The industry of fueling cannot exist without the dispenser being at the center of fueling operations: thus, from modern urban gas stations to remote refueling points. Increased technology and simultaneous innovations in efficiency, accuracy, and sustainability have completely altered the face of the modern fuel dispenser. This article takes a closer look at the industry-leading fuel dispenser solution that has been redefining the entire refueling experience, equipping business owners with innovative means to ease operation and simultaneously ameliorate customer satisfaction. Whether you wish to remain a step ahead of contemporary competition or are just curious about the fuel dispensing technology of today, this expedition into advanced fuel dispensing technology will equip you with greater insight and an array of vivid possibilities.

Understanding Fuel Dispensers

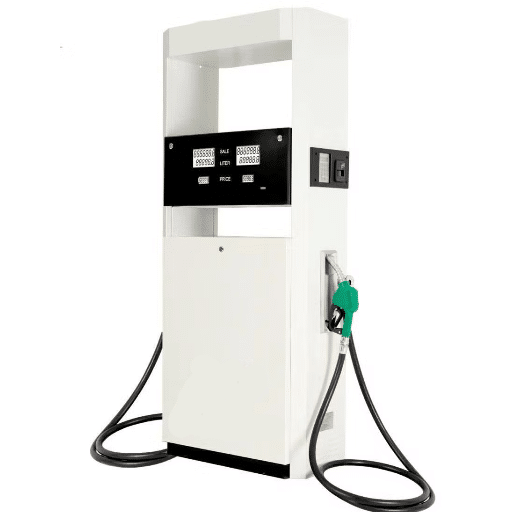

One of the fuel dispenser machines pumps fuel, such as gasoline, diesel, or other petroleum products, into vehicles or containers. They Dispensers combine the mechanical system of fuel delivery with digital display for transaction information. The modern fuel dispensers have been designed with precise measurement, safety, and efficiency in mind. This means that dispensers are often fitted with advanced technologies to assist customers such as contactless card payment and real-time monitoring, so support comes in real-time if there are concerns. These systems basically strive to make the refueling process easier for the dispenser, while still ensuring that it adheres to environmental controls and regulations.

What is a Fuel Dispenser?

Sometimes called gas pumps or fuel pumps, fuel dispensers usually transfer and measure liquid fuel such as gasoline, diesel fuel, ethanol blends, or CNG into vehicles, machinery, or portable containers. This is a must-have piece of equipment in any gas station. Fuel dispensers are equipped with complex systems for the precise measurement of fuel and for the safe dispensing of the fuel during sale.

Incorporating high-tech features aim to upgrade functionality. In doing so, they operate electronically: displays for volume of fuel, price, and other transaction details that appear and update in real-time. Most of the newer types were built to accept various contactless payments, creating an even quicker and more modern paying experience for the customer. Moreover, some safety features are integrated into the dispenser, including vapor recovery so that dangerous emissions can be kept away.

Global fuel dispenser market was valued at nearly $2.6 billion in 2021 and is forecasted to grow at a CAGR of more than 5% between 2022 and 2030.

Several statistics now indicate that a global fuel dispenser market is at a stage of rapid evolution. In 2021, the world’s size was valued at nearly $2.6 billion and is forecasted to grow at a CAGR of more than 5% between 2022 and 2030. That’s mostly because increased vehicle numbers accompany a growing acceptance of alternative fuel. Dispenser manufacturers have also begun researching biofuel and EV charging dispensers with sustainability being pushed from all quarters; hence, the fuel dispenser becomes an important player for cleaner energy solutions.

Components of a Fuel Dispenser

Fuel dispensing systems are quite sophisticated and contemporary, trying to cater to traditional and modern fueling needs. Several important components are involved in the intricate interactions that form an integrated whole and ensure the fuel gets into the vehicle accurately and quickly.

Hydraulics System

The dispenser’s heart, the hydraulics system, is a fuel transfer mechanism that carries fuel from an underground storage tank to the vehicle. The components of this system encompass the pump, motor, and valves. In the current scenario, with emphasis on sustainability, the advanced dispensers manufacture and use high-efficiency pumps to cut energy consumption and increase flow rates.

Metering Unit

The metering unit is a necessary component to measure the fuel dispensed. Modern metering units use positive displacement meters or Coriolis flow meters to guarantee accuracy so as not to lose errors or fuel, which will be great for legal enforcement as well as consumer goodwill.

Hoses and Nozzles

Hoses connect the dispenser to the vehicle fuel tank while providing durability and resistance to wear and environmental elements. The nozzle prevents overfilling and leakage of fuel by means of an internal automatic shut-off mechanism.

Electronics and Control System

It included the user interface, controls, and safety mechanisms. The electronics system has LED displays, touchscreens, and card readers set up from one end to another for efficient customer interface. Underneath this are programs that allow you to monitor data in real-time, inventory, and diagnose problems remotely for better operational efficiency.

Vapor Recovery Systems

High-end dispensers come with vapor recovery systems to meet environmental regulations. Such systems recover fuel vapors emitted during refueling to reduce emissions of pollutants and increase adherence to clean air regulations.

Compatibility with Alternative Fuels

In the changing era, fuel dispensers accommodate alternative and cleaner types of fuels like ethanol, hydrogen, and electricity. For example, electric vehicle chargers often are equipped with fast-charging capability to meet the demand for EV infrastructure.

Technology Innovation: The technology advancements speak of an industry endeavoring to fuse innovation with sustainability, in support of a global move toward more efficient and environmentally friendly methods of fuel.

How Fuel Dispensers Work

Fuel dispensers operate by mechanical and electronic system combinations to deliver fuel to vehicles in an efficient manner. At a fundamental level, these dispensers pump fuel from an underground storage tank through a pipe and out of the nozzle. Flowmeters inside the dispenser accurately transact the volume of fuel dispensed, thus maintaining accuracy and consistency.

Modern fuel dispensers embrace advanced technologies such as programmable logic controllers (PLCs), sensors, and secure payment systems. These technologies increase levels of precision while maintaining payment process accuracy. Industry data suggest that the meter in a high-grade dispenser is usually accurate to ±0.3%, which is an important element in reliable customer service.

High-grade dispensers maintain accuracy to ±0.3% and can reduce downtime by up to 25% through smart technology integration.

The amalgamation of digital displays and communication networks adds more functions to the fuel dispensers. In many of the latest models, real-time data are transmitted to the station operators for inventory and operational efficiency. Moreover, advancements in smart fuel dispensers have allowed them to be integrated with centralized systems for remote monitoring and diagnostics, with downtime reduction all the way up to 25%. Thus, these continuing fuel dispenser developments remain geared toward customer and industry needs.

Types of Fuel Dispensers

There are different types of fuel dispensers depending on their functioning and construction:

Dispenser Types Overview

- Mechanical Fuel Dispensers – The old models use mechanical parts to measure and show the quantity of fuel dispensed. Such dispensers are dependable, although these avoid many features like having a digitized interface or coming with a digital interface or smart capability.

- Electronic Fuel Dispensers – They are equipped with digital interfaces and advanced sensors that grant them mass precision in measurement and provide a good user interface. The most outstanding features include card payment systems and data tracking.

- Self-Service Type – It is the most popular one among gas stations, and customers dispense fuel all on their own. Often they are coupled with payment systems for the convenience of the customers.

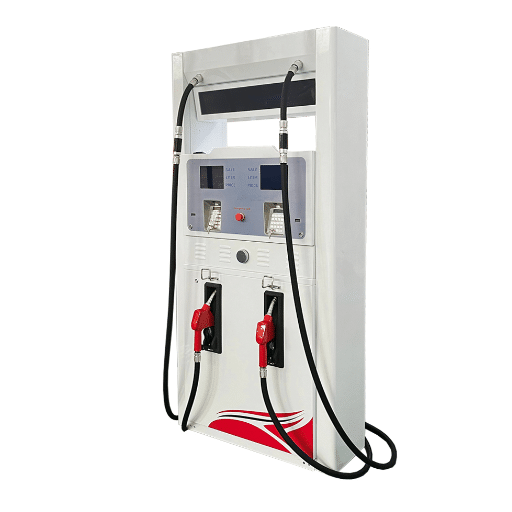

- Multi-Product Fuel Dispenser (MPD) – For one unit to dispense different types of fuel (for instance gasoline, diesel, or alternative fuels), MPDs save space and efficiency of operation.

- High-flow fuel dispenser – These are commercial-type dispensers serving large vehicles which dispense fuel at high flow rates to reduce filling time.

These kinds of categorization are indicative of the range of the fuel dispensers in order to satisfy various operational and consumers’ requirements.

Traditional vs. Modern Fuel Dispensers

| Aspect | Traditional Dispensers | Modern Dispensers |

|---|---|---|

| Components | Mechanical components, analog dials, manual controls | Digital touchscreens, sensors, automated systems |

| Payment Options | Limited payment methods | Contactless cards, mobile payments, EMV compliance |

| Monitoring | Manual monitoring required | Real-time tracking, remote diagnostics |

| Flow Rate | Lower flow rates | Higher flow rates, faster service |

| Safety Features | Basic safety mechanisms | Automatic shutoff, leak detection, vapor recovery |

| Maintenance | Frequent manual maintenance | Predictive maintenance, IoT monitoring |

Traditional fuel dispensers have served their purpose for some decades by selling fuel to the consumer. These machines have mostly mechanical components, including analog dials and manual controls that need frequent maintenance to assure accuracy. In other words, these dispensers, although reliable, do not accept-credit cards, or have the option for digital remote monitoring, thus adversely affecting their convenience level and the abilitiy of para-economic management. Old systems with low flow rate encourage more refuel time at peak hours.

On the contrary, contemporary fuel dispensers have been fitted with state-of-the-art technology to ensure desired productivity, safety, and user experience. A considerable number of them are equipped with digital touchscreens, real-time fuel-tracking, and payment mechanisms, including contactless card payments or mobile payments. The use of sensors for the automatic shutoff of fuel pumps, leak detection, and vapor recovery has now ensured environmental safety. Moreover, due to their ability to deliver fuel at higher flow rates, modern fuel dispensers have lead to shortened service times for both the consumer and commercial sector.

60% of fuel station operators with IoT-enabled dispensers reported significant decrease in operational downtime within the first year.

IoT adoption is one of the key technological advancements seen in modern systems for remote monitoring and predictive maintenance. An industry survey suggested that nearly 60% of fuel station operators who installed IoT-enabled fuel dispensers reported a remarkable decrease in operational downtime within the first year of installation.

From data, it is observed that the demand for modern fuel dispensers is increasing due to increased adoption of alternative fuels like compressed natural gas (CNG), hydrogen, and electric vehicle charging. Many of the modern dispensers are multi-functional, which makes them functional for future needs as fuel types get more diversified.

The shift from traditional to modern fuel dispensers exemplifies the broader transformation of the fuel industry towards sustainability, convenience, and smart automation. These systems, with their advanced technologies, are bound to further revolutionize the operations of fuel stations and rest assured the global customers’ satisfaction.

Gilbarco Dispensers: A Closer Look

Gilbarco Veeder-Root continues to stand at the forefront of dispensing technologies, providing pioneering solutions to evolving needs of the modern fuel industry. It is said that these dispensers never compromise on durability, usability, or integration with the latest technologies.

So, advanced payment capabilities are a feature that sets Gilbarco dispensing systems apart from the rest. The solutions provide smooth and secure transactions, following the digital payment trend, by allowing users to pay with contactless cards, mobile wallets, or EMV. Apart from that, the cloud-based platform prompts in monitoring data in real time, predictive maintenance, and troubleshooting remotely, which all together minimize downtime and optimize efficiency.

Added to that, Gilbarco dispensers have also been engineered keeping sustainability in mind. Many models support alternative types of fuels such as CNG, LNG, and hydrogen-that are pushing the industry toward a green transportation solution. The latest dispensers can handle biofuels and EV charging, making them a very workable option for fuel stations that are diversifying into energy offerings.

Gilbarco installations show up to 15% reduction in maintenance costs through predictive diagnostic tools.

Statistically, with the installation of Gilbarco technology, enormous increases in efficiencies and customer satisfaction can be seen. The smart automation installations by Gilbarco at any given station ensure smooth operations with up to 15% reduction in maintenance costs, courtesy of predictive diagnostic tools. On the other hand, a highly ergonomic and intuitive design reduces the dispenser service time; therefore, better customer experience awaits.

Through insistence on innovation, Gilbarco secures the position of their products in the forefront of the market. From integrating Internet of Things (IoT) technologies to optimizing systems for regulatory compliance, Gilbarco dispensers are now at the center of the dynamic transformation of fuel station operations.

Encore 700: Features and Benefits

Designed for reliability, efficiency, and a better user experience, the Gilbarco Encore 700 series offers the best in technology. This allows the Encore 700 dispensers to provide EMV compliance for secure payment options-again, protecting the customer from their transactions. The dispensers are also for payment upgrade-ready installations, meaning businesses stay at the cutting edge in the fast-evolving FinTech.

Encore 700 Key Features

- Security: State-of-the-art encryption and anti-skimming techniques

- User Interface: Large colored touch screens with customizable displays

- Integration: Seamless forecourt automation system compatibility

- Durability: Built from solid materials for harsh environmental conditions

- Sustainability: Support for alternative fuels including biofuels

- Efficiency: Advanced fuel efficiency reporting systems

The other significant security feature enjoyed by Encore 700 is state-of-the-art encryption, including an anti-skimming technique that limits potential fraudulent attacks. Large colored touch screens are another feature of the dispensers that are user-friendly, thus allowing customization to display promotional content or instructions for customers during the payment or dispensing process.

The Encore 700 series integrates smoothly into forecourt automation systems, thus making operations more monitorable and manageable by fuel-related station operators. Built to be highly durable, these dispensers are made from solid materials that withstand harsh environmental conditions; hence lower maintenance in the long run.

Armed with better fuel efficiency reporting systems and accepting alternative fuel options like biofuels, the series is made with the modern-day fuel stations in mind, as well as the goals of sustainability. To drive operational efficiency and uplift customer experiences, this series serves any business with a versatile and future-proof option.

Benefits of Upgrading Your Fuel Dispenser

Efficient Operation

Newer models were designed for faster fueling, causing less downtime and creating less bottlenecks down the line.

Customer Satisfaction

Procedures with newer machines are faster, and user-friendly interfaces give customers a pleasant patronizing experience.

Energy-Cost Saving

Newer models use an energy-efficient design and are good for energy savings in the long run.

Sustainability

Considering many of the upgraded dispensers support alternative fuels, this too would be going hand in hand with sustainability goals as well as environmental amendments.

Ready for the Future

With modern technology, it adheres to regulations and prepares businesses for future advancements in the fueling industry.

Increased Efficiency and Speed

Modern fuel dispensers have revolutionized their industry by greatly enhancing operational efficiency and speed of service during fueling operations. High-flow fuel dispensers have, by virtue of technology, come to deliver fuel at the rates of 60 gallons per minute, making them ideal for commercial truck and high-volume fueling sites. Integrated automation systems also automate payment processes, thereby reducing wait times and increasing throughput during peak hours. Newer models usually feature and advanced sensors for remote monitoring so that an operator can perform in-depth diagnostics and resolve issues quickly, reducing downtime. Smart dispensers also allowed accurate measurement and less wastage of fuel, thus bringing about cost savings. Together, these inventions pave the way for faster and more efficient fueling for both businesses and customers alike.

Enhanced Security Features

Modern fuel dispensers are increasingly being provided with security technologies to protect both the public and businesses. Stronger encryption methods secure customers’ financial information during transactions, thus helping to thwart data breaches. The dispenser hardware and software have been made tamper-resistant, attempting to discover imposters and block the installation of skimming devices. For example, point-of-sale systems are now equipped with EMV-chip enforcement to prevent fraud at card-present payments. According to industry analysts, such secure systems have supported a 30 percent reduction in payment fraud over the last five years in the retail fuel industry. Also, remote-monitoring functions provide the chance for operators to be alerted about suspicious activities so that they may take immediate actions on suspicious activities. Such security measures are vital for building trust with customers and for ensuring the safe functioning of fueling stations.

Secure payment systems have achieved a 30% reduction in payment fraud over the last five years.

Improved Customer Experience

With the advent of modern technology, some stations were able to enhance beyond customer service: the station itself. With a complete L&G test that was contactless through NFC or mobile wallet, the transactions are quicker and more convenient, therefore reducing the average wait time by roughly 25. In addition to that, the new-age fuel dispensers provide interface guidance through the entire process to ensure an easy experience for users who may be unfamiliar with digital payment methods. Many stations have the advantage of miles loosely tied to their payment system, so customers can easily collect and redeem points from each purchase. There are also apps that can guide the customer to the nearest station, check fuel price in real time, or arrange payment for fuel ahead of time, giving customers more flexibility and control during the visit. In all, these technological advances deliver a smooth and efficient experience, with a fair share of fun thrown in.

Support and Maintenance for Fuel Dispensers

Proper maintenance and servicing of fuel dispensers ensure their reliability, safety, and regulatory compliance. Remember to inspect the major components like nozzles, hoses, meters, and pumps regularly for early signs of wear and potential faults. These checks would prompt immediate cleaning in case of any leaks or blockages to keep the operation free of disruption. Calibration procedures will also have to be carried out at intervals to ensure that fuel measurements are accurate. Engage with certified technicians for maintenance and upkeep of equipment following manufacturers’ guidelines in turn increases their life and enhances high performance standards.

Regular Maintenance Practices

Effective maintenance ensures the life and efficient functioning of fuel-dispensing equipment while minimizing the chances of unexpected breakdowns. Corrective maintenance carries a 30% reduction in downtime of equipment and extends life by almost 20%, translating to bigger savings for the user over time. Periodic inspections, like weekly inspections for wear and tear, corrosion, or leakage problems, are very critical. For instance, 60% of dispenser faults are often laid on ignored minor wear that finally develops into major failures.

Regular maintenance achieves 30% reduction in equipment downtime and extends equipment life by 20%.

Fuel quality maintenance should be placed under advance care. Research has proven that contaminants in fuel tanks can increase the chances of clogging by 40%, further putting stress on the dispensers. Such a risk can be reduced by replacing the filtration systems every six months or as recommended by the manufacturer. In addition, advanced tools like automatic tank gauges (ATG) provide fuel level measurements and water accumulation detection for greater operational accuracy.

Implementing data-driven maintenance approaches such as predictive maintenance through IoT sensors will boost efficiency in foreseeing component failure before the event itself. Companies employing such predictive toolsets report a 25% increase in system reliability. Going by discipline in application of those approaches ensures further safety to life and property, meanwhile bringing down the cost of maintenance in the long run and keeping operations smooth.

Finding the Right Support Services

The key is to retain operational excellence and nurture sustainability through support services. Companies should find suppliers capable of providing a full package of maintenance services, including on-site support, remote diagnostics, and access to expert knowledge. Recent reports show that organizations have reported up to 30% quicker resolution of issues and 20% reduction in equipment downtime when working with professional service providers. Furthermore, SLAs must remain transparent in order to provide service packages fine-tuned to a business’s particular requirements. This is enhanced best by service providers using next-generation tools, like AI analytics and IoT-based monitoring systems, which anticipate potential hazards and operate on very fast reaction times. By putting their trust in a partner with proven credentials, businesses will ensure that daily operations run on smooth grounds without any interferences.

Confidence Comes Standard with Quality Service

With a commitment to quality service augmented by the latest technology, businesses find themselves at the forefront of an ever-growing competitive landscape. As per recent industry insights, companies that harness AI technology for industrial needs tend to see up to 40% improvement in operational efficiencies, whereby predictive analytics is used to truncate decision-making procedures for efficiency. Furthermore, with IoT solutions, supply chain management can reduce operating costs by 20% with real-time monitoring and informed optimizations.

AI technology implementation results in up to 40% improvement in operational efficiencies.

Ensuring investment is directed to those service providers who implement such innovations will guarantee more than just efficiency: the end result will be reliability and scalability. For example, such industries that implement robotic tools have reported reductions of 35% in human errors, which increase productivity and cause less downtime. Such trusted partnerships with skilled providers that incorporate these augmentations give strong support for growth and longevity of all varieties of businesses.

Fuel Dispensing Solutions for Your Business

Fuel dispensing solutions are essential for businesses that rely on efficient and reliable fuel management. Modern systems offer features such as exact measurements of the fuel delivered, secure transaction processing, and easy-to-use interfaces that help in operations. With this solution, fuel waste can be preventable, consumption monitored, and increase operational efficiency. Working with trusted dealers guarantees providing reliable equipment and service support along with the latest technology to meet your needs.

Customizing Your Fueling Solutions

Tailoring fueling solutions to suit specific business needs ensures operational efficiency to the fullest and cost reduction. Businesses have the choice when it comes to system customization via the integration of advanced fuel management softwares that keep track of real-time fuel consumption, record vehicle mileage, and monitor for predictive maintenance alerts.With RFID technology, automatic fuel dispensers can be installed to automate authorization procedures and provide an additional layer of security to prevent unauthorized usage.

Data from recent studies indicates for the reduction of fuel wastage by up to 20% and an increase of 15% in dispensing accuracy with automated fueling systems. Also, the addition of fuel monitoring devices enabled with IoT offers remote monitoring facility to operators who can then make data-driven decisions to optimize fleet performance. The customization of these solutions comprises identifying the operational challenges, the key performance indicators, and technologies that gels with company goals. Riding on these technologies, companies are able to increase productivity, reduce operational costs, and sustain themselves for a long time in fuel management operations.

Automated fueling systems reduce fuel wastage by up to 20% and increase dispensing accuracy by 15%.

Cost Considerations and Quotes

While talking costs, at the core lies the analysis of initial investment against long-term values. Price is dependent on the type of technology used and the level of customization needed for a particular fuel management solution. I would recommend getting fine quotes from multiple vendors, then comparing the features, scalability, and support options. My primary goal is to create a balance between initial costs and potential efficiency gains and reduced costs moving forward so that the solution fits our operational objectives and budget.

Future Trends in Fuel Dispensing Technology

The future of fuel dispensing technology lies in various aspects of automation, sustainability, and digital integration. Automated and self-dispensing systems, armed with sophisticated sensors and real-time monitoring, are being implemented to manage fuel more efficiently. Sustainability is another trending factor, with newer innovations powering alternative energies such as biofuel, hydrogen, and electricity to establish an environmental stance. IoT integrated with cloud-based platforms has changes fuel management to deliver data analytics, remote diagnostics, and smooth payment experiences for timeline user satisfaction and operator-side efficiency. So, apart from advancing the utilities regarding pinpoint accuracy and flawless transactions, the technology greases the wheels for the push towards reducing carbon footprints and courses of energy optimization.

Emerging Technology Trends

- Automation: Self-dispensing systems with sophisticated sensors and real-time monitoring

- Alternative Energy Integration: Support for biofuels, hydrogen, and electric vehicle charging

- IoT and Cloud Platforms: Advanced data analytics and remote diagnostics

- Smart Payment Systems: Enhanced digital payment experiences

- Environmental Focus: Technologies aimed at reducing carbon footprints

- Energy Optimization: Systems designed for maximum energy efficiency

Conclusion

The fuel dispensing industry continues to evolve rapidly, driven by technological innovations, environmental concerns, and changing consumer expectations. Modern fuel dispensers represent a significant advancement over traditional systems, offering enhanced efficiency, security, and user experience. From Gilbarco’s cutting-edge Encore 700 series to the integration of IoT and AI technologies, today’s fuel dispensers are sophisticated systems that do much more than simply dispense fuel.

The benefits of upgrading to modern fuel dispensing technology are clear: increased operational efficiency, enhanced security features, improved customer satisfaction, and better environmental compliance. As the industry moves toward greater sustainability and digital integration, businesses that invest in advanced fuel dispensing solutions will be better positioned to meet future challenges and opportunities.

Whether you’re considering an upgrade to improve operational efficiency, enhance customer experience, or prepare for the future of alternative fuels, understanding the full scope of modern fuel dispensing technology is essential. The investment in quality equipment, proper maintenance, and reliable support services will ensure that your fuel dispensing operations remain competitive, efficient, and ready for whatever the future may bring.

Reference Sources

“Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)”

“Automatic Vehicle Fueling System using PLC Controlled Robotic Arm-A Simulation Design”

Frequently Asked Questions (FAQs)

What assures Gilbarco dispensers in compliance with standards?

Gilbarco fuel dispensers are made to meet the stringent compliance requirements of regulatory bodies. They include advanced technology and materials that ensure safety and efficiency; hence, they are trusted dispensers in the market.

How does the Encore 700 dispenser keep it simple and safe for fueling?

The Encore 700 dispenser has intuitive interfaces, a strong frame, and door construction, thus enhancing more usability with safety first. This then makes the fueling experience very simple and safe for customers.

What is the ownership cost of CNG dispensers?

Ownership costs for CNG dispensers can vary according to installation, maintenance, and operational efficiencies. Yet, with quality CNG equipment, one can save more in the future by bringing compressed natural gas to its doorstep.

How can the fuel business be the standard of service with their dispensers?

A fuel business can become the standard of service by having a reliable and simple fuel dispenser, like Gilbarco’s. Keeping good customer service and maintaining high quality of the dispensers makes the whole system feel familiar and efficient for the customer.

What is the role of connectivity in modern fuel dispensers?

Connectivity in modern fuel dispensers ensures that data is monitored in real time while providing a good customer interface at the POS. It helps in inventory management, implementation of insights, and fine-tuning of the overall fueling experience.

Why does an Angi Energy CNG dispenser make fuel easier to sell?

The Angi Energy CNG dispenser consists of features that bring simplicity to the whole process. It is a technology that facilitates fast transactions so that compressed natural gas can be efficiently brought into the vehicle without any delays.

Why are frame and door construction important in fuel dispensers?

Good frame and door construction in fuel dispensers is essential for an item to be designed with durability and safety. A strong enclosure would provide enough protection from the weather elements while assuring a safe and secure fuel experience.

What role does PCI compliance play in fuel dispensers?

Such PCI compliance is enforced on fuel dispensers to protect payment data during transactions. Being able to do so supports customer levels of trust and confidence in the gasoline process; hence, it becomes one challenge in operating the dispenser.

How would trusted dispensers complement a site’s branding?

Superior dispensers stand for incredible reliability and safety. Customers tend to return to any location wherein the dispensers take utmost pride in the quality fueling experience for them, which in turn benefits the branding.