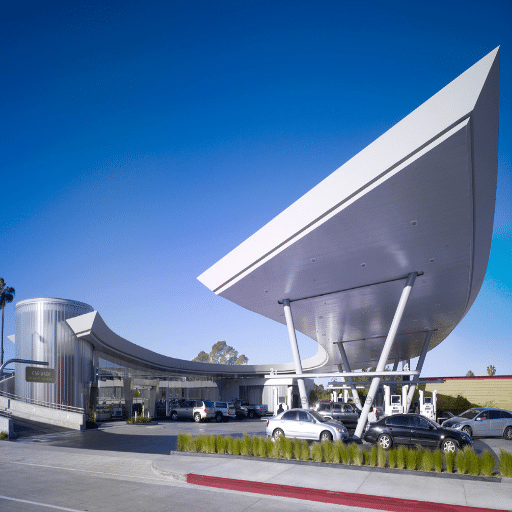

Gas pump dispensers are the very first thing to ensure while starting a fuel station. They are hence necessary to choose not only for the smooth running of operations but also to provide that final touch in a complete customer interface. Amidst the many options, the Encore 700 undoubtedly stands out as one of the finest retail fuel dispensers. This article will cover the specifications and benefits of the Encore 700, as well as other high-quality dispensers designed to meet the challenges of modern fuel retailing. This guide will enable you to make an informed choice that truly meets your business needs, whether you are looking to replace your current equipment or set up a new station.

Understanding Fuel Dispensers

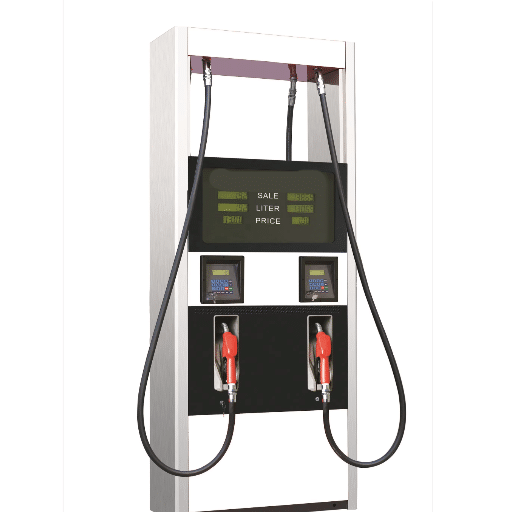

Fuel dispensers are essential equipment for any gas station, designed to dispense fuel into vehicles. A pump moves fuel from an underground storage tank to the car, along with a metering device to provide exact measurement results. Modern fuel dispensers incorporate advanced technology for seamless cash transactions, ease of use, and enhanced safety. The selection of the correct dispenser should be based on criteria such as reliability, efficiency, and payment interface, enabling two-way service to both the operator and the customer.

What is a Fuel Dispenser?

A fuel dispenser is a type of dispenser for liquefied fuel, chiefly gasoline and diesel, and is pumped from underground storage tanks to vehicle fuel tanks. It utilizes pumping to move fuel and metering to measure the exact volume dispensed. Modern fuel dispensers are equipped with modern luxuries, including digital displays, contactless payment systems, and safety features, for added convenience and security. These are a must at gas stations to enable accurate refuelings based on the fuel type given, including alternative fuels such as ethanol or biodiesel. Efficient and reliable operation is key to limiting downtime and serving customer satisfaction.

Types of Fuel Dispensers

Fuel Dispensers. There are many varieties as per different needs and operational conditions. The major types are suction fuel dispensers, submersible fuel dispensers, and multiproduct dispensers.

Suction Fuel Dispenser: The suction fuel dispenser utilizes a suction pump to draw fuel from the underground storage tank to the dispenser nozzle. They are most suitable for the smaller installations and are also easier to maintain due to fewer components.

Submersible Fuel Dispensers: A Submersible pump located in the storage tank pushes fuel to the nozzle of these dispensers with much better efficiency. They are best suited for applications that demand high flow rates and larger installations.

Multiproduct Dispenser (MPD): An MPD, or Multi-fuel Product Dispenser, is used to dispense multiple types of fuel at a single fueling point, including gasoline, diesel, and alternative fuels. They are designed to be compact and convenient, allowing them to fit seamlessly into the modern-day gas station environment, utilizing minimal space while catering to a wide range of customer needs.

Each type of dispenser offers its unique opportunity, and the right choice will depend on the size of the station, the kinds of fuels provided, and the estimated traffic volume.

Key Features of the Encore 700

The Encore 700 upholds high standards in fuel dispensing technology, boasting a rugged design that enhances efficiency and user experience. Key highlights on the Encore:

Fuel Flexibility: The Encore 700 supports a wide range of fuels, including gasoline, diesel, ethanol blends, biodiesel, and CNG, catering to diverse consumer needs while promoting the use of alternative fuels.

High-End Metering Technology: Precision metering in the dispenser ensures the dispensing metric is accurately served, lending transparency and building customer confidence.

Heavy-Duty yet Ergonomic Design: Designed for heavy usage, the Encore 700 features a rugged exterior and intuitive design. Its compact footprint maximizes space, making it an ideal choice for high-traffic stations.

Maintenance-Easy and Environment-Friendly: Energy-efficient lighting and low maintenance reduce operational costs and minimize environmental impact.

Integrated Media Solutions: The Encore 700 will provide high-definition screens and multimedia capabilities for displaying promotions, fuel options, and instructions live at the pump.

Secure Payment Systems: It has integrated EMV-compliant card readers and contactless payment options, along with advanced cybersecurity protocols, to ensure seamless and secure transactions.

With these cutting-edge qualities, the Encore 700 becomes a versatile and formidable instrument in the hands of present-day fuel station operators who value technology, convenience, and sustainability.

Choosing the Right Gas Pump Dispenser

The right gas pump dispenser depends on and takes a close look at the needs of your fuel station. These may include expected visitor volume, type of fuel offered, and level of technology wanted. Look for dispensers that promise long life, efficiency, and an easy-to-use interface. Consider payment security, transparent displays, and compatibility with future fuel choices. Consider the customer and after-sales service support provided by the manufacturer as an essential factor in your decision. Focusing on such basics will help you choose a dispenser that escapes any obstacles regarding functionality or customer satisfaction.

Factors to Consider When Purchasing

Several key factors should be considered when selecting a fuel dispenser to ensure optimal performance and long-term value. First, reliability and durability should be critical factors since a dispenser is expected to be made from materials that environmental elements cannot easily erode. Secondly, accuracy and efficiency should be highly considered by ensuring that they are equipped with advanced metering systems to reduce errors and increase throughput. Third, from a technological perspective, evaluate aspects such as seamless automation integration, user-friendly interfaces, or the capability to work with modern payment systems that can provide a great customer experience. Consideration should also be made on whether the dispensers would support alternative fuel types, such as electric or biofuels, as a way of future-proofing your investment. Lastly, ensure that the manufacturer offers responsive customer support, training, and reliable maintenance services to ensure that operations continue to run smoothly. When these points are addressed, one can make an informed purchasing decision with confidence.

Standard vs. High Flow Dispensers

When searching for gas pump dispensers for sale, options include standard flow dispensers, high-flow dispensers, combination models, electric fuel dispensers, and those with advanced payment integration capabilities.

|

Key Point |

Standard |

High Flow |

|---|---|---|

|

Flow Rate |

Up to 10 GPM |

10-60 GPM |

|

Ideal For |

Cars, for small use |

Trucks, heavy use |

|

Fuel Types |

Gasoline, diesel |

Gasoline, diesel |

|

Cost |

Lower |

Higher |

|

Installation |

Simple |

Complex |

|

Maintenance |

Limited |

Frequent |

|

Payment |

Basic |

Advanced |

|

Durability |

Moderate |

High |

This table highlights the differences between standard and high flow dispensers, helping users select the appropriate option for their specific needs and usage environments.

Trustworthy Brands in the Market

To ensure reliability, long life, and efficiency, opt for trusted brands. There are some esteemed names, identified with quality products:

Gilbarco Veeder-Root has carved out a niche in the fuel dispenser industry, offering a wide range of products that cater to both standard and high-flow needs. Being at the forefront of technology, their dispensers typically feature innovative payment systems, accurate metering, and sturdy construction, which promise years of reliable service.

Wayne Fueling Systems, a division of Dover Fueling Solutions, is well-regarded for its innovative solutions in both modern dispenser technology and forecourt technology. Their units are designed to be energy-efficient and easy to service, making them suitable for any operation, whether big or small.

Tokheim: The Tokheim Dispenser system is designed and built with utmost precision, consideration, and convenience for the user. Safety and global regulatory compliance foster trust in the business world. Tokheim also employs digital technology to develop a seamless platform for integration with management systems.

Bennett Pump Company: Renowned for its quality and affordability, Bennett Pump Company distributors are a trusted and reliable source for the supply of various fuels, including gasoline, diesel, ethanol, and alternative fuels. High durability and performance stand as priorities for the industry.

Tatsuno Corporation has a long history of innovation. Tatsuno is one of the largest manufacturers of fuel dispensers in Asia and globally. Their dispensers offer high accuracy, low energy consumption, and a robust design to meet various market demands.

Choosing these trusted brands means you gain the benefit of long-term support, consistent performance, and innovations that meet customer demands efficiently.

Retail Fuel Dispensers: Efficiency and Reliability

Retail fuel dispensers are designed to work accurately, provide reliable operation, and offer user-friendly functionality. These dispensers maintain precision in fuel delivery, ensuring that no loss occurs. Top brands utilize sturdy and energy-efficient materials in constructing their dispensers, thereby maximizing performance while minimizing operational costs. For any businessman, investing in high-quality dispensers should be a matter of choice, with the understanding that it guarantees long-term reliability, assures customer satisfaction, and meets industry standards.

The Importance of Flow Rate

The overflow rate into fuel dispensing systems is considered a crucial factor leading to efficiency and customer satisfaction. The flow rate, measured in L/min or GPM, determines how fast fuel is delivered. For instance, high-speed fuel dispensers for commercial fleets operate at rates ranging from 90 to 120 L/min, thereby reducing downtime for the vehicles through such deliveries, as opposed to the ordinary dispensers, which deliver fuel at around 40-50 L/min.

Ensuring that the flow rate maintains a precise and appropriate delivery of fuel prevents overfilling and fuel waste. Optimizing flow rates benefits the business by increasing throughput without eliminating the precision of measurement. Technology has enabled modern fuel dispensers to automatically regulate flow rates according to demand, ensuring discretion is maintained for customers with varying needs while meeting all regulatory requirements.

Energy consumption depends on the rate of flow optimization. Dispensers with efficient flow rates use less power in operation, thus saving money for the fuel station operator. By investing in a system with superior flow rate control and monitoring capabilities, the business can achieve operational efficiency while ensuring the best fuel-filling experience for its patrons.

Maintenance Tips for Fuel Dispensers

Proper maintenance of the fuel dispensers ensures their longevity, optimal performance, and safety. Here, however, are some fine-tuned tips to keep the dispensers operating in their proper condition:

Regular Inspection of Hoses and Nozzles: Check hoses and nozzles for wear, cracking, or leaks. Damaged hoses should be replaced immediately to prevent fuel loss and potential safety hazards. Studies show that an unattended hose problem can lead to a 5-10 percent increase in fuel leaks annually.

Check Calibration: These fuel dispensers should always be calibrated to ensure that dispensing accuracy is intact. Miscalibrated pumps can result in discrepancies in fuel volume delivery, leading to financial losses and potential lawsuits. Industry standards typically require a recalibration every six months or so in practice.

Cleaning and Checking Filters: Filters in the dispensing system clog with dirt over time, reducing flow and malfunctioning the dispenser. Replacing filters quarterly maintains proper fuel flow and keeps internal parts from being damaged.

Inspecting Electronics and Software Updates: Contemporary dispensers use advanced digital systems for monitoring and control. Regularly test the electronics and keep the software up to date to enhance performance and security. Emerging data show that this reduces systems’ downtime by 15% annually.

Prevent Corrosion: Weather conditions play a significant role in causing rust or corrosion of metal parts. A protective coat applied monthly to clean exposed areas will prevent it. Check tanks for signs of water contamination, as this can accelerate corrosion.

Lubricate Moving Parts: Apply lubricant to moving parts, such as lever arms or parts that rotate, to ensure smooth operation. Lack of lubrication causes unnecessary wear and ultimately leads to mechanical failure.

Test Safety Features: Emergency shut-off valves and other safety features shall be tested daily to ensure their proper operation. These are vital in controlling spills or leaks, thereby minimizing environmental damage and safety incidents.

With these maintenance practices, fuel station operators can significantly extend the working life of dispensers, promote energy efficiency, and create a stress-free environment for customers while adhering to industry standards.

Ensuring Compliance with Industry Standards

Ensuring compliance with fuel station operations involves respecting laws related to environmental protection, equipment maintenance, and safety. In this regard, operators conduct regular audits and inspections to ensure that equipment complies with the specifications mandated by ASTM International or other authoritative organizations. Maintenance and safety inspections must be documented to prove compliance in the event of a regulatory review. Additionally, training should be provided to staff so that employees understand the procedures involved in handling hazardous materials, responding to emergencies, and operating equipment. Adopting every change that comes with local, state, and federal regulations will help operators prevent fines and ensure a safe and efficient operation, working in accordance with industry best practices.

Getting a Quote for Your Gas Pump Dispenser

You would start by contacting credible suppliers or manufacturers to obtain a quote for your gas pump dispenser. You would need to share all of your requirements, including the type of dispenser, volume, and type of fuel it will store, along with any additional features you may require, such as payment systems or safety enhancements. Then ask them to break down the prices, including installation costs, potential maintenance, and warranty coverage. Obtaining price breakdowns from multiple vendors will help you evaluate and choose the one that best suits your operational and budget needs.

How to Request an Accurate Quote

Before requesting a quotation, ensure that you clearly and explicitly list your requirements. Specify the types of fuel dispensers you need, including considerations such as capacity and compatibility, as well as the additional features they should have, such as digital meters, payment systems, or safety devices. Additionally, consider the operational parameters that will help tailor the offer, such as the daily volume of expected use, environmental factors, and any site-specific requirements.

The next step is to request a detailed costing. This should include the cost of the dispenser, installation costs, maintenance charges, and warranty coverage options. You may also want to inquire about after-sales support and the availability of spare parts. Declare any budget restrictions and deadlines, if applicable.

Lastly, contact as many quality suppliers as possible to compare their prices and costs. Check not only for price, but also for material quality, customer reviews, and the supplier’s reputation in similar projects. What is best is to communicate openly and provide complete information upfront with the supplier to make for a more accurate and well-suited proposal, saving both time and resources along the way.

Understanding Pricing Factors

When considering pricing factors for any product or service, the first step is to examine several key factors that contribute to the cost of every product. Material and other manufacturing inputs contribute to the formation of prices, and their availability can fluctuate when market demand increases or decreases, or due to geopolitical factors. For example, steel prices have increased globally by about 3 percent in the last quarter, amid disruptions in the supply chain and rising demand for construction.

Labor cost is another critical factor. It differs from country to country and within industries. For instance, in high-wage economies, labor costs may account for more than 30 percent of total production costs, thereby directly influencing pricing decisions. Other factors that contribute to pricing include operational costs such as energy consumption, transport, and warehousing. For example, the total transport cost last year increased by around 4.8 percent due to rising fuel prices and logistic delays.

Market competition and demand trends also play a significant role in shaping the market. Pricing decisions are often made based on what the customer expects or the benchmark set by their competitors. For instance, industries that leverage advanced technologies like AI or automated processes can price their products or services competitively, owing to the lower long-term operational costs. However, the initial investment price is somewhat higher.

At the other end, indirect factors such as tariffs, import duties, or internal taxes may alter the pricing structure for various goods and services in global markets. Recent changes in export taxes observed at specific locations have added anywhere between 5% and 7% to the cost of exported goods, which in turn affects the end consumers. Considering such factors provides considerable clarity in evaluating pricing frameworks and establishing realistic budgets for purchases or projects.

Financing Options for Retail Stations

The retail station, such as a fuel station or convenience store, needs heavy investments in physical capital to be built and maintained. A multitude of financing options, however, does exist that entrepreneurs or companies may use to fund such ventures effectively.

Traditional Bank Loans: Banks or financial institutions provide term loans tailored to meet the needs of retail businesses. Interest rates for such loans typically range from 5% to 10%, depending on the borrower’s credit profile and the loan’s length. Typically, the loan’s duration ranges from 5 to 15 years, offering flexibility in repayment schedules. Banks or lenders may also require collateral, which can be in the form of real estate or other valuable assets.

Equipment Financing: Equipment financing for retail stations involves substantial investments in essential equipment, including fuel dispensers, tanks, and point-of-sale systems. Such funding enables businesses to purchase equipment without having to pay the entire amount up front. Interest rates on such loans vary from approximately 6% to 12%, and the equipment itself is typically offered as collateral for these loans.

Franchise Financing: Many retail stations operate under well-known franchise brand names, such as Shell or Chevron, each offering special financing programs tailored to their specific needs. These programs might include discounted fees, assistance with property leasing, or even low-interest loans. Franchisors work with lending institutions to ensure that new operators have access to deals like these.

SBA Loans: The SBA offers SBA loans for retail businesses under favorable terms. Under specific SBA loan programs, such as the 7(a) loan, loans can be as high as $5 million, with competitive rates ranging from 6% to 9%. Besides being long-term loans, repayments can be stretched over as long as 25 years when purchasing a home or other real estate.

Alternative Lenders: Non-traditional lending setups, such as online lenders or fintech companies, have expanded the financing options available to small businesses they serve. They may offer speedy loan approvals and flexible terms, but the interest rates can be somewhat higher, ranging from 10% to 25%.

Government Grants and Subsidies: Some governments provide grants or subsidies to businesses that promote sustainable practices, such as setting up electric vehicle charging stations. For example, a program could potentially pay 30 percent of the cost of installing EV-related infrastructure, thereby easing the financial load on retail station owners.

Knowing the different options available to them and selecting the most suitable mix, depending on their enterprise financing needs, will go a long way in covering startup costs as well as operational costs. A carefully thought-out examination of the financing option’s terms and conditions, as well as long-term implications, should pave the way for the sustainable growth and profitability of retail station ventures.

Confidence Comes Standard with Encore Family Products

The Encore Family Products are designed and manufactured for reliability and performance, ensuring that every use inspires confidence in the user. Top-line technology, easy-to-use features, and rugged durability guarantee trouble-free operation in many applications. Because Encore family products were created with quality and user satisfaction in mind, they are a recognized name for long-term success.

Advantages of Choosing Encore Products

Cutting-Edge Technology: Encore products are at the forefront of innovation, utilizing technologies that enable superior product execution. For example, the new designs incorporate energy-conserving systems to reduce operational costs by approximately 30% – a win-win for both the user and the Earth.

Hence, Reliability and Durability: Having earned a reputation for reliability, Encore products are truly built to withstand harsh conditions. Constructed with the highest-quality materials, these products perform reliably even under the most rigorous conditions. Studies have shown that the performance levels of Encore products are maintained for a minimum of 10 years with minimal upkeep, which is a boon to users’ budgets.

User-Friendliness: Encore strives to keep its products as convenient and straightforward as possible. The product design allows any user, regardless of experience, to operate the product with minimal effort, thereby saving much time and energy.

Eco-Conscious Design: Sustainability is at the very heart of Encore’s existence. While reducing the carbon footprint, the use of biodegradable materials and energy-saving mechanisms is of primary importance in Encore products, whose environmentally conscious activities align well with the goals of modern-day sustainability. In essence, this is the responsible course of action to take.

Highly Regarded Support: Customer satisfaction matters to Encore beyond the product. The professionally trained staff stands ready to quickly and efficiently resolve issues. Across multiple industries, their customer satisfaction rating averages at 95%.

Thus, when you buy an Encore product, you bind your fate to innovation, long-term durability, and trusted support, ensuring that, with great confidence, any task that needs to be done is sure to get done for you.

Future Innovations in Fuel Dispenser Technology

The future of fuel dispenser technology will likely focus on being more efficient, sustainable, and user-friendly. Contactless payment and interfacing with renewable fuels will be allowed, as well as analytical accounting for operational insights. Of course, the Internet of Things standards, along with automated maintenance alarms, will only enhance operational reliability and consumer convenience.

Reference Sources

1. Evaluation of the Internal Control System for Inventory at U.D. Nina Usman SPBU

2. Building a Hydrogen Infrastructure in Norway

Frequently Asked Questions (FAQs)

What Should I Consider When Buying a Fuel Dispenser for My Fueling Station?

When purchasing a fuel dispenser for your fueling station, consider factors such as compatibility with your existing equipment, whether you want to offer alternative fuel options, and the overall cost of installation and maintenance. It’s also essential to evaluate the security features of the dispenser to protect your investment and ensure customer safety.

How Does the Encore Ultra-Hi Flow Dispenser Enhance Fueling Experience?

The Encore Ultra-Hi Flow dispenser is designed to provide fast fueling capabilities, making it an excellent choice for high-demand fueling stations. Its advanced technology enables a more efficient fueling experience, reducing wait times and enhancing customer satisfaction.

Can I Trust Gilbarco Veeder-Root Equipment for My Business?

Yes, Gilbarco Veeder-Root is a reputable brand known for producing reliable fueling equipment. Their products, including the Encore family of dispensers, are built to meet industry standards and are trusted by businesses worldwide for their durability and performance.

What Are the Benefits of Installing a CNG Dispenser?

Installing a CNG dispenser makes it easy to bring compressed natural gas to your fueling station. This alternative fuel option can attract environmentally conscious customers and provide additional revenue streams for your business. Moreover, CNG dispensers are often designed with user-friendly interfaces for a seamless customer experience.

How Can a Payment Management System Improve My Fueling Station?

A payment management system can enhance your fueling station’s efficiency by streamlining transactions and providing customers with a secure payment method. This system can also help you manage sales data effectively, allowing you to make informed business decisions and optimize your operations.

What Is the Cost of Upgrading My Fuel Dispenser Equipment?

The cost of upgrading your fuel dispenser equipment can vary depending on the type of dispenser, its features, and the installation requirements. Investing in modern equipment, such as the Encore Ultra-Hi Flow, can save you money in the long run by improving efficiency and reducing maintenance costs.

How Can I Ensure the Security of My Fuel Dispenser?

To ensure the security of your fuel dispenser, consider investing in upgradeable security features and secure payment options. Additionally, regular maintenance and monitoring can help prevent unauthorized access and protect your fueling station’s assets.

What Makes the Encore CNG Dispenser a Good Choice for Fuel Businesses?

The Encore CNG dispenser is an excellent choice for fuel businesses because it combines efficiency with user-friendly technology. It allows you to offer compressed natural gas easily, appealing to a growing market of customers seeking alternative fuel options while enhancing your site’s overall service offerings.

What Should I Look for in a Complete Fuel Dispenser Solution?

A comprehensive fuel dispenser solution should encompass high-quality equipment, extensive support services, and a reliable payment management system. Look for dispensers that offer fast flow rates, compatibility with various fuel types, and features that enhance the customer experience, such as easy-to-use interfaces and secure payment options.