Understanding Portable Fuel Dispensers

Portable fuel dispensers are small, mobile devices that are meant to store and deliver fuel easily in different places. Usually, they have a pump, hose, nozzle, and sometimes a built-in metering system for delivering fuel accurately. These devices are of great use to sectors like agriculture, construction, and transportation, which need on-site fueling solutions. Among their main pros are being mobile, easy to use, and lessening downtime, as there would be no need to take the vehicles to fixed fueling stations. Portable fuel dispensers are made to be tough and safe; thus, they are a reliable option for tough places.

What is a Portable Fuel Dispenser?

A portable fuel dispenser is a small and easy-to-move device that can store, transport, and dispense fuel effectively in different places. It generally consists of a pump, hose, meter, and nozzle, which make it possible to transfer fuel straight into the machines, vehicles, or equipment. These are mostly utilized in agriculture, construction, and logistics, where on-site fueling is necessary. Made from tough materials and designed to meet safety and environmental regulations, portable fuel dispensers are made for reliability, easy use, and spillage control. Their design makes it possible to save a lot of time and money by not having to rely on the old style of fueling stations.

Types of Portable Fuel Pumps

Portable fuel pumps can be divided into different categories according to their way of working and the applications they are used for. The main types are mentioned below:

Manual Fuel Pumps

The hand-operated mechanism is used in these pumps, and therefore, they are perfect for small-scale fueling operations. They are light in weight, very convenient to carry around, and they do not need any external power source, thus making them very handy in remote places or for emergency fuel transfer.

Electric Fuel Pumps

Electric pumps are driven by a motor and are appropriate for medium to large fueling activities. They deliver faster rates of transfer than the manual pumps and cope with different varieties of fuel, such as gasoline, diesel, and kerosene. These come with switches and meters for accurate fuel transfer and monitoring.

Pneumatic Fuel Pumps

These pumps use pressurized air systems to drive them, and are built for industrial-scale applications. Pneumatic pumps are very tough, doing well in terms of resistance to wear from constant use, and their usage is common in places where electric power is not at hand.

Every single type of portable fuel pump comes with its own set of benefits, thus allowing the user to select the most suitable answer according to their particular operational needs. The right choice aids in effective usage, security, and adherence to rules and standards.

| Pump Type | Power Source | Best Applications | Key Advantages | Limitations |

|---|---|---|---|---|

| Manual Fuel Pumps | Hand-operated, no external power needed | Small-scale operations, remote locations, emergency transfers | Lightweight, portable, no power dependency, cost-effective | Slow transfer rate, requires physical effort, not suitable for large volumes |

| Electric Fuel Pumps | Electric motor (battery or AC powered) | Medium to large fueling operations, fleet management, commercial use | Fast transfer rates, handles multiple fuel types, automated monitoring, accurate metering | Requires power source, higher initial cost, needs battery maintenance |

| Pneumatic Fuel Pumps | Pressurized air systems | Industrial-scale operations, locations without electricity | Very durable, wear-resistant, suitable for constant use, no electrical requirements | Requires compressed air supply, more complex setup, higher cost |

Key Features of Portable Fuel Dispenser Pumps

Portability and Compact Design

Portable fuel dispenser pumps are intended to be very easy for a consumer to carry or store this way. Their lightweight and small size still allows them to work efficiently, thus these units are very suitable for remote fuel supply operations or to be used on-site.

High Pumping Efficiency

These pumps are of very high quality, with the ability to produce great flow rates and the same good performance. This means fast fuel transfer with no downtime. The motor power and pump mechanisms are effective even in very high-demand situations.

Material Durability and Resistance

Portable pumps made of strong and resilient materials like stainless steel or corrosion-resistant alloys can still function optimally even in bad weather. These pumps are designed primarily to face the harshness of the fuel, oils, and contaminants from the outside.

Versatile Compatibility

In the class of portable fuel dispenser pumps, you will find models that are capable of pumping almost any type of fuel, for instance, gasoline, diesel, kerosene, and even biofuels. In addition, a lot of models also permit the use of additives without any reduction in flow or safety standards.

Integrated Safety Features

Modern portable fuel pumps integrate safety features that consist of automatic shut-off valves, anti-spark technology, and leak detection systems. Such features not only lessen the potential for accidents but also ensure strict compliance with safety regulations.

The combination of these features results in the provision of trustworthy and efficient solutions by portable fuel dispenser pumps, which are customized according to the various needs of industrial, agricultural, and commercial operations.

Applications of Mobile Fuel Dispensers

Mobile fuel dispensers are preferred in various industries, thanks to their multifaceted nature and ease of use. The main fields of application are as follows:

- Industrial Operations: The fuel is supplied directly to the machines and heavy equipment at the sites, which reduces the time of inactivity and increases productivity.

- Agricultural Practices: Tractors, harvesters, and irrigation pumps are being refueled in the far-off or large farming areas.

- Construction Sites: The fuel supplied to construction vehicles and equipment is on-site; thus, the operations are not interrupted.

- Logistics and Transportation: Fleet vehicles are refueled quickly and effectively, even in places where there are no permanent filling stations nearby.

- Emergency Services: The disaster relief efforts are backed up by the fuel delivery to generators, medical equipment, or rescue vehicles when the situation is critical.

- Maritime and Aviation: The refueling of small boats or aircraft takes place in places where there is no fixed refueling infrastructure.

These usages reflect the versatility and adaptability of mobile fuel dispensers in catering to the fuel needs of different sectors in a very effective way.

Portable Fuel Dispensers in Agriculture

Portable fuel dispensers are essential in the agricultural industry as they make the refueling of the farming machines more efficient and convenient. They are like a universal charger for all kinds of farm equipment, from tractors and combine harvesters to irrigation pumps, all of which need a constant fuel supply to function without a break in the field. Dispensers that can be moved around allow farmers to fill up their machines right at the remote working places, hence reducing downtime and increasing productivity. Furthermore, today’s portable fuel tanks sometimes come with sophisticated metering systems that not only improve the accuracy of fuel dispensing but also lessen the waste and keep an eye on the consumption rates. This functionality brings to light the importance of such tanks in the running of farms more efficiently and the proper management of resources.

Industrial Uses of Fuel Transfer Pumps

Fuel transfer pumps are an essential part of industrial processes, and their main function is the safe and efficient transfer of liquids like fuels, including diesel, gasoline, kerosene, and others. This equipment is widely used in the agricultural, construction, manufacturing, and transport sectors for quickly and efficiently resupplying vehicles, machines, and tools with fuel.

The modern fuel transfer pumps are designed and built to perform the high-flow requirements in demanding environments such as construction sites and logistics centers without any disturbances. These devices have parts made of sturdy materials that can withstand tough conditions, and their usage includes the chemicals, high temperatures, and very stringent industrial settings. Furthermore, the pump designs often have various safety features, for instance, the automatic shut-off systems, to prevent spilling and leaking, hence minimizing the possibility of pollution of the soil and water areas.

Now, industrial-grade fuel transfer pumps are mostly fitted with digital flow meters and filtration systems, as they are generally equipped with. The latest trends in industrial processes have led to the pumps being equipped with digital flow meters and filtration systems, and made them indispensable for accurate fuel tracking and the cleanliness of the fuel delivered. Moreover, the pumps are more than just equipment with the above-mentioned capabilities; they become part of the operations of various industries that are already co-existing with the stringent nature of the laws and the safety standards.

Home and Recreational Uses

Fuel transfer pumps are very versatile instruments that fulfill many home and recreation purposes. These pumps are the ones primarily used for refueling small engines that are found in lawnmowers, generators, motorcycles, and RVs. Their portability and ease of use really make them ideal for homeowners who have to deal with fuel storage or for outdoor enthusiasts who need quick and efficient refueling solutions. There are many models available that will work with gasoline, diesel, and kerosene, thus giving the user the option of the fuel type required. Moreover, modern pumps generally have user-friendly features like mechanical or electric operation, safety shut-off valves, and lightweight construction, providing not only convenience but also safety.

| Industry/Application | Primary Uses | Key Benefits | Recommended Pump Type |

|---|---|---|---|

| Agriculture | Refueling tractors, harvesters, irrigation pumps in remote fields | Reduces downtime, increases productivity, eliminates travel to fuel stations | Electric or Battery-Operated |

| Construction | On-site fueling of heavy equipment, vehicles, generators | Minimizes operational interruptions, improves efficiency | Electric or Pneumatic |

| Transportation & Logistics | Fleet vehicle refueling, emergency fuel delivery | Quick refueling, cost savings, flexible operations | Electric with Metering |

| Emergency Services | Fueling generators, rescue vehicles, medical equipment | Critical fuel access during disasters, rapid deployment | Manual or Battery-Operated |

| Marine & Aviation | Refueling boats, small aircraft in remote locations | Eliminates dependency on fixed infrastructure | Electric with Safety Features |

| Home & Recreation | Lawnmowers, generators, motorcycles, RVs | Convenience, safe fuel storage management | Manual or Small Electric |

Choosing the Right Portable Fuel Pump

In choosing a portable fuel pump, think about the kind of fuel that is going to be used—gasoline, diesel, or kerosene—to guarantee compatibility. Check the pump’s flow rate, because the refueling time will be shorter for big tanks with high flow rates. Pick a model that has the most critical safety features, like automatic shut-off and a strong, leak-proof build. Portability is another important factor; if less weight and small size are major conditions, then go for the lightest and most compact design. At last, check that the pump matches the official standards for each type of fuel handling so that it can be trusted and recognized as up to date.

Factors to Consider

The selection of a fuel transfer pump should start with a thorough examination of the fuel type that will be used; in other words, if it’s petrol or gasoline, kerosene, or even other fuels, one has to check the compatibility of the product. Next, the consideration of flow rate should be done very carefully as the higher flow rate (gallons or liters per minute are the two common measures) is suitable for fast refilling of big tanks, while low rates will perfectly work for small-scale applications. Besides, the factors of safety and durability should take the first place—pumps with automatic shut-off devices to stop the spillages and leak-resistant designs using top quality materials for the long use should be the ones to be considered first. In case portability is a concern, check the pump’s dimensions and weight; the small-sized and lightweight models are the ones that will be able to support mobile operations. Moreover, consider the pump’s power type (electric, manual, or battery-operated) as this will influence your operational requirements and the available infrastructure. Lastly, the pump must be checked whether it corresponds with the necessary safety and compliance standards, for example, UL, ATEX, or ISO certifications, to be sure about its reliability and being in line with fuel handling regulations.

💡 Key Selection Criteria

- Fuel Type Compatibility: Ensure the pump is rated for your specific fuel (gasoline, diesel, kerosene, biofuel)

- Flow Rate Requirements: Match pump capacity to your volume needs (GPM or LPM)

- Safety Features: Look for automatic shut-off, anti-spark technology, leak detection

- Portability Needs: Consider weight, size, and ease of transport for your operations

- Power Source Availability: Choose between manual, electric, battery, or pneumatic based on infrastructure

- Durability Requirements: Assess construction materials for your environmental conditions

- Certification & Compliance: Verify UL, ATEX, ISO, or other relevant certifications

- Budget Constraints: Balance initial cost with long-term operational value

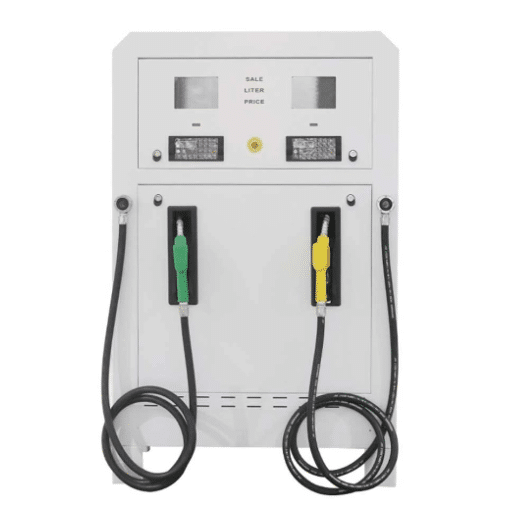

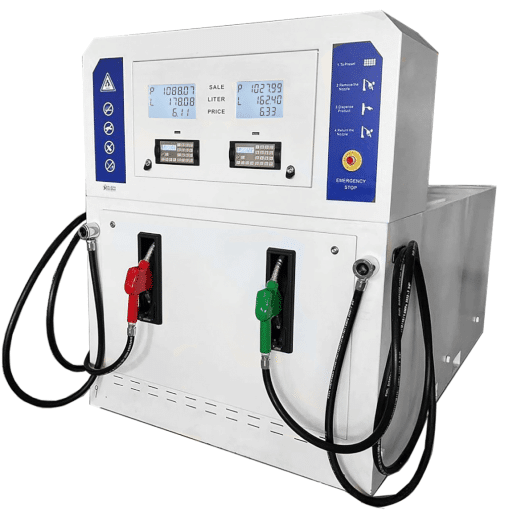

Best Portable Fuel Dispenser Models

In the process of choosing the top portable fuel dispenser models, the buyer has to take into account several principal factors. Here is a thorough comparison of three outstanding models concerning performance, usability, and safety, extracted from the most authoritative online sources and put together:

Fill-Rite FR1210G 12V Fuel Transfer Pump

The Fill-Rite FR1210G is a tough and trustworthy pump that is ideal for demanding professionals who require mobile fuel-transfer equipment. High flow rate, up to 15 gallons per minute, is its feature that makes it good for agricultural, industrial, and automotive applications. It is a 12V DC-powered model, and it has an explosion-proof motor that complies with both UL and CSA safety standards. The pump comes along with a manual nozzle, suction pipe, and is housed in a sturdy, corrosion-resistant aluminum body.

GPI M-180S Fuel Transfer Pump

The GPI M-180S pump is a well-known, trustworthy machine that combines a lightweight and compact design with dependable performance. The flow rate of 18 GPM is its characteristic, and it is driven by a 12V DC motor that makes it perfect for portable fueling operations. Besides, the premium cast aluminum body construction provides the pump with durability and resistance to tough conditions. Its safety certification is from the industry, and it has quick-connect power that makes the setup easy. The package also includes a fuel nozzle and a flexible suction hose that further enhance convenience.

TERA PUMP TRFA01 Portable Fuel Pump

The TERA PUMP TRFA01 is a battery-operated fuel transfer pump designed for portable use and is ideal for small-scale operations. It works with gasoline, diesel, and non-corrosive liquids and provides a flow rate of 2.4 gallons per minute. The unit comes with an auto-stop sensor that shuts it down in case of overflow and spill, thus safety takes precedence in its design. Light in weight, it has an ergonomic handle that makes it easy to use in a sunny place, mainly for refueling off-road vehicles, ATVs, or boats.

All these models have their own merits that may correspond to your needs in terms of operations. No matter what you value most – high flow rate, compactness, or battery-powered ease – these portable fuel dispensers will consistently meet your demands at the required level of security and compliance.

| Model | Flow Rate | Power Source | Key Features | Best For |

|---|---|---|---|---|

| Fill-Rite FR1210G | 15 GPM | 12V DC | Explosion-proof motor, UL/CSA certified, aluminum body, manual nozzle included | Agricultural, industrial, automotive professionals |

| GPI M-180S | 18 GPM | 12V DC | Cast aluminum construction, quick-connect power, fuel nozzle and hose included | Portable fueling operations, commercial use |

| TERA PUMP TRFA01 | 2.4 GPM | Battery-operated | Auto-stop sensor, lightweight, ergonomic handle, works with multiple fuel types | Small-scale operations, ATVs, boats, off-road vehicles |

Battery Operated vs. Manual Pumps

Battery-operated and manual pumps are distinct in terms of their application areas, strengths, and weaknesses, depending on user needs and operational limitations. Battery-operated pumps offer significant convenience and energy efficiency, using an electric motor for quick and even fuel transfer. They are well-suited for frequent automated dispensing scenarios where one person is involved in fueling more than one vehicle at a time, thus minimizing labor and time spent on refueling operations. At the same time, these pumps may come with various features like automatic shutoff and flow rate control, but their functional drawbacks include dependency on battery recharging/maintenance and higher initial cost.

In contrast, manual pumps are very basic yet very reliable devices that can work without drawing any power. The fact that they do not need a power source makes them an economical and portable solution for isolated places or crises where the use of electricity or batteries is not possible. Nevertheless, they require human strength and patience to work and provide a small flow rate that makes it easier to be oriented towards the less frequently used areas of fuel transfer.

In the end, the selection between the two types of pumps revolves around the mentioned aspects, like how often the pump is to be used, the flow rate required, the available source of power, and the budget. All these factors should be carefully considered by the user to find the most suitable tool for their specific operational needs.

| Feature | Battery-Operated Pumps | Manual Pumps |

|---|---|---|

| Convenience | High – automated operation, minimal effort | Moderate – requires physical effort |

| Flow Rate | High – fast fuel transfer | Low – slower transfer rate |

| Power Dependency | Requires battery charging/maintenance | No power required – fully independent |

| Initial Cost | Higher investment | Lower cost – economical option |

| Best Applications | Frequent use, multiple vehicles, time-sensitive operations | Remote locations, emergencies, infrequent use |

| Features | Auto-shutoff, flow control, digital displays | Simple mechanism, no electronics |

| Maintenance | Battery care, electrical components | Minimal – mechanical parts only |

| Reliability | Dependent on battery condition | Very reliable – no electrical failures |

Portable Fuel Dispenser Components

- Pump Mechanism: The principal part that can transfer the fuel most efficiently. Depending on the model and application of the dispenser, this may be either manual, battery-operated, or electric.

- Hose and Nozzle: The pump is connected to the place where the fuel is dispensed by a sturdy hose, and the nozzle provides the transfer of the fuel with control and accuracy.

- Filter System: Its purpose is to clean the fuel and to make it safe for delivery by removing impurities and contaminants.

- Metering Unit: Shows the exact amount of the fuel dispensed, thus enabling the users to either monitor their consumption or sales.

- Storage Tank or Container: The fuel is stored at a safe place, and over this, there is usually a protective coating with materials that resist corrosion and leakage.

All parts are designed in a manner that allows safe, efficient, and reliable fuel transfer even under the most challenging operational scenarios.

Understanding the Fuel Transfer Tank

A fuel transfer tank is an enormous container that has the capacity to store and move fuel in a very safe and efficient manner. The foremost purpose of the tank is to make sure that fuel is always in the spot needed, whether it is an on-site or remote operation, and God knows there are many cases of such operations, like, for example, construction, agriculture, or fleet management. A fuel transfer tank, if well-made made will have the following features:

Durable Construction

Fuel transfer tanks are almost always made of heavy-duty materials such as aluminum or steel, which are both resistant to rust and corrosion, thus ensuring a long lifespan and safe fuel containment. DOT (Department of Transportation) regulations, which are meant for the transport of hazardous materials, are sometimes even met by these tanks.

Pump and Dispensing System

A manual or electric pump, together with a dispensing nozzle, is the usual pump; controlled and efficient fuel transfer is then made possible. Pumps are normally fitted with a hose that allows longer reach and have optional flow meters that enable very exact fuel measurement.

Safety Mechanisms

Some of the major safety features are the vent caps, which allow the gas to escape and thus avoid pressure building up, the baffles, which help prevent sloshing of the fuel during transport, and the locks, which prevent unauthorized access to the fuel.

Compatibility

Fuel transfer tanks can be used for a variety of fuels such as gasoline, diesel, and biodiesel. Still, an extra caution is required to ensure that the tank and its parts are fit for the particular type of fuel to be stored.

Using a fuel transfer tank correctly, along with its regular maintenance, will be highly beneficial in terms of maximizing its performance, meeting safety standards, and prolonging the product’s life.

Importance of Hoses and Nozzles

Hoses and nozzles are the vital parts of any fuel transfer system. The transferring of fuel through operations will be done safely, efficiently, and in a controlled manner. Premium quality fuel transfer hoses are made to resist pressure, wear, and undergo chemical degradation to a certain extent, and still transfer the fuel being transferred well. One of the principal points is their length, diameter, and material compatibility that corresponds to the particular fuel type and the operational requirements.

Nozzles, however, are the ones that guarantee accurate fuel dispensing, and at the same time, they are the ones that minimize the chances of spills happening. Automatic shutoff nozzles are the most sought-after ones because of their capability to stop overfilling, thus making things safer and less fuel wastage. Moreover, nozzles with ergonomic designs are easier to use, and their material life is longer since it is of better quality. Operators can gradually reach the best performance by the ideal combination of hoses and nozzles, thus keeping their operations within the bounds of regulations and cutting down on downtime caused by equipment failure. Moreover, proper inspection, cleaning, and timely replacement further ensure the reliability of these components in demanding environments.

Filters and Maintenance Tips

Filters are an essential part of fuel systems because they prevent contamination of sensitive parts with dirt, rust, and water by removing these impurities beforehand. Therefore, it is necessary to perform filter inspections regularly, and the replacement should coincide with the intervals set by the manufacturer of the equipment to ensure the best performance possible. The most common fuel filter types are particulate filters designed to take care of solid contaminants and water separators that skew moisture effectively.

As far as maintenance is concerned, begin by watching out for symptoms like clogged filters, decreased flow rates, or fuel changing color, which may be signals for instant replacement. It is a good practice to use only those filters that are in line with the specifications of your system to prevent operational troubles or warranty loss. Cleaning the filter housing during each replacement stops dirt from building up and guarantees that the new filter fits tightly.

Moreover, it is advisable to conduct a preventive maintenance schedule that incorporates checking seals and connections for signs of wear or leaks. So by following these practices, you will be able to keep your fuel clean, increase the life of the components in the system, and eliminate the expensive downtimes that are associated with failures from contamination.

🔧 Essential Maintenance Checklist

- Inspect filters regularly for clogs or discoloration

- Replace filters according to manufacturer’s recommended intervals

- Use only filters that meet your system’s specifications

- Clean filter housing during each replacement

- Check hoses for cracks, wear, or chemical degradation

- Inspect nozzles for proper automatic shutoff function

- Examine seals and connections for leaks or wear

- Monitor flow rates for any decrease in performance

- Keep equipment clean and free from debris

- Store portable dispensers in dry, protected locations when not in use

Safety Considerations

When working with fuel systems, prioritize the safety of people and the environment. Always use the correct personal protective equipment (PPE), which must include gloves and eye protection, to avoid contact with fuel and toxic substances. Make sure that the fumes are not a problem for you by working in well-ventilated areas and by preventing the occurrence of fires through the keeping of ignition sources at a safe distance from the fuel. To save the environment, filter disposal and fuels that have been contaminated must be done in accordance with local legislation. Make it a habit to read and observe equipment-specific safety rules regularly to minimize the chances of accidents or injuries.

Proper Storage and Handling of Fuels

As for the correct storage and handling of fuels, my first action is to ensure that at least the containers are properly labeled, accepted for fuel storage, and tightly shut off to guard against leaks or spills. I place my fuels in cool, ventilated areas that do not receive direct sunlight, heat, or flames. When I handle them, I make sure to put on the right PPE and take accident-preventive measures by using only the designated tools for fuel transferring. Moreover, I observe all local government rules about maximum amounts for storage and discarding, giving priority to safety as well as environmentally friendly practice.

⚠️ Critical Safety Guidelines

- Personal Protective Equipment: Always wear gloves, eye protection, and appropriate clothing

- Ventilation: Work in well-ventilated areas to prevent fume accumulation

- Fire Prevention: Keep all ignition sources (sparks, flames, cigarettes) away from fuel

- Proper Containers: Use only approved, properly labeled fuel storage containers

- Secure Closures: Ensure all containers are tightly sealed when not in use

- Storage Location: Store fuels in cool, dry, well-ventilated areas away from direct sunlight

- Spill Prevention: Use designated fuel transfer tools and have spill cleanup materials ready

- Equipment Inspection: Regularly check for leaks, wear, or damage to equipment

- Regulatory Compliance: Follow all local regulations for fuel storage and disposal

- Emergency Preparedness: Know the location of fire extinguishers and emergency contacts

Understanding Fuel Types: Diesel vs. Gasoline

Diesel and gasoline are two separate kinds of fuels, each with its own unique traits, uses, and performance characteristics. Diesel fuel is heavier and has more energy per gallon, which makes diesel engines more fuel-efficient, particularly under heavy loads or long distances. It is widely used in trucks, tractors, and some other machines. The principle of compression ignition is used in diesel engines, where high compression is applied to air, and the fuel is ignited by the heat of the compressed air rather than using a spark to ignite it.

Gasoline, on the contrary, is a lighter and more volatile fuel that is intended for spark-ignition engines, which constitute the majority of car engines. Gasoline engine cars are able to accelerate faster and are quieter than diesel engine cars. Nevertheless, in the case of gasoline, it normally has a shorter range than diesel and produces less energy per gallon. In addition, gasoline is usually more susceptible to evaporative emissions that add to its environmental impact.

In the decision-making process of which fuel to use, one should weigh all the factors like vehicle type, fuel efficiency, maintenance, and cost of purchase, etc. Diesel engines are normally long-lasting but entail a specialized kind of maintenance, so their initial cost may also be high. On the other hand, gasoline engines are cheaper at the beginning, but they may be inefficient in case of high mileage or heavy-duty applications. It is very important to know the contradictions to choose the right fuel type according to the requirements of operation and environmental concerns.

| Characteristic | Diesel Fuel | Gasoline |

|---|---|---|

| Energy Content | Higher energy per gallon | Lower energy per gallon |

| Ignition Method | Compression ignition | Spark ignition |

| Fuel Efficiency | More efficient, especially for heavy loads and long distances | Less efficient but faster acceleration |

| Common Applications | Trucks, tractors, heavy machinery, industrial equipment | Passenger cars, light vehicles, small engines |

| Engine Characteristics | Durable, long-lasting, specialized maintenance required | Quieter operation, faster acceleration, simpler maintenance |

| Initial Cost | Higher upfront cost for engines | Lower initial investment |

| Environmental Impact | Lower CO2 emissions but higher particulates | Higher evaporative emissions |

| Volatility | Heavier, less volatile | Lighter, more volatile |

Conclusion: Maximizing Your Portable Fuel Dispenser Investment

Key Takeaways

Portable fuel dispensers have revolutionized fuel management across multiple industries, offering flexible, efficient, and cost-effective solutions for on-site fueling needs. Understanding the various types, features, and applications of these systems is essential for making informed purchasing decisions that align with your operational requirements.

Summary of Essential Points

- Versatility Across Industries: Portable fuel dispensers serve critical functions in agriculture, construction, transportation, emergency services, and recreational applications, demonstrating their broad utility and adaptability.

- Pump Type Selection: Choose between manual, electric, and pneumatic pumps based on your specific needs regarding power availability, flow rate requirements, and operational frequency.

- Key Features Matter: Prioritize portability, pumping efficiency, material durability, fuel compatibility, and integrated safety features when evaluating different models.

- Safety is Paramount: Always follow proper storage and handling procedures, use appropriate PPE, maintain equipment regularly, and comply with all relevant safety regulations.

- Component Quality: The reliability of hoses, nozzles, filters, and storage tanks directly impacts system performance and longevity—invest in quality components.

- Regular Maintenance: Implement preventive maintenance schedules to ensure optimal performance, extend equipment life, and prevent costly downtime.

- Fuel Type Considerations: Understand the specific requirements and characteristics of different fuel types (diesel, gasoline, kerosene) to ensure proper equipment selection and handling.

Making the Right Investment

When selecting a portable fuel dispenser, balance your immediate operational needs with long-term reliability and safety considerations. Consider the total cost of ownership, including maintenance requirements, replacement parts availability, and compliance with evolving regulations. Reputable models like the Fill-Rite FR1210G, GPI M-180S, and TERA PUMP TRFA01 offer proven performance across different application scales and requirements.

Future-Proofing Your Operations

As fuel management technology continues to evolve, look for systems that offer upgradeability, compatibility with multiple fuel types, and integration capabilities with digital monitoring systems. The trend toward automation, enhanced safety features, and environmental compliance will continue to shape the portable fuel dispenser market, making it essential to choose solutions that can adapt to changing requirements.

Best Practices for Success

- Conduct thorough needs assessment before purchasing

- Verify all safety certifications and regulatory compliance

- Invest in proper training for all operators

- Establish and maintain regular inspection schedules

- Keep detailed records of fuel transfers and maintenance activities

- Build relationships with reliable suppliers for parts and service

- Stay informed about regulatory changes affecting fuel handling

- Consider environmental impact in all fuel management decisions

Final Recommendations

Portable fuel dispensers represent a smart investment for any operation requiring flexible, on-site fueling capabilities. By carefully evaluating your specific requirements, prioritizing safety and quality, implementing proper maintenance procedures, and staying compliant with regulations, you can maximize the value and performance of your fuel dispensing system. Whether you’re managing a large agricultural operation, construction fleet, or recreational equipment, the right portable fuel dispenser will enhance efficiency, reduce costs, and provide reliable service for years to come.

🎯 Action Steps for Getting Started

- Assess your fuel volume requirements and frequency of use

- Determine which fuel types you need to handle

- Evaluate power source availability at your locations

- Research and compare models that meet your specifications

- Verify safety certifications and regulatory compliance

- Calculate total cost of ownership including maintenance

- Read user reviews and check manufacturer reputation

- Plan for proper storage and security of equipment

- Develop training procedures for all operators

- Establish maintenance schedules and record-keeping systems

Maximize EfficiencyWith proper selection, maintenance, and operation, portable fuel dispensers can reduce refueling time by up to 75% compared to traditional fueling methods

Reference Sources

Design and Fabrication of Shoe/Slippers Sanitizing Ramp

Frequently Asked Questions (FAQs)

What is a portable fuel dispenser pump?

A portable fuel dispenser pump is a small and transportable device that is handy for transferring fuel, e.g., gasoline or diesel, from a storage tank or container to cars or machines. These dispensers are very efficient in areas where gas stations are not easily accessible, such as remote locations and farms that use gas for operations.

How does a mobile fuel pump work?

A mobile fuel pump works by using a motor to create a vacuum that sucks fuel from the fuel tank or container through a hose and nozzle. The fuel is then released at a predetermined rate, which is usually expressed in gallons per minute (GPM), for instance, 2.4 GPM, thus facilitating fast refueling of vehicles and machines.

What are the benefits of using a portable fuel dispenser?

Portable fuel dispensers come with a lot of benefits, such as being user-friendly and advantageous in terms of both cost and flexibility. They make it possible to refuel on the go, which simplifies the process of refilling a fleet of vehicles or machines at the location without the need to go to a gas station. Moreover, they can be modified to meet particular fueling requirements.

Can I use a portable fuel dispenser for diesel fuel?

Absolutely, a number of portable fuel dispensers can process diesel fuel. Such dispensers are typically made of robust materials to resist the aggressive nature of diesel and might feature a premium filter for clean fuel transfer.

What is included in a fuel transfer pump kit?

The components of a fuel transfer pump kit usually comprise the pump, hoses, nozzles, and in some cases, a flowmeter for calculating the amount of dispensed fuel. Some kits may include a hose reel for convenient storage and quick refueling, thereby making the whole fueling process more efficient.

How do I install a portable fuel dispenser?

Setting up a portable fuel dispenser usually requires locating the pump on a sturdy surface, connecting it to a fuel container or storage tank, and double-checking that all hoses are tight. In the case of certain models, some dispensers might need a power supply or a battery-operated setup as a requirement.

What features should I look for in the best portable fuel dispenser?

While hunting for the best portable fuel dispenser, keep in view features like precision in fuel measurement, robust design, ease of use, and the capacity to deal with various fuels like petrol and diesel. More features, like a hose reel for storage and a dependable discharge nozzle, can improve convenience and efficiency.

Are portable fuel dispensers safe to use?

Definitely, portable fuel dispensers are made with security measures to prevent any hazards during fuel transfer. Such measures can include the use of shut-off valves that automatically shut down the flow in case of a leak, devices that contain and collect spills, and grounding wires correctly to avoid any buildup of static electricity. It is very important to read and follow the manufacturer’s instructions and safety rules.

What is the cost of a portable fuel dispenser pump?

The price of a portable fuel dispenser pump can be greatly influenced by its technical specifications, functions, and the manufacturer. On the whole, you will be able to find the price range for dispensers from economical ones to those that have high quality and are suitable for intensive use; so it’s essential to evaluate your own needs and budget before buying.