Dispensers

The most common type worldwide for cars, trucks, and other vehicles. Modern installations feature advanced metering systems and vapor recovery mechanisms to prevent emissions during refueling, with focus on improving accuracy and environmental conservation.

🌱 Alternative Fuel Dispensers

Designed for biodiesel, CNG (Compressed Natural Gas), and ethanol blends like E85. These dispensers help reduce greenhouse gas emissions compared to conventional gasoline and operate under high-pressure conditions with enhanced safety protocols.

💧 Hydrogen Fuel Dispensers

Crucial for fuel-cell vehicles, operating under extreme pressures (up to 700 bar) with rigorous safety protocols. Features include vehicle communication systems to control fueling rates and prevent over-pressurization.

⚡ Electric Vehicle (EV) Charging Stations

While technically not “fuel dispensers,” these are essential components of modern energy infrastructure. Range from Level 1 home chargers to ultra-fast DC charging networks, with exponential growth worldwide.

Industry Growth: This variety in fuel dispensers reflects dynamic changes in fueling technologies, aiming to keep pace with shifts in the energy landscape while prioritizing sustainability and efficiency.

Components of Fuel Dispensers

Fuel dispensers consist of several complex components, each performing crucial functions in ensuring accurate, efficient, and safe fuel delivery:

📊 Metering System

Advanced systems with sensors for precise volume measurement. High-precision flow meters ensure accuracy and minimize discrepancies in fuel dispensing operations.

⚙️ Pumps and Motors

Move fuel from storage tank to nozzle with enhanced energy efficiency. Modern designs focus on reducing both energy consumption and operational costs.

🔧 Nozzle and Hose Assembly

Control fuel flow through pressure-sensitive mechanisms. Feature automatic shut-off technology as a crucial safety feature for spill prevention.

💻 Electronic Control Systems

Monitor and manage operations including pricing and dispensing data. Latest generation includes IoT technology for real-time connectivity and remote diagnosis.

📱 Display Screens

LCD or touchscreen interfaces displaying transaction details, fueling instructions, and interactive advertisements for enhanced user experience.

🛡️ Safety Measures

Include pressure relief valves and emergency shut-off controls, crucial for handling volatile fuel types safely and efficiently.

Technology Integration: Higher integration of sustainable technologies is being observed, including biofuel blending capabilities and electric charging modules within conventional fuel dispensers, supporting the shift towards low-emission energy alternatives.

How Fuel Dispensers Work

The entire system works to deliver fuel safely from underground storage tanks into vehicle fuel tanks through a sophisticated process:

Mechanism of Fuel Dispense

🎯 Advanced Technology Performance

- Accuracy: ±0.2% precision with sophisticated flow meters (positive displacement or turbine types)

- Speed: 40 L/min for standard vehicles, 130 L/min for commercial fleets

- Temperature Compensation: Automatic adjustment for fuel expansion/contraction

- Vapor Recovery: Captures evaporated fuel vapors, improving air quality around fuel stations

- Payment Integration: Contactless methods with digital displays for additional services and loyalty rewards

- IoT Monitoring: Real-time fuel inventory management, predictive maintenance, and transaction records

Role of Pumps in Fuel Dispenser Systems

Pumps are essential components ensuring efficient and accurate fuel delivery within dispenser systems. Contemporary fuel pumps feature cutting-edge technology:

🔧 Advanced Pump Technologies

- Variable-speed control for maintaining constant fuel flow

- High-precision flow meters minimizing variations during fueling

- Modern sensors monitoring pressure and flow rates for safety compliance

- Energy management systems reducing power consumption by 30%

- Predictive maintenance alerts for fault prevention and extended lifespan

Performance Range: High-performance pumps achieve flow rates from 10-130 L/min, accommodating everything from private vehicles to large commercial transport. Designs vary by fuel type (gasoline, diesel, biofuels, CNG) to meet expanding energy requirements.

Remote Monitoring and Control

🌐 IoT-Enabled Revolution

Remote monitoring and control have revolutionized fuel station operations, enabling operators to manage systems more effectively through IoT-enabled solutions.

💰 Cost Benefits

Up to 25% reduction in operational costs through improved data visibility and early incident detection before equipment failure or downtime.

📊 Real-Time Tracking

Monitor flow rates, inventory levels, and pump status remotely via cloud-based solutions

🎛️ Remote Control

Suspend pump activities, reconfigure settings, or update software in emergencies

🔍 Leak Detection

Alert systems for anomaly detection, reducing fuel loss and ecological risks

📈 Data Analytics

Optimize resource allocation and enhance overall fuel distribution network efficiency

Design Considerations for Fuel Dispensers

Designing fuel dispensers requires consideration of numerous critical factors for maximum performance and longevity:

🏗️ Durability and Material Selection

Corrosion and wear-resistant materials ensuring long working life in harsh environmental conditions

👤 User-Friendly Interfaces

Intuitive controls, clear displays, and ergonomic design for quick and efficient fueling operations

🛡️ Safety Features

Automatic shut-off valves, grounding systems, and fire suppression to prevent accidents

🌍 Environmental Compliance

Meeting regulations on emissions and leakage to support sustainability initiatives

💻 Technology Integration

Digital payment systems, data tracking, and remote monitoring for enhanced operational efficiency

🔧 Maintenance and Accessibility

Easy accessibility to internal components for simple maintenance and minimal downtime

Ergonomics and User Experience

Modern fuel dispenser design prioritizes user convenience across diverse clientele. Studies show significant improvements in customer experience through thoughtful design:

- 30% increase in customer satisfaction with digital payment integration

- Intuitive interfaces (touchscreens, visual instructions) drastically reduce processing time

- Ergonomic nozzle designs accommodate vehicles of all sizes and reduce user strain

- Strategic lighting improves safety during nighttime and low-visibility conditions

- Inclusive designs with multiple language support and accessibility features

Safety Standards and Regulations

⚠️ Critical Safety Overview

Safety standards and regulations protect consumers and the environment through comprehensive guidelines enforced by various international bodies.

🔥 Fire Protection Standards

NFPA 30 & NFPA 58: National Fire Protection Association codes for safe storage and handling of flammable and combustible liquids and gases, minimizing fire exposure risks.

⚡ Electrical Safety Certifications

IEC & UL Standards: International Electrotechnical Commission and Underwriters Laboratories certifications ensuring electrical safety and component robustness.

🌍 Environmental Protection

EPA Regulations: Environmental Protection Agency rules for VOC emission reduction through vapor recovery systems.

🔍 Maintenance Compliance

Regular Inspections: Mandatory leak detection, nozzle recalibration, and software updates ensuring continued safe operation.

📊 Safety Performance Statistics

- UL-certified dispensers: 30% reduction in circuit malfunctions

- Stage II vapor recovery: 95% reduction in VOC emissions from refueling operations

- Enhanced reliability: Improved safety performance through rigorous testing and certification

Innovative Features in Modern Dispensers

🚀 Cutting-Edge Technology Integration

Modern dispensing units incorporate state-of-the-art technology to enhance efficiency, safety, and user experience:

🌐 IoT Integration

Real-time monitoring and diagnostics for fuel levels, equipment health, and usage trends

💳 Multi-Payment Systems

NFC transactions, mobile app payments, and contactless solutions

📺 Digital Displays

Enhanced interfaces with targeted advertising capabilities for additional revenue streams

🌱 Environmental Features

Advanced vapor recovery systems and emission reduction technologies

💡 Energy Efficiency

Low-energy motors, LED lighting, and automated shutdown systems

🤖 Automation

Customizable configurations and operational excellence features

📈 Adoption Statistics

Contactless payments: 40% increase in adoption at fuel stations (2023), driven by convenience and hygiene considerations.

Popular Brands and Models

The fueling equipment industry is dominated by several leading brands providing innovative and reliable dispensers:

🏆 Gilbarco Veeder-Root

Industry leader known for durable and efficient fuel dispensers with advanced payment options and energy-saving features. Recognized globally for quality and innovation.

🔧 Tokheim

Renowned for user-friendly interfaces and precision engineering, addressing various fuel-related needs with reliable performance solutions.

🌍 Wayne Fueling Systems

Global leader with cutting-edge technology, balancing performance and environmental considerations in modern dispenser generation.

⚙️ Bennett Pump Company

Known for dependable fueling solutions with customization options designed to exceed industry standards and meet specific requirements.

Gilbarco: A Leader in Fuel Dispenser Technology

Gilbarco Veeder-Root stands as the leading innovator in fuel dispensers, recognized for offering advanced technologies and solutions to address contemporary fueling challenges. With over 150 years of tradition, the company continues shaping the fueling landscape.

🌟 Key Innovations

- Encore 700S: High-performance dispenser with seamless payment integration and advanced security

- EMV Compliance: Contactless payment protection and mobile wallet support

- Modular Design: Reduced maintenance costs for high-traffic locations

- Alternative Fuels: Support for E85, biodiesel, and hydrogen dispensing

- EV Integration: Fast-charging solutions supporting green mobility transition

- Insight360 Platform: Cloud-based real-time monitoring and analytics

Comparing Different Fuel Dispenser Models

Several key criteria should be considered when comparing fuel dispenser models to determine the best fit for specific business needs:

| Criteria | Basic Models | Advanced Models | Premium Models |

|---|---|---|---|

| Technology & Connectivity | Basic digital display | IoT-enabled monitoring | Full cloud integration & analytics |

| Flow Rate & Capacity | Standard flow rates | Variable capacity options | High-flow for commercial use |

| Durability & Build Quality | Standard weather-resistant | Enhanced corrosion protection | Heavy-duty, harsh climate design |

| Payment Integration | Basic card readers | Contactless & mobile support | Full digital wallet & interactive displays |

| Best For | Small-scale operations | Medium-traffic stations | High-volume commercial facilities |

Selection Criteria: Choosing the right model involves balancing initial cost, required features, and operational scale of the fuel station for optimal return on investment.

Customer Support and Service Options

Quality customer support and maintenance services are essential for sustained functionality and reliability of fuel dispenser investments:

🔧 Service Network

24-hour technical support, on-site maintenance, and extended warranty packages

📡 Remote Diagnostics

Proactive monitoring solutions enabling quick problem identification and resolution

🎯 Customizable Plans

Service plans tailored to individual fuel station operator needs

📚 Training Programs

Operator training and spare parts availability ensuring smooth operations

📊 Service Impact

Companies investing in after-market support enjoy: 30% higher retention and increased satisfaction scores. Efficient customer service minimizes downtime, protects revenue streams, and increases user satisfaction.

Retail Station Fuel Dispenser Management

🏪 Essential Management Practices

Fuel dispensers at retail stations require comprehensive management including regular maintenance, accurate calibration, and safety checks to ensure proper operation.

Key Benefits: Proper management prevents costly breakdowns, preserves operations, reduces losses, gains customer confidence, and ensures compliance with industry standards.

Best Practices for Retail Fuel Stations

🔍 Routine Maintenance and Inspections

Ensure regular maintenance on dispensers, tanks, and related equipment to prevent downtime and heavy repair costs. Monitor for wear, leaks, or damage to guarantee operational reliability.

⚖️ Accurate Calibration and Measurement

Plan periodic calibrations of fuel dispensers to ensure correct measurement, build customer confidence, and prevent financial loss due to inaccuracies.

🛡️ Focus on Safety Standards

Emphasize industry safety procedures including safe storage of flammable materials, adequate ventilation, and comprehensive employee emergency training.

🌍 Environmental Compliance

Ensure monitoring and reporting compliance with local regulations. Address vapor recovery, spill prevention, and waste disposal for sustainability.

👨🎓 Invest in Staff Training

Conduct periodic training on equipment use, safety procedures, and emergency response. Well-informed staff enhance station performance and customer satisfaction.

🔧 Preventive Maintenance

Regular cleaning of nozzles and hoses, calibration checks for accuracy, and prompt problem resolution following manufacturer timelines to extend equipment lifespan.

Future Trends in Fuel Dispensing Technology

🚀 Evolution of Fuel Dispensing

Fuel dispensing technology continually evolves in response to changing demands for efficiency, sustainability, and convenience:

🌐 IoT Integration

Intelligent systems for real-time monitoring and predictive maintenance, reducing downtime and ensuring optimal performance

🔋 Alternative Energy Solutions

Advanced dispensing systems for hydrogen and electric energy, supporting the transition to cleaner transportation

🤖 Automation & Contactless

Enhanced automation and contactless payment systems for faster, more secure customer transactions

🌱 Sustainability Focus

Green technology integration supporting environmentally friendly and sustainable energy solutions

Industry Direction: These developments facilitate operations and align with the broader pursuit of greener, sustainable energy solutions for the future of transportation and industry.

Reference Sources

- “Automatic Vehicle Fueling System using PLC Controlled Robotic Arm”

- “Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)”

- “Examining The Suitable Palliatives In Cushioning The Removal Of Fuel Subsidy In Nigeria”

Frequently Asked Questions (FAQs)

❓ What is a fuel dispenser pump, and how does it work?

A fuel dispenser pump is a device used to dispense various types of fuel, including petrol and kerosene, at petrol stations. It works by drawing fuel from an underground storage tank through a pipe and delivering it to the vehicle through a nozzle. The operation can be manual or automated, with remote dispensers often used to enhance convenience at the forecourt.

🔧 What are the key components of a fuel dispenser?

The key components include the pump, nozzle, meter, and control system. The pump moves fuel from the tank to the nozzle, while the meter measures the amount dispensed. The control system manages operation and ensures safety during the dispensing process.

🏗️ How is a fuel dispenser installed at a site?

Installation requires careful planning and execution, including proper site assessment, adherence to safety regulations, and coordination with local authorities. The process includes setting up hardware, connecting pipes, and ensuring all components are certified for safe operation.

🏪 What types of fuel dispensers are available for retail stations?

Various types are available including single and dual-hose dispensers that can dispense multiple fuel grades. Modern dispensers feature integrated payment systems and digital displays that enhance the customer experience.

⚙️ How do OPW components contribute to fuel dispenser functionality?

OPW components, such as nozzles and breakaway fittings, play crucial roles in functionality and safety. These components handle the demands of dispensing petroleum products while ensuring robust operation and minimizing leaks or spills.

🧪 What testing procedures are required for fuel dispensers?

Testing encompasses performance testing for accurate fuel measurement, safety testing to verify absence of leaks, and compliance testing to ensure adherence to regulatory standards. Regular maintenance and testing are crucial for safe operation.

💰 How can I get a quote for a new fuel dispenser installation?

Contact suppliers or manufacturers directly for quotes. They will assess your site, discuss your needs, and provide detailed quotes including installation costs, equipment specifications, and additional services required.

🌍 Are fuel dispensers suitable for use in Africa?

Yes, fuel dispensers are suitable for use in Africa where demand for petroleum products is growing. Manufacturers develop robust dispensers designed to withstand various environmental conditions typical in the region, ensuring reliable service at petrol stations.