Understanding the differences between a gas pump and a dispenser may appear trivial initially; however, these terms hold distinct meanings in the realm of fuel service stations. Differentiating between these components will certainly enable an inquisitive consumer or an industry professional to understand the working of fuel delivery systems better. This blog will be the key to unlocking the differences between gas pump and dispensers, their functions, and usages, and ultimately why this difference matters. By the time you’re done with this, I can assure you that you will get an answer on the subject and respect for the technology behind everyday fuel transactions. Stay tuned as we unpack the finer details of these fuel station essentials!

What is a Gas Pump?

A gas pump transfers fuel from the underground storage tank into a vehicle’s fuel tank. It consists of a nozzle, a hose, and control systems that enable the user to select the fuel type or quantity. Modern gas pumps are fitted with meters to indicate how much fuel has been dispensed and often have payment systems for user convenience. These machines pump fuel efficiently and safely into vehicles at a gas station.

How does a gas pump work, and what does it do?

Gas pump work incorporates mechanical and electronic arrangements to dispense fuel quickly. When a customer picks up the nozzle and selects the fuel type, the pump starts an internal motor that sucks gas from the underground tank. This fuel is pushed through the filtration system to remove impurities before being pushed up through the hose to the nozzle. The flow rate sensors and meters inside the pump accurately calculate the amount and the cost of dispensed fuel, putting it on a real-time display on the pump.

Modern gas pumps are equipped with newer systems for safety and convenience. Vapor recovery systems, for example, prevent harmful fumes from venting into the atmosphere during refueling, causing pollution reduction. Payment modules such as card readers and even contactless payment systems are integrated into pumps, thus easing the transaction process. Industry estimates indicate that gas pumps dispense fuel at approximately 10 gallons per minute, which is just the right speed without compromising safety. These systems are designed to have an auto-stop mechanism to prevent overtopping by stopping the fuel flow when the tank gets full.

How does a gas pump move fuel from an underground tank?

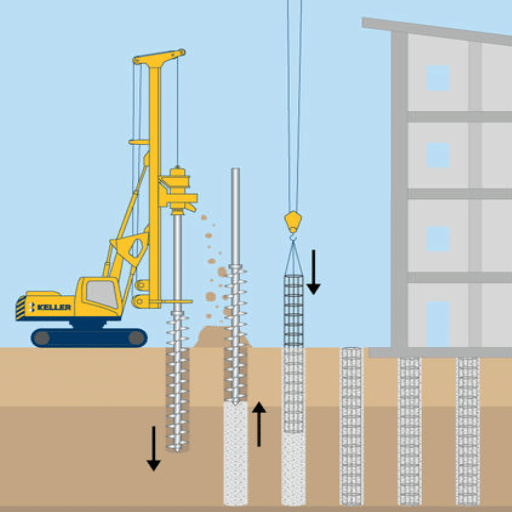

Fuel does not simply drift from an underground tank to a waiting vehicle; an intricate blend of engineering disciplines moves it along. Many dispensers employ a submersible pump, a rugged device perched at the bottom of the tank, or occasionally a suction pump that generates its vacuum. The submersible version pushes the liquid upward, while the suction counterpart yanks it through tight plumbing by lowering pressure at the nozzle.

After that initial stage, almost every pathway is guarded by at least one filter intended to snare dust, rust, or stray water droplets before the gasoline reaches the driver. A flow meter, often no larger than a fist, sits in line to tally the volume; the best of these instruments maintain their calculations within half a percentage point even after thousands of gallons have passed.

Every modern dispenser relies on an air-separator plate that traps gas bubbles before entering the delivery hose. That simple safeguard keeps the fuel stream consistent and engine-friendly.

On the mechanical side, pressure regulators and spring-loaded check valves rein in surges, helping the system stay under control even if conditions change. That burst of discipline can be critical, especially in older vehicles that are less forgiving of wild pressure spikes.

Typical retail pumps pass between 5 and 10 gallons per minute, a range most passenger cars consume without hesitation. Larger commercial nozzles push the limit to 60 gallons per minute, feeding heavy haulers that all but drain the tank in one gulp.

Electronic watchdogs hide behind the panel doors, recording flow counts, temperature shifts, and leak conditions with obsessive frequency. Their outputs feed a cloud-linked dashboard where engineers can scan hundreds of sites simultaneously, catching anomalies before a driver is inconvenienced. Combining stout steel parts with that invisible intelligence allows the industry to deliver fuel as routinely as a morning commute.

How Does a Dispenser Function?

To dispense fuel, the dispenser uses a pump that draws fuel from the underground tank and delivers it to the vehicle. When the nozzle is inserted into the vehicle’s fuel tank and the handle is squeezed, the dispenser starts the fuel pump. Sensors control the flow rate with the valves to ensure safety and precision, interrupting the flow once the tank is full. Electronic systems review and monitor this activity for maximum efficiency and accuracy.

What is the fuel delivery system in a dispenser?

Fuel delivery from the tank to the vehicle is an intricate operation that protects all the stages from the underground tank through the placement into the vehicle storage tank. The system starts with pumps submerged within the tank or suction pumps drawing fuel through underground pipelines. The meter inside the dispenser ensures that the amount of fuel dispensed into the vehicle is truly equal to that read by the meter, often with an accuracy greater than 0.5%; many nations uphold strict regulations over this matter for the credibility of the consumer.

Modern dispensers include pressure and flow sensors and nozzles fitted with automatic shut-off systems to prevent overfilling and spillage. When dispensing is monitored in real time, the Electronic Dispenser Controller (EDC) controls these; the EDC also communicates with point-of-sale (POS) systems to allow transaction handling of fuel delivery operations.

In addition, many dispensers are fitted with vapor recovery systems to lessen the environmental impact by capturing fuel vapors escaping into the air at refueling. Key survey data include flow rates ranging from 5 to 40 liters per minute, while fast-flow dispensers at commercial stations for large vehicles may go higher. These systems are ever-changing, and the integration of IoT technology is currently used for predictive maintenance, thus enhancing reliability and customer experience.

How does a fuel dispenser use a submersible pump?

A submersible pump is the heart of many modern fuel-dispensing setups, from neighborhood gas stations to large commercial terminals. The unit is dropped into the storage tank and operates beneath the liquid surface. By working underwater, the pump keeps vapors in check, bolsters safety, and moves fuel without the delays that surface installations sometimes face.

Operators appreciate the steady, muscular output these pumps deliver over substantial stretches of piping. Typical models push 15 to 40 liters per minute during ordinary refuels, while high-speed variants comfortably top 80 to 130 liters per minute when called upon. That level of performance lets a single pump feed several dispensers at once, a necessity when rush-hour traffic fills every lane.

Recent progress in submersible pump engineering has pushed reliability and output well beyond earlier benchmarks. New models come fitted with electronic gauges that log pressure, temperature, and voltage every second so operators can spot trouble before it starts. Developers claim these innovative features slash unplanned outages by making routine maintenance easier to schedule. Updated seals paired with corrosion-resistant alloys now give the same unit a fighting chance against ethanol-blended fuels and other aggressive blends that used to chew up internals in months.

Along with that technical leap, the global retail fueling sector has come to rely on submersible hardware as its backbone for moving product from buried tanks to surface dispensers. No other setup marries speed to safety while meeting the ever-thicker layer of environmental regulations.

What makes a dispenser a self-contained unit?

The term self-contained fits a modern fuel dispenser because designers have packed the pump, flow meter, valves, filters, piping, and nozzle into a single housing. By keeping all those parts together, the unit can deliver fuel quickly while the outside world, at tanks or service lines, becomes less of a concern. The compact arrangement sharply reduces the chances that a loose fitting somewhere else in the system will disrupt a sale.

Today’s dispensers trade gears and levers for dedicated printed-circuit boards that compute, monitor, and control every product move. Upgraded metering systems seal in volume accuracy so owners stay within tightening regulatory margins and waste as little product as possible. Tiers of environmental protection join the mix, including automatic leak sensors and vapor-recovery hardware that guard air quality and personal safety.

Breakthroughs keep rolling in. High-flow variants now push 40 gallons a minute, shaving wait times at the busier locations that drive most profit for station owners. Integrated communication links even talk directly with point-of-sale systems, marrying fuel delivery to instant payments and live inventory counts.

That squeeze of technology saves valuable forecourt square footage and cuts the number of conduits a technician must thread through concrete. Installation becomes a one-day job for most crews, and routine upkeep rarely demands more than a tablet and a service password. Today’s dispenser, in short, has become the beating heart of the modern fueling operation.

Key Differences between a Gas Pump and a Dispenser

One must consider operational principles and location, to name an essential difference between a gas pump and a dispenser. A gas pump pumps fuel underground from storage tanks to stations or vehicles. On the other hand, dispensers dispense fuel to cars and help with payment processing and inventory control.

Gas pumps are underground and practically invisible to curious eyes, whereas dispensers consist of above-ground structures acting as customer interfaces. Simply put, the gas pump mainly involves the mechanical transfer of fuel. At the same time, dispensers pack a lot more technology, such as flow meters and communication systems, to ensure smooth fueling operations.

What distinguishes a dispenser from a pump?

Gas dispensers and gas pumps are two pairs of terms that trip up just about everybody on the self-serve island. People tend to say I’ve used the pump even when they mean the big silver unit they lean against, partly because convenience beats accuracy in everyday chatter. Yet, pumping action itself happens underground in a motorized unit that silently drags gasoline up through pressurized pipes so that that piece can be tucked away and still do its work. The visible dispenser, by contrast, is the chrome-and-plastic face that lets a customer pick a grade, see the dollar readout, and swipe a card- all in plain view.

Inside each dispenser are flow meters, microchips, and a small storm of sensors that quarrel until they agree on how many gallons have left the nozzle. A modern piece of equipment, wired to headquarters, forwards inventory tallies and error codes every few seconds, helping store managers avoid surprises when Monday morning rolls around. Those high-accuracy meters are so finicky that they register only within ±0.3%, which means the woman pumping unleaded at 8:13 a.m. can trust she got what the screen claimed.

Safety designs also divide the two machines in interesting ways. The underground pump is built to withstand explosive pressures while buried two meters below asphalt, a feat borrowed from old petroleum-engineering textbooks. On the other hand, the above-ground dispenser streams power to a shut-off relay, grounds itself to drain static sparks, and seizes any runaway fault before the driver has time to finish a phone call.

Recent breakthroughs in dispensing technology keep appearing almost by surprise. Newer models accept contactless payment, connect to cloud dashboards, and often sport screens that flash short commercials or station promotions. Combined, these features separate dispensers from traditional pumps and streamline the customer experience at the nozzle.

How do gas pumps and dispensers handle liquid fuel?

Gas pumps are surprisingly complex machines, built to handle gasoline quickly and without the slightest mess. Under the black plastic shroud, as many as three separate pumps may sit, each stirring the fuel out of a tank buried ten feet underground. Friction loss is a quiet enemy, so most garages rely on a submersible turbine pump that seals vapor away before it can escape. The oil-stained pipes that follow a zig-zag under the pavement, crossing filters and shut-off valves so the stream stays steady and any grit gets caught.

A small computer springs to life when a driver squeezes the nozzle, timing every drop through a meter fixed beside the pump head. A positive-displacement design lies at the heart of that gadget, logging volume with an accuracy that can drift by no more than 0.2 percent. Safety comes next, written not in manuals but in brass regulators and spring-loaded cuts that slam shut long before a hose bursts. Any fume that does slip out is yanked back into the ground tank by a recovery line, answering the quiet pressure from state inspectors and, not least, from the neighbors downwind.

Most consumer pumps are tuned to deliver around ten gallons per minute, a pace that feels quick enough for a compact sedan yet leaves plenty of room for heavier rigs. In a different lane, high-flow commercial dispensers can push fuel at rates approaching sixty gallons per minute, shaving precious minutes off a long-haul driver’s stop. Real-time flow sensors and pressure gauges now sit inside the console, vigilantly watching every liquid pulse to guard against drips or miscalculations. These upgrades keep modern dispensers accurate, efficient, and gentle on the surrounding air and asphalt.

How Does a Gas Pump and Dispenser Work?

Fuel pumps and dispensing systems primarily draw fuel from underground storage tanks needed for supply into the automobile fuel tank. The pump system draws the fuel through the pipe when the nozzle is inserted and the trigger is operated. The dispenser meters the exact volume of fuel that goes out for appropriate charges. The safety systems will shut off the flow to prevent spills once the tank is filled. A safe system and these components allow the customer to experience smooth and efficient fueling operations.

Fuel Delivery System Explained

Modern fuel delivery systems have come a long way from the pump-lever-and-hose setup many remember from childhood. Manufacturers now wire in miniature computers that boost efficiency, tighten safety protocols, and sharpen transaction accuracy. A widely noted breakthrough is the electronic flow meter, which measures product volume within ±0.5% and beams that information to back-end inventory or billing software without human intervention.

Another advancement worth mentioning is the vapor-recovery valve just behind the nozzle. That equipment traps fumes that would otherwise drift into the atmosphere, preventing the release of volatile organic compounds. Industry data suggests the best systems snag as much as 95% of escaping vapors, a statistic environmental groups cite when arguing for faster modernization.

Customer-facing dispensers are now little more than touch-screen kiosks tied to the cloud. Users swipe, tap, and watch real-time totals update while hidden IoT sensors ping technicians if a pump starts to linger out of specification. Predictive algorithms sort through that data, schedule repairs before serious faults develop, and keep interruptions bare minimum.

Recent advancements in automation have substantially strengthened the safety framework surrounding energy systems. Pressure sensors paired with automatic shut-off valves now react within milliseconds to conditions like over-pressurization or leaks, halting potential accidents before they escalate. In addition, modern installations are engineered to meet the latest regulatory benchmarks, incorporating features aimed at fire containment and secure fuel management.

Such developments highlight the progress in fuel-distribution technology, balancing operational efficiency with reduced environmental impact and heightened safety for personnel.

How the System Pulls Fuel from Underground Tanks

Today’s fuel-distribution technology rests on clever engineering that lifts gasoline from buried tanks with surprising speed and reliability. A submersible or inline suction pump does the heavy moving; the former is more common at card-swipe stations because it sits directly in the liquid. Pressurized plumbing pushes the fuel upward and onward, often at enough volume to fill a standard passenger tank in under three minutes. The apparatus draws power efficiently, wasting little energy as it hurries fuel to the nozzle.

Safety and cleanliness go hand in hand. Level, heat, and leak sensors send real-time numbers to an inventory computer that tracks every product splash. Many operators rely on double-walled fiberglass tanks for extra insurance against groundwater spills. On the surface, laser-calibrated filters strip out water, sludge, and rust particles so that what finally reaches a car’s engine meets ASTM quality benchmarks.

Corrosion-proof piping, frequently stainless steel or polymer-lined metallic tube, carries the fuel from the reservoir to the dispenser. The pipe walls can endure the hydrostatic force from a whole gasoline column and the occasional scrape from road grit. Industry reports put a sound submersible installation at 8 to 12 gallons per minute, a flow that keeps customers moving and convenience-store coffee hot.

Automated control frameworks oversee every operation phase, leaving little room for human error. Sensors logged on the pipeline measure product velocity while software governors modulate the pump motors so that power draw stays lean. Mechanical smartness paired with continuous digital oversight keeps deliveries dependable, safe, and forgiving to the landscape. Such integrated design marks a clear step forward in fuel handling, where peak performance now walks hand-in-hand with environmental responsibility.

Role of the Fuel Pump in the System

The fuel pump is crucial in delivering fuel from the storage tank to the engine or burner with the required pressure and flow rate for efficient operation. Contemporary fuel pumps are perfectly engineered to compensate for any irregularities in fuel delivery, thus reducing wastage and enhancing system performance. For example, electric fuel pumps operating in automotive applications can supply a near-constant pressure of about 40 to 70 psi, depending on combustion and engine demands.

Other fuel pump technologies incorporate variable flow rates and adaptive control systems to adjust fuel supply in real time to actual engine demand, cutting fuel consumption and emissions in half. Large-scale industrial fuel pumps are engineered for use with heavy machinery and power generation systems. They generally provide much higher flow rates – up to several hundred gallons per minute- and adhere to industry safety standards for leak prevention and thermal resistance. Such refinements reveal how instrumental fuel pumps are in energy transmission, sustainability, and operational pertinence in varying industries.

Why is Understanding Gas Pumps and Dispensers Important?

Gas pumps and dispensers are central to the safe and efficient fuel distribution, making their understanding a must! These systems are designed to dispense fuel accurately and safely per consumer requirements. Suppose a person knows how to operate these systems. In that case, many risks are minimized- risks of spilling or leaking might lead to contamination or over-dispensing of fuel, all of which are safety hazards that cause financial loss to the client. Moreover, with maintenance and working knowledge, smooth functioning with little downtime is ensured, giving continuous energy access to the vehicles and machines.

How does knowledge of a fuel pump improve station efficiency?

An in-depth understanding of the fuel pump helps me operate and maintain it efficiently, ensuring accurate fuel dispensing and reducing downtime. Being familiar with its workings helps me quickly diagnose problems, prevent leaks or malfunctions, and best arrange the station’s workflow. On one hand, this will result in some extra safety in operation; on the other hand, customer satisfaction will rise with the plant’s operational efficiency.

Why is it crucial to understand the fuel delivery system?

Understanding the fuel delivery system is vital for guaranteeing peak performance, safety, and cost-effectiveness of fuel operations. Hence, a neatly maintained fuel delivery system allows fuel to be accurately transferred; otherwise, mistakes and inconvenience due to spills, leaks, and contamination can initiate dire environmental consequences and hefty fines. Some research states that minor leaks can cause a delivery system to waste between 2000 and 10,000 gallons of fuel per annum, which can bear a heavy cost from any business perspective.

On the other hand, with technological innovation, today, fuel delivery systems are fitted with automated monitoring and pressure sensors to ensure impeccable precision. For instance, a system imbued with tank monitoring solutions can inform the operator about the inventory levels in real time, thus preventing overfill or underfill and maintaining a continuous supply. Having a fair amount of knowledge about the different components opens the doors to fast troubleshooting, avoidance of more costly equipment failures, and adherence to regulatory standards. A thorough understanding of the fuel delivery system can thus improve operational efficiency for businesses, reduce downtime, and ensure safety standards are upheld.

Reference Sources

1. Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)

Frequently Asked Questions (FAQs)

Q: What is the main difference between a gas pump and a dispenser?

A: The main difference lies in how they deliver fuel. A gas pump uses a submersible pump placed inside the storage tank that pushes fuel to multiple nozzles. In contrast, a dispenser uses a self-contained pump unit to pull fuel up from underground tanks.

Q: How does a gas pump work?

A: A gas pump works by using a submersible pump that is located inside the storage tank. This pump pushes fuel up to the fuel flow meter and nozzle, allowing fuel to be delivered to vehicles efficiently.

Q: How does a dispenser operate differently from a gas pump?

A dispenser operates with a pump unit that pulls fuel from underground tanks. The fuel is then measured by a flow meter and delivered to the vehicle through a fuel nozzle.

Q: What role does the submersible pump play in a gas pump system?

A: The submersible pump placed inside the storage tank is crucial as it pushes fuel up to the dispensing unit, ensuring that fuel can be delivered to the vehicle through the fuel nozzle.

Q: Why is a submersible pump used in gas pumps?

A: A submersible pump is used because it is placed inside the storage tank and is more efficient at pushing fuel up to the dispensing unit, allowing for a more consistent and reliable fuel delivery.

Q: Can a dispenser handle multiple nozzles like a gas pump?

A: A dispenser can handle multiple nozzles, but it pulls fuel up from underground tanks. The system is designed to efficiently manage fuel distribution through the flow meter and fuel nozzle to different vehicles.

Q: What is the function of the fuel flow meter in both systems?

A: The fuel flow meter measures the amount of fuel delivered and ensures that the correct fuel volume is dispensed through the fuel nozzle to the vehicle.

Q: Is there a difference in fuel delivery speed between a gas pump and a dispenser?

A: The delivery speed can vary depending on the design and capacity of the pump or dispenser. Generally, gas pumps with a submersible pump may deliver fuel faster due to the pushing mechanism.

Q: What maintenance is required for gas pumps and dispensers?

A: Regular maintenance for both gas pumps and dispensers includes checking the pump unit, ensuring the fuel flow meter is accurate, inspecting the fuel nozzle, and guaranteeing the submersible pump or self-contained pump is functioning correctly.

Q: How does the fuel pump unit contribute to the efficiency of fuel delivery?

A: The fuel pump unit, whether in a gas pump or dispenser, ensures that fuel is efficiently moved from the storage tank to the vehicle. It is vital in maintaining a steady fuel flow through the system.