The fuel dispensing system is of great importance in energy distribution today, thus becoming the mainstay of different industries like transportation, agriculture, etc. This complex system comprises the latest equipment, strong management tactics, and creative solutions that are aimed at improving delivery and maintaining efficiency. This article gives a view of the fundamental parts of fuel dispensing systems, investigates good practices for effective management, and unveils the latest technological advances that have been pushing the industry forward. It does not matter whether you are an industry expert looking to improve your processes or just a curious mind wanting to know about this vital infrastructure; this thorough guide will still give you precious insights into the systems that support our planet.

Understanding Fuel Dispensing

Fuel dispensing means that the transfer of fuel is done in a controlled way, and that the receiving side can be either a car or a machine. It uses a fuel dispenser that measures and delivers with safety and efficiency. The main parts are the pump that brings the fuel up from the tank, and the metering, which guarantees the accuracy of measurement throughout the transfer. Safety features like automatic shutoff nozzles not only protect against overfilling and spilling but also make sure that safety and environmental regulations are being met. Continuous and unbreakable functioning of fuel dispensing systems is very important as it keeps the operation running smoothly and saves a lot of fuel that would otherwise be lost.

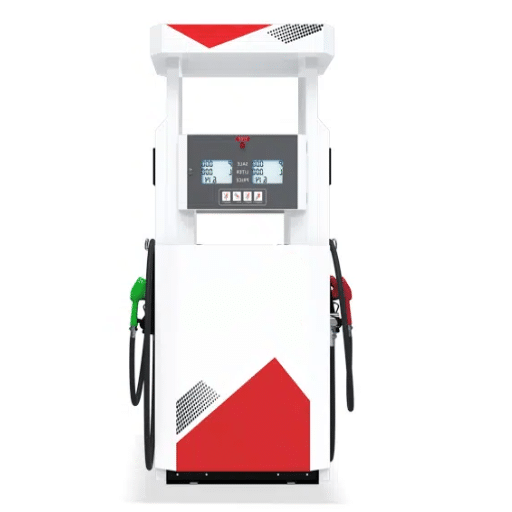

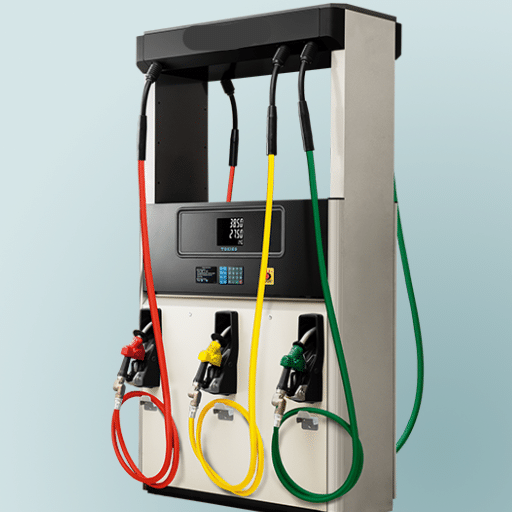

What is a Fuel Dispenser?

A fuel dispenser, which is widely known as a gas pump or petrol pump, is a high-tech machine that not only transfers the fuel but also regulates and monitors the whole process of dispensing fuel into vehicles or containers. Modern dispensers are highly sophisticated and equipped with the latest technology to ensure the delivery of the correct amount of fuel and accurate measurement. They usually have a hydraulic system, a flow meter, a hose, and a nozzle as their main parts, with each one taking a significant part in the continuous realization of power and safety.

The fuel dispensers’ applications are based either on submersible or suction systems, which are responsible for pulling the liquid fuel from the underground storage tanks. The precision flow meters then measure the fuel, and that is done with a very small error of about 0.5%. With this accuracy, the cases of disputes regarding the transactions are minimized, and the regulatory compliance is given support. To not let even a little emission go, the advanced models are often equipped with vapor recovery systems, which are effective and advantageous to the planet in that respect.

Modern Innovation: Modern dispensers are not only used to be simple machines but are now considered more as a fast means of communication due to the inherent advanced digital interfaces like touchscreen, and payment systems that allow just-in-time transactions. They are connected to the main administrator software, which enables real-time monitoring of stock levels and sales data. At the same time, the multi-product nozzles, which are provided in the dispensers, help in conveniently dispensing the various kinds of fuels like gasoline, diesel, and biofuels through one device only. Safety features such as emergency shutdown valves and anti-spill systems make the machines more trustworthy during operations, and hence, fuel dispensers have become the main players in the modern refueling infrastructure.

Components of Fuel Dispensing Equipment

In order to have accurate, efficient, and safe fuel delivery, fuelling equipment consists of several integral parts that work together. The components usually cover:

Fuel Pump

The main mechanical part that moves the fuel from the storage tank to the dispensing nozzle is the fuel pump. Mostly electronically-controlled pumps are used to increase the precision and efficacy of the current pumps.

Dispensing Nozzle

This part of the machine is the one that faces the customer and regulates the flow of fuel into the car’s tank. The state-of-the-art nozzles usually come equipped with an automatic valve shutoff feature that protects against overflows and spills.

Metering Unit

An essential component for sustaining accuracy, the metering unit measures the amount of fuel dispensed. Precise meters mostly have electronic sensors that allow them to monitor the fuel flow in real-time.

Hose and Swivel Assembly

The flexible hose carries the fuel from the pump to the nozzle, and the swivel joints improve the mobility of the system and the life of the system by stopping the twists or kinking that might happen during its operation.

Control System

The dispenser functions are controlled by embedded software and electronic control units, which make features such as saving the transaction, troubleshooting from a distance, and linking with the point-of-sale systems possible.

Filters

Fuel filters are fitted on the dispensing system, and they take out the contaminants and make sure that the fuel is pure enough to go into the engine and prevent the engine from being damaged.

Safety Systems

Emergency shutoff valves, anti-spill mechanisms, and grounding cables are the major safety features that are aimed at eliminating the risks of fire, voltage surges, or fuel leaks.

All these components together determine the working and dependability of fuel dispensers, making them a must-have in the private and commercial fueling activities.

Types of Fuel Dispensing Systems

The fuel dispensing systems can be classified according to their application, design, and functionality into several categories. Among those are:

| System Type | Description | Best Use Case |

|---|---|---|

| Manual Fuel Dispensers | These systems operate manually, and usually involve a hand pump as part of the process to transfer fuel. | Small-scale operations or places with no reliable electricity supply |

| Mechanical Fuel Dispensers | Equipped with analog dials and manual calibration systems; dependent on lower electronics. | Environments relying on simpler technology with low maintenance requirements |

| Electronic Fuel Dispensers | Utilize digital interfaces for precision, simplicity, and the ability to record transaction data. | Modern fueling stations requiring efficiency and automated systems |

| Fleet Fueling Systems | Tailored for business operations with large vehicle fleets, featuring advanced monitoring. | Commercial operations needing to track fuel consumption and reduce wastage |

| Portable Fuel Dispensers | Light and mobile systems perfect for flexibility and fast deployment. | Remote areas, on-site fueling, or emergencies |

Every type is directed to a certain industry and operational need, thus providing customized solutions for various fueling problems.

Fuel Management Systems

Fuel management systems are the tools that control and manage the consumption of fuel efficiently by monitoring and optimizing it. The main functionalities are the following:

- Real-Time Fuel Tracking: Keeps an eye on fuel levels, rates of consumption, and refill activities in order to rule out any misuse or theft.

- Automated Reporting: Provides very detailed and accurate reports on trends in fuel usage and operational efficiencies.

- Access Control: Allows only the authorized personnel to carry out the fueling through secure identification methods that may include PINs or RFID.

- Integration Capabilities: Works with fleet management software and thus increases the operational oversight.

- Cost Optimization: Spots the inefficiencies and cuts down the fuel-related costs by applying accurate analysis.

These systems are crucial for establishing transparency, cutting costs, and providing accountability in fuel-dependent operations.

The Importance of Fuel Management

Organizations that rely on fuel-powered operations will need effective fuel management to cope with rising costs, environmental concerns, and reliability issues. Fuel is generally the biggest item in an operational budget, thus making its careful monitoring and control very necessary in the fight against waste and unnecessary costs. Besides this, good fuel management practices also mean that there will be less fuel theft, leakage, and even consumption if they are good at tracking usage, which is one of the ways they account for fuel usage.

Besides, advanced systems will also be able to connect with fleet management solutions to help with the crafty decision-making, not just in route scheduling but also fuel use overall. This will not only save fuel costs but also help in cutting the amount of greenhouse gases released into the atmosphere, thus making the company’s operations in line with the sustainability goals. One has to be armed with modern technology, thorough data analysis, and strict procedural enforcement in order to manage fuel effectively. Thus, it becomes a cornerstone of responsible and efficient operational management.

Key Features of Fuel Management Systems

Real-Time Monitoring and Tracking

Fuel management systems provide operators with real-time monitoring of fuel levels, consumption rates, and tank status. This function provides operators with the possibility to observe the consumption trends, spot abnormalities, and react quickly to possible fuel robbery or leaks. Besides, through the use of GPS, the systems can also link fuel consumption information to vehicle location, thus providing a clearer view of operations.

Automated Reporting and Analytics

The sophisticated fuel management systems automatically produce reports and analytics that make it easy to evaluate fuel usage. The underlying insights that come out of it can help identify inefficiencies, optimize consumption patterns, and plan for cost-saving measures. The operators can then be empowered to take data-driven decisions based on the key metrics such as miles per gallon (MPG) or fuel consumed per trip.

Access Control and Authorization

Fuel access control limits the dispensers to a select pool of authorized personnel only. This limitation of access is often done via the use of PIN codes, RFID tags, or smart card systems. Organizations benefit from such protection measures through reduced fuel wastage and more efficient adherence to internal rules, in addition to the enhanced security.

Integration with Fleet Management Systems

Fuel management systems are more often than not designed with the possibility of easy integration with large fleet management platforms. With a single data source, all vehicle diagnostics, service scheduling, and route optimization will thus be sharing the same data, which further leads to increased efficiency.

Environmental Compliance Features

Modern fuel management systems can track emissions and monitor fuel efficiency as per the environmental regulations. This capability not only helps organizations with their sustainability goals but also ensures they are in line with the legal standards.

Through the adoption of these features, companies can enhance their consistency in operations, cut down on fuel-related costs, and realize their financial as well as ecological targets.

Benefits of Efficient Fuel Management

- It cuts down operational costs considerably, as the use of fuel is optimized and waste is minimized thanks to the advanced tracking and analysis tools that are applied.

- The fleet performance is improved as the vehicles are operated within the perfect standards, which in turn reduces the wear-and-tear and prolongs the life of the assets.

- The environmental regulations compliance is made easier, as the exact fuel monitoring helps in emissions tracking and meeting sustainability standards.

- The fuel management systems are offering through data and analytics, real-time actionable insights, which are making smarter decision-making and better resource allocation possible.

- These advantages lead to an operational model that is more sustainable and cost-effective while also being in line with the environment and regulatory standards.

Fuel Dispensing Solutions

Today’s fuel dispensing machines are developed to secure the precision, effectiveness, and dependability in the distribution of fuel. The advanced metering technologies are used by the systems to give exact readings and to eliminate fuel waste as well. Most of these systems have the automatic features of flow-rate control and leak detection that contribute to the safety of the operations and support compliance with the industry standards. Besides that, the digital interfaces and fuel management software are a part of the many systems that enable easy monitoring of the amount of fuel dispensed and transaction data. This makes sure there is no uncertainty, minimizes loss, and eases the reporting processes, thereby making them a vital part of the smooth fuel distribution activities.

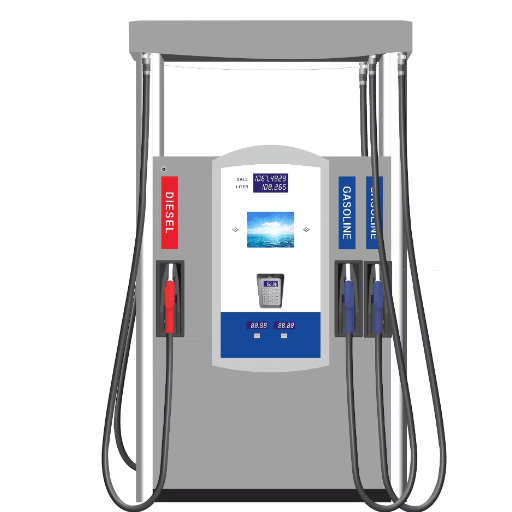

Mechanical vs. Electronic Fuel Dispensing

Mechanical Fuel Dispensers

Mechanical fuel dispensers rely on analog components and are characterized by their long-lasting performance and limited dependence on electronic systems. Usually, the designs of these dispensers are quite simple, equipped with manual dials or rotating counters used for showing the volume and cost of fuel delivered.

Advantages: Lower initial costs, ease of upkeep, and dependability in isolated places where electric power may not be available.

Disadvantages: Not very precise and cannot be connected to modern fuel management systems.

Electronic Fuel Dispensers

Electronic fuel dispensers make use of digital technology to improve their functionality and precision. The electronic systems of these dispensers utilize electronic displays and sensors to give very precise measurements of the fuel being dispensed.

Advantages: State-of-the-art features including setting flow rates, automatic turn-off, and connecting with cloud-based fuel management software for real-time data tracking. Better efficiency and integration capabilities.

Disadvantages: Usually come at a higher price and require a constant power supply, along with calibration on a regular basis for the best performance.

In the end, the selection between mechanical and electronic dispensing systems is all about the specific operational requirements of the fuel distribution site and the conditions in which the site operates, such as the need for advanced data integration, scalability, and so on.

Innovative Solutions for Fuel Dispensing

The fuel dispensing solutions that are innovative are coming up with new and better ways to meet the changing demands of modern fuel distribution. Smart dispensers, which have IoT technology and digital monitoring systems, and among these advancements are the ones that are really changing the way things are done more efficiently. These systems make it possible to have real-time data collection, remote diagnostics, and predictive maintenance, which simultaneously minimize downtime and maximize fuel management.

Furthermore, the merging of mobile payment systems and touchless interfaces is not only making the user experience better but also taking care of hygiene and accessibility issues. Some systems even go as far as incorporating high-tech metering, which is definitely one of the best ways to be in compliance with the regulations and to be cost-effective. The modular design in fuel dispensers is a great solution for businesses that are operating in environments that need scalability because it allows them to adapt as their capacity demands increase.

Lastly, eco-friendly solutions such as dispensers that are suitable for alternative fuels like biodiesel or hydrogen are gaining popularity as the industry concentrates more on sustainability. The process of achieving the right solution involves looking into the operational requirements, the compatibility of the existing infrastructure, and the long-term goals; this way, one can be sure of striking a good balance among innovation, reliability, and cost-efficiency.

Risk Management in Fuel Dispensing

Effective risk management practices in fuel dispensing require not only the identification of potential dangers but also the implementation of appropriate measures for risk reduction. The main risks involve, among others, fuel spills, static electricity, fire hazards, and contamination of the environment. Proper precautions shall include compliance with the safety regulations of the organizations, such as OSHA, EPA, and NFPA. Regular maintenance of the equipment, which includes inspections of nozzles, hoses, and meters, guarantees safety in operation, and malfunctions are less likely to happen.

Critical Safety Measures: Installation of grounding systems and automatic shut-off devices, among others, would help to drastically reduce the risks posed by static and overfilling. Besides, the training of employees that concentrates on safe handling practices and emergency responses should be very important. In addition to such avoidance measures, secondary containment systems and spill response kits should be located at potential leak or spill points to effectively deal with the situation in case it happens. All these measures taken up early will not only make the operation of fuel dispensing safe, compliant, and efficient but also risk-free.

Natural Gas and Compressed Natural Gas (CNG)

Natural gas is an efficient fossil fuel with significant clean-burning characteristics and is mainly composed of methane. The areas of its usage include heating, electricity generation, and as a vehicle fuel when compressed into Compressed Natural Gas (CNG). CNG is kept in a gas form under pressure, thus trapping it as a good option for the reduction of greenhouse gas emissions because it does not produce as much pollution as gasoline or diesel. It is widely used in the transportation sector, especially among fleets, because of its price attractiveness and environmental friendliness, which translate to reduced operational costs and less harmful emissions.

Understanding Natural Gas as a Fuel Source

Natural gas is the primary energy source that is used extensively around the world. It is the most abundant, economical, and cleanest fossil fuel that causes less environmental pollution than coal and oil to some extent. The burning of natural gas as a fuel results in the cleaner combustion of approximately 50–60% less carbon dioxide during the burning process in the case of power plants. Thus, it is a major shift toward the low-carbon energy system. Besides, it is versatile, so it can be used for power generation, domestic heating, and even as a car fuel if compressed natural gas (CNG) is used.

Natural gas, however, has drawbacks. Methane, its chief ingredient, is a powerful greenhouse gas with melting potential much greater than that of carbon dioxide, especially if it is lost to the air while being extracted, transported, or stored. The use of hydraulic fracturing (fracking) for the extraction of natural gas has raised concerns over water pollution and earthquakes. Natural gas is a bridge between coal and renewables; it can support the transition to the sustainable energy of the future, but, at the same time, by addressing the issue of emissions from methane and improving the extraction process, the environmental impact can be no less than the benefit of gas being the cleanest fossil fuel.

CNG Fuel Dispensing Equipment

Compressed Natural Gas (CNG) fuel dispensing devices are a must for the quick and secure refueling of vehicles utilizing CNG. These systems include dispensers, storage tanks, compressors, and safety systems, which are the main parts. CNG dispensers are made to precisely measure and supply fuel at the pressures suitable for the cars using the fuel; this is usually done by means of mass flow meters for accuracy. The high-pressure storage tanks guarantee that there is always a sufficient amount of CNG at the station, while the compressors are responsible for raising the gas pressure to the level required for the refueling of the vehicle. Safety is of utmost importance, and therefore, features such as emergency shut-off valves and gas leak detectors are included in the design to avert accidents. Regular maintenance and compliance with the industry quality standards, like the ISO and ANSI standards, are critical in securing the dependability and durability of this equipment.

Advantages of Using CNG

- CNG is a lot less harmful to the environment than conventional fuels such as gasoline and diesel, significantly reducing the emissions of harmful gases and other particles like carbon monoxide, nitrogen oxides, and particulates. Thus, CNG becomes an important tool to fight air pollution and to support climate change mitigation.

- Using CNG allows for significant cost savings in the long run, as it is usually charged at a lower cost per energy unit than fossil fuels. Its widespread use not only keeps the price low but also helps to reduce the importing of oil, thus, countries’ energy security is boosted.

- CNG-powered vehicles receive less maintenance because the clean burning of the fuel leads to minor engine wear and longer service intervals.

- CNG has a very positive image when it comes to safety issues. Due to its property of being lighter than air, it vanishes very quickly in case of a leak, thus the chance of encountering a situation where fire or explosion might occur is much less than with the liquid fuels.

- The coming of the eco-friendly transportation era brings with it the growing popularity of CNG among private motorists, companies, and public transit systems.

Future Trends in Fuel Dispensing

Automation and Smart Systems

The future of the fuel dispensing market is primarily driven by automation and the incorporation of intelligent technologies, smart systems, and IoT. IoT-enabled automated fueling systems, along with real-time data analytics, will optimize operations and lead to the most productive, accurate, and error-free operations. Besides, these systems will take care of monitoring the fuel levels, foreseeing the maintenance requirements, and thereby optimizing the inventory management, which is going to be a win-win situation with reduced operational costs and improved service reliability.

Shift to Renewable Fuel Infrastructure

Another noteworthy trend is the enhancement of the fuel dispensing infrastructure for renewable fuels like hydrogen, biodiesel, and charging stations for electric vehicles (EVs). Heavy investments in sustainable fuel dispensing solutions will make the alternative energy sources readily available, as governments around the globe are enforcing strict environmental regulations. The transition that takes place with the decarbonization of the transportation sector will also help in the climate change goals, so it is a win-win situation.

Enhanced User Experiences

Fuel stations are changing and upgrading themselves for customers’ needs and desires by going digital and providing mobile apps, contactless payment systems, and customer-centric services. Moreover, digital platforms offer people’s interaction through remote payment, loyalty programs, and personalized account management, which will also add to the convenience of the end-users.

Safety Innovations

Next-generation gas dispensers will be equipped with the latest innovations in safety technology. Examples include real-time leak detection sensors, automatic shutoff systems, and improved fault diagnostics. The goal of these measures is to earn the trust of the public while remaining compliant with very strict safety regulations.

Integration of AI and Machine Learning

AI and machine learning will greatly impact fuel dispensing by allowing for predictive maintenance, better energy management, and business insights that are directly usable. Thus, these technologies will give the fuel suppliers the power to not only predict but also to dynamically adjust their operations according to the market trends.

The merging of these trends indicates a change that favors the fuel and energy sector and is in line with the global push for sustainability and technological advancements.

Technological Advancements in Fuel Dispensing Systems

The latest fuel dispensing technology has led to a tremendous improvement in the areas of efficiency, sustainability, and customer service. Today’s fuel dispensers are more and more connected with IoT (Internet of Things) sensors and telematics, which allow for the monitoring of equipment performance and carrying out of predictive maintenance in real-time. This not only stops the units from being idle but also helps in extending the period that the dispensing units can work; thus, operational costs are significantly reduced.

In addition, the use of automated payments and contactless technologies is becoming a norm, and thus, the customer experience is improving while operational efficiency is being enhanced. The backend systems of these systems are often combined with mobile applications that allow users to choose the type of fuel, track their usage, and manage payments all at once.

Environmental sustainability is a major concern, as newer dispensers are specifically engineered to maximize the accuracy of the dispensing operation, thereby reducing fuel spillage and vapor emissions. With the same high-tech meters, gas stations can tell exactly how much fuel they have, so they can reduce waste and still be within the limits of the strictest rules.

Moreover, the adoption of cutting-edge data analysis has empowered companies to a new level, granting them the ability to predict consumer choices, know peak usage times, and spot areas of inefficiency in operations. Thus, these retailers will always be one step ahead and able to refine their services, manage their inventory, and actively adapt to the changing customer needs.

In summary, the journey towards modernised fuel dispensing systems is paved with tech-driven operational efficiency, customer-oriented services, and environmentally friendly methods. This is a significant step forward for the fuel and energy industries.

The Role of Sustainability in Fuel Management

The role of sustainability in fuel management is pivotal in making companies environmentally responsible through their operations. To my mind, going sustainable is concentrating on the reduction of carbon emissions, improvement of energy consumption, and the mixing of renewable energy with conventional fuel sources. Through the use of progressive technologies like fuel monitoring systems and the provision of energy-efficient buildings, waste can be cut down, and resource conservation can be encouraged. Not just that, but these measures also take care of the environmental issues, plus, the companies become more efficient and their economic durability is guaranteed for the long term.

Predictions for the Fuel Dispensing Industry

The fuel dispensing sector will definitely go through a process of large shift, which will mainly be driven by technological progress, consumers’ changing needs, and the general trend of sustainability across the globe. First and foremost, automation and data analytics will have a tremendous impact on operational efficiency. It is expected that smart fuel dispensers with IoT and cutting-edge telemetry systems will be common practice in the future and will allow such features as real-time supervision, anticipatory maintenance, and efficient fuel management to take place.

In the second place, the transformation in the energy market will affect the product mix. As the number of electric vehicles (EVs) used worldwide keeps growing, fuel stations will probably start to compose the picture by pairing charging points for EVs with regular fuel pumps in addition. Besides that, biofuels and synthetic fuels might also appear as companions that are in line with the worldwide carbon reduction targets.

Finally, the industry might see new and improved payment and customer convenience options. The demand of the current consumers for smooth transactions will be fully satisfied through the usage of AI-driven touch-free payment systems, app-based fuel ordering, and custom-made user experiences. It will be the combination of these technological advancements and government incentives for clean habits that will pave the way for the fuel dispensing business for the next ten years.

Reference Sources

1. Automatic Vehicle Fueling System using PLC Controlled Robotic Arm

2. Design and Operation of the Hydrogen Supply Chain for Fuel-Cell Vehicles in Expo Shanghai 2010

3. Fuel Cell Electric Vehicles (FCEV): Policy Advances to Enhance Commercial Success

Frequently Asked Questions (FAQs)

What is a fuel dispensing system?

A fuel dispensing system consists of a complete arrangement for moving fuel from the ground storage tank to a vehicle or machine. Such systems play a major role in the field of particular fueling applications, such as diesel fuel dispensing systems, which are built especially for giving out diesel fuel. Common parts in such operations are fuel pumps, nozzles, and billing terminals, and they provide a continuous and certain process of fuel transfer.

What are the main components of fuel dispensing equipment?

Fuel dispensing equipment is comprised of a few main components, including the pumps, hoses, nozzles, and electronic control systems. All these parts function in accordance to provide the customer with the best possible fueling experience, while at the same time assuring the safe and efficient dispensing of fuel. Moreover, the use of accessories, such as fuel filters and meters, can result in increased overall system performance and reliability.

How do fuel storage solutions impact fuel dispensing applications?

Fuel storage solutions are of utmost importance in fuel dispensing applications, as they affect both the quality and the supply of the fuel being dispensed. Good storage practices reduce contamination and make the fuel trustworthy for industrial and off-road machinery applications. Aboveground storage tanks are a popular choice for easy accessibility and safety.

What are the benefits of using a diesel fuel dispensing system?

Numerous advantages come along with the use of diesel fuel dispensing systems, such as reliability and efficiency. The systems are made to accommodate the particular characteristics of diesel fuel, thereby making them suitable for use in construction and industrial applications. The systems can deliver the fuel quickly and safely, which will consequently enhance the overall experience of fueling for the operators and will also reduce the downtime.

What role do payment terminals play in fuel dispensing systems?

Payment terminals are one of the most important parts of modern fuel dispensing systems, as they provide ease and convenience for the customer to pay for the fuel that has been dispensed. The terminals can work with a wide range of payment methods that include credit cards and mobile payments, thus making the transaction smooth. The use of cloud-based payment solutions has the potential to not only improve security but also make the operations more efficient.

How can one ensure safer fuel transfer with dispensing systems?

It is of utmost importance to install only the best fuel dispensing systems, which come power-packed with the latest safety features, so as to ensure safe transfer of fuel. Conducting regular upkeep and checks on the machines will help to spot and eliminate any potentially dangerous situations. Furthermore, educating the workers in safe fueling methods can considerably heighten the safety standards and ensure that the company complies with the regulations.

What are the different types of fuel dispensing solutions available?

There exists an array of fuel dispensing solutions that are available to meet various fueling needs. Among them are mechanical and electronic systems, which can be customized for different fuel types such as diesel, natural gas, and compressed natural gas (CNG). Every solution is constructed to fulfill specific requirements, including industrial applications and retail fueling stations.

What is the importance of selecting reliable fuel for dispensing applications?

Fuel reliability is one of the main factors affecting the performance and lifespan of the vehicles and equipment used in dispensing applications. Poor fuel quality leads to engine problems and, consequently, higher maintenance costs. Operators can, however, keep on running smoothly and at an efficient rate if high-quality fuel is consistently supplied for their systems.