Fueling stations help to fuel the vehicles in our lives, and in doing so, they enable us to go about our daily activities. Around us, we hardly think of the massive structures operating out of sight, especially the vast underground fuel storage containers. How large are these containers? What are the safety and operational strategies deployed to maintain the fuel flow to these containers? Fuel Storage and Dispensers delve into the world of Fuel Storage and Dispensers to uncover the impressive scale, design, and functionality of the gas station tank. This article is for curious motorists and engineering enthusiasts who wish to understand how fuel is stored and dispensed to propel the world.

Overview of Gas Station Tanks

Fuel storage tanks for gas stations are underground tanks made to store fuel in bulk while maintaining safety. Such tanks are made of strong materials, like steel or fiberglass, for leak protection and strength. Although sizes vary, typical fuel storage capacities range from 10,000 to 30,000 gallons of fuel or diesel. Newer tanks are equipped with safety features such as double-wall construction to reduce the likelihood of leaks, as well as systems to monitor pressure and volume changes. Such systems are crucial in ensuring that the environment is not harmed and that the operations are dependable. When designed and adequately maintained, fuel storage tanks can meet daily demands safely and consistently.

Types of Gas Station Tanks

Fuel storage facilities are divided into two groups based on the site and the construction of the fuel storage tank: Above-Ground Storage Tanks (ASTs) and Underground Storage Tanks (USTs). Each type comes with its own unique features, benefits, and considerations.

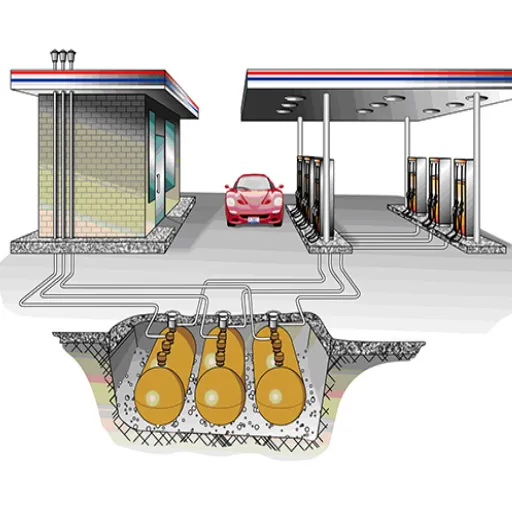

Underground Storage Tanks (USTs)

As the name suggests, USTs are installed below the surface because of their fuel storage capabilities. USTs are typically constructed from steel with corrosion-resistant coatings or fiberglass-reinforced plastic. Since they can store fuel in large quantities ranging from 10,000 to 50,000 gallons per tank, they are usually found in commercial fueling stations. USTs are also required by environmental regulations to have a leak detection system, spill containment devices, and cathodic protection to reduce contamination risks. Because of their inconspicuous design and sturdiness, USTs are, according to industry information, the preferred option for urban or congested areas.

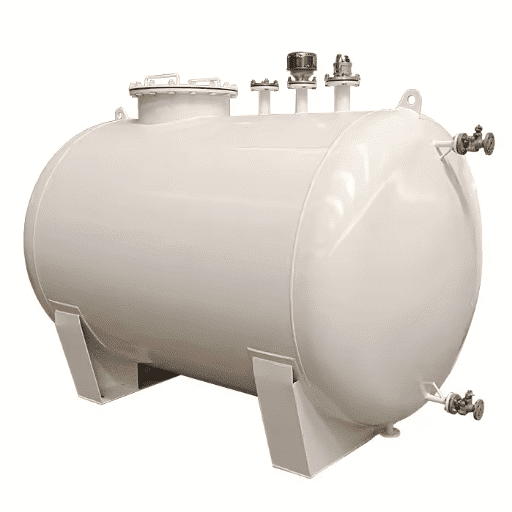

Above-Ground Storage Tanks (ASTs)

Unlike USTs, ASTs are set up above the surface and are commonly used in areas where there are no concerns regarding space limitations or other environmental issues. Depending on demand, these tanks are made of steel or aluminum, with capacities ranging from 5,000 gallons. Since the entire structure of ASTs is visible, they can be easily inspected and maintained. These tanks are typically found in rural gas stations, industrial facilities, or commercial premises. In addition, ASTs pose a risk of potential harm or leakage and thus require additional safety measures, such as protective barriers or secondary containment systems.

Current innovations in tank construction incorporate double-wall construction for extra safety and automation equipment for real-time checking of fuel levels, pressure, and temperature. Compliance with regulations and periodic servicing under proper supervision ensures that both USTs and ASTs can store fuel safely and effectively as required.

Common Sizes of Fuel Storage Tanks

There are different fuel tanks for specific industrial, commercial, and residential uses. The most suitable sizes to use depend on the purpose and the amount of fuel required for storage.

| Tank Category | Capacity Range | Typical Applications | Key Features |

|---|---|---|---|

| Residential Tanks | 275 – 1,000 gallons (1,041 – 3,785 liters) |

Home heating oil, gasoline, diesel | Small capacity, easy installation |

| Commercial Tanks | 2,000 – 10,000 gallons (7,570 – 37,850 liters) |

Fleet management, gas stations | Intermediate size, frequent refueling |

| Industrial Tanks | 25,000 – 100,000+ gallons (94,635 – 378,540+ liters) |

Large-scale operations, diesel, jet fuel | High capacity, specialized materials |

| Portable Tanks | 500 – 1,500 gallons (1,893 – 5,678 liters) |

Construction, farming, temporary projects | Mobile, easy to relocate |

| Special Tanks | 1 million+ gallons (3,785,000+ liters) |

Aviation, maritime, energy production | Custom configurations, massive scale |

The use of a specific fuel storage tank size depends on the application, the available space, and the environmental laws governing a particular area. Choosing the correct size allows the industry to save fuel, maintain safety, and reduce costs.

Importance of Tank Size in Service Stations

Fuel storage tank sizes at service stations significantly impact daily operations and customer service. It is the desire for service stations to ensure that the tank sizes are based on the sales volumes of the respective stations. In essence, the tanks should be able to contain enough fuel to serve customers while also ensuring there are no stockouts. On the other hand, fuel tanks should not be too large as to cause fuel to age. Consider that in the United States, service stations sell 4000 gallons of petrol a day. This step greatly aids the service stations in planning for the tanks, which should be in the range of tens of thousands of gallons to cater to high-demand periods as well as deliveries.

Additionally, larger tanks also help reduce costs because fuel can be purchased in bulk at a lower price. This also helps reduce the frequency of refueling. On the other hand, tanks that are too large do incur higher costs due to increased maintenance and infrastructure, including environmental safety and leak prevention measures.

Moreover, the use of different fuel types, such as electric vehicle charging or compressed natural gas (CNG) fuel stations, highlights the need for appropriately sized tanks and modifications to the infrastructure. Stations must reconfigure and re-tank sustainably and efficiently to comply with the new fuel requirements. Service stations can optimize supply needs, reconfiguration, and other operational costs, while also meeting environmental standards by optimizing tank sizing.

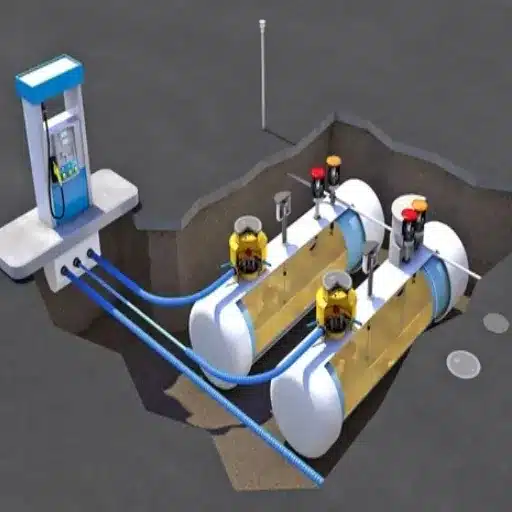

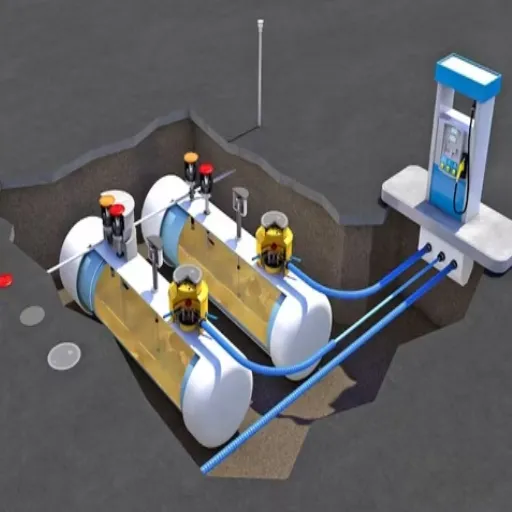

Underground Fuel Storage

Serving the purpose of safely storing bulk fuel, underground fuel storage tanks at service stations play an integral role. These tanks are usually constructed from fiberglass or steel, designed to resist corrosion and leaks. To maintain compliance with regulatory requirements, fuel stations must perform regular maintenance and undergo inspections to ensure the safety of both fuel and the environment. The tanks are also equipped with fuel monitoring systems, which modern tanks possess to ensure prompt leak detection and avoid contamination. This storage method is strategic in space management and helps preserve fuel quality. It is designed to distribute fuel in large quantities efficiently.

What is an Underground Storage Tank?

An Underground Storage Tank (UST) is a fuel storage system that stores liquids or gases underground. Heavily used in fuel retailing and chemical processing, USTs are an integral part of today’s economy, storing petroleum products, chemicals, or other hazardous materials. The United States alone has more than 550,000 UST systems, underscoring their widespread adoption.

Advances in technology have made it possible to construct USTs with newer materials such as steel with protective coatings and fiberglass-reinforced plastic. To further prevent spills, double-walled construction is the norm for newer tanks, making them leak-resistant. Newer tanks also feature integrated advanced leak detection and inventory management systems, providing real-time product quantity tracking and alerts for any abnormal situations.

To ensure the safety of USTs, proper installation, as well as their operation and maintenance, is regulated at both the federal and state levels, including the Environmental Protection Agency (EPA). For instance, there are now more stringent controls in place to prevent spills, as well as overfilling, and periodic checks are conducted. As a result, the number of accidental discharges has declined drastically. All of these improvements ensure USTs operate at optimum efficiency while being a safe and highly regulated solution for the storage of liquids and gases on a large scale.

Benefits of Underground Fuel Storage

Fuel storage tanks located below the surface offer a greater range of benefits compared to above-ground tanks, particularly in terms of efficient use of space and environmental safety. Firstly, underground tanks help save important surface space, which can be used for parking, landscaping, or additional structures. This is particularly important in urban and industrial settings, where space is limited.

Furthermore, modern UST systems pose minimal ecological threats. Today’s tanks are designed with double-walled fuel sleeves, corrosion-resistant coatings, and advanced fuel leak detection technologies, significantly reducing the chances of fuel contamination. Industry reports on double-walled tanks indicate that such tanks reduce the risk of leaks by 90%, representing a significant improvement in environmental safety.

From a cost perspective, USTs facilitate the storage of fuel in bulk, allowing the purchase of fuel at lower rates when market conditions are favourable. This can lead to significant cost advantages for companies. For instance, one single large-scale UST can store tens of thousands of gallons, providing economies of scale for businesses with large fuel requirements.

Finally, the USTs enhance both efficiency and safety of operations. The underground systems reduce the amount of fuel exposed to weather and possible dangers such as vandalism or fires, offering a safer method of fuel storage. In addition, the adoption of routine checks and maintenance plans has proven to provide greater control over accidental releases, highlighting the durability of the systems over time.

Installation and Regulation Requirements

The process of installing Underground Storage Tanks (USTs) is a comprehensive one that requires a significant amount of planning to comply with all relevant safety regulations, protect the environment, and ensure that everything works as intended. To begin, the site is inspected for several reasons, including analysis of the soil for storage, the groundwater level, and the proximity to any local ecosystems. The tank also requires proper excavation, specialized backfilling, and support materials. Fiberglass-reinforced plastic and double-walled steel are examples of materials used in UST systems today to increase durability and prevent leaks.

Different regions will have different laws regulating USTs, but in general, a particular set of environmental agencies will oversee the matter. As an example, the Environmental Protection Agency’s (EPA) guidelines regulate USTs in the United States. As a general rule, systems are required to have spill, overfill, and leak detection devices. USTs, as of the latest amendments, are required to have secondary containment for both tanks and piping to reduce risks of contamination in the event of a breach. Additionally, petroleum tanks must be corrosion-resistant and undergo regular inspection and maintenance.

According to the latest industry analysis, corrosion accounts for approximately 26% of UST failures, highlighting the importance of using corrosion-resistant materials and implementing cathodic protection during installation. More interestingly, compliance with regulations appears to have led to a reduction in leakage incidents over the last ten years, providing an example of the impact that adherence to updated policies can have.

The training required for personnel handling UST operations, along with the use of checklists for system inspections, helps ensure system safety and compliance, which in turn assures the reliability of these storage systems.

Dispenser and Pipe Systems

The underground storage tank (UST) operations cannot function without the dispenser and pipe systems, as they are the primary means of transferring stored materials to their intended destinations. These systems require proper flow with minimal risk of leaks; thus, they are designed for durability and precision. Advanced safety mechanisms, such as those designed to prevent corrosion and mechanical failures, as well as the materials used in modern dispenser and pipe systems, further enhance their safety. Industry standards and regular maintenance carried out on these systems improve their operational safety and reliability.

How Dispensers Work with Storage Tanks

Storage tanks and dispensers work together, with storage tanks housing materials for later transfer, and the dispensers drawing from the tanks. The storage tank stores the material, which is kept under controlled conditions. The tank may be equipped with temperature or even pressure control systems, especially if the material stored is a liquid or a gas.

Dispensers are linked to the tanks with pipes or hoses. Their material must be corrosion-resistant. Stainless steel and reinforced polymers are common examples. Dispensers utilize pumps, valves, and flow meters to regulate the release of materials. They also feature modern dispensers equipped with flow rate sensors and anomaly detectors, ensuring safe and proper dispensing.

To illustrate, fuel dispensing systems may have flow rates ranging from 10 to 40 gallons per minute, depending on the system type, whether commercial or industrial. To reduce waste during transfers, modern dispensers utilize digital interfaces and automatic shut-off valves for precise control. They are also equipped with dispensing volume tracking systems, which can be valuable for inventory management.

The combination of robust storage tanks and dependable dispensing equipment ensures that the systems are both practical and environmentally protective.

Pipeline Considerations in Fuel Stations

When considering pipeline design for fuel stations, efficiency and safety are the primary concerns to be ensured. Well-designed pipelines take into consideration the type of fuel to be transported, the expected volume throughput, and the environmental conditions. Commonly used materials include carbon steel, stainless steel, and polyethylene, each selected based on its corrosion resistance and the fuels they are designed to carry, such as gasoline, diesel, or aviation fuel.

Effective leak prevention measures must be implemented. The consequences of a leak can include fuel spills, which can be both economically and environmentally damaging. Modern fuel stations now use advanced underground pipeline monitoring and leak detection technologies. For example, fuel stations now use automated sensors that continuously monitor fuel pressure and instantly notify operators in the case of a pressure change. It is estimated that the use of these technologies can reduce the chances of undiscovered leaks by 70%.

Fuel station automation now integrates them with pipelines through advanced coupling systems at the fuel station to ensure minimal losses at the connection points. Optimizing the flow also requires the proper gradient of the pipelines to be set, which often allows gravity to reduce the pumping energy.

To comply with further regulatory requirements, double-walled pipelines are required in many countries to provide additional protection against leaks. This system has an outer protective shell and a monitoring system that alerts when the space between the layers is breached, indicating failure of the inner pipeline. Such improvements play an essential role in protecting the environment in sensitive areas.

The considerations for pipelines help ensure operational performance, user safety, and environmental protection. These practices reflect the growing need for sustainability in fuel station management.

Maintenance of Dispenser Systems

Fuel stations benefit from regular maintenance of dispenser systems for safety, efficiency, and longer operational life. The maintenance policy should also cover periodic checks for leaks, malfunctions, or erosion on the fuel station components, such as hoses, nozzles, and pumps. Preventive maintenance checks are recommended by industry standards to be performed at least once every six months.

Recent developments in fuel dispenser technology bring the lack of system calibration controls to the forefront. It has been noted that low-maintenance dispensers can cause fuel delivery measurement errors to rise to 0.5%. The use of automated diagnostic tools can help reduce the downtime resulting from a system failure.

Moreover, payment systems linked to the modern fuel dispensers need to be maintained as a priority for the operators. There needs to be safeguards in place to protect these systems from cybersecurity threats, given the current use of innovative and cashless payment systems. According to modern industry studies, nearly 40% of fuel dispenser malfunctions stem from software issues, necessitating scheduled software testing and updates.

In the end, it helps in the maintenance and service of fuel stations that they keep an accurate and up-to-date record of inspections and service schedules. Such records help maintain customer trust and ensure compliance with regulatory norms. By following these guidelines, fuel stations can enhance the efficiency of their fuel dispensers, minimize operational downtime, and reduce environmental risks.

Efficiency and Management of Fuel Storage

To minimize waste, fuel storage must be carefully managed to ensure quality, safety, and reduced fuel loss. Some essential practices include regular monitoring of tank levels to prevent overfilling and fuel wastage, regular inspections to identify any fuel leaks or tank damage, and the use of proper ventilation systems to minimize fuel evaporation. Automated monitoring systems are also very useful in improving accuracy and easing tracking. Moreover, fuel contracts and storage systems must comply with regulations and be appropriately labeled and stored to ensure effective storage management. Fuel stations can maintain reliable and cost-effective storage systems provided that these systems receive special attention to ensure compliance with storage management practices.

How Tank Size Affects Fuel Efficiency

The size of a fuel tank has essential consequences for multifaceted fuel efficiency. The benefits and costs of a larger tank are well understood: it stores more fuel, allowing for longer trips without refueling. However, with more fuel comes more weight, and a vehicle that is heavier demands more fuel to run, reducing net efficiency. A study often cited for its findings shows that fuel economy suffers by 1% for every additional 100 pounds of weight on a vehicle.

Smaller fuel tanks encourage refilling more often, with the advantage of potentially having ‘fresher’ fuel, which is particularly valued in performance fuel. Hybrid and compact cars, which are efficiency-minded, tend to be fitted with smaller fuel tanks, supporting the design philosophy of using less overall fuel. In addition, older-style engines and basic aerodynamics are being replaced by newer, more advanced engines and aerodynamic technologies, which help in cutting the losses resulting from smaller fuel tanks and fuel metering.

Understanding how a customer drives and uses a vehicle is just as important. Smaller fuel tanks are ideal for inner-city driving, where the focus is on reducing weight and vehicle emissions. Larger fuel tanks shine in long-distance travelling, where ease and convenience are more important. Analyzing tank size in relation to the vehicle’s purpose helps both the manufacturer and the driver improve the vehicle’s fuel economy and performance.

Best Practices for Managing Fuel Storage

Inspection and Servicing of Fuel Storage Equipment

Ensure that fuel storage tanks and related equipment are inspected and serviced according to a regular schedule. The presence of corrosion, leaks, or sediment buildup can pose serious dangers and degrade fuel quality. Sediment and corrosion can reduce fuel quality and pose dangers. Schedules suggested by industry standards reduce risk and could extend the lifespan of the tanks.

Fuel Tanks Sealing

Proper sealing of fuel tanks is crucial for maintaining fuel quality. Water contamination is a common type of damage to fuel, frequently caused by the growth of microorganisms due to condensation in partially filled fuel tanks. Microbial growth damages fuel. Using an adequate sealing mechanism and keeping fuel tanks as full as possible minimizes this risk.

Storing Fuel With Additives Preserves Its Quality

Fuel stabilizers and biocides help prevent fuel oxidation and microbial contamination during long-term storage. Diesel requiring multiple blends, in particular, benefits from these additives, which ensure proper functioning and reduce maintenance problems.

Keep Temperature and Environment in Check

Controlling fuel for storage in stable temperatures delays evaporation as well as fuel quality degradation. Tanks should be kept in temperature-controlled or shaded areas to avoid extreme temperature changes. Studies have shown that stable temperatures and stored fuel can help prolong its shelf life.

Routine Tests For Fuel

Timely testing of fuel ensures that the product in storage is safe and usable. Testing for fuel stability, sediment, and water content helps tackle problems at their inception. Early signs of contamination can be detected using fuel quality analyzers or by submitting samples to certified laboratories.

Carry Out Fuel Storage Safety Measures

Volatile fumes pose several risks that can be mitigated by adhering to fire safety standards and installing proper venting systems. Fuel storage safety measures must include emergency response plans and spill containment measures to safeguard personnel and the environment.

Fuel storage and handling may pose serious risks to users and the environment; therefore, it is crucial to take all necessary measures to mitigate these risks. The measures highlighted above will enable users and companies to avoid opposite fuel safety risks and environmental risks, as well as fuel storage noncompliance risks.

Impact of Fuel Dispensers on Storage Efficiency

Fuel dispensers are crucial in enhancing storage efficiency in the commercial and industrial sectors. Today’s fuel dispensers come equipped with enhanced fuel management and control systems that ensure accurate fueling and minimal fuel wastage. For example, fuel flow meters with greater accuracy and automatic shut-off devices that eliminate the chances of overfilling help reduce fuel loss and eliminate safety risks.

Fuel dispensers are now equipped with digital inventory management systems. This enables organisations to manage inventory levels remotely. Dispensing fuel on demand reduces fuel downtime. One study reveals that dispensing fuel systems increases efficiency by 20%; this is evident in the logistics and construction industries.

Additionally, fuel dispensers equipped with vapor recovery systems reduce fuel evaporation during dispensing. This increases storage efficiency by conserving fuel and has a positive impact on the environment, as it reduces the release of volatile organic compounds (VOCs) into the atmosphere.

With the use of advanced fuel dispensers, businesses can reduce their losses, improve accuracy, and operate within rigorous safety and environmental regulations. The technologies fostered in fuel dispensers speak volumes about the critical fuel challenges efficiency innovations seek to address.

Future Trends in Gas Station Storage Solutions

Increased Use of Automation and Smart Tech

The most notable development is the use of automation and innovative tech that’s based on IoT. Such systems provide real-time fuel levels, temperature, and pressure data, allowing for better fuel storage and early detection of potential problems. Automation also leads to improved fuel storage management as it reduces errors in carrying out repetitive tasks.

Improved Safety Standards

Advanced safety systems, such as gas leak detectors and automatic shutoff systems, will be a key focus for future fuel storage solutions. Such systems would help improve safety in gas storage and dispensing while adhering to relevant safety standards and protecting the environment.

Move Towards New Fuel Types

As the world focuses on new sustainability initiatives, fueling station storage systems are beginning to support new fuels, including hydrogen, biofuels, and even electricity. Addressing this need fuels further innovation in storage systems that would safely store these new fuels while complying with new standards and requirements.

Fueling Station Storage Flexibility

The need for modular and scalable storage is expected to increase to accommodate changing fuel demands. With modular and scalable designs, fueling stations can increase or improve their storage capacity without facing high costs and without needing to change the underlying structure.

Innovations in Fuel Storage Technology

Smart Tank Monitoring Systems

The IoT fuel level monitoring and leak detection systems mark a significant advance in fuel storage solutions. Such innovations enhance stock optimization and fuel management, enabling a quick response to anomalies and reducing environmental risks while minimizing operational costs.

Advanced Materials for Fuel Tanks

The use of corrosion-resistant alloys and composites is changing the face of fuel storage tanks. They are fuel storage solutions that are lightweight and durable under severe conditions, thereby improving safety and extending useful life. Moreover, they counter fuel contamination and vapor emission problems, thereby meeting environmental safety standards.

Integration of Renewable Energy Solutions

The integration of biofuels or hydrogen-powered systems, which cater to renewable energy, is increasing in fuel storage facilities. This evolution facilitates the expansion of fossil fuels. It enables the fueling of hybrid stations that also serve as alternative fueling outlets, thereby enhancing sustainability and adhering to the principle of clean energy.

Regulatory Changes Affecting Storage Tanks

Storage tanks are subject to new regulations aimed at protecting the environment, preventing leaks, and reducing the risk of contamination. For me, compliance means keeping a close eye on changes in the area, such as increased inspections, the use of advanced leak detection technology, and new materials designed for long-term use. Additionally, I strive to comply with laws that promote green practices, such as the use of secondary containment systems and stricter emission limits.

Environmental Considerations for Gas Station Tanks

To address environmental concerns regarding gas station tanks, the primary focus must be on leak prevention and protecting soil and groundwater from contamination. The use of double-walled tanks and spill prevention equipment as per EPA guidelines minimizes the risk of damage and therefore must be complied with. Advanced leak detection systems must be in place to detect and prevent leaks. Regular inspections and maintenance should be scheduled to enable early detection of potential issues. Long-term tank integrity is also ensured by following industry-standard installation practices, adhering to secondary containment requirements, and utilizing corrosion-resistant materials in conjunction with containment materials. The use of recovery systems, sustainable operations, and reduction of greenhouse gases in operations are positive steps towards sustainable work practices, thereby further contributing to environmental recovery. All of the above measures ensure the safety of ecological resources and facilitate compliance with relevant laws.

Key Environmental Protection Measures:

- Double-walled tank systems – Provide secondary containment

- Advanced leak detection – Real-time monitoring capabilities

- Corrosion-resistant materials – Extended tank lifespan

- Secondary containment systems – Additional environmental protection

- Vapor recovery systems – Reduce emissions and environmental impact

- Regular maintenance schedules – Prevent issues before they occur

Conclusion

The world of fuel storage and dispensing systems represents a complex interplay of engineering excellence, environmental responsibility, and operational efficiency. From the massive underground storage tanks that can hold tens of thousands of gallons to the sophisticated dispenser systems that deliver fuel safely to vehicles, every component plays a crucial role in our daily transportation needs.

As we’ve explored throughout this comprehensive guide, the evolution of fuel storage technology continues to advance with smart monitoring systems, improved materials, and enhanced safety features. The industry’s commitment to environmental protection through double-walled tanks, leak detection systems, and regulatory compliance demonstrates the balance between operational needs and ecological stewardship.

Looking toward the future, the integration of renewable energy sources, automation, and flexible storage solutions will shape the next generation of fuel infrastructure. Whether you’re a curious motorist, an engineering professional, or someone interested in the mechanics of our fuel supply chain, understanding these systems helps us appreciate the sophisticated technology that keeps our world moving.

The continuous innovation in fuel storage and dispensing technology ensures that as our energy landscape evolves, the infrastructure supporting it will adapt to meet new challenges while maintaining the highest standards of safety, efficiency, and environmental protection.

Reference Sources

Frequently Asked Questions (FAQs)

How much fuel can a station’s tank typically store?

A station’s tank can store from 10,000 to 30,000 gallons of fuel. The exact capacity depends on the size and type of station. Large service stations often have the option of installing multiple fuel tanks, allowing them to store large volumes of fuel, whether it be gasoline, diesel, or both.

What is the impact of regulations on the installation of underground fuel storage tanks?

The installation and further management of underground fuel storage tanks (USTs) is strongly impacted by regulations. Moreover, the construction of tanks is affected. To further enhance environmental safety, local regulations often include strict guidelines on tank placement, the materials used in tank construction, and anti-corrosion measures that must be taken to ensure the tanks do not leak or cause contamination.

What are the different types of fuel tanks used at service stations?

Service stations restock fuel to be sold at either underground or aboveground storage tanks. The underground storage tanks are typically cylindrical in design and are buried below the surface for ease of access. Both fuel tank varieties have their own advantages, and strict regulations govern their use.

How is leak detection implemented in gas station tanks?

Detecting leaks in gas station tanks is very important because of the risk it poses to the environment. Gas stations that age their fuel should comply with the rules that require leak checks to be performed using specific techniques. Tanks constructed recently should have monitoring systems installed that detect leaks. This enables issues to be addressed promptly and ensures regulatory compliance is maintained.

What maintenance is required for a fuel storage tank?

For a fuel storage tank, regular maintenance includes scheduled inspections to assess the condition of the fuel storage structure, maintenance checks on leak detection systems, and routine monitoring to check for any signs of contamination. Additionally, the expenses incurred for maintaining the storage system will depend on the size of the fuel storage and the inspection and monitoring intervals specified in local regulations.

How does a gas station make sure that its fuel storage system is safe?

Fuel storage safety at gas stations is ensured by adhering to specific procedures, including the installation of overfill protection systems, conducting regular safety audits, and utilizing corrosion-resistant steel for fuel storage tanks. Such procedures go a long way in preventing fire hazards and environmental contamination.

What operational costs are associated with fuel storage systems?

When operational costs are discussed in terms of fuel storage systems, the most notable feature that comes to mind is the purchasing system. With the adoption of fuel financing systems, fuel suppliers purchase fuel in bulk and store it before selling it, thereby enabling customers to buy products at lower rates and with greater convenience. This, however, requires that the fuel be kept in reasonable condition through proper maintenance and monitoring.

Can a gas station store multiple fuel products in one tank?

Generally, safety regulations and the risks posed by contamination do not allow gasoline stations to keep multiple products in a single tank. Each product, whether gasoline or diesel, requires a dedicated underground fuel storage tank, not only to preserve its quality but also to comply with regulations.